This section provides comprehensive insights into the upkeep and troubleshooting of a specific outboard motor model renowned for its reliability and performance. Understanding the intricacies of engine functionality is crucial for boat enthusiasts who wish to extend the lifespan of their watercraft.

From addressing common mechanical issues to routine servicing tasks, this guide covers vital aspects that every owner should know. Whether you’re a novice or an experienced boater, familiarizing yourself with the workings of this engine will enhance your boating experience and ensure smooth sailing.

By delving into maintenance techniques and operational tips, readers will gain a clearer understanding of the components that contribute to optimal engine performance. This knowledge empowers boat owners to make informed decisions, ultimately leading to a more enjoyable and hassle-free time on the water.

1982 Evinrude 35 HP Overview

This section provides a comprehensive examination of a notable outboard engine from a renowned manufacturer. Designed for versatility and reliability, this power unit is an excellent choice for a variety of watercraft applications. Its engineering combines performance with ease of use, making it suitable for both recreational boating and more demanding tasks.

Engine Specifications

The unit features a robust two-stroke design, which is known for its lightweight and efficient operation. This engine is equipped with a powerful displacement capacity, allowing it to deliver impressive thrust while maintaining fuel efficiency. The configuration is tailored for optimal torque and horsepower output, making it a preferred choice among boating enthusiasts.

Features and Benefits

Notable for its user-friendly controls, this model offers smooth handling and straightforward maintenance. Durability is a key aspect of its construction, ensuring long-lasting performance even in challenging marine environments. Additionally, it provides a remarkable balance between power and fuel consumption, which is vital for those who prioritize both performance and cost-effectiveness.

Common Issues with Evinrude Motors

Marine engines, particularly those designed for smaller vessels, can experience a range of challenges that may affect performance and reliability. Understanding these potential problems is crucial for maintaining optimal functionality and ensuring safe operation on the water.

- Fuel System Problems:

- Clogged fuel filters can restrict flow.

- Contaminated fuel may lead to engine misfires.

- Faulty fuel lines can cause leaks and pressure issues.

- Electrical Failures:

- Dead batteries can prevent engine starting.

- Corroded connections may result in power loss.

- Faulty ignition systems can disrupt performance.

- Cooling System Issues:

- Overheating can result from clogged cooling passages.

- Failed water pumps may lead to insufficient cooling.

- Leaking hoses can cause coolant loss.

- Mechanical Failures:

- Worn-out bearings can create excessive noise.

- Piston rings may wear down, affecting compression.

- Faulty gaskets can result in oil leaks.

Identifying and addressing these common issues promptly can significantly enhance the longevity and efficiency of marine engines. Regular maintenance checks and timely interventions play a vital role in ensuring a trouble-free experience on the water.

Essential Tools for Repairs

When it comes to maintaining and fixing outboard motors, having the right equipment is crucial. The right tools not only simplify the process but also enhance efficiency and ensure high-quality outcomes. Understanding the various implements available can make the difference between a successful task and an arduous struggle.

Basic Hand Tools

Hand tools are fundamental for any maintenance work. Essential items include wrenches, pliers, and screwdrivers. These tools are indispensable for accessing hard-to-reach areas and making precise adjustments. Investing in a good-quality set can significantly impact the ease with which tasks are performed.

Diagnostic Equipment

In addition to hand tools, diagnostic devices play a vital role in troubleshooting. Multimeters and compression gauges allow for quick assessments of electrical systems and engine performance. Utilizing these instruments helps identify issues early, preventing more significant complications in the future.

Step-by-Step Maintenance Procedures

Regular upkeep of your outboard motor is essential for optimal performance and longevity. This section outlines a series of systematic tasks designed to ensure your engine runs smoothly, providing guidance on what actions to take and when. Following these procedures will help you avoid costly repairs and extend the life of your equipment.

1. Checking the Oil Level

Start by inspecting the oil level. Ensure the engine is on a level surface, then remove the dipstick, clean it, and reinsert it to check the reading. If the oil is low, top it up with the appropriate type of lubricant.

2. Inspecting the Fuel System

Examine the fuel lines for any signs of wear or leaks. Replace any damaged hoses and ensure that all connections are secure. It’s also advisable to check the fuel filter for blockages and replace it if necessary.

3. Cleaning the Spark Plugs

Remove the spark plugs and inspect them for carbon buildup or damage. Clean the plugs with a wire brush and replace them if they appear worn or damaged. Properly gapped spark plugs contribute to efficient combustion.

4. Testing the Battery

Check the battery connections for corrosion and ensure they are tight. Use a multimeter to measure the voltage, and if the voltage is low, recharge or replace the battery as needed to maintain optimal starting power.

5. Inspecting the Cooling System

Examine the cooling system components, including the water pump and hoses, for any blockages or damage. Ensure that water is flowing freely through the cooling system when the engine is running, as proper cooling is vital for engine longevity.

6. Assessing the Propeller

Remove the propeller and inspect it for any nicks or damage. Clean the propeller shaft and check for any fishing line or debris that may cause issues. Reinstall the propeller securely after inspection.

7. Final Checks

After completing the above tasks, conduct a final inspection of all components. Ensure that all fasteners are tightened, and look for any signs of wear or needed repairs. Regularly performing these procedures will help maintain performance and reliability.

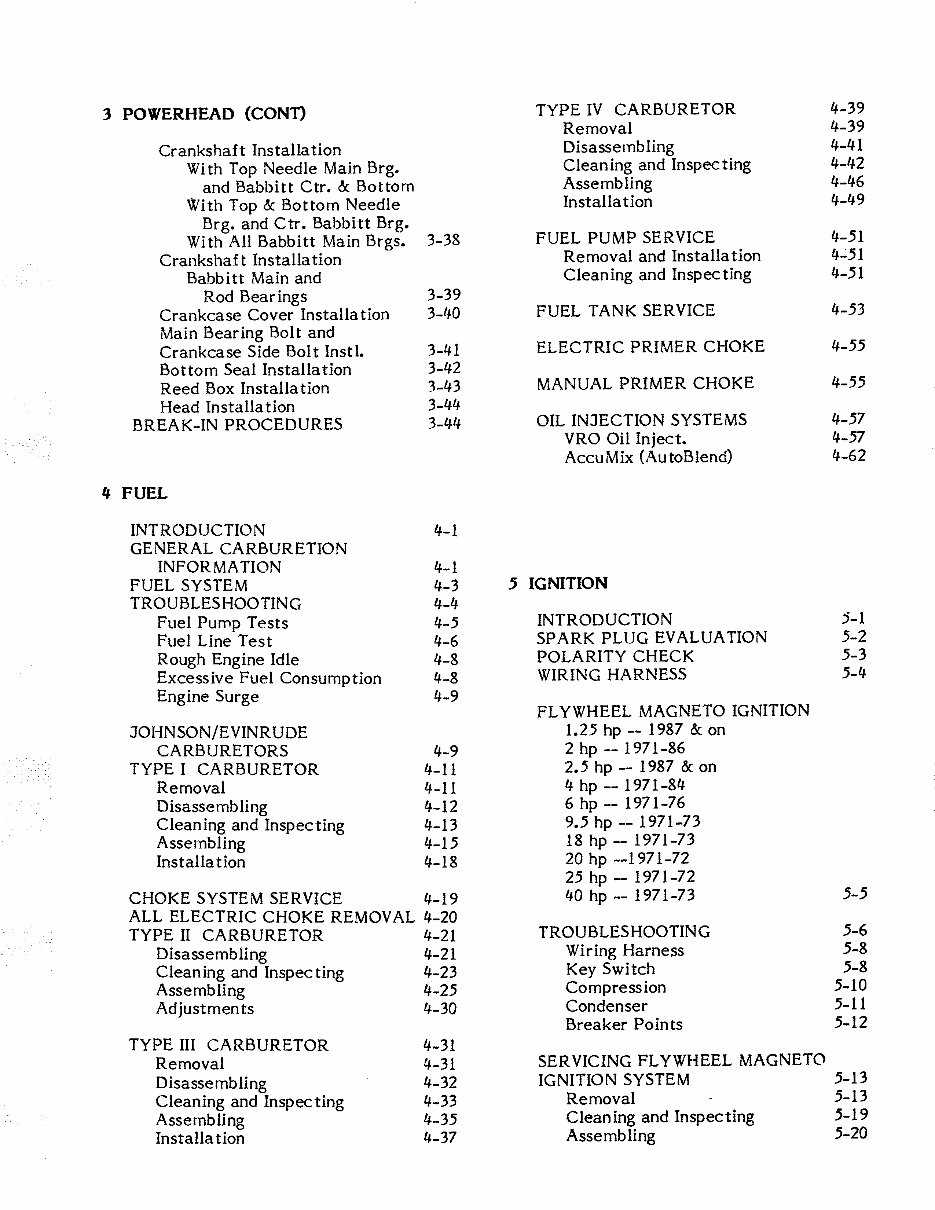

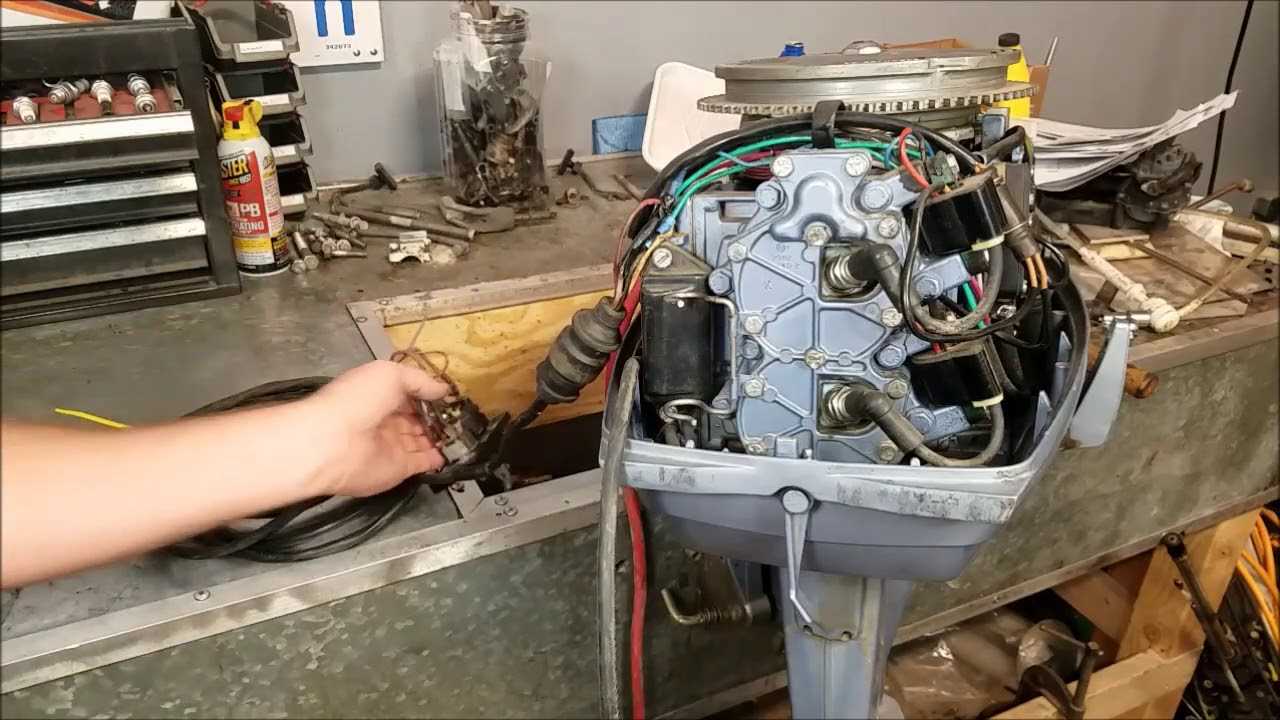

Understanding the Electrical System

The electrical system of a small outboard motor plays a crucial role in ensuring optimal performance and reliability. It encompasses various components that work together to provide power for starting, lighting, and ignition systems. A thorough understanding of these elements is essential for effective troubleshooting and maintenance.

Key components of the electrical system include:

- Battery: Supplies the necessary voltage to start the engine and power electrical accessories.

- Alternator: Recharges the battery while the engine is running, ensuring a continuous power supply.

- Ignition System: Responsible for creating the spark needed to ignite the fuel-air mixture in the engine cylinders.

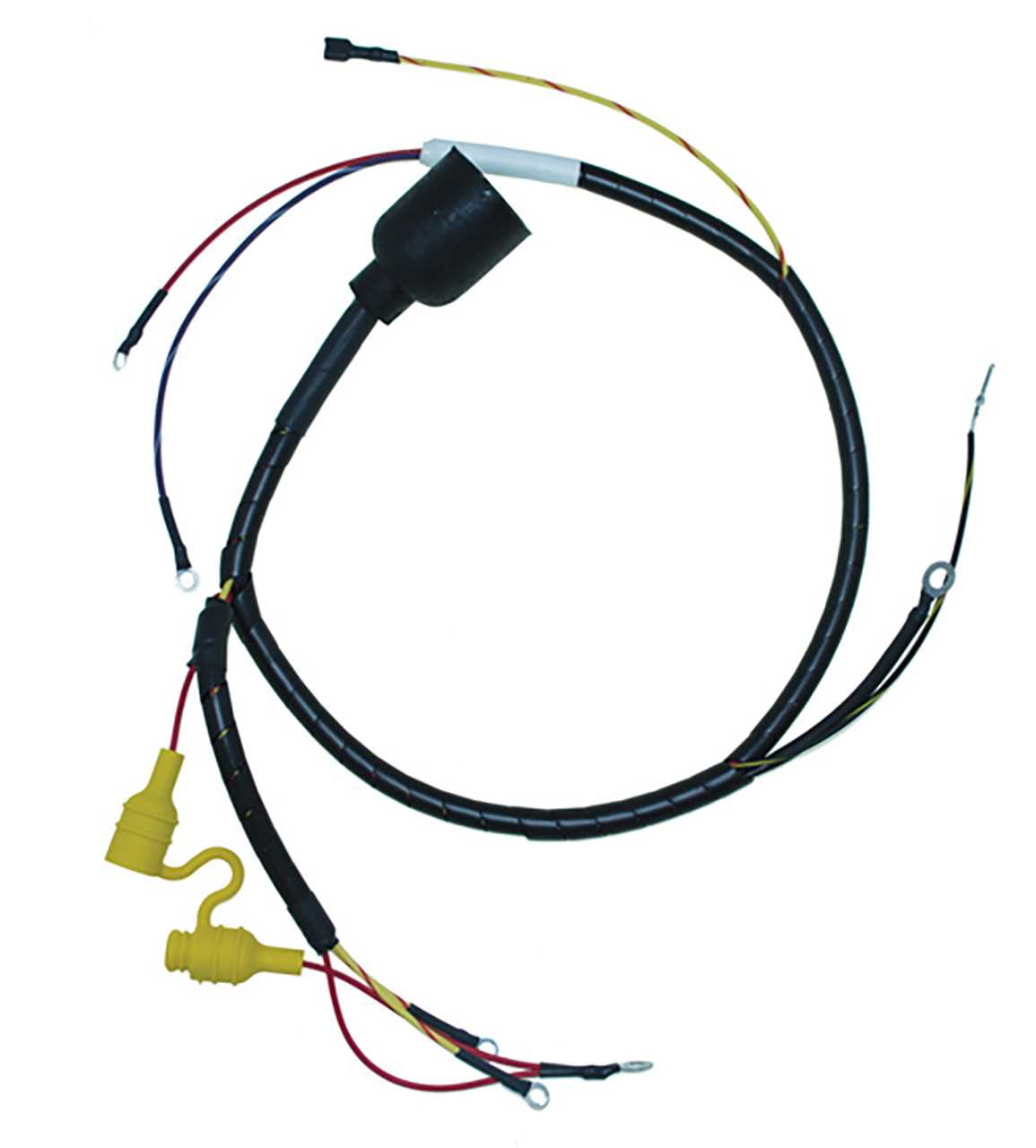

- Wiring Harness: Connects various electrical components and facilitates the flow of electricity throughout the system.

- Switches and Fuses: Protect the electrical system from overloads and ensure safe operation by controlling the flow of current.

Regular inspection and maintenance of these components can prevent electrical failures and enhance the overall efficiency of the motor. Understanding the specific functions and interconnections of each part will aid in diagnosing issues and implementing effective solutions.

When addressing electrical problems, consider the following troubleshooting steps:

- Check the battery’s charge level and connections for any signs of corrosion or looseness.

- Inspect the wiring for frays, breaks, or other damage that could disrupt power flow.

- Test the ignition system to ensure it is generating the required spark for ignition.

- Examine the alternator’s performance to confirm it is recharging the battery adequately.

- Replace any faulty switches or blown fuses to restore functionality.

By familiarizing yourself with these components and their roles, you can ensure a reliable electrical system that supports the effective operation of your motor.

Fuel System Troubleshooting Tips

Ensuring optimal performance of the fuel system is essential for efficient engine operation. Common issues can arise from various components, and identifying these problems early can save time and resources. Below are some practical recommendations to assist in diagnosing fuel-related concerns effectively.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Fuel Blockage | Engine sputters, loss of power | Check fuel lines for clogs and inspect filters for dirt accumulation. |

| Fuel Leak | Visible fuel under the engine, strong odor | Examine all connections and hoses for signs of leakage and wear. |

| Improper Fuel Mixture | Hard starting, rough idling | Verify the fuel mixture ratio according to specifications and adjust as necessary. |

| Contaminated Fuel | Engine misfires, poor acceleration | Test fuel quality and replace if contaminated; ensure clean storage methods. |

| Clogged Carburetor | Engine stalls, poor performance | Disassemble and clean the carburetor; check jets and float for proper operation. |

By methodically addressing these issues, one can enhance fuel system efficiency and ensure reliable engine performance. Regular maintenance and attentive observation will also contribute significantly to preventing future complications.

Lower Unit Service Guide

The lower unit is a critical component that requires regular attention to ensure optimal performance and longevity. Proper maintenance can prevent common issues, such as leaks and mechanical failures. This section outlines essential procedures for servicing this vital part, focusing on routine inspections, fluid changes, and necessary repairs.

Inspection and Maintenance

Fluid Replacement Procedure

To change the lubricant, start by draining the old fluid from the lower unit. Remove the drain plug and allow the oil to fully exit. Afterward, replace the plug and refill with fresh lubricant using the appropriate type for the specific application. Ensure the fill plug is securely fastened once completed.

Propeller Selection and Replacement

Choosing the right propeller is crucial for achieving optimal performance and efficiency from your outboard engine. The appropriate blade design, diameter, and pitch can significantly influence acceleration, top speed, and fuel consumption. Understanding the specific requirements of your watercraft and engine characteristics will guide you in making an informed decision.

Factors to Consider for Selection

When selecting a propeller, several key factors must be evaluated to ensure compatibility and performance:

| Factor | Description |

|---|---|

| Diameter | The width of the propeller, which affects thrust and speed. A larger diameter can provide better grip in the water. |

| Pitch | The angle of the blades relative to the water surface. A higher pitch can increase top speed but may reduce acceleration. |

| Blade Design | The shape and number of blades can influence the efficiency and handling. More blades generally improve stability. |

| Material | Common materials include aluminum and stainless steel. Stainless steel is more durable and provides better performance. |

Replacement Guidelines

Replacing a propeller involves a few essential steps to ensure proper installation and alignment. Begin by removing the old propeller, which typically requires loosening the retaining nut and pulling it off the shaft. Before installing the new propeller, inspect the shaft for any damage or debris. Position the new propeller carefully, aligning it with the keyway on the shaft, and secure it by tightening the nut to the manufacturer’s specified torque settings. Regular inspections and maintenance of the propeller are vital for optimal performance and longevity.

Cooling System Inspection Techniques

The effectiveness of an engine’s cooling system is vital for optimal performance and longevity. Regular examination of this system can prevent overheating and related issues. By employing specific techniques, one can ensure the cooling mechanism operates efficiently, maintaining the appropriate temperature during use.

Visual Inspection

Start with a thorough visual assessment of the cooling components. Look for any signs of wear, corrosion, or leaks in hoses, connectors, and the radiator. Pay attention to the condition of the water pump and ensure it is securely mounted. A damaged or loose component may indicate the need for replacement.

Fluid Levels and Condition

Check the coolant levels to ensure they are within the recommended range. The fluid should be clean and free from contaminants. If the coolant appears discolored or contains debris, it may require flushing and replacement. Maintaining proper fluid levels and quality is crucial for efficient heat dissipation.

By following these inspection techniques, one can effectively monitor the cooling system, addressing any potential problems before they escalate into more significant concerns.

Safe Operation Practices for Outboards

Ensuring the safety of both the operator and passengers is paramount when using outboard engines. Adhering to best practices not only enhances the experience but also mitigates risks associated with boating. Understanding the fundamentals of safe navigation, equipment handling, and emergency preparedness contributes significantly to a secure environment on the water.

Before embarking on any voyage, it is essential to familiarize oneself with the specific features and limitations of the outboard engine. Regular inspections of fuel levels, engine components, and safety equipment can prevent mechanical failures and ensure optimal performance. It is also advisable to keep a comprehensive checklist that covers all necessary safety items, such as life jackets, fire extinguishers, and communication devices.

When operating, maintaining a safe speed and distance from other vessels, as well as being aware of weather conditions, enhances safety. It is crucial to remain vigilant for potential hazards, including submerged obstacles or changing water currents. Additionally, ensuring that all passengers are securely seated and briefed on safety procedures can help prevent accidents.

In case of emergencies, having a well-defined plan is vital. Familiarize yourself with rescue signals and have a reliable means of communication. Practicing emergency drills can prepare everyone on board for unexpected situations. Prioritizing safety not only protects lives but also promotes a culture of responsibility among boaters.

Finding Replacement Parts and Resources

When it comes to maintaining a marine engine, sourcing suitable components is crucial for optimal performance. Identifying reliable suppliers and utilizing the right resources can significantly enhance the longevity of your outboard. This section outlines various methods to locate the necessary parts and support for your engine.

Online Marketplaces and Retailers

Numerous online platforms offer a vast selection of components for marine engines. Websites like eBay and Amazo provide both new and used parts, often at competitive prices. Additionally, specialized marine retailers maintain extensive inventories, ensuring that you can find both common and hard-to-locate components. Always verify the credibility of the seller and read reviews before making a purchase.

Local Marine Supply Stores

Visiting local marine supply shops can be an invaluable resource. Knowledgeable staff can provide insights and recommendations on suitable replacements. Furthermore, these stores often carry essential tools and accessories that may be necessary for installation. Networking with fellow enthusiasts and mechanics in these locations can also lead to useful recommendations and advice.