Understanding the intricacies of maintaining your outdoor machinery is crucial for optimal performance and longevity. This section aims to provide valuable insights into the essential procedures and techniques that will help you keep your equipment in prime condition. Whether you are a seasoned user or a newcomer, having access to comprehensive guidance can make all the difference in achieving satisfactory results.

Regular upkeep is not merely a task but an investment in the reliability and efficiency of your tools. From troubleshooting common issues to implementing effective solutions, this resource will empower you with the knowledge needed to address a variety of challenges. It emphasizes the importance of being proactive rather than reactive when it comes to maintenance.

Equipped with the right information, users can enhance their experience and extend the lifespan of their devices. The following sections will cover various aspects, including basic servicing techniques, safety precautions, and tips for identifying potential problems early. By familiarizing yourself with these practices, you will ensure that your equipment remains a dependable ally in all your outdoor endeavors.

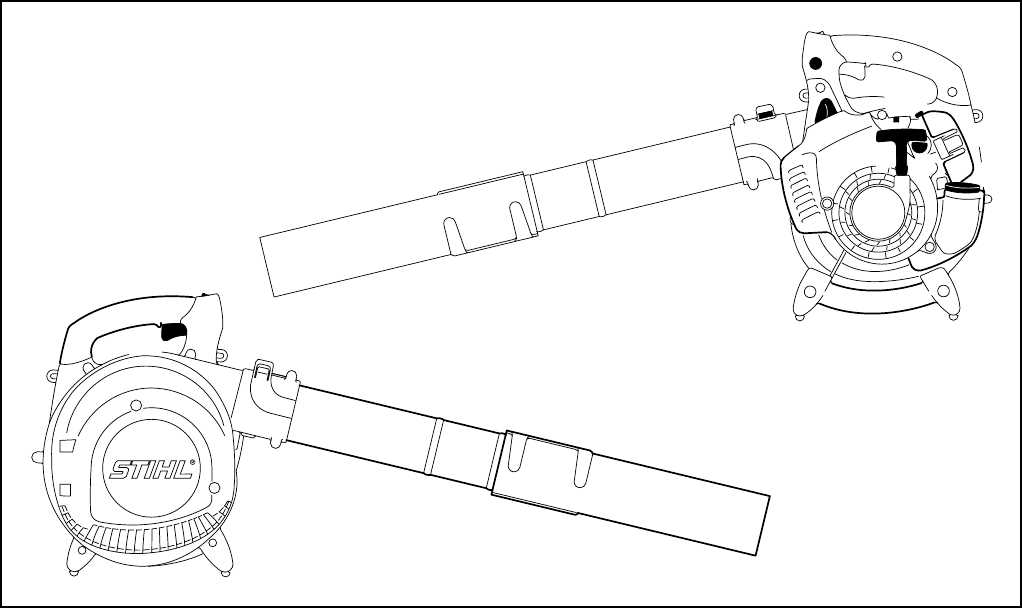

Understanding Stihl Blower Models

This section explores the diverse range of air-moving devices available, emphasizing their distinct features and functionalities. Recognizing the variations among these units is essential for users seeking to choose the right tool for their specific needs, whether for residential or commercial applications.

Categories of Devices

The devices can typically be categorized into handheld and backpack styles. Handheld units are generally more portable and suited for smaller tasks, while backpack versions offer enhanced power and endurance, making them ideal for larger areas and more intensive use. Understanding the purpose and capacity of each category helps in selecting the most effective tool for the job.

Model Specifications

Each model comes with unique specifications, including engine power, airflow rates, and weight. Familiarity with these technical details allows users to evaluate performance and efficiency, ensuring they find a model that aligns with their requirements. Additionally, features such as noise levels and ease of operation can significantly impact user experience.

Common Issues with Stihl Blowers

When operating outdoor equipment designed for air movement, users may encounter a variety of challenges that can hinder performance. Understanding these common problems is essential for maintaining efficiency and ensuring longevity. This section delves into frequent malfunctions and their potential causes.

Performance Degradation

A noticeable decline in performance can be frustrating. This issue may arise from various factors, including fuel quality, air filter blockage, or improper spark plug function. Regular maintenance is key to preventing such problems.

Starting Difficulties

Many users report trouble when attempting to start their devices. This can stem from several issues, such as a weak battery, incorrect fuel mixture, or worn-out ignition components. Addressing these areas can often resolve starting challenges.

| Issue | Possible Cause | Solution |

|---|---|---|

| Performance Degradation | Poor fuel quality or clogged air filter | Replace fuel and clean or replace the filter |

| Starting Difficulties | Weak battery or incorrect fuel mixture | Recharge battery and verify fuel mix |

| Excessive Vibration | Loose components or imbalanced rotor | Tighten screws and check rotor balance |

| Noise Issues | Worn bearings or loose parts | Inspect and replace worn components |

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right instruments at your disposal can significantly ease the process. A well-equipped toolkit not only streamlines tasks but also enhances the overall efficiency of your work. Understanding which tools are essential ensures that you can tackle various challenges that may arise during upkeep.

Start with basic hand tools such as screwdrivers, wrenches, and pliers. These versatile implements allow for adjustments and disassembly of components with ease. Additionally, a good set of sockets can provide access to hard-to-reach fasteners, ensuring that every part can be effectively handled.

Power tools also play a vital role in modern maintenance tasks. Drills and impact drivers can expedite the process of loosening stubborn screws or bolts, while a quality set of replacement blades and bits can enhance versatility. Always consider the specific needs of your equipment when selecting these tools.

Lastly, don’t overlook the importance of safety gear. Gloves, goggles, and ear protection can prevent accidents and ensure a safe working environment. With the right combination of instruments and precautions, you’ll be well-prepared to maintain your equipment efficiently and effectively.

Step-by-Step Repair Procedures

This section provides detailed guidance for addressing common issues that may arise with your outdoor equipment. By following these systematic instructions, you can effectively troubleshoot and restore optimal functionality, ensuring your device performs at its best.

Identifying the Problem

Before diving into fixes, take a moment to observe any symptoms your equipment exhibits. Look for signs such as unusual noises, lack of power, or difficulty starting. Documenting these issues will help you focus your efforts more efficiently.

Disassembly and Inspection

Once you’ve pinpointed the issue, carefully disassemble the unit following the provided guidelines. Inspect each component for wear and tear, dirt, or damage. This thorough examination will reveal whether parts need cleaning or replacement, leading you closer to a solution.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a smooth workflow. Awareness of potential hazards and adherence to best practices can significantly reduce risks and protect both the individual and the equipment.

Essential Safety Measures

Before starting any work, consider the following essential precautions:

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and ear protection to safeguard against injuries. |

| Work Area Organization | Ensure that your workspace is clean and free of clutter to avoid tripping hazards. |

| Proper Tools | Utilize the correct tools for each task to enhance safety and efficiency. |

| Emergency Plan | Have a clear plan for emergencies, including access to first aid supplies. |

Final Thoughts

Adhering to these guidelines not only promotes personal safety but also contributes to a more effective maintenance process. Taking the time to prepare can lead to ultimate success and satisfaction in your tasks.

Maintenance Tips for Longevity

Ensuring the durability and performance of your outdoor equipment requires regular care and attention. By implementing a few simple practices, you can significantly extend the lifespan of your tools and maintain their efficiency. This section outlines essential maintenance tips that will help keep your equipment in optimal condition.

Regular Cleaning

Keeping your device free of debris and dirt is crucial for its functionality. After each use, take a few moments to remove leaves, dust, and other materials that may have accumulated. Use a soft brush or cloth to gently clean the exterior and avoid using harsh chemicals that could damage components.

Routine Inspections

Conducting periodic checks can help identify potential issues before they become major problems. Examine hoses, connections, and filters for wear and tear. Look for any signs of leaks or irregularities that may affect performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean exterior | After each use | Use soft brush/cloth |

| Inspect components | Monthly | Look for wear and leaks |

| Replace filters | Every 3 months | Ensure optimal airflow |

| Check fuel and oil levels | Before each use | Avoid running on low levels |

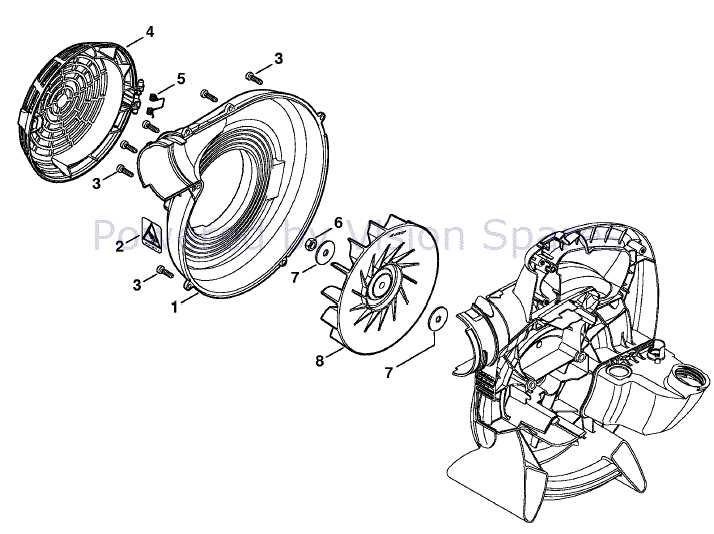

Identifying Parts and Components

Understanding the various elements and mechanisms of your device is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, and recognizing them can aid in diagnosing issues and ensuring optimal performance.

Main Components: The core structure typically includes a housing, engine, and airflow system. The housing serves as the protective shell, while the engine generates power to drive the unit. The airflow system is responsible for directing air where it is needed most.

Additional Parts: Familiarity with auxiliary components like filters, spark plugs, and fuel lines is also important. Filters help maintain air quality within the system, while spark plugs ignite the fuel mixture. Fuel lines transport the necessary liquids for operation, and any damage to these elements can hinder performance.

Identification Tips: When examining your device, look for part numbers or labels that may provide specific information about each component. Utilizing a parts diagram can also facilitate the identification process, allowing for easier navigation and understanding of the assembly.

Troubleshooting Starting Problems

When faced with issues initiating your outdoor equipment, it’s essential to identify common factors that can impede performance. Understanding these aspects can help restore functionality and ensure reliable operation. This guide outlines key areas to inspect and common solutions to address starting difficulties.

Common Causes of Starting Issues

There are several typical reasons why starting may be problematic. Issues can stem from fuel quality, ignition components, or air supply. Below is a table summarizing these potential causes and suggested solutions:

| Cause | Solution |

|---|---|

| Poor fuel quality | Replace with fresh, high-quality fuel. |

| Clogged air filter | Clean or replace the air filter. |

| Faulty spark plug | Inspect and replace the spark plug if necessary. |

| Blockages in fuel lines | Check for obstructions and clean fuel lines. |

| Insufficient compression | Test compression and address any issues in the cylinder. |

Steps for Effective Diagnosis

To effectively diagnose starting problems, follow a systematic approach. Begin by examining fuel and air systems, then move on to ignition components. Thoroughly check each area to pinpoint the issue, as many problems can stem from a combination of factors.

Cleaning and Maintaining the Air Filter

Proper upkeep of the air filtration system is essential for optimal performance and longevity of your outdoor equipment. Regular attention to this component ensures that the engine receives clean air, which is vital for efficient operation and fuel economy. Neglecting the filter can lead to reduced power, increased emissions, and potential engine damage.

To clean the air filter, start by removing it according to the manufacturer’s guidelines. Use a soft brush or compressed air to eliminate any dust and debris, taking care not to damage the filter material. For foam filters, rinsing in warm, soapy water followed by thorough drying is often effective. Always check for signs of wear or damage, and replace the filter if necessary to maintain peak performance.

Establishing a routine schedule for inspection and cleaning–typically every few hours of operation–will help ensure that your equipment continues to function smoothly. Keeping the air filter clean not only extends the life of your machine but also enhances its efficiency, making your outdoor tasks easier and more enjoyable.

Replacing the Fuel System Components

Maintaining optimal performance in outdoor power equipment often requires attention to the fuel delivery system. Over time, components such as hoses, filters, and pumps can wear out or become clogged, leading to inefficiencies. This section outlines the necessary steps to replace these critical elements, ensuring that your device runs smoothly and effectively.

Identifying the Components: Begin by familiarizing yourself with the various parts of the fuel system. Essential components include fuel lines, filters, and the fuel pump. Each plays a vital role in ensuring that the engine receives a consistent and clean supply of fuel.

Tools Needed: Before starting the replacement process, gather the necessary tools. You will typically need a screwdriver, pliers, and a replacement kit containing the new components. Having everything at hand will streamline the task and reduce downtime.

Step-by-Step Replacement: Start by ensuring the equipment is powered off and cool. Disconnect the fuel lines carefully, avoiding any spillage. Replace the filters and any damaged hoses with the new parts, ensuring a secure fit. Reattach the fuel pump, if necessary, and double-check all connections for leaks.

Final Checks: After replacing the components, it’s crucial to test the system. Turn on the engine and observe for any irregularities in fuel flow or performance. If everything operates smoothly, you’ve successfully revitalized the fuel system.

Regular maintenance and timely replacement of fuel system parts will enhance the longevity and reliability of your equipment, making it more efficient and effective in its performance.

Fixing Electrical Issues in Blowers

Electrical malfunctions can significantly hinder the performance of outdoor power equipment. Understanding common problems and their solutions is essential for effective troubleshooting. This section aims to provide insights into identifying and addressing electrical issues that may arise in these machines.

Identifying Symptoms

The first step in addressing electrical concerns is recognizing the signs of trouble. Common symptoms include the device failing to start, inconsistent power output, or unexpected shutdowns. Pay close attention to any unusual noises or smells, as these can indicate deeper issues.

Common Problems and Solutions

One frequent issue is a faulty ignition system. If the equipment does not start, check the spark plug for wear or damage. Replacing a worn spark plug can often resolve the problem. Another common issue is a broken power cord, which can lead to power interruptions. Inspect the cord for frays or cuts and replace it if necessary.

Checking Connections

Loose or corroded connections can also cause significant problems. Regularly inspect all electrical connections for tightness and signs of corrosion. Cleaning connections with a suitable solvent and ensuring they are secure can help restore proper function.

Testing Components

If issues persist, testing individual components may be necessary. A multimeter can be used to check the voltage and continuity of various parts, such as switches and fuses. This helps pinpoint the specific component that may be malfunctioning and requires replacement.

Preventive Measures

To avoid future electrical problems, regular maintenance is crucial. Keep the equipment clean and stored in a dry place to prevent moisture-related issues. Additionally, schedule periodic checks of all electrical components to catch potential problems early.

When to Seek Professional Help

Understanding when to enlist the expertise of a professional is crucial for maintaining the longevity and efficiency of your equipment. Certain issues may seem manageable at first glance, but they can escalate if not handled correctly. Recognizing the signs that indicate a need for external assistance can save both time and resources.

Signs of Complex Issues

If you notice unusual sounds, persistent leaks, or performance drops that don’t improve with basic troubleshooting, it may be time to consult an expert. Attempting to resolve complex mechanical problems without the right knowledge can lead to further complications, making professional intervention a wise choice.

Safety Concerns

Safety should always be a priority. If you encounter electrical issues or other hazards that could pose risks to you or your surroundings, it is imperative to seek help. Don’t compromise your well-being–experts are trained to handle potentially dangerous situations effectively and safely.