Ensuring the longevity and performance of your vehicle’s engine is crucial for a seamless driving experience. This section offers invaluable insights into maintenance procedures, troubleshooting techniques, and effective solutions tailored for specific engine models. Whether you’re a seasoned mechanic or a novice enthusiast, having access to detailed information can significantly enhance your repair skills.

Understanding the intricacies of engine mechanics is essential for diagnosing issues accurately. Common problems can arise from various factors, including wear and tear, fluid leaks, or electrical failures. By familiarizing yourself with the engine’s components, you can identify symptoms early and apply the appropriate fixes.

Moreover, access to detailed instructional content not only boosts your confidence but also helps you save time and money on repairs. With a structured approach to engine care, you can ensure optimal performance and reliability, making every journey more enjoyable.

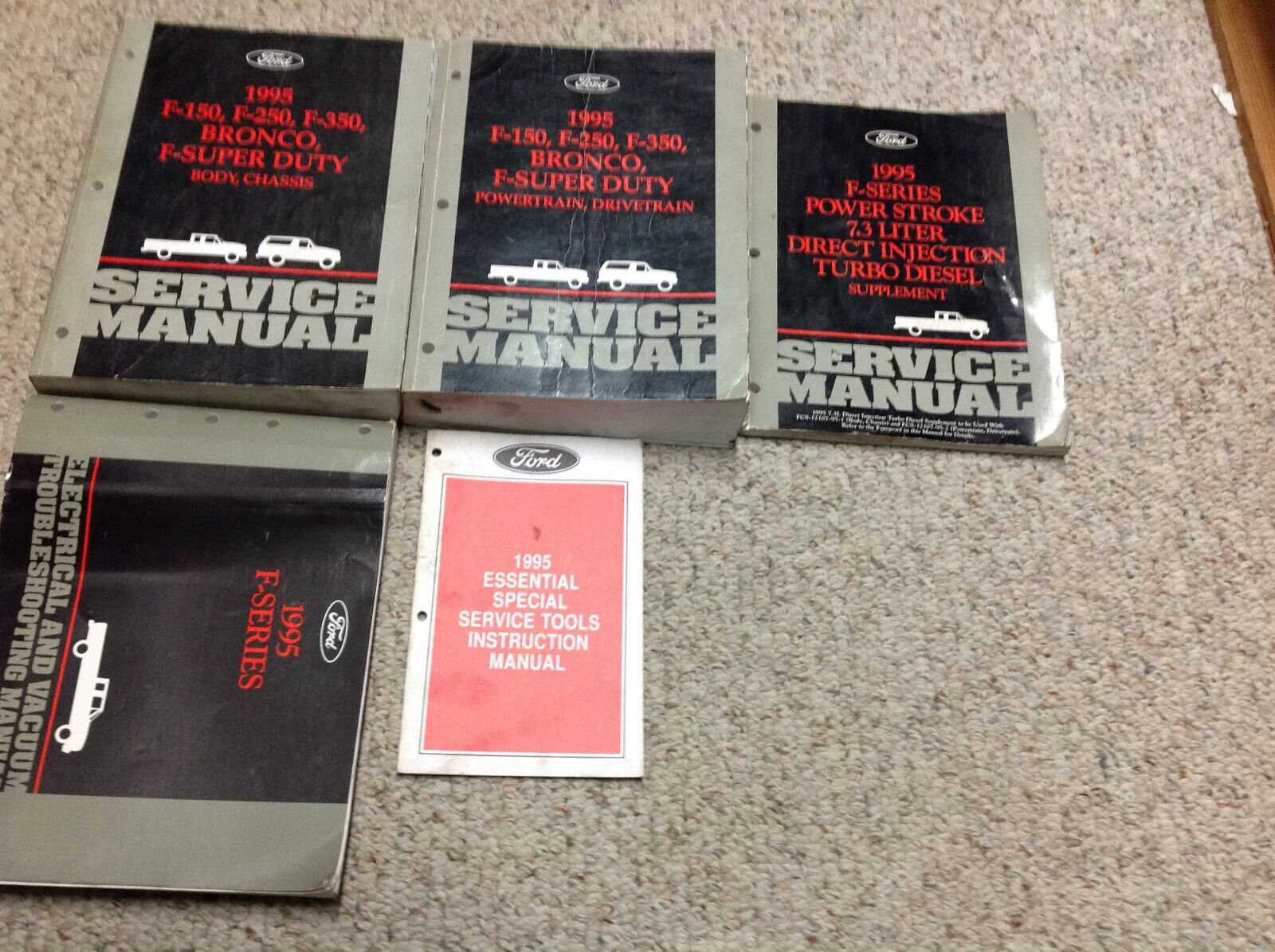

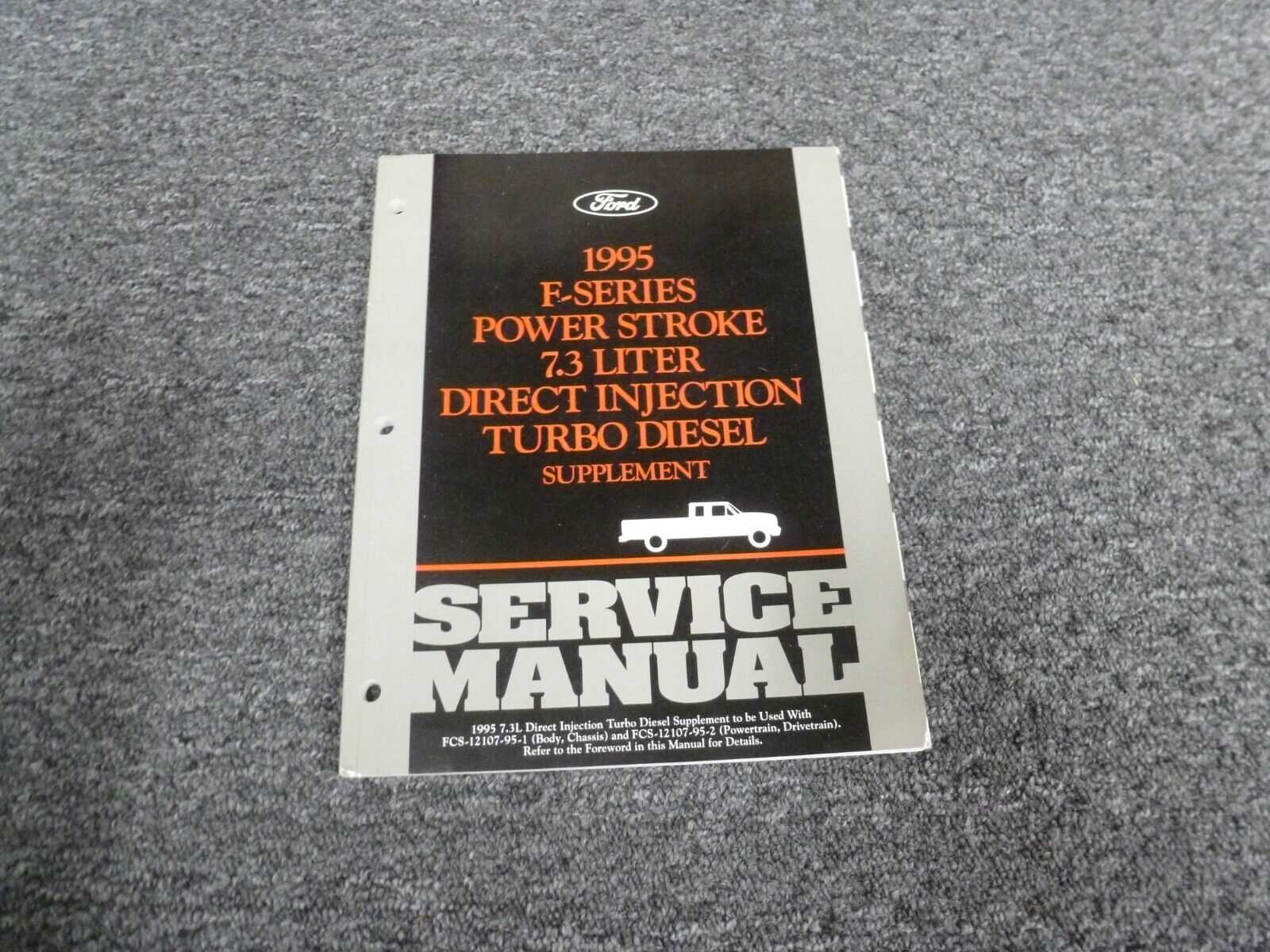

Overview of the 1995 7.3 Powerstroke

This section provides a comprehensive look at a notable diesel engine produced during the mid-1990s. Known for its robust performance and reliability, this engine has earned a reputation among enthusiasts and professionals alike. Its design emphasizes durability and efficiency, making it a favored choice for various applications, from heavy-duty trucks to recreational vehicles.

Key Features

One of the standout characteristics of this engine is its impressive torque delivery, which ensures strong performance in challenging conditions. The incorporation of advanced fuel injection technology enhances power output while maintaining fuel efficiency. Additionally, its sturdy construction contributes to long service life, appealing to those who seek dependability in their machinery.

Maintenance Considerations

To keep this engine performing optimally, regular maintenance is essential. Key components such as the fuel system and cooling mechanisms require periodic checks to prevent potential issues. Engaging in preventive measures can significantly extend the lifespan of the engine and improve its overall functionality. Understanding the intricacies of this powerplant is crucial for anyone looking to maximize its potential.

Common Issues with the 7.3 Engine

The engine in question is renowned for its durability and performance, yet it is not without its share of challenges. Understanding these common issues can help owners maintain optimal functionality and longevity. Below are some frequent problems that enthusiasts and mechanics encounter, along with their potential causes and solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Oil Leaks | Worn gaskets, seals, or improper installation | Inspect and replace gaskets, check seal integrity |

| Overheating | Coolant leaks, faulty thermostat, or radiator issues | Check coolant levels, replace thermostat, flush radiator |

| Starting Difficulties | Weak batteries, faulty glow plugs, or fuel issues | Test battery condition, replace glow plugs, check fuel supply |

| Excessive Smoke | Fuel injector problems or oil contamination | Inspect injectors, monitor oil levels |

| Rough Idling | Air leaks, injector issues, or dirty fuel filters | Check for leaks, clean or replace injectors, change fuel filter |

Awareness of these issues allows for proactive measures, ensuring a smoother and more reliable operation. Regular maintenance and timely interventions can significantly extend the life of the engine and enhance overall performance.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance and restoration tasks. Whether you’re tackling minor adjustments or major overhauls, a well-equipped workspace enhances efficiency and ensures precision. This section highlights the fundamental instruments that every enthusiast should consider for their projects.

Basic Hand Tools

Start with a solid collection of hand tools, including wrenches, sockets, and screwdrivers. Adjustable wrenches and ratchet sets are particularly versatile, allowing you to handle various fasteners with ease. Additionally, torque wrenches are essential for applying the correct tension to bolts, preventing damage during assembly.

Specialized Equipment

For more intricate tasks, specialized equipment becomes necessary. Multimeters and oscilloscopes are invaluable for diagnosing electrical issues, while compression testers can assess engine health. Investing in quality tools not only improves accuracy but also enhances the longevity of your equipment.

Step-by-Step Maintenance Procedures

Maintaining a vehicle’s performance and longevity requires a systematic approach to upkeep. Following a series of structured tasks ensures that all components function optimally, preventing issues before they arise. This guide outlines essential steps to keep your engine running smoothly, enhancing reliability and efficiency.

1. Check Fluid Levels

Start by inspecting all essential fluids, including engine oil, coolant, transmission fluid, and brake fluid. Make sure to top off any low levels and replace fluids as needed, following the manufacturer’s recommendations for intervals.

2. Replace Air Filters

Regularly changing the air filter is crucial for optimal air intake. A clean filter ensures that the engine breathes efficiently, improving performance and fuel economy. Check the filter every 15,000 miles or as specified in your vehicle’s guidelines.

3. Inspect Belts and Hoses

Examine the engine’s belts and hoses for signs of wear, such as cracks, fraying, or leaks. Replace any damaged components promptly to prevent breakdowns. It’s advisable to conduct this inspection during routine service intervals.

4. Monitor Battery Health

Check the battery terminals for corrosion and ensure that connections are tight. Test the battery’s voltage regularly, and replace it if it shows signs of weakening, typically every three to five years.

5. Examine the Exhaust System

Inspect the exhaust system for any leaks, rust, or damage. Ensure that all components, including the catalytic converter and muffler, are in good condition to maintain optimal performance and emissions standards.

6. Change Engine Oil

Changing the engine oil is one of the most critical maintenance tasks. Follow the recommended intervals for oil changes to ensure proper lubrication and to extend the life of the engine. Always use high-quality oil that meets the specifications outlined in your vehicle’s documentation.

7. Brake Inspection

Regularly assess the braking system, including pads, rotors, and fluid levels. Look for signs of wear and replace any components that are nearing the end of their lifespan. Effective brakes are essential for safety.

By adhering to these systematic procedures, vehicle owners can significantly enhance the reliability and performance of their engines, ensuring a safer and more enjoyable driving experience.

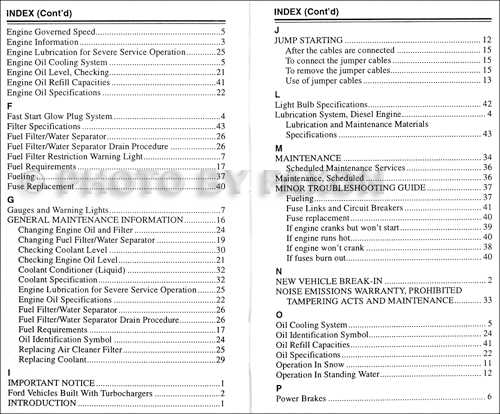

Fuel System Troubleshooting Guide

This section provides essential insights into diagnosing issues within the fuel delivery framework of diesel engines. A well-functioning fuel system is crucial for optimal performance, and identifying common problems can significantly enhance engine reliability and efficiency.

Common Symptoms and Their Causes

Several indicators can point to malfunctions within the fuel system. Difficulty starting the engine may suggest issues with fuel supply or pressure. Unusual noises during operation can indicate air in the fuel lines or failing components. Additionally, reduced power or poor acceleration often results from clogged filters or faulty injectors. Recognizing these symptoms early can prevent more extensive damage and costly repairs.

Troubleshooting Steps

Begin by inspecting the fuel lines for leaks or blockages. Ensure that the fuel filter is clean and replace it if necessary. Check the fuel pump for proper operation and listen for any abnormal sounds. Use a pressure gauge to verify that fuel pressure meets the engine’s specifications. Lastly, examine the injectors for any signs of wear or malfunction, as these can drastically affect engine performance.

Electrical System Diagnostics Techniques

The effective analysis of electrical systems in vehicles is crucial for ensuring optimal performance and reliability. Various diagnostic strategies allow technicians to identify issues accurately, minimizing downtime and enhancing safety. This section delves into essential methods for evaluating electrical components, emphasizing the importance of systematic troubleshooting.

Common Diagnostic Tools

Utilizing the right instruments is vital for accurate diagnosis. Below is a table outlining common tools and their primary functions:

| Tool | Function |

|---|---|

| Multimeter | Measures voltage, current, and resistance to assess electrical integrity. |

| Oscilloscope | Visualizes electrical signals over time, helping identify waveform irregularities. |

| Scan Tool | Interrogates the vehicle’s computer systems for error codes and performance data. |

| Power Probe | Provides power and ground to components for testing purposes. |

Troubleshooting Methodologies

Adopting a structured approach is essential for effective problem resolution. Start by gathering information about the symptoms and any relevant history. Next, perform a visual inspection to check for obvious issues such as frayed wires or corrosion. Utilize diagnostic tools to measure electrical parameters, ensuring that each component operates within specified ranges. Document findings thoroughly to track progress and aid in future maintenance.

Upgrading Components for Better Performance

Enhancing vehicle performance often involves upgrading key components to achieve optimal efficiency and power. By focusing on specific areas of your engine and related systems, you can significantly improve overall functionality and driving experience. This section outlines various modifications that can lead to noticeable performance gains.

Key Areas for Upgrades

When considering enhancements, several components stand out as crucial for boosting performance:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Turbocharger | High-flow or upgraded turbos | Increased air intake, improved throttle response |

| Exhaust System | Performance exhaust headers and pipes | Enhanced exhaust flow, reduced back pressure |

| Fuel System | Higher capacity injectors | Better fuel atomization, increased power potential |

| Intake System | Cold air intakes | Improved airflow, cooler air for combustion |

Considerations for Upgrading

Before making modifications, it’s essential to assess compatibility with your existing setup. Careful planning ensures that new components work harmoniously with one another, optimizing the benefits of each upgrade. Additionally, consider the balance between performance and reliability to maintain the longevity of your vehicle.

Cooling System Maintenance Tips

Maintaining an efficient cooling system is crucial for the longevity and performance of your vehicle. Regular upkeep can prevent overheating and extend the life of essential components. Here are some key practices to ensure your cooling system remains in optimal condition.

- Check Coolant Levels: Regularly inspect the coolant reservoir and maintain the appropriate level to prevent overheating.

- Inspect for Leaks: Look for signs of leakage around hoses, the radiator, and the water pump. Address any leaks promptly.

- Flush the System: Perform a coolant flush every couple of years to remove debris and sediment that can hinder performance.

- Replace the Thermostat: Consider changing the thermostat if the engine frequently overheats or struggles to reach operating temperature.

- Examine Hoses: Check all hoses for wear and tear, replacing any that show signs of cracking or bulging.

- Inspect the Radiator: Ensure that the radiator is free of blockages and that the fins are clean to promote efficient airflow.

- Test the Water Pump: Regularly check the water pump for leaks and ensure it’s functioning correctly to circulate coolant effectively.

Following these maintenance tips will help keep your engine cool and running smoothly, reducing the risk of overheating and associated damage.

Transmission Repair Insights

This section delves into the intricacies of addressing common issues within automatic and manual gear systems. Understanding the mechanisms involved is crucial for diagnosing problems and implementing effective solutions. Whether facing shifting irregularities or fluid leaks, a comprehensive grasp of the transmission’s workings can significantly enhance maintenance efforts.

Common Issues and Their Solutions

Among the frequent complications are slipping gears and unexpected delays in shifting. These symptoms often indicate low fluid levels or contamination. Regular inspections can help identify such problems early. Replacing worn-out components and ensuring proper fluid quality are essential steps to prolonging the lifespan of the entire system.

Preventative Maintenance Tips

Implementing routine maintenance practices is vital for optimal performance. Regular fluid changes and filter replacements can prevent buildup and ensure smooth operation. Additionally, monitoring the vehicle’s behavior during gear transitions can provide valuable insights into the overall health of the transmission. Addressing minor issues promptly can save time and resources in the long run.

Safety Precautions During Repairs

When undertaking any maintenance or modification task on a vehicle, ensuring personal safety and the safety of others is paramount. Proper precautions can prevent accidents and injuries, making the process smoother and more efficient. Understanding the potential hazards and taking the necessary steps to mitigate them is essential for a successful undertaking.

Essential Safety Gear

- Gloves: Protects hands from sharp objects and harmful substances.

- Goggles: Shields eyes from debris and chemical splashes.

- Steel-toed Boots: Safeguards feet against heavy equipment and falling parts.

- Dust Masks: Helps prevent inhalation of harmful particles.

Work Environment Safety

- Ensure the workspace is well-ventilated to avoid the buildup of fumes.

- Keep the area clean and organized to minimize trip hazards.

- Use appropriate tools for each task to avoid injury and damage.

- Be aware of your surroundings, especially when working near moving parts.

By adhering to these guidelines, individuals can significantly reduce risks associated with automotive tasks. Prioritizing safety not only protects the mechanic but also enhances the quality of the work performed.

Finding Quality Replacement Parts

When it comes to maintaining and enhancing your vehicle, sourcing high-quality components is crucial. The market offers a plethora of options, making it essential to distinguish between reliable products and subpar alternatives. Investing time in identifying trusted suppliers can significantly impact the performance and longevity of your engine.

Start by researching reputable brands known for their durability and reliability. Look for customer reviews and testimonials that provide insights into the performance of various components. Online forums and communities can be invaluable resources, offering firsthand experiences from other enthusiasts.

Additionally, consider purchasing from certified dealers or authorized distributors. These sources often guarantee authenticity and quality, minimizing the risk of counterfeit parts. It’s also wise to inquire about warranties or return policies, ensuring that you have recourse in case a component does not meet expectations.

Lastly, don’t overlook local auto parts stores. They can be a great option for immediate needs and may offer personalized advice based on your specific requirements. Balancing online research with local insights can lead to finding the best possible replacements for your vehicle.

Resources for Further Learning

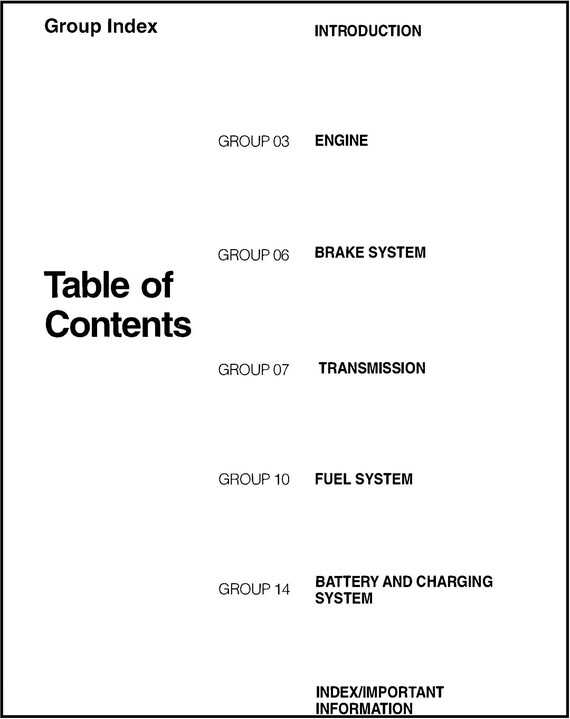

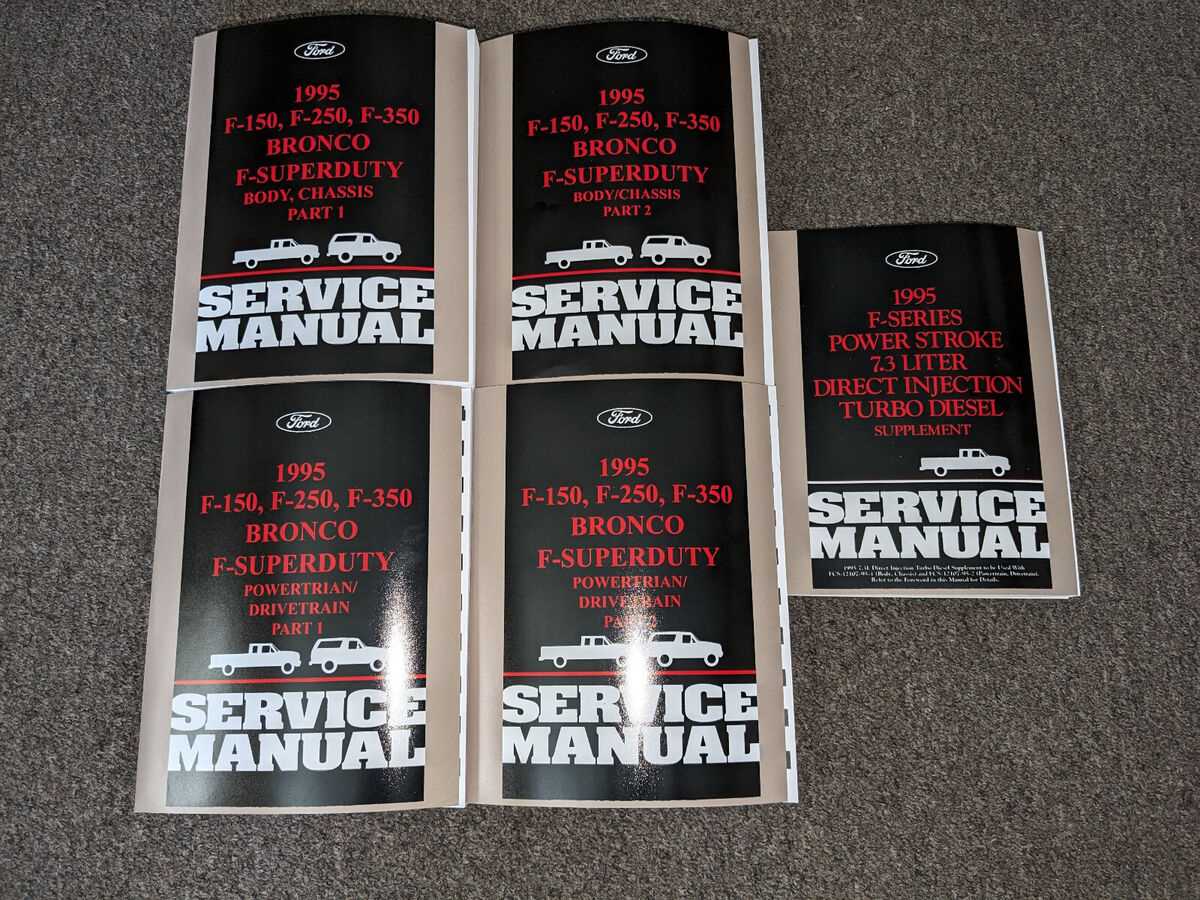

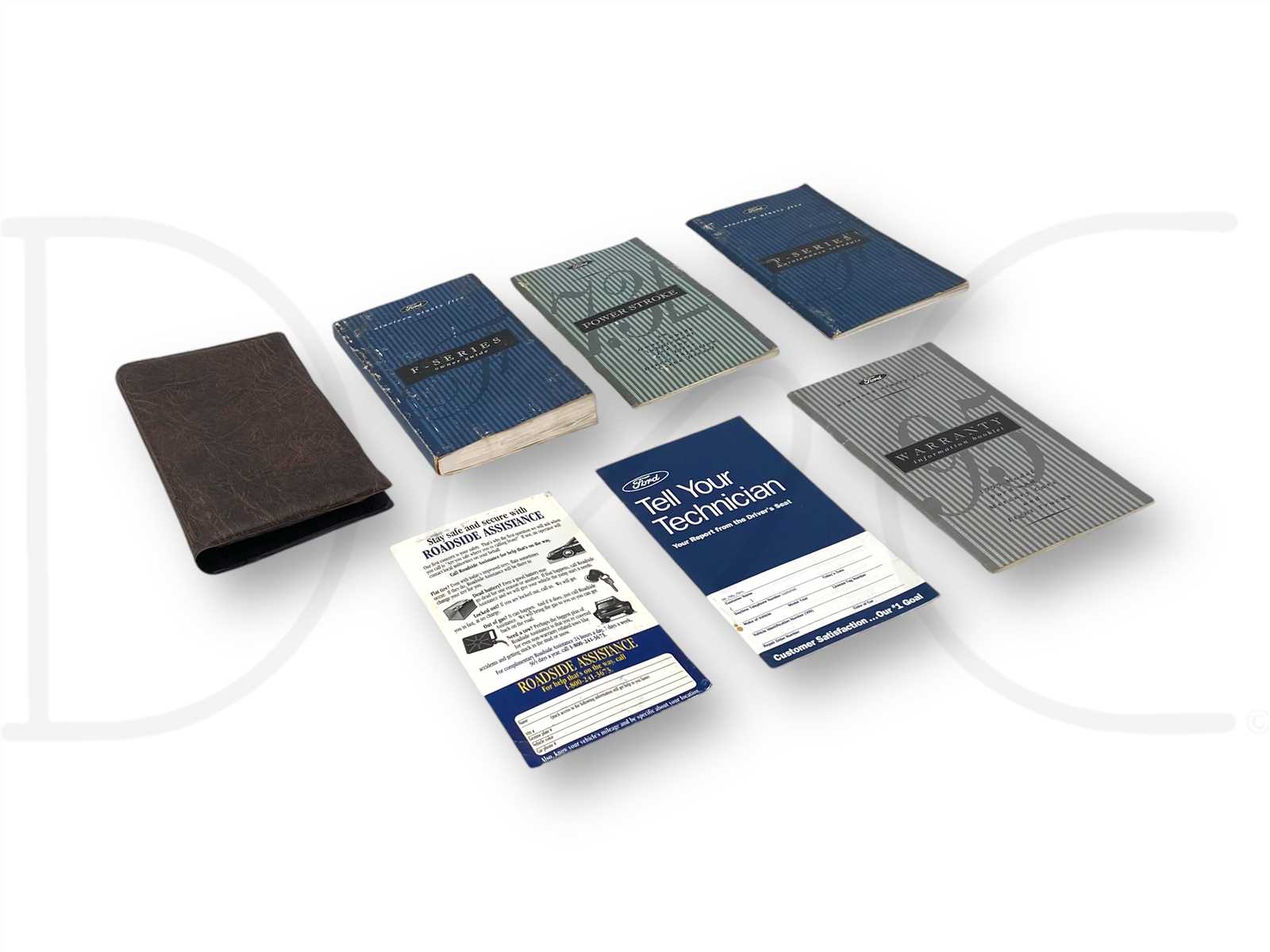

Expanding your knowledge in automotive maintenance and engine diagnostics is essential for anyone looking to enhance their skills. Numerous resources are available that cater to various learning styles, from hands-on guides to comprehensive online courses.

Books and publications focused on engine performance and troubleshooting can provide valuable insights. Technical manuals often contain detailed illustrations and specifications that aid in understanding complex systems. Additionally, consider exploring automotive forums where enthusiasts and experts share experiences and solutions to common challenges.

Online platforms offer interactive learning opportunities. Websites dedicated to automotive education feature video tutorials, step-by-step instructions, and user-generated content that can help solidify your understanding. Don’t overlook community workshops or local classes, as these can provide practical experience under the guidance of knowledgeable instructors.

Utilizing these resources will empower you to tackle various automotive tasks with confidence and expertise.