The maintenance and troubleshooting of agricultural equipment are essential for ensuring optimal performance and longevity. A well-organized resource can serve as an invaluable companion for those seeking to enhance their understanding of machinery upkeep, addressing common challenges encountered in the field. This guide provides a structured approach to tackling various mechanical issues, equipping operators with the knowledge to perform necessary adjustments and repairs effectively.

Whether you’re a seasoned operator or new to the world of agricultural implements, this comprehensive resource aims to simplify complex processes and enhance your technical skills. By offering clear instructions and detailed insights, it empowers users to confidently navigate through maintenance tasks. A focus on practical advice and systematic procedures ensures that you can keep your equipment running smoothly, thus maximizing productivity during critical periods.

Throughout this section, readers will discover a wealth of information designed to address a variety of scenarios. From understanding key components to executing routine checks and adjustments, the content is tailored to foster a deeper appreciation for the mechanics involved. This knowledge not only facilitates effective repairs but also promotes a proactive mindset towards equipment care, which is vital in the demanding landscape of modern agriculture.

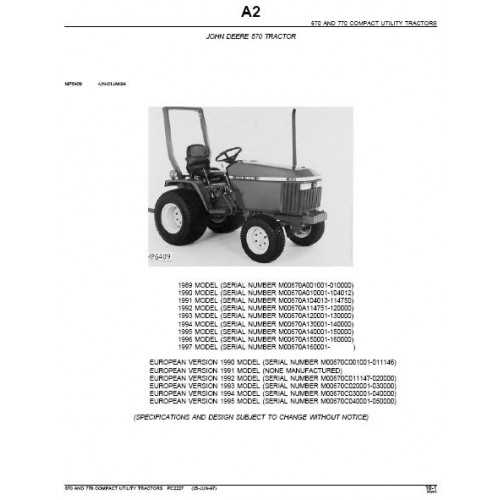

Understanding the John Deere 770

This section provides insights into a popular agricultural machine designed for a variety of tasks. Known for its reliability and efficiency, this equipment is an essential tool for many users in the farming industry. Its robust construction and advanced features enable effective performance in diverse environments.

Equipped with a powerful engine, this model excels in handling heavy loads and challenging terrains. The ergonomic design ensures comfort during prolonged use, while innovative technology enhances operational efficiency. Understanding its components and functionality is crucial for maximizing productivity and longevity.

Regular maintenance is vital to keep this machinery in optimal condition. Familiarity with its specifications and troubleshooting methods can help users address common issues promptly. Whether for routine checks or in-depth diagnostics, knowledge of this machine’s workings is invaluable for any operator.

Common Issues with the Tractor

Every agricultural vehicle may encounter specific challenges during operation, affecting overall performance and efficiency. Understanding these prevalent complications can aid in timely intervention and maintenance.

One frequent concern involves engine performance, where a lack of power or irregular running can stem from various factors, including fuel supply issues or air intake obstructions. Regular checks on filters and fuel lines can help identify these problems early.

Another common issue is related to the hydraulic system. Low fluid levels or leaks can lead to reduced functionality, impacting tasks that rely on hydraulic power. It’s crucial to monitor fluid levels and inspect for any signs of leakage regularly.

Transmission troubles are also notable, often presenting as difficulty in shifting gears or strange noises during operation. Ensuring that the transmission fluid is at appropriate levels and free of contaminants is vital for smooth operation.

Lastly, tire wear can significantly affect maneuverability and stability. Regular inspection for uneven wear patterns or pressure issues can prevent more serious problems and enhance safety while working in the field.

Essential Tools for Repairs

When it comes to maintaining agricultural machinery, having the right equipment is crucial for ensuring effective and efficient service. A well-equipped workspace not only speeds up the process but also enhances the quality of the work performed. Below is a list of vital instruments that should be part of any maintenance toolkit.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening various fasteners. |

| Wrench Set | Essential for adjusting and securing bolts and nuts. |

| Screwdriver Set | Used for various types of screws in machinery components. |

| Multimeter | For measuring electrical parameters and diagnosing issues. |

| Torque Wrench | Ensures fasteners are tightened to specified limits. |

| Pliers | Helpful for gripping, bending, and cutting tasks. |

| Hammer | Useful for driving nails or adjusting components. |

| Diagnostic Tools | Assist in identifying and troubleshooting mechanical problems. |

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your machinery. Regular upkeep is essential for preventing breakdowns and enhancing efficiency. Following a systematic procedure can help you manage tasks effectively and maintain your equipment in peak condition.

Below is a structured guide to assist you in your maintenance efforts:

| Task | Description | Frequency |

|---|---|---|

| Check Fluid Levels | Inspect and replenish oil, coolant, and hydraulic fluid as needed. | Every 50 hours of operation |

| Inspect Filters | Examine air and fuel filters for dirt and clogging; replace if necessary. | Every 100 hours of operation |

| Tire Pressure | Ensure that tire pressure is within the recommended range for safe operation. | Every month |

| Battery Maintenance | Clean terminals and check for corrosion; ensure proper charge level. | Every 3 months |

| Grease Points | Apply lubricant to designated points to prevent wear and tear. | Every 10 hours of operation |

| Visual Inspection | Conduct a thorough check for any visible signs of damage or wear. | Before each use |

By adhering to this guide, you can prolong the lifespan of your machinery and ensure it operates efficiently when you need it most.

Engine Troubleshooting Tips

Understanding the complexities of engine functionality is crucial for effective diagnostics and maintenance. When faced with performance issues, identifying the root cause can significantly enhance the longevity and efficiency of the machinery.

Listen for Unusual Noises: Pay attention to any abnormal sounds during operation. Knocking or rattling noises may indicate underlying mechanical issues that require immediate attention.

Monitor Temperature: An overheating engine can lead to severe damage. Regularly check the temperature gauge and ensure that the cooling system is functioning properly.

Check Fluid Levels: Insufficient oil or coolant can adversely affect engine performance. Regularly inspect fluid levels and top them off as needed to maintain optimal operation.

Inspect Filters: Clogged air and fuel filters can hinder performance. Replace these components at recommended intervals to ensure proper airflow and fuel delivery.

Examine Electrical Connections: Loose or corroded electrical connections can lead to starting problems or erratic engine behavior. Regularly inspect and clean connections to ensure reliable operation.

Utilize Diagnostic Tools: Employing diagnostic equipment can help pinpoint issues quickly. These tools provide valuable insights into engine performance and alert you to potential problems before they escalate.

Hydraulic System Overview

The hydraulic system plays a crucial role in the overall functionality of various agricultural machines. This intricate network is designed to facilitate the efficient transfer of power through fluid dynamics, allowing for the operation of multiple components. Understanding the basic principles of this system is essential for effective maintenance and troubleshooting.

Components and Functionality

The primary elements of this system include the pump, reservoir, actuators, and control valves. The pump generates pressure, while the reservoir stores hydraulic fluid. Actuators convert hydraulic energy into mechanical motion, enabling the machine to perform tasks such as lifting, pushing, and steering. Control valves manage the flow and direction of the fluid, ensuring precise operation.

Maintenance Considerations

Regular inspection and maintenance of the hydraulic system are vital to ensure optimal performance. Check fluid levels and quality, looking for signs of contamination or leaks. Timely replacement of filters and seals can prevent costly damage and maintain system efficiency. Familiarity with the system’s layout and functions aids in identifying potential issues early.

Transmission Repair Techniques

Addressing the intricacies of gear shifting systems is crucial for maintaining optimal performance. Understanding the core principles and methods involved can greatly enhance efficiency and extend the lifespan of these essential components. This section delves into various strategies and practices to effectively troubleshoot and rectify issues related to transmission mechanisms.

Identifying Common Issues

Before undertaking any maintenance tasks, it is vital to recognize typical problems that may arise. Signs such as unusual noises, difficulty in engaging gears, or fluid leaks often indicate underlying issues. Performing a thorough examination can help pinpoint the source of the malfunction, allowing for precise interventions.

Effective Techniques for Resolution

Once problems are identified, employing suitable techniques becomes essential. Disassembly of the transmission unit allows for a detailed inspection of internal components. Replacing worn-out parts, ensuring proper lubrication, and adjusting alignments can significantly restore functionality. Additionally, systematic testing after repairs ensures that all adjustments have been successful, confirming the unit operates smoothly.

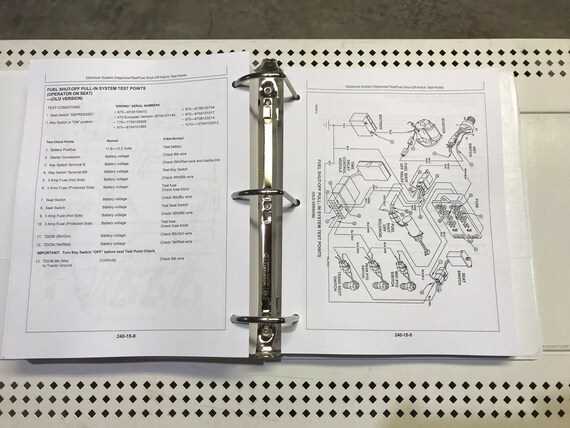

Electrical System Diagnostics

The ability to effectively troubleshoot and assess the electrical components of machinery is crucial for maintaining optimal performance. This section provides guidance on identifying and resolving issues within the electrical framework, ensuring that all systems function seamlessly. By utilizing a systematic approach, operators can efficiently diagnose faults, thereby enhancing reliability and safety.

Key aspects of electrical diagnostics involve understanding circuit schematics, utilizing diagnostic tools, and performing thorough inspections of wiring and connections. Below is a summary of essential diagnostic procedures and tools used in the field:

| Diagnostic Procedure | Description | Tools Required |

|---|---|---|

| Visual Inspection | Check for obvious signs of damage, wear, or corrosion in wires and connectors. | Flashlight, magnifying glass |

| Voltage Testing | Measure voltage levels at key points to verify electrical supply integrity. | Multimeter |

| Continuity Testing | Ensure that electrical paths are complete and free of breaks. | Multimeter or continuity tester |

| Resistance Testing | Assess resistance in components to identify potential failures. | Multimeter |

| Ground Testing | Check for proper grounding of circuits to prevent shorts and ensure safety. | Multimeter |

Implementing these diagnostic techniques will aid in effectively identifying electrical issues, thus prolonging the lifespan of the equipment and ensuring its reliability in the field.

Replacing Key Components

Maintenance of essential parts is crucial for optimal performance and longevity of any machinery. Regularly inspecting and swapping out worn or damaged components ensures efficient operation and reduces the risk of unexpected breakdowns. This section covers the process and considerations involved in replacing vital elements within the equipment.

When addressing component replacement, it’s important to follow a systematic approach to avoid complications and ensure safety. Below is a table outlining common components, their functions, and signs that indicate the need for replacement.

| Component | Function | Signs of Wear |

|---|---|---|

| Fuel Filter | Filters contaminants from the fuel system | Reduced engine performance, stalling |

| Air Filter | Prevents dirt and debris from entering the engine | Decreased power, increased fuel consumption |

| Battery | Provides electrical energy for starting and operation | Slow cranking, dim lights, corrosion |

| Hydraulic Fluid | Transfers power in hydraulic systems | Overheating, discoloration, strange noises |

By regularly monitoring these components and replacing them as necessary, operators can maintain efficiency and extend the lifespan of their equipment. Always consult specific guidelines and safety protocols before undertaking any maintenance tasks.

Preventive Maintenance Practices

Routine care is essential for ensuring optimal performance and longevity of heavy machinery. By implementing systematic procedures, operators can significantly reduce the risk of unexpected breakdowns and costly repairs. Proactive measures not only enhance efficiency but also improve safety standards during operation.

Key Aspects of Preventive Care

- Regular Inspection: Conduct frequent checks on critical components to identify wear and tear early.

- Fluid Levels: Monitor and maintain appropriate levels of oil, coolant, and other essential fluids.

- Filter Replacement: Change air and fuel filters according to the recommended schedule to ensure proper operation.

- Tire Maintenance: Inspect and maintain tire pressure, tread depth, and overall condition for improved traction and safety.

Benefits of Routine Maintenance

- Increased Efficiency: Well-maintained equipment operates more smoothly, leading to better fuel economy.

- Extended Equipment Life: Regular upkeep can prolong the lifespan of machinery, delaying the need for replacement.

- Enhanced Safety: Routine checks help prevent accidents caused by equipment failure.

- Cost Savings: Investing time in maintenance reduces the likelihood of major repairs, saving money in the long run.

Safety Protocols During Repairs

When undertaking maintenance tasks on agricultural machinery, it is crucial to adhere to established safety guidelines. These protocols are designed to protect individuals from potential hazards, ensuring a secure environment while performing essential work. Proper preparation and awareness can significantly reduce the risk of accidents and injuries.

Preparation and Personal Protective Equipment

Before commencing any work, it is vital to equip oneself with appropriate personal protective gear. This may include gloves, safety glasses, and sturdy footwear to safeguard against physical injuries. Additionally, one should ensure that the workspace is organized, with tools and equipment readily accessible, minimizing the chance of accidents due to clutter.

Understanding Equipment and Procedures

Familiarity with the machinery and its operational guidelines is essential. Carefully reviewing documentation related to the equipment helps in understanding its specific features and safety requirements. Following step-by-step procedures can further mitigate risks, enabling a more effective and secure working process.

Upgrading Your John Deere 770

Enhancing the capabilities of your agricultural machinery can significantly improve performance and efficiency. Whether you’re looking to boost power, enhance comfort, or integrate modern technology, there are several key areas to focus on for optimal upgrades.

Performance Enhancements

Upgrading various components can lead to noticeable improvements in operational efficiency. Consider the following options:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance air filter | Improved airflow and fuel efficiency |

| Transmission | Enhanced fluid | Smoother shifting and better power transfer |

| Suspension | Upgraded shock absorbers | Increased comfort and stability |

Technology Integration

Modernizing your equipment with the latest technology can streamline operations and improve productivity. Consider these technological advancements:

| Technology | Integration Method | Advantages |

|---|---|---|

| GPS Guidance | Install a GPS receiver | Precision farming and reduced overlap |

| Telematics Systems | Connect to a telematics module | Remote monitoring and diagnostics |

| Advanced Display | Upgrade to a multifunction display | Enhanced user interface and data access |

Resources for Further Learning

Expanding your knowledge on machinery maintenance and troubleshooting can significantly enhance your skills and confidence. This section provides valuable materials and platforms to help you deepen your understanding of equipment servicing and operation.

Books and Guides

Comprehensive literature offers in-depth insights and step-by-step instructions. Consider exploring the following resources:

| Title | Author/Publisher | Year |

|---|---|---|

| Heavy Equipment Maintenance | Tech Press | 2020 |

| Understanding Agricultural Machines | Farm Knowledge | 2019 |

| Field Operations Handbook | Industry Insights | 2021 |

Online Resources

In addition to printed materials, various online platforms provide tutorials, videos, and forums where you can interact with experts and fellow enthusiasts:

- Mechanics Forum – A community for sharing tips and experiences.

- YouTube – Channels dedicated to machinery maintenance and repair.

- Online Courses – Websites offering structured learning on equipment operation.