Ensuring the optimal functionality of your air-propelled projectile system requires a comprehensive understanding of its components and mechanisms. This section provides essential insights into troubleshooting and enhancing the performance of your device, enabling users to maintain it in peak condition. By following systematic approaches, users can easily address common issues that may arise during operation.

Understanding the intricacies of the internal workings is crucial for effective maintenance. This guide emphasizes practical steps and methodologies designed to help enthusiasts identify problems and implement solutions efficiently. Whether dealing with minor adjustments or significant malfunctions, the information presented here aims to empower users with the knowledge needed to keep their systems operating smoothly.

Through detailed explanations and user-friendly instructions, individuals will gain confidence in managing their devices. Embracing a hands-on approach fosters a deeper appreciation for the technology at play, encouraging users to engage actively in the upkeep and enhancement of their air-propelled projectile systems.

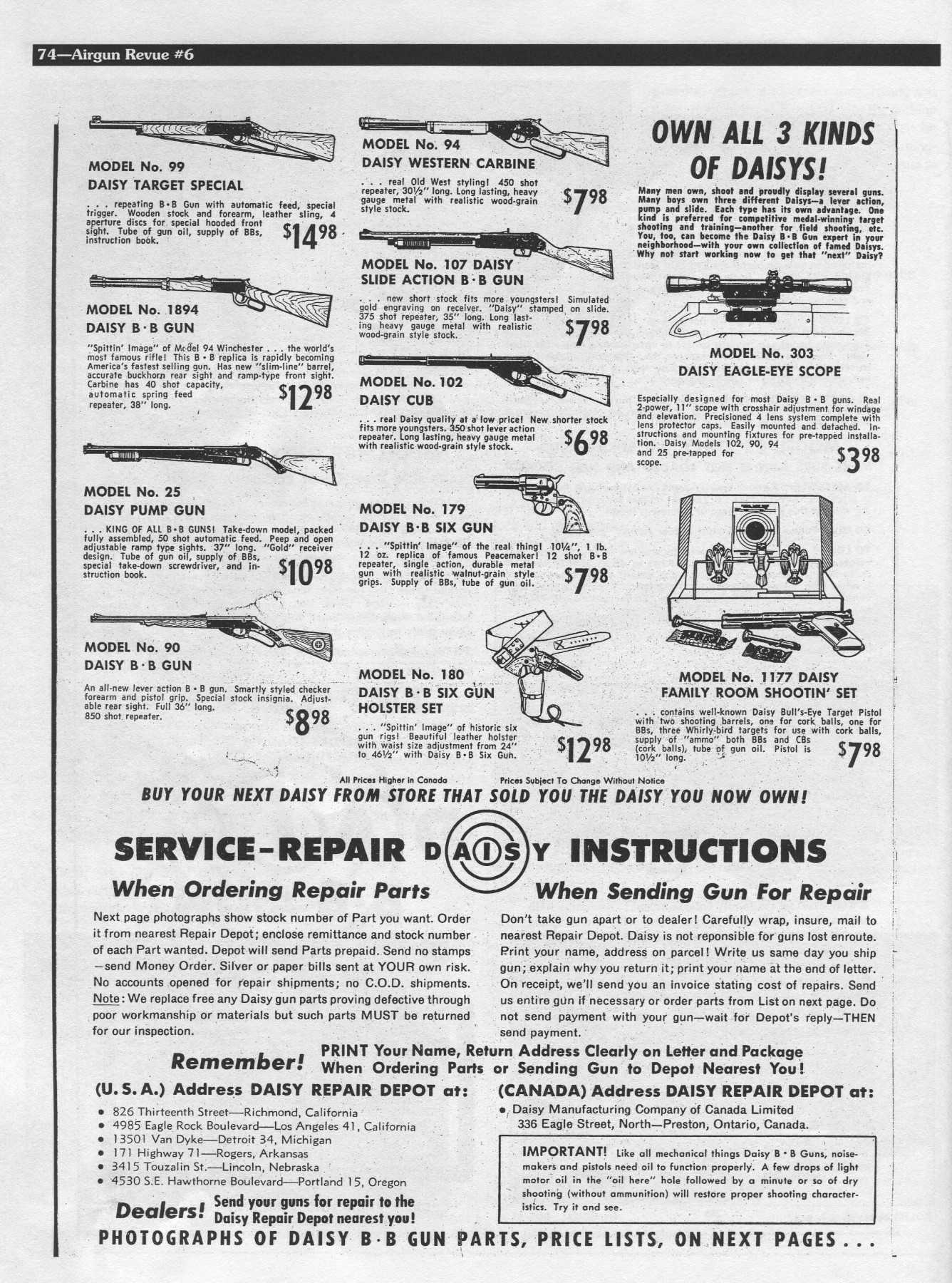

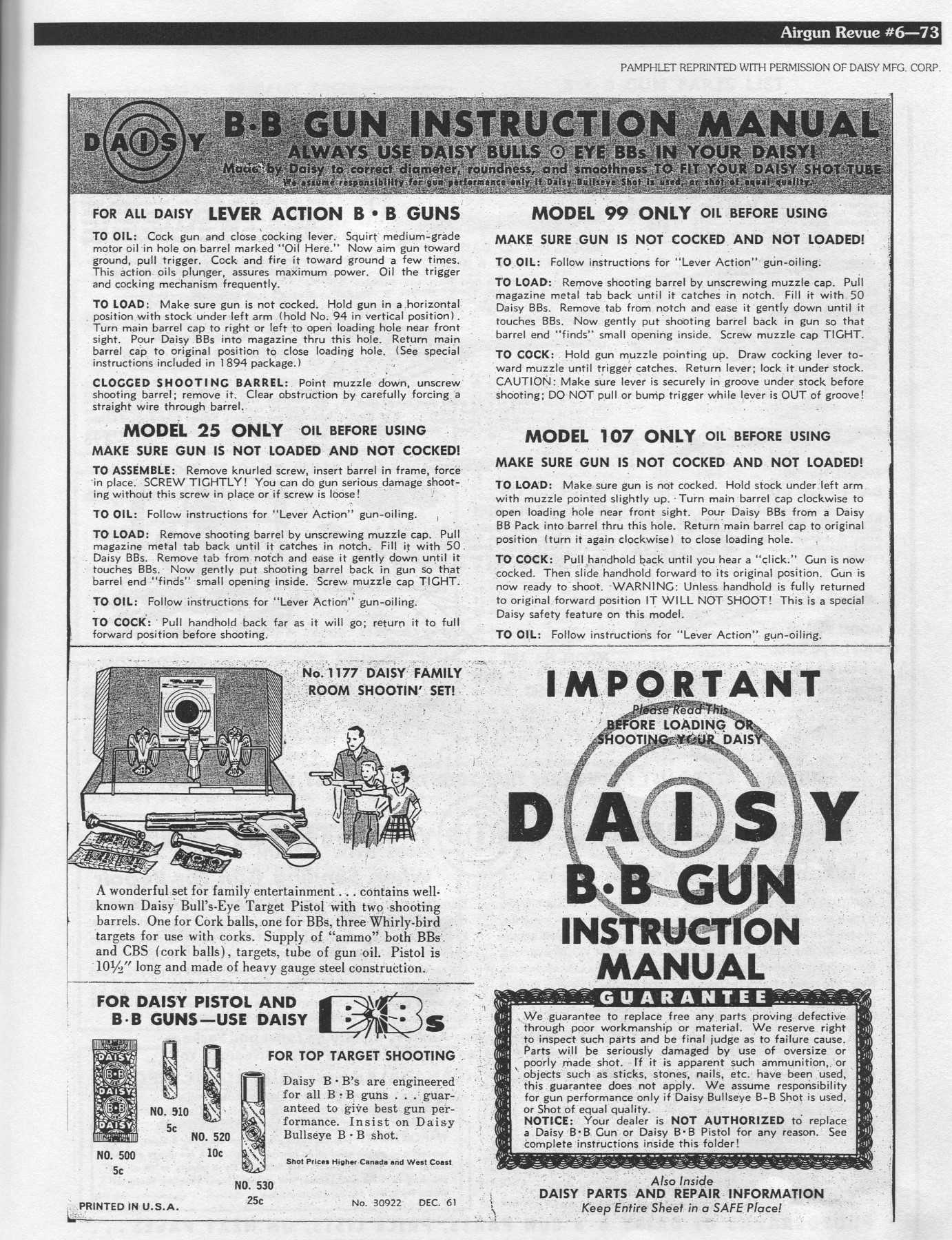

Daisy BB Gun Repair Manual

This section provides essential guidance for restoring and maintaining a popular air-powered projectile device. Whether you are dealing with performance issues, wear and tear, or simply looking to enhance its longevity, understanding the internal workings and common problems is crucial for effective troubleshooting.

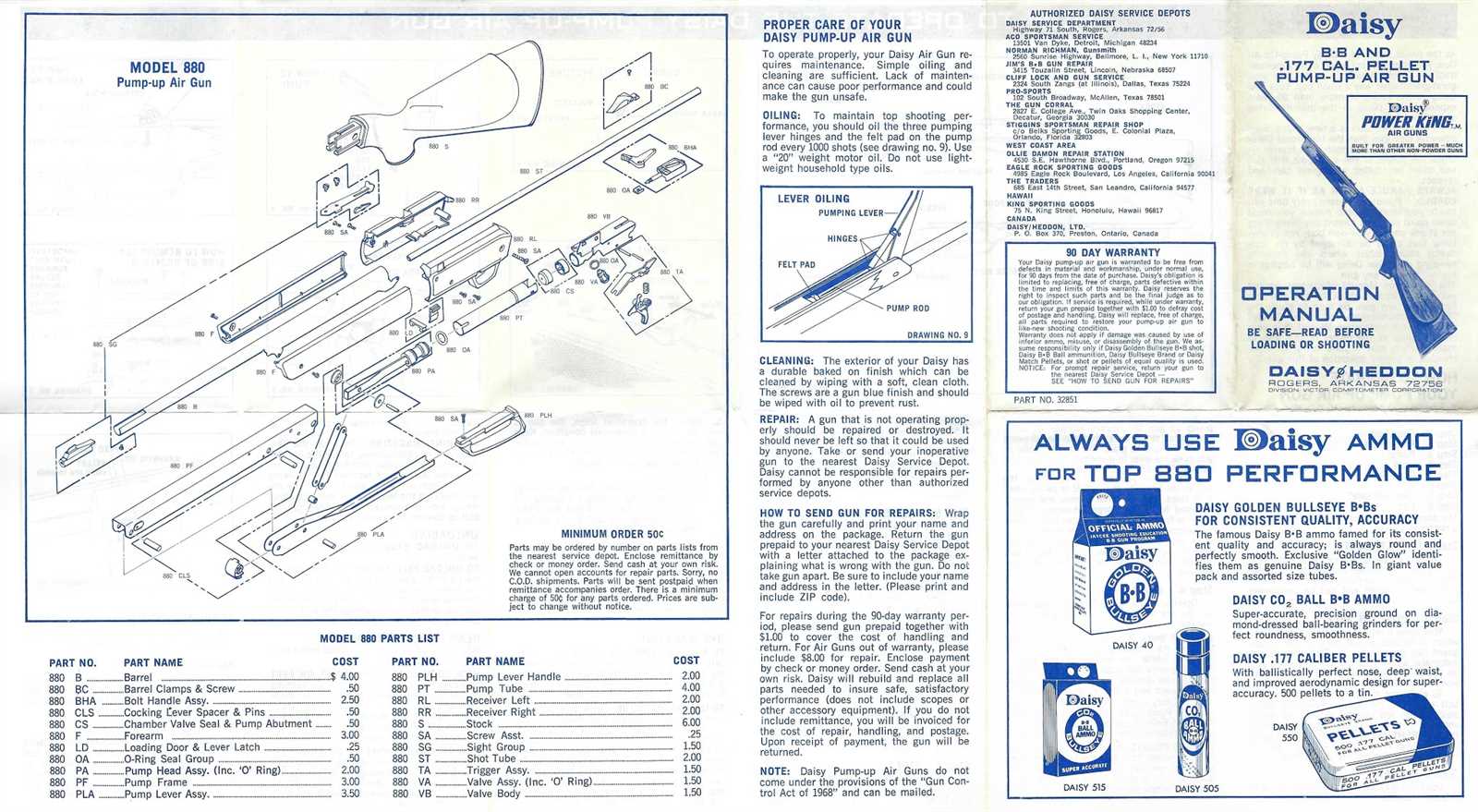

Regular maintenance is key to ensuring optimal functionality. Start by checking for any visible damage or malfunctioning components. Clean the internal mechanisms to prevent dirt and debris from affecting performance. Pay close attention to seals and springs, as these parts often require replacement over time to maintain accuracy and reliability.

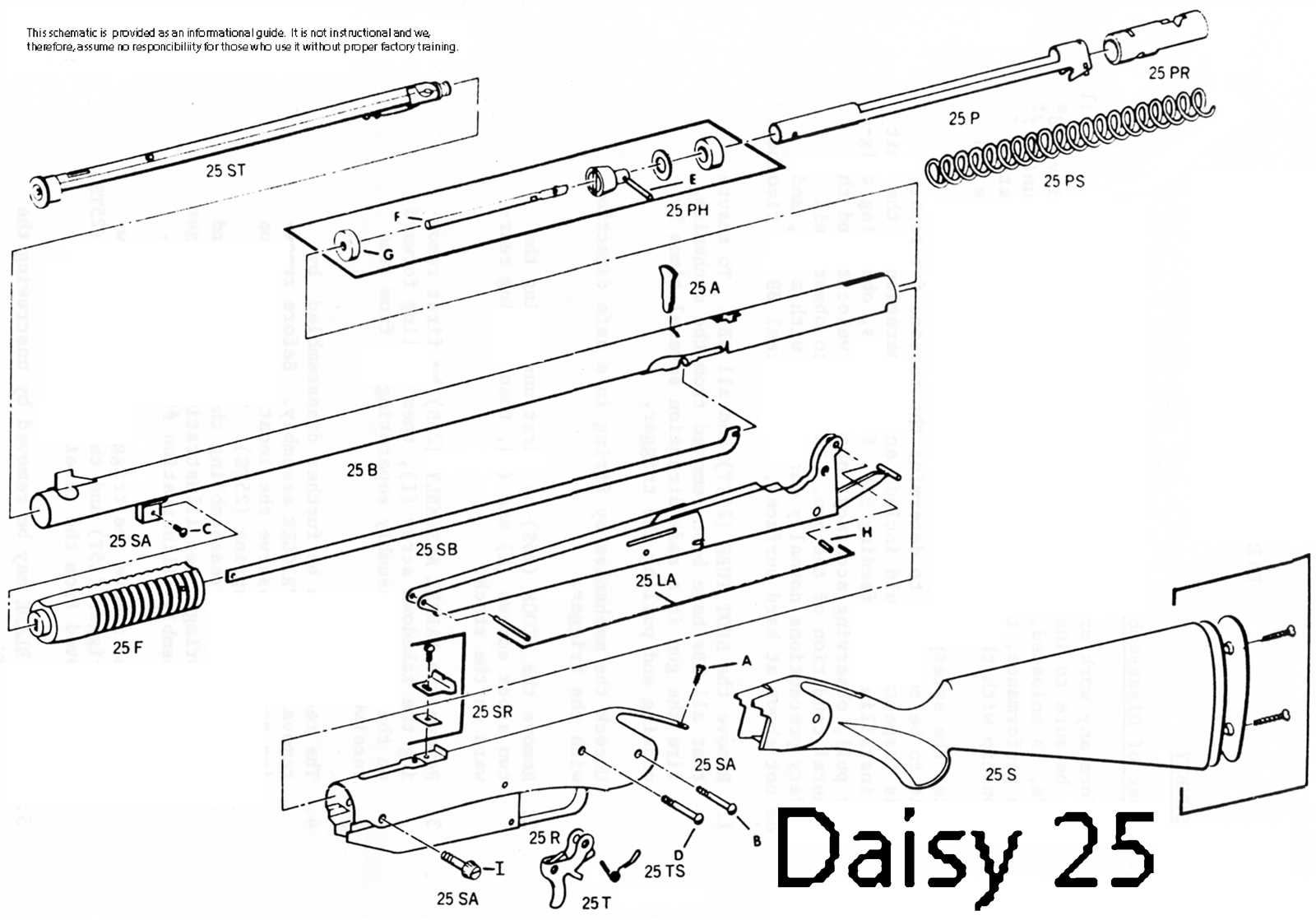

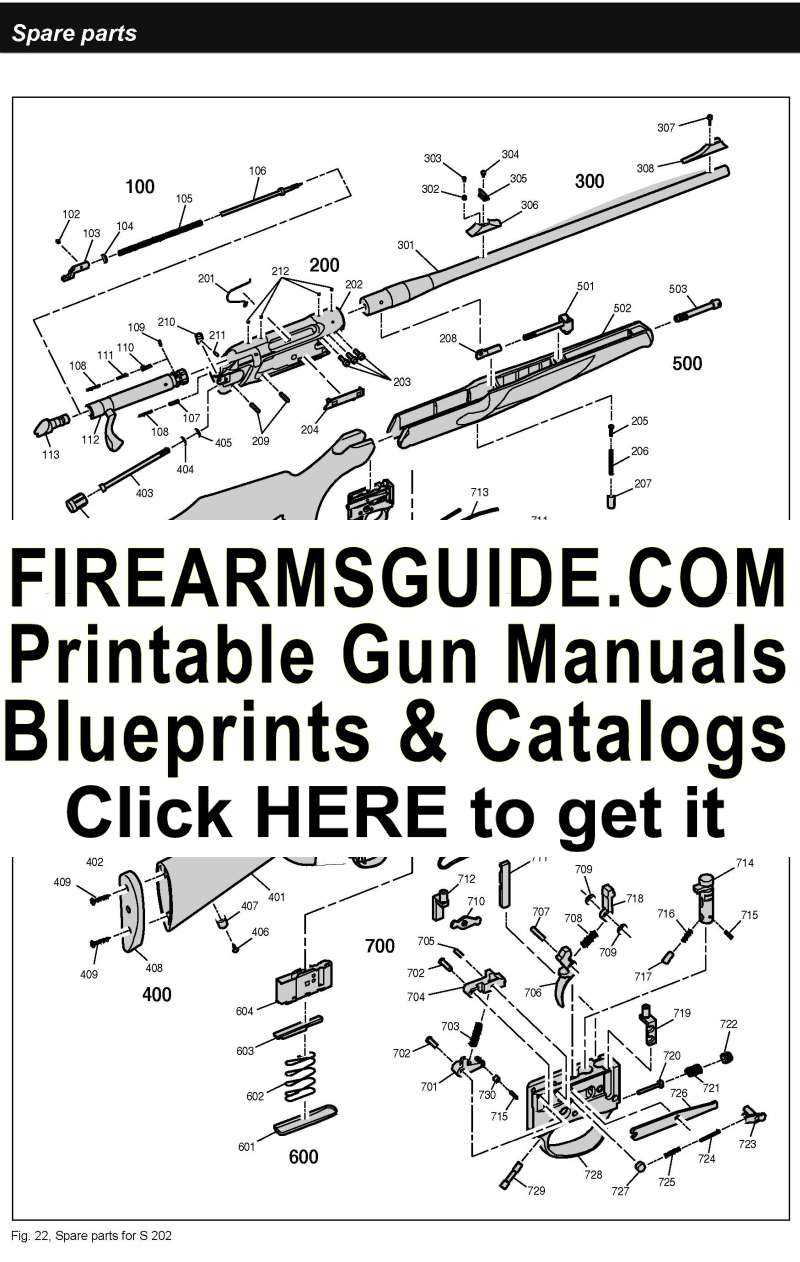

If you encounter specific challenges, consulting detailed diagrams and component lists can be invaluable. Familiarize yourself with the assembly process, as reassembling correctly after service is vital for safe operation. For more complex issues, consider reaching out to experienced technicians who specialize in this type of equipment.

Remember, a well-cared-for device not only performs better but also enhances the overall shooting experience. By following these tips and best practices, you can ensure that your equipment remains in excellent condition for years to come.

Understanding Your Daisy BB Gun

Every enthusiast should familiarize themselves with the intricacies of their air-powered projectile device. Knowing the key components, functions, and maintenance practices can enhance performance and prolong lifespan. This section aims to provide insights into the structure and operation of your equipment, ensuring a rewarding experience during use.

Key Components

Focusing on essential parts, such as the propulsion system and loading mechanism, is crucial for optimal functionality. Understanding how these elements work together allows for better troubleshooting and enhances shooting accuracy. Regular inspection of these components can prevent malfunctions and improve overall reliability.

Maintenance Practices

Implementing proper care techniques can significantly impact the longevity of your device. Regular cleaning, lubrication of moving parts, and careful storage will keep it in prime condition. Additionally, being aware of potential issues, such as air leaks or blockages, enables swift action to ensure consistent performance.

Common Issues with Daisy Models

Understanding typical problems associated with various models can enhance performance and longevity. Many users encounter similar challenges that can often be resolved with basic troubleshooting techniques.

Frequent Problems

- Loss of Power: A decrease in velocity can be attributed to several factors, including low energy source levels or blockages in the chamber.

- Inconsistent Firing: This issue may arise from misalignment of components or issues with the firing mechanism.

- Jamming: Misfeeds can occur, often resulting from improper loading or damaged feeding mechanisms.

- Leaking Seals: Over time, seals may degrade, leading to air loss and diminished functionality.

Troubleshooting Tips

- Check the energy source to ensure it is fully charged or properly installed.

- Inspect for obstructions in the barrel or feeding pathway.

- Examine seals and replace them if they show signs of wear or damage.

- Regularly clean and lubricate moving parts to maintain optimal performance.

Tools Required for Repairs

When addressing issues with your shooting device, having the right tools at hand is essential for effective maintenance and troubleshooting. The appropriate instruments not only facilitate the process but also ensure that adjustments are made accurately, promoting optimal functionality.

Essential Instruments

Key items include a set of precision screwdrivers, which allow for the careful removal of screws without damaging surrounding components. Additionally, pliers and tweezers can be invaluable for gripping and manipulating small parts that are difficult to handle with fingers alone.

Additional Supplies

Incorporating lubricants and cleaning agents into your toolkit can greatly enhance performance. These substances help maintain smooth operation and prolong the lifespan of internal mechanisms. It is also wise to have a clean workspace and organizational containers for parts to prevent loss or confusion during the process.

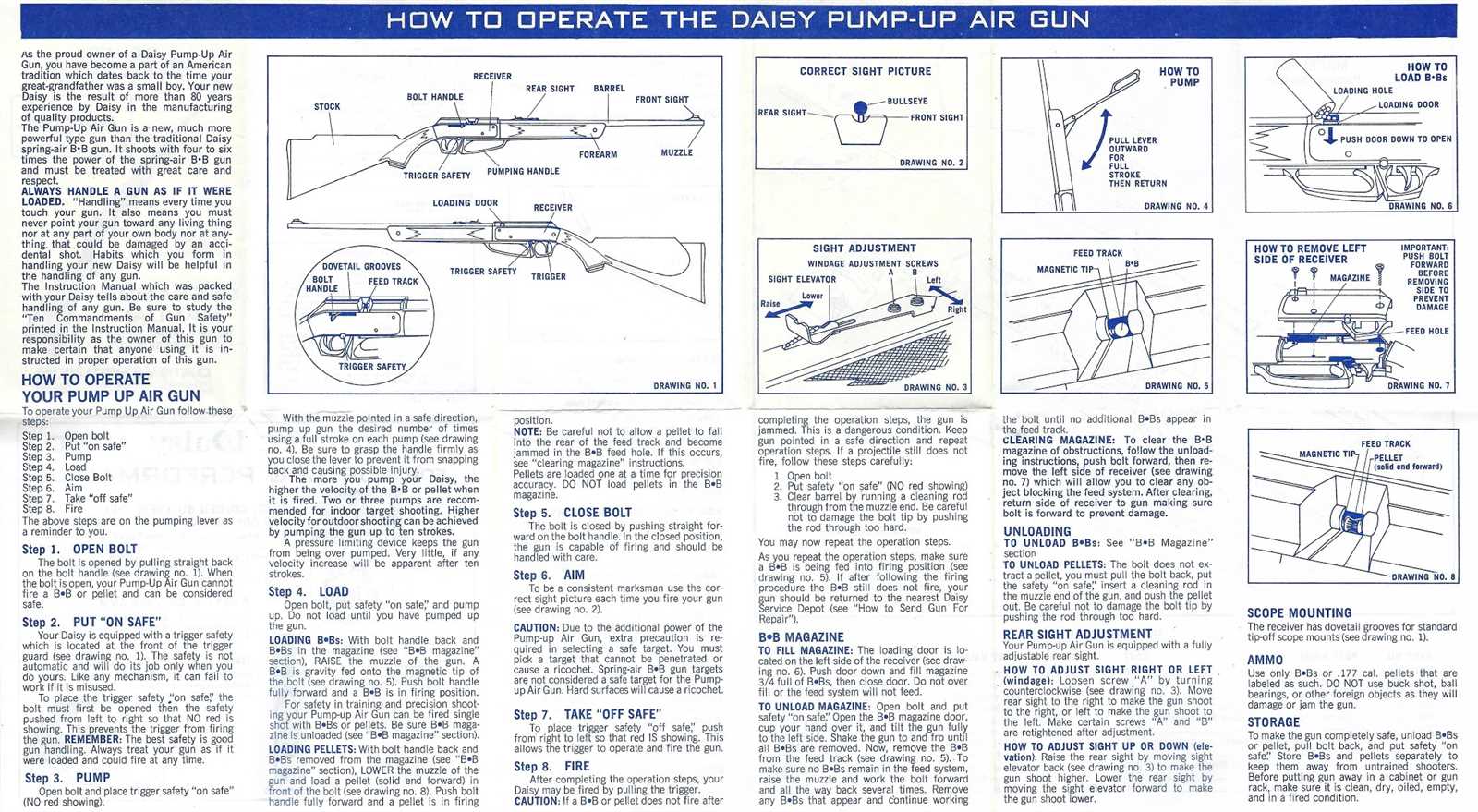

Step-by-Step Disassembly Guide

This section provides a comprehensive outline for taking apart your air-powered device safely and effectively. Disassembly is essential for maintenance, cleaning, or troubleshooting. Follow these detailed steps to ensure a smooth process.

-

Gather Your Tools: Before starting, make sure you have the necessary tools at hand.

- Screwdriver (Phillips and flathead)

- Allen wrench set

- Pliers

- Cleaning cloth

- Container for small parts

-

Safety First: Ensure the device is unloaded and not pressurized. Wear safety goggles if needed.

-

Remove External Components: Start by taking off any accessories or attachments.

- Detaching the sight

- Removing the stock or handle

-

Unscrew the Main Housing: Locate and carefully remove screws that secure the outer casing.

- Keep track of all screws and components in your container.

-

Access Internal Parts: Once the housing is removed, identify the internal mechanisms.

- Gently disconnect any wiring or springs attached to the main assembly.

- Take note of the arrangement of parts for reassembly.

-

Remove the Barrel Assembly: Unscrew or detach the barrel from the main body.

- Ensure you understand how it connects to avoid damage.

-

Document Your Process: As you disassemble, consider taking pictures or notes to assist with reassembly.

Following this guide will facilitate the disassembly of your air-powered device while minimizing the risk of damage. Be patient and methodical to ensure a successful experience.

Inspecting and Cleaning Components

Regular examination and maintenance of essential parts are crucial for optimal performance and longevity. Ensuring that each component is free from dirt, debris, and wear will help maintain functionality and accuracy.

Begin the process by carefully disassembling the unit, taking note of the order and orientation of each piece. This practice will aid in reassembly and help prevent potential issues later on. After disassembly, focus on the following areas:

- Barrel: Check for any obstructions or buildup that could affect trajectory. Clean with a suitable rod and cloth to remove residues.

- Trigger Mechanism: Inspect for smooth operation. Apply lubricant if necessary, ensuring not to over-saturate.

- Seals and O-rings: Look for signs of cracking or deterioration. Replace any compromised seals to prevent air leaks.

- Loading Chamber: Remove any foreign objects and clean surfaces to ensure proper feeding of ammunition.

Once the inspection is complete, reassemble the components in the reverse order of disassembly. Test the functionality to confirm that all parts are operating as intended. Consistent care will enhance performance and extend the lifespan of the equipment.

Replacing Worn Out Parts

Over time, components of your air-powered device may experience wear and tear, leading to decreased performance. Identifying and replacing these aged elements is crucial to maintaining functionality and ensuring longevity. This section provides guidance on how to effectively replace these worn-out components, helping you restore optimal operation.

Identifying Worn Components

Before initiating any replacements, it’s essential to thoroughly inspect each part for signs of damage or degradation. Common indicators include unusual noises, decreased accuracy, and failure to function properly. Pay special attention to seals, springs, and other moving parts, as they are often the first to wear out.

Steps for Replacement

Once you’ve identified the components that require attention, gather the necessary tools for the job. Follow these steps to ensure a smooth replacement process: 1. Disassemble the device carefully, taking care to document each step for reassembly. 2. Replace the damaged parts with new ones that meet the original specifications. 3. Reassemble the unit, ensuring all components fit snugly and securely. Testing the device after reassembly is vital to confirm that the issue has been resolved.

Reassembly Process Explained

The reassembly of your device is a crucial step that ensures its optimal functionality and longevity. This process involves meticulously putting together various components after maintenance or modifications have been made. Proper attention to detail during this phase is essential to avoid any potential issues that may arise from incorrect assembly.

Begin by gathering all parts and tools needed for the task. Organizing components in a systematic manner will facilitate a smoother assembly process. Make sure to follow the sequence specified in the guidelines to ensure each piece is correctly placed. Pay particular attention to alignments and connections, as these elements are vital for the device’s performance.

Once all parts are positioned, perform a thorough inspection to confirm that everything is secure. If applicable, ensure that any fasteners are tightened to the recommended specifications. Testing the functionality of the assembly before finalizing the process can help identify any misalignments or loose connections.

Testing for Proper Functionality

Ensuring optimal performance is crucial for any precision device. Regular assessments can help identify issues that may affect functionality. This section outlines steps to verify the effectiveness of your equipment and troubleshoot common problems.

Initial Assessment Steps

- Examine the exterior for any visible signs of wear or damage.

- Check all components to ensure they are securely attached and undamaged.

- Inspect the trigger mechanism for smooth operation.

Performance Testing

- Load the device according to the manufacturer’s specifications.

- Conduct a series of test activations to evaluate consistency.

- Observe the discharge process for accuracy and reliability.

- Note any irregular sounds or movements during operation.

After completing these evaluations, compare your findings with standard performance criteria to determine if further adjustments or maintenance are necessary.

Adjusting Sight and Accuracy

Achieving precise aim and enhanced performance requires careful adjustments to the sighting mechanism. Proper alignment not only improves targeting but also boosts overall consistency in shooting results. This section will guide you through the essential steps to fine-tune your sight for optimal accuracy.

Understanding the Components

Before making any adjustments, it’s crucial to familiarize yourself with the sighting elements involved:

- Front Sight: The component that helps focus your aim.

- Rear Sight: This aids in aligning the target with the front sight.

- Windage Adjustment: Alters the horizontal position of the point of impact.

- Elevation Adjustment: Modifies the vertical position of the impact point.

Steps for Adjusting the Sight

Follow these steps to ensure precise adjustments:

- Set up a stable target at a predetermined distance.

- Take a few test shots to assess the initial accuracy.

- Observe where the shots land in relation to the target.

- Adjust the rear sight using the appropriate settings for windage and elevation:

- For horizontal corrections, move the rear sight left or right.

- For vertical corrections, adjust the sight up or down.

Regular maintenance and adjustments will ensure that your aiming device remains effective, leading to improved shooting experiences over time.

Maintenance Tips for Longevity

Ensuring the longevity of your equipment requires regular care and attention. By following a few essential practices, you can keep your device in excellent working condition for years to come. Proper maintenance not only enhances performance but also prevents premature wear and tear.

Regular Cleaning

Routine cleaning is vital to maintain the functionality of your device. Use a soft cloth to remove dust and debris from both the exterior and interior components. For stubborn residues, a gentle cleaning solution can be applied, but avoid harsh chemicals that might damage the finish.

Periodic Inspections

Conducting regular inspections is crucial to identify any potential issues before they escalate. Check for any signs of wear, such as fraying parts or loose connections. Addressing these concerns promptly can save time and costs associated with more extensive repairs.

Additionally, always ensure that the mechanism operates smoothly. Lubricate moving parts as needed, using appropriate oils or greases recommended for your equipment type. This practice will significantly enhance performance and durability.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the inherent risks involved in working with mechanical devices allows for a more secure and effective process. Taking appropriate measures ensures not only personal well-being but also the longevity and functionality of the item being serviced.

First and foremost, always wear protective gear, such as safety goggles and gloves, to safeguard against potential hazards. These items can help protect your eyes and hands from sharp objects or hazardous materials. Additionally, working in a well-lit environment reduces the risk of mistakes and enhances visibility, making it easier to identify any potential dangers.

Moreover, ensure that you have a clean and organized workspace. A clutter-free area minimizes distractions and the likelihood of accidents. It is also advisable to keep all tools and components securely stored when not in use to avoid any unintended injuries. Always be aware of your surroundings and avoid working in areas where children or pets may inadvertently interfere.

Finally, if you are uncertain about any aspect of the process, do not hesitate to consult professionals or reference reliable resources. Taking the time to understand the procedures involved significantly decreases the chances of mishaps. Remember, safety should always come first to ensure a successful and trouble-free experience.

Resources for Further Assistance

When seeking additional support for your project, numerous options are available to enhance your understanding and skills. Whether you are experiencing challenges or aiming to improve your technique, tapping into various resources can provide valuable insights.

Online Forums: Engaging with communities dedicated to similar interests can be immensely beneficial. Forums often host discussions where users share their experiences, tips, and solutions to common issues.

Video Tutorials: Platforms like YouTube offer a wealth of instructional videos. Visual guides can help clarify complex processes, allowing you to follow along step-by-step.

Instructional Guides: Many websites provide comprehensive guides that cover a range of topics related to your endeavor. These resources can serve as excellent references for troubleshooting and maintenance.

Local Workshops: Participating in hands-on workshops can enhance your skills significantly. Look for local clubs or organizations that offer training sessions led by experienced individuals.

Manufacturer Support: Don’t hesitate to reach out to the manufacturer directly for assistance. Many companies offer customer service that can address specific concerns and provide expert guidance.

Utilizing these resources can empower you to tackle challenges effectively and expand your expertise in the field.