Engine Troubleshooting Essentials

Understanding the fundamentals of engine troubleshooting can help vehicle owners quickly identify and resolve common issues that affect performance. This section provides an overview of key diagnostic methods and essential tips for assessing engine functionality, allowing for effective and efficient problem-solving.

Identifying Symptoms

Begin by observing any unusual sounds, odors, or changes in engine behavior, as these can often indicate underlying issues. Pay close attention to the sounds during startup, idling, and acceleration, as each can point to different components. Odd smells, especially those of fuel, oil, or burning, may signal leaks, overheating, or other malfunctions. Recording these details can help with diagnosis and repairs.

Basic Diagnostic Techniques

Using diagnostic tools like an engine code reader or checking for dashboard warning lights can help pinpoint specific faults. Many modern systems provide error codes, simplifying the process. Additionally, regular inspection of key components like belts, hoses, and fluid levels aids in recognizing early warning signs. Taking these steps can pre

Transmission System Diagnosis

The transmission system is essential for managing the power flow between the engine and the wheels. Effective diagnosis of transmission issues can prevent minor problems from becoming severe, costly repairs. Early identification of potential faults enhances vehicle performance and prolongs the lifespan of the components.

Below are common signs and diagnostic steps that can help in identifying and resolving transmission issues:

- Unusual Sounds: Listen for any grinding, whining, or clunking noises that may indicate issues within the transmission system.

- Fluid Leaks: Check for transmission fluid leaks under the vehicle, as these can lead to slipping or overheating.

- Shifting Delays: Notice if the transmission hesitates when changing gears, which could signify low fluid levels or worn internal parts.

- Warning Lights: Pay attention to any dashboard warning lights that may indicate an issue with the transmission.

To further diagnose transmission issues, follow these inspection steps:

- Examine the transmission fluid level and quality, noting any unusual odors or discoloration.

- Inspect the transmission pan for metal shavings, which could indicate internal wear.

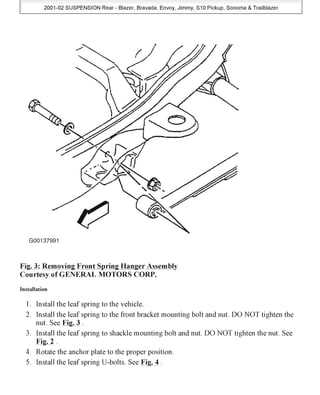

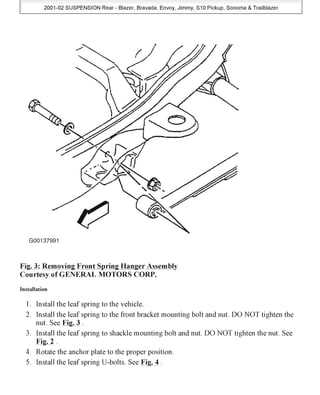

Suspension Maintenance Tips

Keeping the suspension in optimal condition enhances driving comfort and stability. Regular care helps extend the lifespan of components and prevents wear that can affect vehicle handling.

Begin by routinely inspecting all suspension parts for any signs of damage, such as cracks, corrosion, or loose bolts. Focus on areas like control arms, ball joints, and shock absorbers, as these are crucial to a stable ride. Early detection of issues can prevent more significant problems.

It’s also important to maintain proper alignment and balance. Misalignment can lead to uneven tire wear and impact handling, so check alignment regularly, especially if the vehicle feels unsteady or pulls to one side. Keeping tires balanced helps reduce strain on suspension parts and minimizes vibrations.

Lastly, ensure that bushings and mounts are free of damage or excessive wear. These small components support the suspension system, absorbing shocks and vibrations. Replacing them when necessary will improve comfort and reduce strain on other suspension elements.

Brake System Repair Guide

The brake system plays a crucial role in vehicle safety, ensuring controlled stops and responsive handling in diverse driving conditions. This section provides guidance on maintaining this vital system, covering essential steps for inspection and upkeep.

Identifying Common Brake Issues

Brake performance can deteriorate due to wear, fluid loss, or mechanical faults. Symptoms like grinding sounds, reduced responsiveness, or unusual pedal feel signal potential issues. Identifying these warning signs early helps avoid further complications and enhances safety.

Steps for Brake Component Maintenance

Regular inspection and replacement of brake pads, rotors, and fluid ensure reliable performance. Begin by checking pad thickness, rotor surfaces, and fluid levels. Replace pads if they are below the recommended thickness. Ensure rotors are smooth and without significant wear. Lastly, maintain proper brake fluid levels and flush as needed to prevent system corrosion and ensure optimal pressure.

Taking the time to check these elements regularly will help maintain the braking system’s effectiveness, ensuring smoother stops and contributing to overall vehicle control.

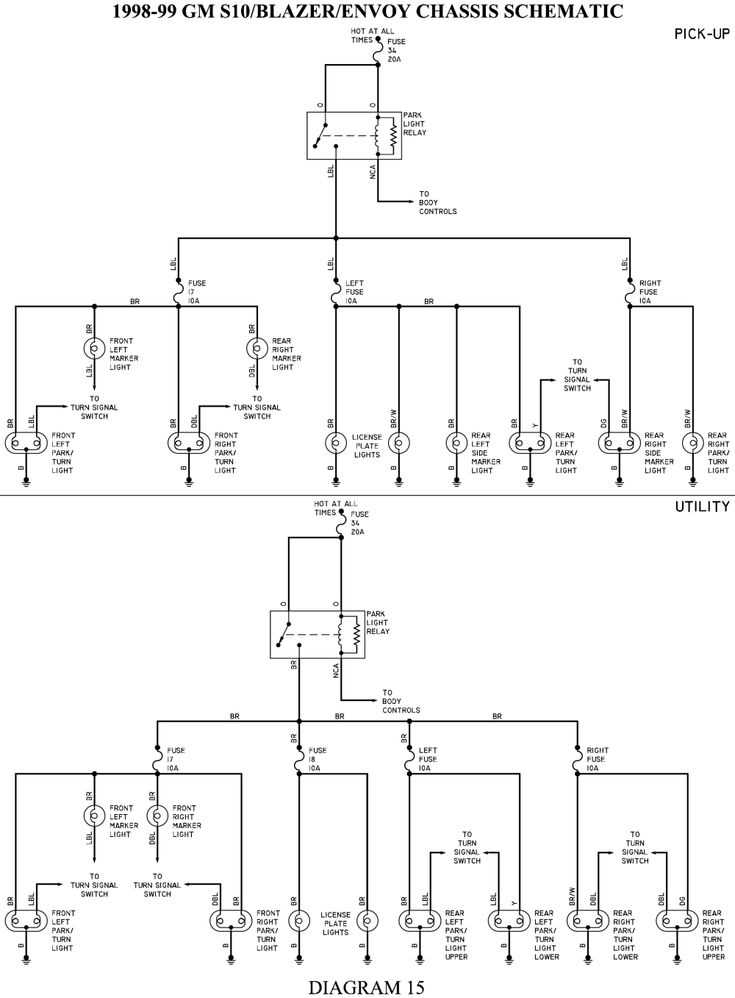

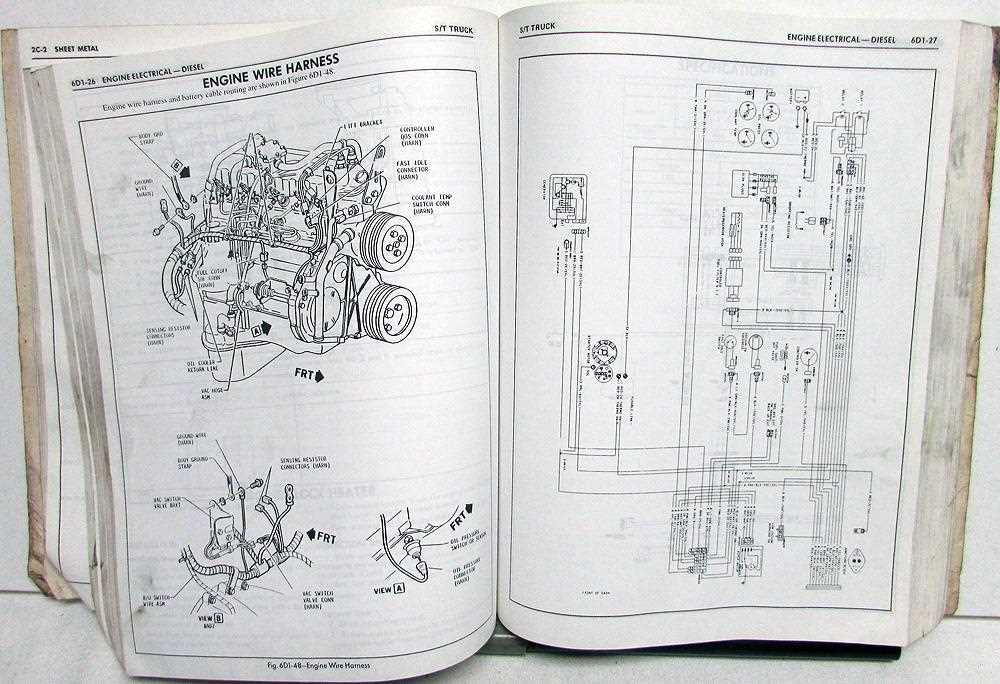

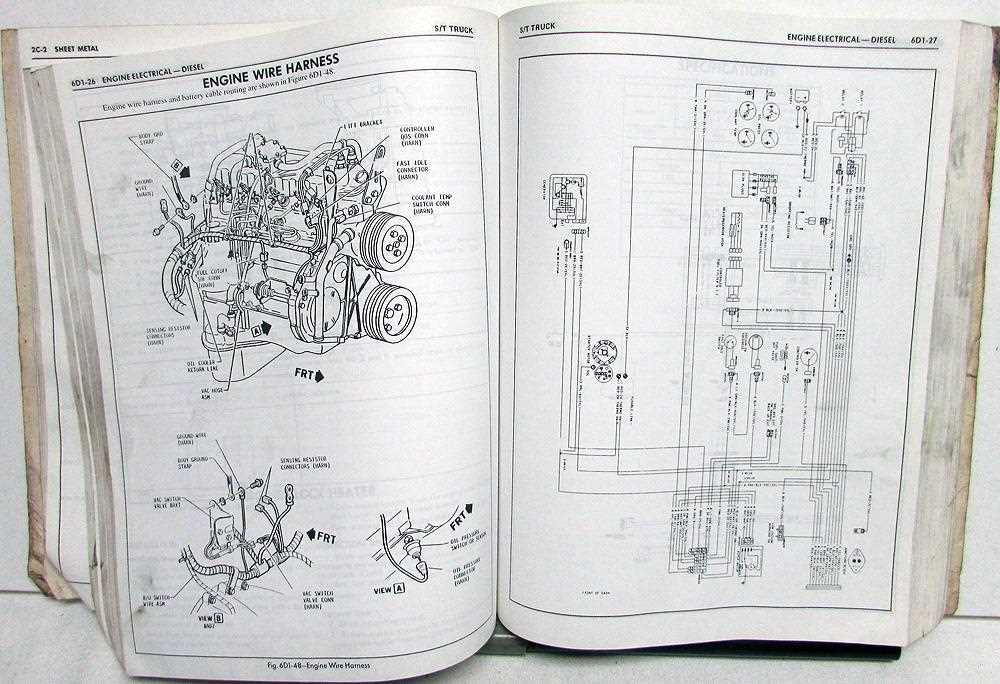

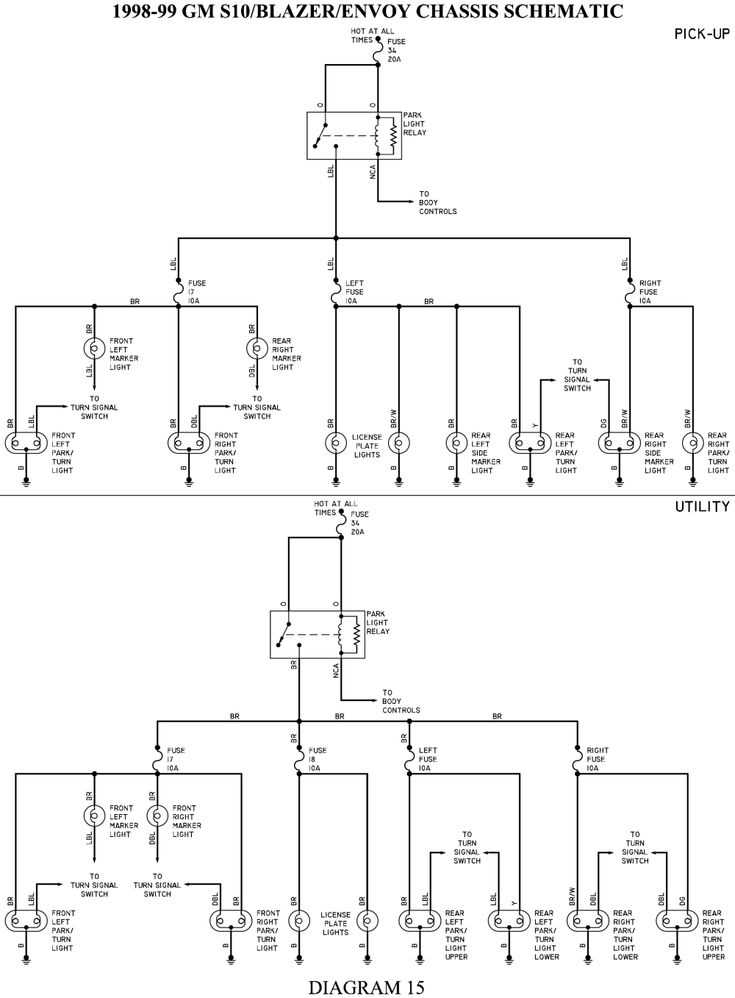

Electrical Wiring and Connections

The integrity of the electrical system is vital for the overall performance of any vehicle. Proper connections and wiring ensure that all components function seamlessly, providing safety and efficiency. Understanding the layout and functionality of these systems is essential for troubleshooting and maintenance.

Wiring Layout

The wiring harness serves as the nervous system of the vehicle, linking various electrical components. Familiarizing yourself with the layout of wires and their corresponding functions will aid in diagnosing issues effectively. It’s important to refer to a wiring diagram specific to your model for accurate information.

Connections and Terminals

Connections must be secure to prevent voltage drops and potential malfunctions. Regularly inspect terminals for corrosion or damage. Using dielectric grease can help protect connections from moisture and improve conductivity.

Testing Electrical Components

Utilizing a multimeter is essential for verifying the functionality of electrical components. This tool allows you to measure voltage, current, and resistance, helping to pinpoint faults in the system. Always ensure the vehicle is off before performing any tests to avoid electrical shock or damage.

Safety Precautions

When working with electrical systems, safety should be a priority. Disconnect the battery before beginning any repairs or modifications to avoid short circuits. Wear protective gear and work in a well-ventilated area to mitigate risks associated with electrical work.

Fuel System Inspection Procedures

The examination of the fuel system is crucial for ensuring optimal performance and efficiency of the vehicle. Regular inspections can help identify potential issues that may affect fuel delivery and engine operation. This section outlines the essential steps to effectively assess the fuel system components.

Key areas to focus on during the inspection include:

- Fuel Tank: Inspect for any signs of damage, corrosion, or leaks. Ensure that the tank is securely mounted.

- Fuel Lines: Check for cracks, leaks, or wear. Make sure connections are tight and free from corrosion.

- Fuel Pump: Listen for unusual noises during operation. Verify proper functioning by checking fuel pressure.

- Fuel Filter: Assess for clogs or contamination. Replace if necessary to maintain efficient fuel flow.

- Injectors: Inspect for leaks or blockages. Clean or replace as needed to ensure proper fuel atomization.

It is advisable to follow a systematic approach during the evaluation process. Document any findings and address issues promptly to prevent further complications.

For thorough diagnostics, utilizing specialized tools can enhance the inspection process. Consider employing a fuel pressure gauge and a multimeter for electrical components. Adhering to manufacturer specifications will provide accurate insights into the system’s condition.

Cooling System Maintenance

Regular upkeep of the cooling system is essential for optimal performance and longevity of the vehicle. Proper maintenance helps prevent overheating and ensures that the engine operates efficiently. Below are key practices to maintain this critical system.

- Inspect Coolant Levels: Regularly check the coolant reservoir to ensure it is filled to the recommended level. Low coolant can lead to overheating.

- Flush the System: Periodically flushing the cooling system removes debris and old coolant, helping to maintain efficiency. Follow the manufacturer’s guidelines for the flushing interval.

- Examine Hoses and Connections: Inspect all hoses for signs of wear, leaks, or cracks. Replace any damaged hoses to prevent coolant loss.

- Check the Radiator: Ensure the radiator is clean and free of obstructions. A clogged radiator can impede airflow and cooling efficiency.

- Monitor Temperature Gauge: Keep an eye on the temperature gauge while driving. If it shows higher than normal readings, investigate the cooling system for potential issues.

- Inspect the Thermostat: A malfunctioning thermostat can disrupt the flow of coolant. Regular checks can help identify problems early.

By adhering to these maintenance practices, you can help ensure the longevity and reliability of the cooling system, contributing to the overall performance of the vehicle.

Battery Testing and Replacement

Ensuring the proper functionality of your vehicle’s energy source is crucial for optimal performance. Regular examination and timely substitution of the power unit can prevent unforeseen breakdowns and enhance overall efficiency. This section outlines the essential steps for assessing battery health and executing a successful replacement.

Testing the Battery

Start by utilizing a multimeter to measure the voltage of the battery. A fully charged unit should display a reading between 12.6 and 12.8 volts. If the voltage falls below 12.4 volts, the battery may be partially discharged. Additionally, consider performing a load test, which simulates the battery’s performance under typical conditions. This can help identify any issues that might not be apparent through voltage readings alone.

Replacing the Battery

When it’s time for a replacement, ensure you choose a compatible unit for your vehicle. Begin by disconnecting the negative terminal first to prevent any electrical shorts. Next, remove the positive terminal and secure the old battery. Place the new power source in the same orientation as the old one, connecting the positive terminal first, followed by the negative. Finally, check all connections to ensure they are secure and free from corrosion.

Exhaust System Repairs

The exhaust system plays a crucial role in maintaining engine performance and ensuring a smooth operation. Proper maintenance and timely interventions are essential to prevent potential issues that can lead to reduced efficiency or increased emissions. Addressing exhaust-related problems can enhance vehicle longevity and provide a better driving experience.

Common issues within the exhaust system may include leaks, rust, or damaged components. Identifying these problems early can save time and resources. It is important to inspect various parts such as the muffler, catalytic converter, and exhaust pipes regularly. Replacing worn-out parts is often necessary to ensure the system functions optimally.

To perform effective fixes, first, assess the condition of the exhaust components. Utilizing appropriate tools for removal and installation will facilitate smoother repairs. Following guidelines for installation is vital to maintain the integrity of the exhaust system. Lastly, always test the system after repairs to ensure everything operates as intended, confirming that all components are secure and functioning correctly.

Ignition System Overview

The ignition system plays a crucial role in the operation of an internal combustion engine. It is responsible for igniting the air-fuel mixture within the engine cylinders, ensuring efficient combustion and optimal performance. Understanding the components and functioning of this system is essential for effective troubleshooting and maintenance.

This system consists of several key components that work together to create a spark at the right moment. The main parts include the ignition coil, distributor, spark plugs, and various sensors. Each component contributes to the overall efficiency and effectiveness of the ignition process.

| Component |

Function |

| Ignition Coil |

Transforms low voltage from the battery into high voltage needed to create a spark. |

| Distributor |

Distributes the high voltage to the correct cylinder at the appropriate time. |

| Spark Plug |

Ignites the air-fuel mixture by producing a spark when high voltage is applied. |

| Ignition Module |

Controls the timing of the spark and the operation of the ignition coil. |

| Sensors |

Provide data to the ignition module to optimize spark timing based on engine conditions. |

Proper functioning of the ignition system is vital for engine performance. Issues such as weak spark, misfiring, or starting difficulties can often be traced back to faults within this system. Regular inspections and maintenance are recommended to ensure all components are in good working order.

Body and Frame Restoration

The process of rejuvenating the external structure and chassis of a vehicle is essential for maintaining its integrity and aesthetic appeal. Over time, exposure to elements can lead to rust, dents, and other forms of deterioration. A thorough restoration not only enhances the visual aspect but also contributes to the overall performance and safety of the automobile.

Assessment and Preparation

Before embarking on the restoration journey, a detailed examination of the body and frame is necessary. Identify areas of concern, such as rust spots or structural weaknesses. Preparation involves removing any damaged components and cleaning surfaces to ensure optimal adhesion for repairs. Utilizing appropriate tools and protective gear is crucial during this stage to maintain safety.

Repair Techniques and Finishing Touches

Various techniques can be employed to address the identified issues. Welding, for instance, is effective for mending structural damage, while body filler may be used to smooth out imperfections. Once repairs are completed, finishing touches like sanding and painting restore the vehicle’s original charm. Employing high-quality materials ensures durability and a professional appearance, bringing the project to a successful conclusion.

Steering System Adjustment Tips

Properly calibrating the steering mechanism is essential for optimal vehicle handling and safety. A well-adjusted system ensures smooth operation, enhances driver control, and extends the lifespan of steering components. This section outlines effective methods for fine-tuning your vehicle’s steering system.

Essential Tools for Adjustment

- Wrench set

- Screwdrivers

- Torque wrench

- Measuring tape

- Alignment tool

Adjustment Procedures

- Begin by inspecting the steering linkage for any signs of wear or damage.

- Check the alignment of the front wheels; improper alignment can lead to handling issues.

- Adjust the tie rod ends to achieve the correct toe angle, ensuring that the wheels are parallel.

- Tighten all connections to the manufacturer’s specified torque settings.

- Test drive the vehicle to verify smooth steering operation and make further adjustments if necessary.