Understanding the intricacies of maintaining outdoor power equipment is crucial for ensuring longevity and optimal performance. This section aims to provide comprehensive insights into the various aspects of servicing a popular model, focusing on essential procedures, troubleshooting techniques, and preventive measures. Proper upkeep not only enhances functionality but also reduces the likelihood of costly repairs in the future.

In the realm of gardening and landscaping, having reliable tools at your disposal is paramount. This guide covers everything from routine checks to in-depth servicing, enabling users to tackle common issues effectively. Whether you are an experienced user or a novice, the information presented here will assist in navigating the maintenance process with confidence.

Equipped with the right knowledge and techniques, individuals can ensure that their equipment remains in peak condition, ready to handle various tasks. From understanding the key components to identifying potential problems, this section serves as a valuable resource for enhancing your operational skills.

When it comes to maintaining outdoor equipment, having the right set of instruments is crucial for effective troubleshooting and upkeep. This section outlines the necessary tools that ensure efficient servicing and longevity of your device. By equipping yourself with the appropriate gear, you can streamline the maintenance process and address any issues that may arise.

Basic Hand Tools

- Wrenches: Useful for loosening and tightening various components.

- Screwdrivers: Essential for handling screws of different sizes and types.

- Pliers: Handy for gripping, twisting, and cutting wire or small parts.

Specialized Equipment

- Fuel Line Pliers: Designed for working with fuel lines without causing damage.

- Compression Tester: Helps to evaluate the engine’s compression levels.

- Feeler Gauge: Useful for checking and adjusting clearances in various parts.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular maintenance not only ensures optimal performance but also prevents costly repairs in the future. By implementing a few simple practices, you can keep your tools in peak condition for many years.

1. Regular Cleaning: After each use, make it a habit to clean the exterior and any accessible components. Removing dirt and debris helps prevent buildup that can cause malfunctions.

2. Inspect and Replace Worn Parts: Regularly check for signs of wear or damage on components such as blades and filters. Promptly replacing worn parts can significantly enhance performance and safety.

3. Lubrication: Apply lubricant to moving parts as recommended by the manufacturer. Proper lubrication reduces friction and wear, promoting smooth operation.

4. Fuel Quality: Always use high-quality fuel to prevent engine issues. Contaminated or poor-quality fuel can lead to performance problems and may damage internal components.

5. Storage: Store your equipment in a dry, sheltered area to protect it from harsh weather conditions. Proper storage helps prevent rust and deterioration of materials.

By following these maintenance tips, you can ensure that your equipment remains reliable and effective for years to come.

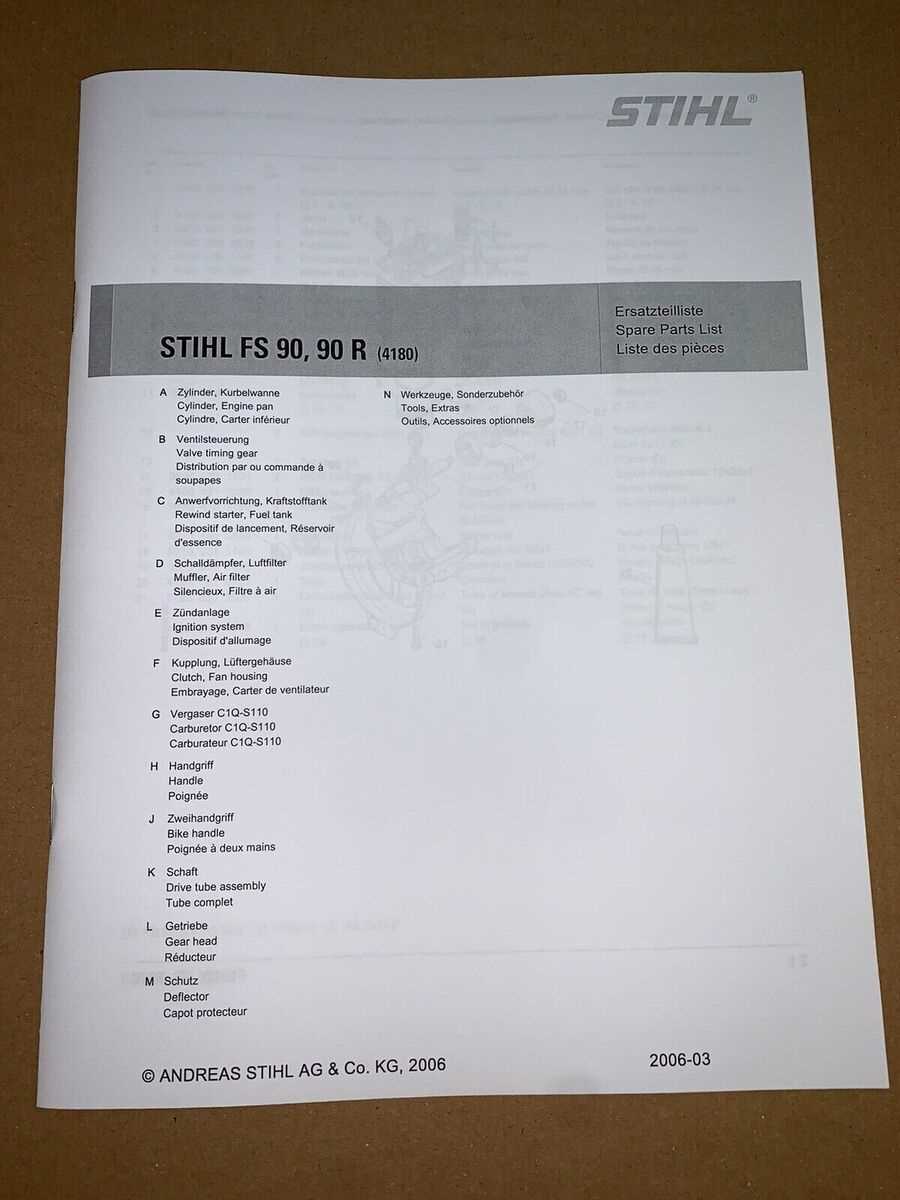

Parts Replacement Guide

This section aims to provide a comprehensive overview of the essential steps and considerations involved in substituting components within your equipment. Understanding when and how to replace parts can enhance performance and prolong the lifespan of your device.

When undertaking component changes, it is crucial to identify the specific parts that require attention. Regular maintenance checks can help in spotting wear and tear before they escalate into more significant issues. Additionally, having the right tools and following manufacturer specifications ensures a smoother replacement process.

Always consult the relevant documentation or resources for guidance on compatible components. Properly sourcing replacement parts from trusted suppliers guarantees quality and reliability. Once the new parts are procured, carefully follow the outlined procedures for installation to maintain the integrity of your equipment.

Finally, after replacing any parts, it’s advisable to test the equipment to confirm that everything functions as intended. This step not only validates the replacement but also helps in identifying any further adjustments that may be necessary.

Troubleshooting Electrical Components

When dealing with machinery, understanding the electrical systems is crucial for optimal performance. Issues may arise in various components, leading to malfunctions that can hinder functionality. This section focuses on identifying common electrical problems and providing solutions to restore efficiency.

Identifying Common Issues

Electrical components may experience various challenges such as faulty connections, damaged wires, or malfunctioning switches. These issues can often result in intermittent operation or complete failure. To diagnose these problems, start by examining all connections and ensuring they are secure and free from corrosion.

Resolving Electrical Problems

If a problem is detected, it is important to take immediate action. Replacing damaged wires or connectors can often resolve the issue. Additionally, checking the voltage output of the power source can help determine if the supply is adequate. Always refer to the specifications to ensure compatibility and safety when making repairs.

How to Clean the Carburetor

Maintaining the optimal performance of your engine often requires regular cleaning of the fuel delivery system components, particularly the carburetor. A clean carburetor ensures proper fuel-air mixture, which is crucial for efficient operation and longevity of the equipment.

Here are the essential steps to effectively clean the carburetor:

- Gather Necessary Tools and Materials:

- Screwdrivers (flathead and Phillips)

- Cleaning solution or carburetor cleaner

- Soft brush or cloth

- Compressed air (optional)

- Safety goggles and gloves

- Remove the Carburetor:

Carefully detach the carburetor from the engine following the manufacturer’s guidelines. Make sure to disconnect any fuel lines and cables, taking note of their positions for reassembly.

- Disassemble the Carburetor:

Take apart the carburetor by removing the screws and separating the components. Keep all parts organized to simplify reassembly.

- Clean the Parts:

Using the cleaning solution, thoroughly clean all parts of the carburetor, including:

- The float bowl

- The jets

- The diaphragm

- The gaskets

Use a soft brush or cloth to remove any buildup or debris.

- Rinse and Dry:

If necessary, rinse the components with clean fuel or carburetor cleaner and let them dry completely before reassembly.

- Reassemble and Reinstall:

Carefully put the carburetor back together, ensuring all parts are in their correct positions. Reattach it to the engine, reconnecting all lines and cables securely.

Following these steps will help maintain the efficiency of your engine and prevent performance issues caused by a dirty carburetor.

Safety Precautions During Repairs

When undertaking maintenance tasks on equipment, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to proper guidelines ensures a secure working environment and promotes efficient operation. Being aware of potential hazards and following established protocols can significantly reduce the risk of harm.

Before beginning any maintenance work, it is advisable to wear appropriate protective gear, such as gloves, goggles, and sturdy footwear. This equipment provides essential safeguards against flying debris and sharp components. Furthermore, ensuring that the workspace is well-lit and organized can help in identifying potential hazards early on.

Disconnecting the power source is a fundamental step to avoid accidental activation of machinery during servicing. Always refer to the manufacturer’s recommendations regarding specific disassembly and assembly procedures. It is also wise to keep a first-aid kit readily accessible in case of emergencies.

Lastly, maintaining a clean and clutter-free workspace is essential. Clearing away unnecessary tools and materials helps prevent tripping hazards and allows for better focus on the task at hand. Following these precautions not only enhances safety but also improves overall efficiency during maintenance tasks.

FAQs about Stihl FS90R Maintenance

This section addresses common inquiries related to the upkeep and care of a particular model of outdoor power equipment. Regular maintenance ensures optimal performance and longevity, helping users troubleshoot and resolve issues effectively.

1. How often should I perform maintenance on my equipment?

It is recommended to conduct maintenance checks at least once every few months, or more frequently if the machine is used regularly. Regular inspections can help identify any potential issues before they become major problems.

2. What type of fuel should I use?

Using the correct fuel type is crucial for the performance of the machine. Typically, a high-quality gasoline mixed with the appropriate oil is advised. Always check the specifications to ensure compatibility.

3. How do I clean the air filter?

To clean the air filter, remove it from the machine and gently tap it to dislodge any dirt or debris. For a more thorough cleaning, wash it in soapy water and allow it to dry completely before reinstallation.

4. What should I do if the engine does not start?

If the engine fails to start, check the fuel level, spark plug condition, and ensure that the safety features are properly engaged. If the problem persists, consult a professional for assistance.

5. How can I extend the lifespan of my equipment?

To extend the lifespan, perform regular maintenance, use high-quality fuel and oil, store the equipment in a dry place, and avoid overworking the machine. Following these guidelines will contribute to its durability.

Where to Find Replacement Parts

Locating the necessary components for maintenance and restoration can significantly enhance the longevity and performance of your equipment. Understanding where to seek these items is crucial for ensuring your machine operates efficiently.

Authorized Dealers

One of the most reliable sources for obtaining spare parts is through authorized dealers. These establishments often provide:

- Genuine components that meet quality standards

- Expert advice on compatibility and installation

- Access to a broader range of products

Online Retailers

Numerous online platforms offer convenience and a vast selection of items. When using online resources, consider:

- Checking customer reviews to gauge reliability

- Ensuring the site has a secure payment system

- Comparing prices to find the best deals