Maintaining outdoor power equipment is essential for ensuring optimal performance and longevity. A well-functioning tool can make yard work more efficient and enjoyable. This section provides insights into keeping your string trimming device in peak condition through practical steps and tips.

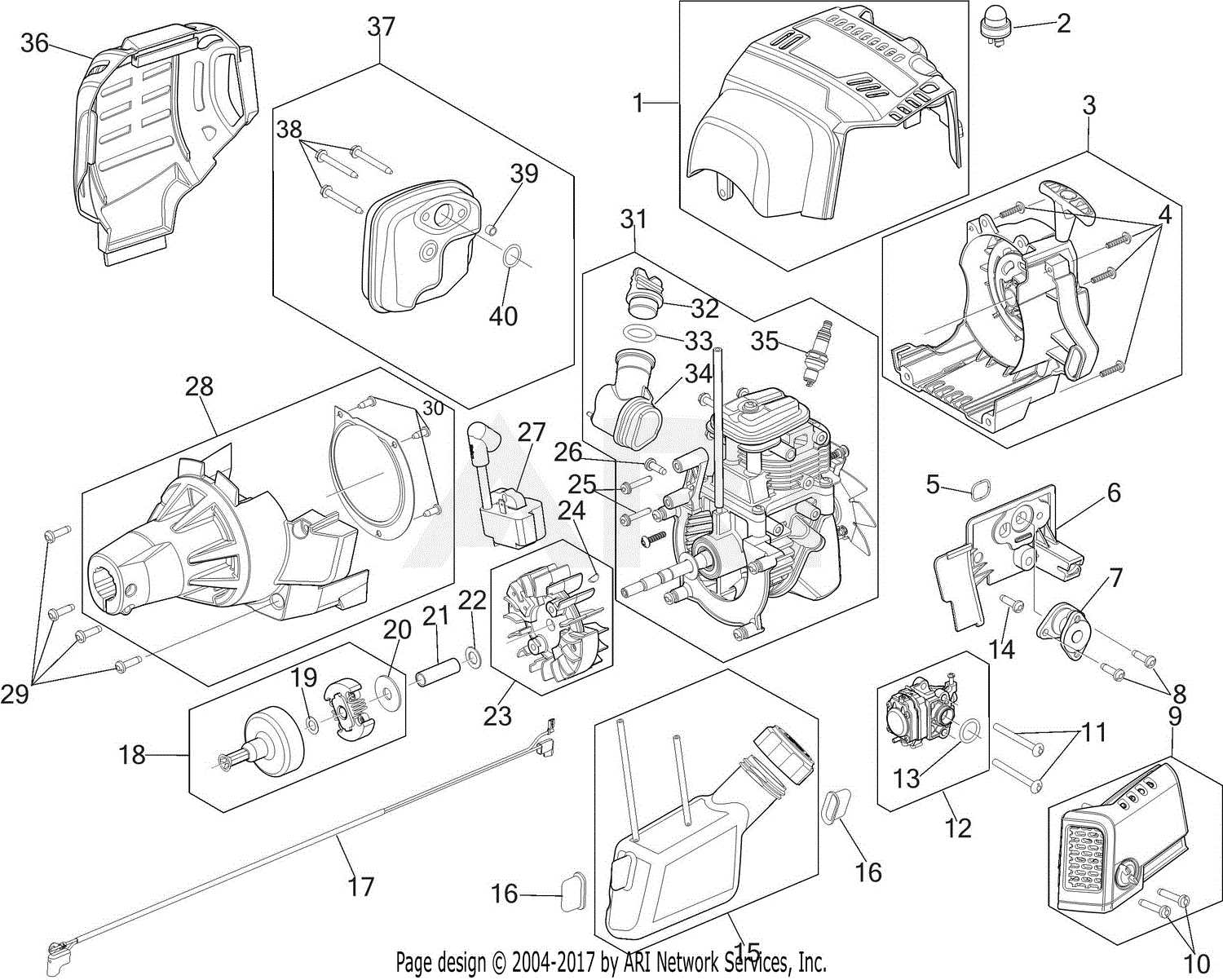

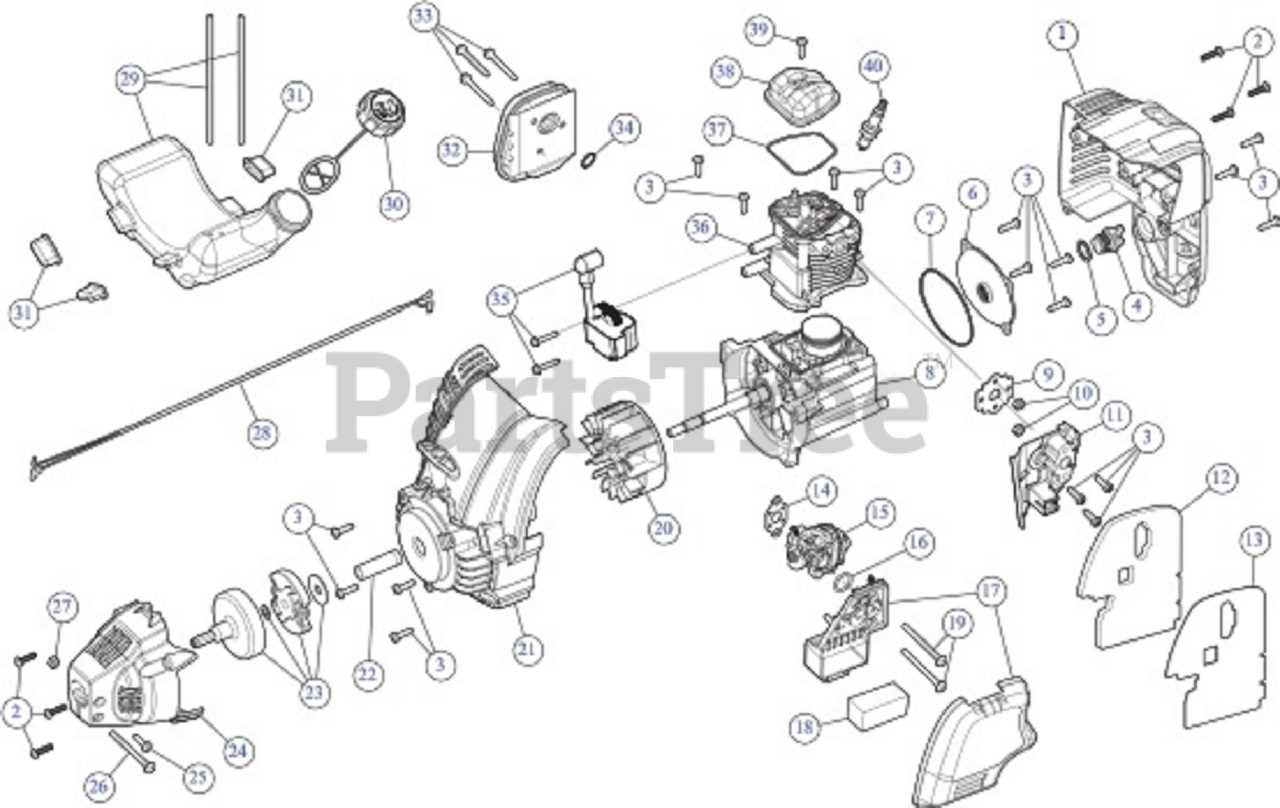

Understanding the Components is crucial for effective upkeep. Familiarizing yourself with the various parts will enable you to diagnose issues and perform necessary adjustments. Each element plays a significant role in the overall operation, and recognizing their functions can simplify the maintenance process.

Common Challenges often arise during usage, from engine difficulties to line feed problems. Addressing these concerns promptly can prevent more significant issues down the line. By learning how to troubleshoot and rectify these common hurdles, you’ll ensure your equipment remains reliable throughout the season.

Troy Bilt Weed Eater Overview

This section provides a comprehensive understanding of a popular outdoor tool designed for trimming grass and clearing overgrown areas. Known for its durability and efficiency, this equipment is favored by both homeowners and professionals alike. Below, we delve into its features, benefits, and maintenance tips to ensure optimal performance.

Key Features

- Powerful Engine: Equipped with a robust motor for effective cutting.

- Lightweight Design: Easy to maneuver, reducing user fatigue.

- Adjustable Handle: Customizable grip for enhanced comfort.

- Variety of Attachments: Compatible with different accessories for versatile tasks.

Benefits of Use

- Efficient Lawn Care: Helps maintain a neat and tidy outdoor space.

- Time-Saving: Allows for quick and effective clearing of grass and weeds.

- User-Friendly: Designed for ease of use, making it suitable for all skill levels.

- Cost-Effective: Provides a reliable solution for landscaping needs without breaking the bank.

Understanding the fundamentals of this equipment can greatly enhance its utility and longevity, making it an invaluable addition to any garden toolkit.

Common Issues with Weed Eaters

Understanding typical challenges faced by garden maintenance tools can enhance their longevity and effectiveness. Identifying these problems early on can save time and ensure a smoother experience during outdoor tasks.

Frequent Problems

- Engine Failure: Difficulty starting or stalling can hinder performance.

- Fuel Issues: Contaminated or improper fuel may lead to poor operation.

- Line Feed Malfunctions: Snapping or jamming can interrupt trimming tasks.

Signs of Trouble

- Unusual Noises: Odd sounds may indicate mechanical issues.

- Vibrations: Excessive shaking can be a sign of imbalance or damage.

- Poor Cutting Performance: Inability to effectively trim grass or weeds can signal problems with the cutting mechanism.

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right instruments at your disposal is crucial. A well-equipped toolkit not only simplifies the process but also enhances the effectiveness of the tasks at hand. Whether you’re performing basic adjustments or more intricate fixes, certain tools are indispensable for ensuring smooth operations and longevity of the equipment.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Essential for tightening and loosening screws in various components. |

| Wrench Set | Used for adjusting nuts and bolts, ensuring secure fittings. |

| Pliers | Helpful for gripping and bending materials, as well as cutting wires. |

| Fuel Container | For safely storing and transporting fuel to avoid spills. |

| Multimeter | Crucial for diagnosing electrical issues and ensuring proper voltage levels. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Brush and Cleaning Supplies | For maintaining cleanliness and preventing buildup that can impair function. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues that may arise with outdoor trimming equipment. Following this structured guide will help you restore functionality and ensure optimal performance.

Identifying the Problem

Begin by carefully examining the unit for any visible signs of damage or wear. Listen for unusual sounds during operation and check for any inconsistent performance. Understanding the specific issue is crucial before moving on to the next steps.

Gathering Tools and Parts

Once you have identified the issue, gather all necessary tools and replacement components. Having everything at hand will streamline the process. Essential tools may include screwdrivers, pliers, and wrenches, while replacement parts could involve spark plugs, filters, or lines.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires consistent care and attention. Implementing proper maintenance practices can significantly enhance performance and extend the lifespan of your tools. Here are essential tips to keep your equipment running smoothly.

Regular Cleaning: After each use, remove dirt and debris from the machine. A clean unit not only performs better but also prevents rust and corrosion from forming.

Inspect Components: Frequently check parts such as lines, blades, and filters for wear and tear. Early detection of damage can prevent more extensive issues later.

Proper Fuel Usage: Use fresh fuel mixed according to the manufacturer’s specifications. Stale fuel can lead to poor performance and engine problems.

Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. This practice enhances efficiency and minimizes the risk of breakdowns.

Storage Conditions: Store your equipment in a dry, sheltered location to protect it from the elements. Use covers or cases to prevent dust accumulation.

Scheduled Maintenance: Adhere to a regular maintenance schedule, including inspections and part replacements as needed. Following a checklist can streamline this process and ensure no steps are overlooked.

By integrating these practices into your routine, you can maintain optimal performance and prolong the life of your equipment, ensuring it remains a reliable tool for your outdoor tasks.

How to Replace the Trimmer Line

Replacing the cutting line of your outdoor equipment is an essential maintenance task that ensures optimal performance. Over time, the line can become worn or broken, reducing efficiency. This guide outlines the steps to successfully change the line, keeping your equipment in peak condition.

Before you start, gather the necessary tools and materials. Ensure your device is powered off and safely positioned to prevent any accidents during the process.

| Step | Action |

|---|---|

| 1 | Disconnect the power source to ensure safety. |

| 2 | Remove the spool from the housing by pressing the release tabs. |

| 3 | Remove any remaining old line from the spool. |

| 4 | Cut a length of new line according to the specifications provided in your equipment’s guidelines. |

| 5 | Insert one end of the line into the spool and wind it in the designated direction. |

| 6 | Secure the line and ensure it is evenly distributed on the spool. |

| 7 | Reattach the spool to the housing, making sure it clicks into place. |

| 8 | Reconnect the power source and perform a test run to ensure proper functionality. |

Following these steps will help maintain the efficiency and longevity of your outdoor equipment, ensuring a clean and effective cutting experience.

Identifying Engine Problems

Recognizing issues within a power tool’s engine is crucial for maintaining its performance and longevity. Various symptoms can indicate underlying mechanical failures or operational inefficiencies, and understanding these signs can lead to timely interventions. Observing unusual behavior or sounds can help pinpoint the source of trouble.

Common Symptoms

One of the most prevalent indicators of engine trouble is difficulty starting. If the equipment struggles to ignite or fails to run smoothly, it may suggest fuel delivery issues or spark plug malfunctions. Additionally, excessive smoke during operation can point to problems such as oil leaks or incorrect fuel mixtures, both of which require immediate attention.

Performance Issues

Another area to monitor is loss of power, which can manifest as reduced efficiency while in use. This can stem from clogged air filters or worn-out components, impacting overall functionality. Moreover, inconsistent operation characterized by stalling or irregular speeds often signifies deeper mechanical problems that necessitate further investigation.

Electrical Components and Troubleshooting

This section focuses on the various electrical elements found in garden trimming devices and the common issues that may arise. Understanding these components is essential for efficient maintenance and effective troubleshooting, allowing users to quickly identify and resolve any electrical malfunctions that may hinder performance.

Common Electrical Components

In most trimming devices, several key electrical parts play crucial roles in their operation:

| Component | Function |

|---|---|

| Motor | Drives the cutting mechanism by converting electrical energy into mechanical energy. |

| Switch | Controls the flow of electricity to the motor, allowing the user to turn the device on or off. |

| Battery | Provides power for cordless models, ensuring portability and convenience. |

| Wiring Harness | Connects various electrical components, ensuring proper communication and power delivery. |

Troubleshooting Electrical Issues

When encountering problems, it is vital to systematically diagnose potential electrical faults. Here are some common symptoms and their possible solutions:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Device won’t start | Faulty switch or dead battery | Check and replace the switch or recharge/replace the battery. |

| Intermittent operation | Loose wiring or poor connections | Inspect and secure all connections, looking for frayed wires. |

| Motor overheating | Blocked air vents or excessive load | Clean air vents and reduce workload or take breaks to allow cooling. |

Carburetor Cleaning Techniques

Maintaining optimal performance of small engines often requires attention to the fuel delivery system. Proper cleaning of the carburetor can significantly enhance efficiency and prolong the lifespan of the equipment. This section outlines effective methods to ensure that the carburetor remains free from deposits and operates smoothly.

Preparation Steps

Before diving into the cleaning process, it’s essential to gather the necessary tools and materials:

- Safety goggles and gloves

- Carburetor cleaner spray

- Soft brushes or toothbrush

- Compressed air (optional)

- Container for small parts

Cleaning Process

Follow these steps for an efficient cleaning procedure:

- Disconnect the spark plug to prevent accidental starting.

- Remove the carburetor from the engine carefully, taking note of how components are assembled.

- Disassemble the carburetor, keeping track of all parts in a container.

- Spray carburetor cleaner into all openings and let it soak for a few minutes.

- Use a soft brush to scrub away any stubborn deposits.

- Rinse all parts thoroughly with clean solvent and let them dry completely.

- If available, use compressed air to blow out any remaining debris.

- Reassemble the carburetor, ensuring all parts are securely in place.

- Reattach the carburetor to the engine and reconnect the spark plug.

Regular maintenance and cleaning of the carburetor can lead to improved performance and reliability, ensuring that your equipment runs smoothly for years to come.

Understanding Fuel System Issues

The fuel system is essential for the proper operation of small engines, influencing their performance and reliability. Recognizing problems within this system can prevent further damage and enhance efficiency.

Common symptoms of fuel system issues include:

- Difficulty starting the engine

- Irregular idling or stalling

- Poor acceleration

- Excessive smoke output

Several factors may contribute to these problems:

- Fuel Quality: Using stale or contaminated fuel can lead to clogs and inadequate combustion.

- Clogged Filters: A dirty fuel filter restricts flow, causing performance issues.

- Carburetor Issues: Misadjustments or wear can affect fuel delivery and mixture.

- Fuel Lines: Cracked or damaged lines may result in leaks or blockages.

Regular maintenance and timely troubleshooting of these components can significantly improve the longevity and effectiveness of your equipment.

When to Seek Professional Help

Determining the right moment to consult an expert can be crucial for maintaining equipment effectively. While some issues may appear manageable, others might require specialized knowledge or tools. Recognizing these scenarios can save time, effort, and potential further complications.

Here are key indicators that it may be time to reach out for assistance:

- Persistent Issues: If a problem continues after multiple attempts at resolution, it may be a sign of a deeper underlying issue.

- Complex Repairs: Tasks that involve intricate components or require advanced technical skills should typically be handled by professionals.

- Safety Concerns: If you encounter risks such as leaks, exposed wiring, or any hazardous conditions, professional intervention is essential.

- Loss of Efficiency: A significant drop in performance or functionality can indicate that the equipment needs expert evaluation.

- Lack of Knowledge: If you feel uncertain about diagnosing or fixing an issue, it’s wiser to seek guidance rather than risk further damage.

Ultimately, prioritizing safety and efficiency can lead to better outcomes and prolong the lifespan of your equipment.