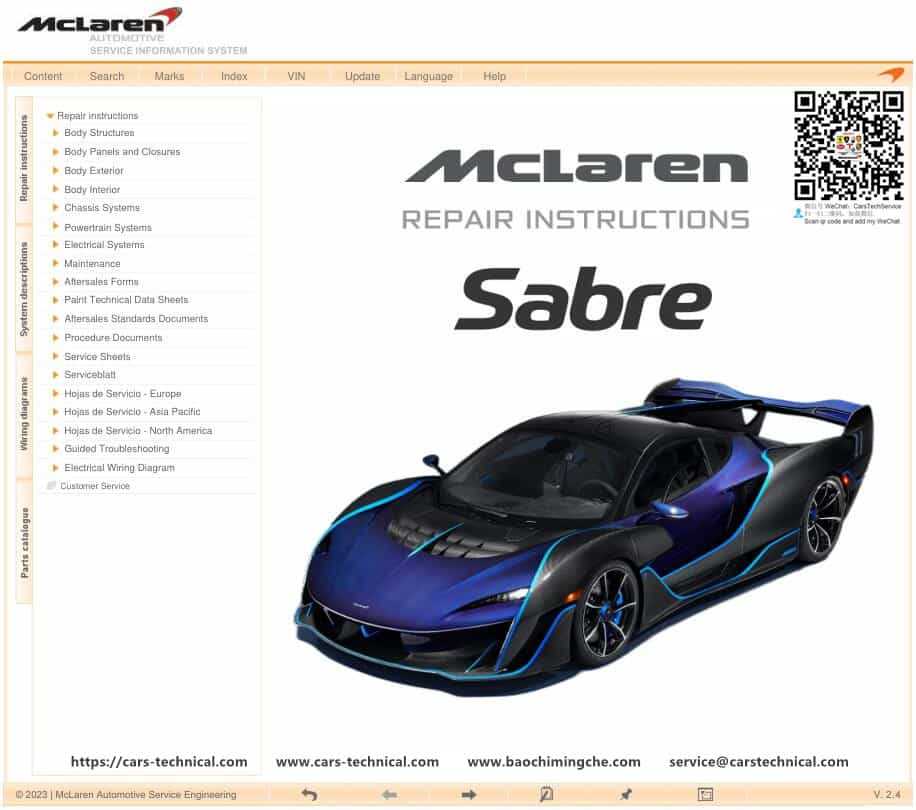

Understanding how various components within a vehicle function is key to maintaining its overall performance. This guide provides insights into the essential processes involved in diagnosing and resolving issues that may arise in different systems. It serves as a helpful resource for both beginners and experienced individuals looking to enhance their skills in vehicle maintenance.

Through practical advice and clear explanations, this guide covers a range of methods for identifying problems and implementing solutions. Whether you are dealing with complex parts or routine check-ups, this resource ensures that you have the knowledge required to keep your vehicle running smoothly.

Detailed instructions and step-by-step approaches are included to assist with common challenges. By following these tips, you can gain confidence in handling the tasks needed to ensure the functionality and longevity of your vehicle’s systems.

Automotive Electrical Repair Manual

A comprehensive guide to restoring and maintaining vehicle components is essential for ensuring smooth and safe performance. It helps diagnose common issues, explains how to address them, and provides practical tips for effective solutions. Clear instructions and illustrations are designed to simplify even the most complex tasks, making it easier to get the job done with confidence.

Understanding Vehicle Power Systems

Key systems that power various functions in a car can sometimes malfunction, leading to performance issues. This guide offers step-by-step assistance in troubleshooting and fixing these common problems, ensuring that all parts function properly and efficiently.

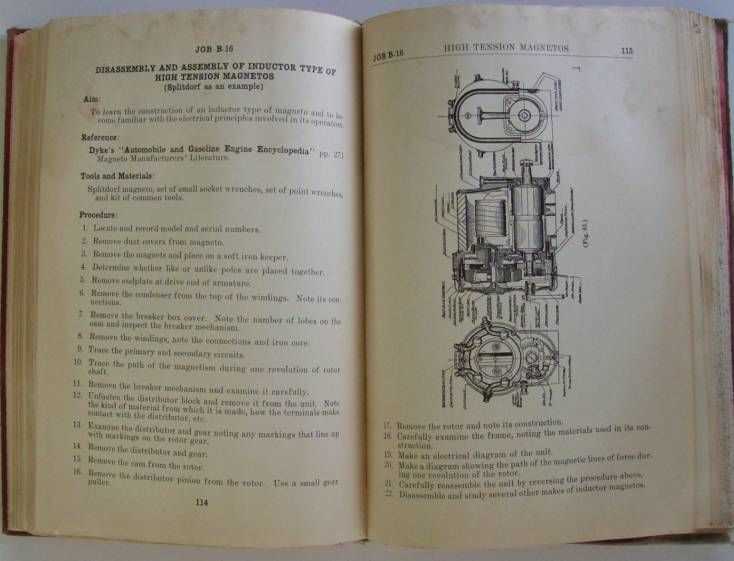

Steps to Identifying Common Malfunctions

By following a systematic approach to locating and addressing issues, users can efficiently resolve complications without needing extensive prior experience. Clear descriptions and detailed procedures provide everything needed to complete the task successfully.

Understanding Basic Electrical Components

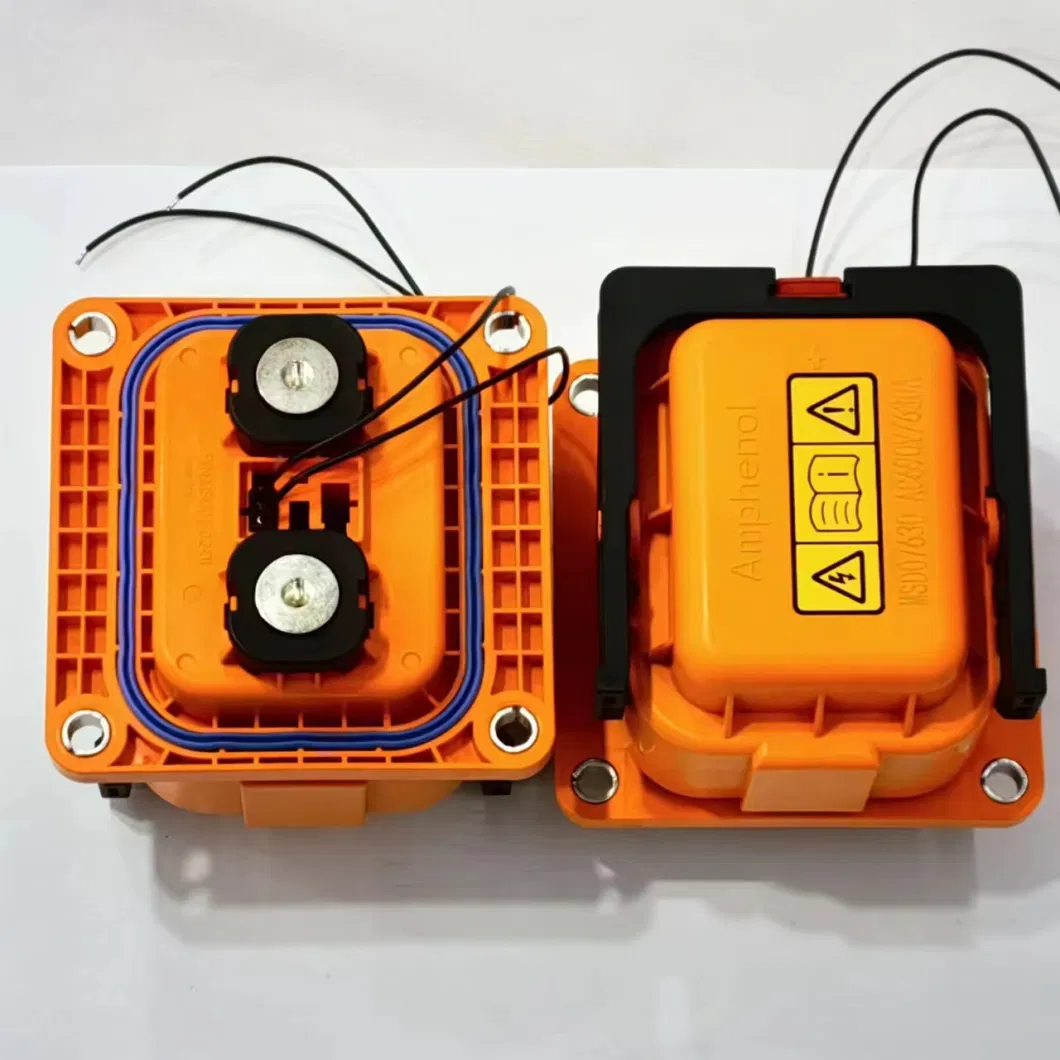

To ensure the smooth operation of various systems, it’s essential to have a foundational grasp of the components involved. These elements help distribute power and control different mechanisms, contributing to the overall functionality of the system. Recognizing their roles and how they interact provides a better understanding of how everything works together seamlessly.

Key Components Overview

The main components responsible for transmitting energy and signals include a few basic parts. They each have a distinct purpose and work in unison to keep the systems running efficiently. Identifying these core elements is the first step in understanding how power is managed and distributed.

| Component | Function |

|---|---|

| Wires | Carry energy between different parts, connecting the system. |

| Fuses | Protect parts from excessive power, preventing damage by breaking the circuit. |

| Relays | Act as switches, allowing parts to operate when needed. |

| Switches | Control the flow of energy, turning parts on or off as required. |

Connection and Interaction

Each component has a specific role, but their effectiveness relies on how well they connect and communicate with one another. Understanding these interactions helps diagnose issues and maintain a well-functioning system.

Common Electrical Issues in Vehicles

Many drivers encounter various problems with the systems responsible for powering different components in their cars. These issues can range from minor inconveniences to more serious problems that affect the overall performance of the vehicle. Recognizing these common faults can help address them more effectively and prevent further complications.

- Battery-related problems: A weak or failing battery often leads to difficulties in starting the engine or keeping the lights and accessories functioning properly.

- Faulty connections: Loose or corroded cables can disrupt the flow of energy to critical parts of the car, leading to malfunctions in lighting, ignition, and other key features.

- Malfunctioning alternator: When the alternator stops working correctly, it may not recharge the battery or supply sufficient power to the car’s systems while driving.

- Blown fuses: If a fuse blows, it can disable important components like headlights, the radio, or safety systems, requiring replacement to restore functionality.

- Short circuits: Damage to wires or connections can result in short circuits, causing intermittent or total loss of power to certain parts of the vehicle.

Tools Needed for Electrical Repairs

To handle complex system tasks effectively, having the right instruments is essential. With the proper gear, the process becomes safer and more efficient, allowing you to diagnose and resolve issues with precision. Investing in quality tools ensures that the work proceeds smoothly, reducing the likelihood of complications during the job.

Multimeters are crucial for measuring voltage, current, and resistance. These devices provide accurate readings, making it easier to locate and fix problems. Ensure that your multimeter is suitable for the systems you’re working on.

Wire strippers help in removing insulation without damaging the conductors underneath. A reliable set allows for clean, safe connections, which are vital for long-lasting results.

Crimping tools are needed for securing connectors to wires. A well-crimped connection is strong and resistant to wear, ensuring a stable link between components.

Additionally, having a set of screwdrivers, specifically insulated ones, is important for safety when working with high-voltage systems. These help with disassembling panels and accessing components safely.

Finally, heat shrink tubing and soldering irons are essential for creating durable, insulated connections. Using them correctly guarantees that connections are both safe and resistant to environmental stress.

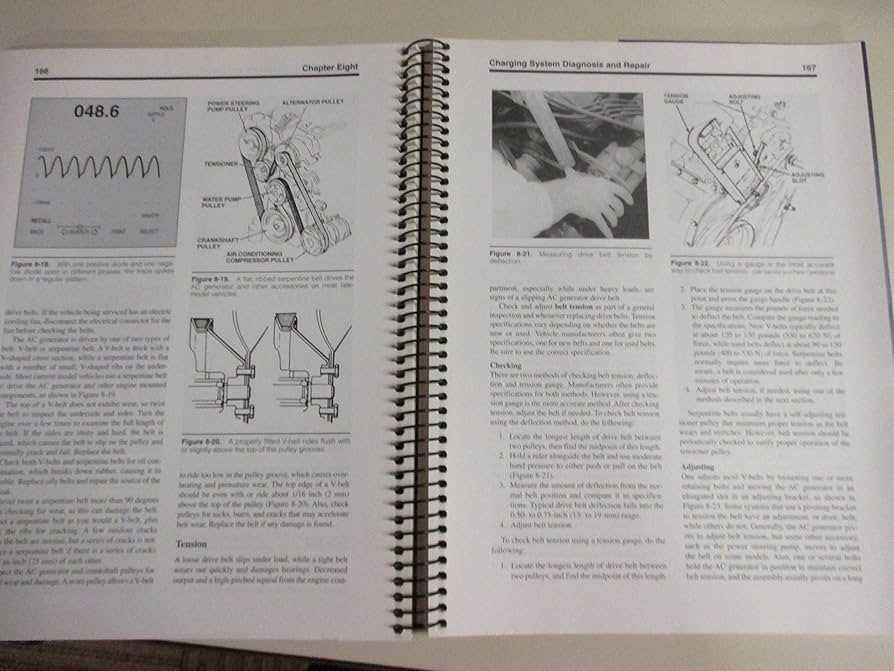

Diagnosing Wiring Problems in Cars

Identifying issues with a vehicle’s wiring system can be challenging, as faults often arise from various sources. It’s essential to inspect the entire network of connections and circuits to find the root of the problem. Understanding how to approach this process systematically will help avoid further complications.

The first step is to visually check all visible wires and connections for signs of wear or damage. Loose or corroded contacts can lead to irregular functioning of different components, while broken or frayed wires may cause complete failure in specific parts of the vehicle. It’s important to address these issues as soon as they are identified.

Next, use basic tools such as a multimeter to test the flow of current through individual sections of the system. This will help you locate areas with interruptions or unexpected resistance, which are often indicators of hidden issues within the circuits. By systematically working through each section, you can narrow down the exact location of the fault.

Finally, it’s crucial to ensure that any repairs or adjustments made are secure and long-lasting. Proper insulation and solid connections will prevent future problems and improve the overall reliability of the system.

How to Check Car Battery Health

Ensuring that a vehicle’s energy source is in optimal condition is crucial for reliable performance. Regular assessments can help identify potential issues before they lead to significant problems. Understanding the health of this vital component can prevent unexpected failures and extend its lifespan.

To evaluate the condition of the power source, start by inspecting for any visible damage, such as corrosion or cracks on the surface. Look at the terminals and connections to ensure they are secure and clean. A buildup of grime can impede proper function.

Next, use a voltage tester to measure the output. A healthy unit typically shows a reading between 12.4 and 12.7 volts when the engine is off. If the reading falls below this range, it may indicate a weakened state.

Additionally, conducting a load test can provide further insight. This test simulates the demands placed on the energy source during operation. If the voltage drops significantly under load, it suggests a decline in performance.

Finally, consider the age of the unit, as most have a lifespan of about three to five years. If the component is nearing the end of its expected life, proactive replacement may be wise, even if immediate issues are not present.

Fixing Faulty Fuses and Relays

Addressing issues with small components in the power distribution system can significantly improve the functionality of various systems in vehicles. These components, although often overlooked, play a crucial role in controlling the flow of electricity to different parts. Recognizing and resolving problems related to these parts can lead to a smoother operation and enhanced reliability.

Identifying the Problem

Common symptoms of faulty components include inconsistent operation of electrical systems, blown circuits, or devices that fail to function altogether. When issues arise, the first step is to conduct a thorough inspection to identify signs of damage or wear. Checking for burnt or broken components is essential, as these can disrupt the normal functioning of the entire system.

Replacement and Maintenance Tips

Once the problematic components are identified, replacing them is often a straightforward process. It is crucial to select the correct specifications to ensure compatibility. After replacement, testing the systems is vital to confirm that everything operates as intended. Regular maintenance, including routine checks, can prevent future issues and prolong the lifespan of these critical components. Keeping an eye on connections and ensuring cleanliness can also mitigate potential problems.

Replacing Damaged Wiring Harnesses

When components within a vehicle experience malfunction due to compromised wiring, it becomes essential to address the issue promptly. Replacing affected wiring systems is crucial to restoring proper functionality and ensuring safety. This process involves identifying the damaged segments, removing them, and installing new wiring with care to maintain the vehicle’s overall integrity.

Identifying Damage

Before proceeding with the replacement, it is vital to pinpoint the specific areas where the wiring is impaired. Look for signs such as fraying, corrosion, or broken connections. A thorough inspection allows for accurate assessment and helps in selecting the right replacement components.

Installation Process

Once the damaged wiring is identified, the next step involves carefully disconnecting the old system. Make sure to document the original setup for reference. After removal, install the new wiring, ensuring all connections are secure. Pay special attention to routing and protecting the wiring to prevent future damage. Finally, test the new system to confirm that functionality has been restored.

Repairing Malfunctioning Alternators

Alternators play a crucial role in ensuring a vehicle’s electrical system functions properly. When these components fail, it can lead to various issues that affect the overall performance and reliability of the vehicle. Understanding the common problems associated with alternators and how to address them can help in restoring optimal functionality.

Here are some frequent issues encountered with alternators:

- Electrical Output Failure: The alternator may fail to generate sufficient power, leading to battery discharge.

- Unusual Noises: Grinding or whining sounds can indicate internal wear or damage.

- Warning Lights: Dashboard indicators may illuminate, signaling alternator problems.

- Corrosion: Accumulation of rust or debris on terminals can disrupt connections.

To effectively address these issues, follow these steps:

- Diagnostic Testing: Use a multimeter to check voltage output. A healthy alternator should read between 13.8 and 14.5 volts.

- Visual Inspection: Examine the component for signs of wear, damage, or loose connections.

- Component Replacement: If any parts are damaged, consider replacing the alternator or its internal components.

- Cleaning Connections: Remove corrosion from battery terminals and connectors to ensure a solid electrical connection.

By recognizing the signs of alternator issues and taking appropriate actions, one can effectively restore the functionality of the vehicle’s electrical system, ensuring reliable operation.

How to Test Electrical Circuits

Testing circuits is essential for diagnosing issues and ensuring proper functionality. This process involves using various tools and techniques to identify faults and verify the operation of components. Understanding how to perform these tests can help maintain optimal performance.

To effectively test circuits, follow these general steps:

- Gather Necessary Tools: Ensure you have the appropriate instruments, such as multimeters, probes, and connectors.

- Safety Precautions: Always prioritize safety by wearing protective gear and ensuring the power is off before beginning tests.

- Visual Inspection: Check for visible signs of damage, such as frayed wires, corrosion, or loose connections.

Once initial checks are complete, proceed with the following testing methods:

- Continuity Test: Use a multimeter to verify the pathway of the circuit. A beep or reading indicates a complete path.

- Voltage Test: Measure voltage across components to ensure they receive the correct amount of power.

- Current Test: Determine the flow of current using a clamp meter, which helps identify any issues with current levels.

By following these steps, one can effectively troubleshoot and ensure the reliability of circuits.

Dealing with Dashboard Warning Lights

Dashboard indicators serve as essential signals, alerting drivers to potential issues within their vehicles. Understanding these alerts is crucial for maintaining safety and ensuring optimal performance. When a warning light activates, it is important to interpret its meaning and respond appropriately to prevent further complications.

Each light on the dashboard corresponds to a specific function or system. For instance, a light indicating engine trouble may suggest a mechanical malfunction, while a symbol for low tire pressure could signal a need for inflation. Recognizing these symbols can empower drivers to take necessary actions, whether it’s conducting simple checks or seeking professional assistance.

When faced with an illuminated warning light, the first step is to consult the vehicle’s documentation to identify the exact nature of the alert. If the light persists after addressing the issue, it may be wise to perform a thorough evaluation or contact a qualified technician. Timely attention to dashboard alerts can help avert serious malfunctions and enhance overall driving safety.

Preventing Future Electrical Problems

Ensuring the longevity and reliability of your vehicle’s systems involves proactive measures. Regular maintenance and attention to details can significantly reduce the risk of complications down the line. Here are some effective strategies to safeguard against potential issues.

| Tip | Description |

|---|---|

| Routine Inspections | Conduct regular assessments of your vehicle’s components to identify wear or damage early. |

| Clean Connections | Keep all terminals and connectors free from dirt and corrosion to ensure optimal performance. |

| Use Quality Parts | When replacing components, opt for high-quality parts to maintain system integrity. |

| Monitor Warning Signals | Pay attention to dashboard alerts and respond promptly to avoid exacerbating issues. |

| Consult Professionals | Seek expert assistance for complex problems to prevent further complications. |