Ignition Components: Issues in the ignition system may prevent the engine from starting

Maintaining Seadoo Fuel and Cooling Systems

Proper upkeep of fuel and cooling mechanisms is essential for optimal performance and longevity. These systems work in tandem to ensure efficient operation and prevent overheating. Regular checks and maintenance can help identify potential issues before they escalate.

Here are key aspects to consider when maintaining these systems:

- Fuel System:

- Regularly inspect fuel lines for cracks or leaks.

- Ensure fuel filters are clean and replace them as needed.

- Check for proper fuel flow to avoid clogs.

- Use high-quality fuel to prevent deposits and improve efficiency.

- Cooling System:

- Examine hoses for wear or damage.

- Keep the cooling intake clear of debris to ensure effective circulation.

- Flush the system periodically to remove any buildup.

- Monitor the coolant level and replace as necessary.

Implementing these practices not only enhances performance but also extends the life of your equipment. Regular maintenance is a crucial part of responsible ownership.

Regular Checkpoints for Seadoo Performance

Maintaining optimal functionality of watercraft involves regular assessments and monitoring of various components. These routine evaluations ensure that the vehicle operates smoothly and efficiently, enhancing both performance and safety. Understanding key areas to inspect can significantly contribute to the longevity and reliability of the craft.

Key Areas to Inspect

- Engine Condition: Regularly check for any leaks or unusual noises. Ensure proper oil levels and examine the fuel system for any signs of contamination.

- Battery Health: Inspect battery connections for corrosion and ensure that the battery is charged adequately. Test the voltage to confirm it meets operational standards.

- Propulsion System: Assess the impeller for damage and ensure it is free of debris. Check the wear ring for signs of excessive wear and replace as necessary.

Maintenance Practices

- Conduct routine cleaning of the exterior to prevent buildup of salt and debris.

- Flush the cooling system after each use to remove any impurities.

- Check the operation of safety features and emergency shut-off systems regularly.

By adhering to these checkpoints and maintenance practices, owners can help ensure that their watercraft performs at its best, providing a safe and enjoyable experience on the water.

Winterizing Your 1997 Seadoo for Storage

Preparing your watercraft for the off-season is crucial to ensure its longevity and optimal performance. Properly winterizing your vessel involves a series of steps designed to protect the engine, components, and systems from the harsh winter elements. This guide outlines essential procedures to follow for a successful hibernation of your craft.

Key Steps for Effective Preparation

To safeguard your vessel, it’s important to complete the following tasks:

| Step |

Description |

| 1 |

Drain and flush the cooling system to remove any residual water, preventing freezing and damage. |

| 2 |

Add fuel stabilizer to the tank and run the engine briefly to circulate it throughout the system. |

| 3 |

Change the oil and filter to remove contaminants, which can cause corrosion during storage. |

| 4 |

Remove the battery and store it in a cool, dry place, ensuring it is fully charged. |

| 5 |

Cover your craft with a breathable cover to shield it from dust and moisture while allowing ventilation. |

Final Tips for Long-Term Storage

Additionally, ensure that all storage compartments are dry and free from any potential contaminants. Regular checks during the off-season can help identify any issues before the next usage. Following these guidelines will help maintain your watercraft in prime condition for the upcoming season.

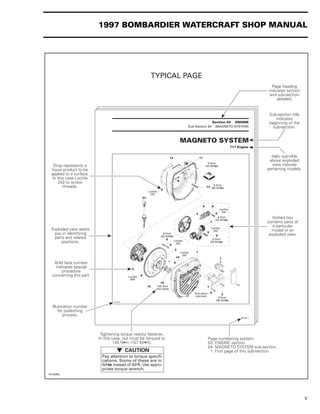

Essential Tools for Seadoo Repairs

Having the right equipment is crucial when addressing maintenance and troubleshooting for watercraft. Proper tools not only enhance efficiency but also ensure safety during the process. This section highlights key instruments that every enthusiast should consider for effective servicing.

Basic Hand Tools

Standard hand tools form the foundation of any maintenance kit. Items such as wrenches, screwdrivers, and pliers are indispensable for tasks ranging from tightening bolts to adjusting components. A well-organized toolbox can significantly streamline the workflow and prevent delays during inspections.

Specialized Instruments

In addition to basic hand tools, specialized instruments may be necessary for more complex procedures. For instance, compression testers, multimeters, and fuel pressure gauges are vital for diagnosing performance issues and ensuring optimal operation. Investing in high-quality specialized tools can make a significant difference in the accuracy and ease of various tasks.

Diagnosing Steering and Pump Problems

Understanding the common issues related to maneuverability and propulsion is essential for maintaining optimal performance. When facing challenges in handling or water jet function, it’s important to approach the diagnosis methodically. This section outlines effective strategies to identify and resolve steering and pump-related issues.

Start by considering the following signs that may indicate underlying problems:

- Unresponsive steering controls

- Difficulty in changing direction

- Weak or inconsistent thrust

- Strange noises coming from the pump

To effectively diagnose these issues, follow this step-by-step approach:

- Inspect the Steering Mechanism: Check for any visible damage or wear in the cables, linkage, and handlebars.

- Examine Fluid Levels: Ensure that the steering and pump fluids are at the recommended levels, as low fluid can lead to performance issues.

- Test the Steering Operation: Manually move the steering to see if it operates smoothly and responds promptly.

- Assess the Pump Function: Start the propulsion system and observe if the pump is generating adequate pressure and thrust.

- Look for Blockages: Inspect the intake for debris or obstructions that could affect water flow.

Once potential problems are identified, implement the necessary repairs or adjustments to restore functionality. Regular maintenance and checks can significantly reduce the likelihood of encountering these issues in the future.

Lubrication and Greasing Best Practices

Proper lubrication and greasing are essential for ensuring the longevity and optimal performance of mechanical systems. Regular maintenance of these components reduces friction, minimizes wear, and enhances overall efficiency. Adopting best practices in lubrication not only safeguards against premature failures but also contributes to smoother operation and improved reliability.

Key Considerations for Effective Lubrication

- Select the Right Lubricant: Always use the appropriate type of lubricant specified by the manufacturer to match the operational requirements.

- Regular Application: Establish a consistent schedule for applying grease or oil to critical areas to prevent deterioration.

- Clean Surfaces: Before applying lubricant, ensure that the surfaces are clean and free from dirt or old grease to achieve better adhesion and effectiveness.

- Check for Over-Lubrication: Avoid excess lubricant, as it can lead to buildup and potential leaks, causing more harm than good.

Best Practices for Greasing Components

- Use a clean grease gun to apply the lubricant, ensuring that no contaminants are introduced into the system.

- Follow the manufacturer’s guidelines regarding the quantity of lubricant needed for each component.

- Inspect fittings and seals regularly for signs of wear or damage that may hinder the lubrication process.

- Store lubricants in a cool, dry place to maintain their efficacy and prevent degradation.

Safety Checks Before Operating Seadoo

Before taking to the water, it is crucial to conduct thorough inspections to ensure a safe and enjoyable experience. Performing these essential checks can prevent accidents and enhance your overall enjoyment. This section outlines key safety measures that should be undertaken prior to embarking on any aquatic adventure.

1. Examine the Equipment: Inspect the craft for any visible damage or wear. Look for cracks, leaks, or loose components that may compromise performance. Pay special attention to the hull and any parts exposed to the elements.

2. Test the Safety Gear: Ensure that all safety equipment is in proper working order. This includes life jackets, fire extinguishers, and signaling devices. Each occupant should wear a properly fitted life jacket throughout the journey.

3. Check Fuel Levels: Verify that there is enough fuel for the intended trip. Running out of fuel can lead to dangerous situations, especially in remote areas. Additionally, inspect the fuel lines for leaks or damages.

4. Review the Operating Manual: Familiarize yourself with the specific guidelines and operating procedures. Knowing how to handle the craft will significantly reduce the risk of mishaps.

5. Plan Your Route: Before setting off, outline your route and inform someone of your plans. Being aware of your surroundings and potential hazards is essential for a safe excursion.

6. Weather Conditions: Always check the weather forecast before heading out. Adverse conditions can pose serious risks. If there are warnings for storms or high winds, postpone your trip.

7. Ensure Communication: Carry a reliable means of communication, such as a fully charged mobile phone or marine radio. This will allow you to call for help if needed.

By diligently performing these checks, you can significantly reduce risks and enhance safety while enjoying your time on the water.