In the realm of outdoor maintenance tools, ensuring optimal functionality is crucial for achieving effective results. This section delves into the intricacies of servicing handheld devices designed for clearing debris, enabling users to maintain peak performance and extend the lifespan of their equipment. Understanding the components and common issues associated with these machines is essential for any user aiming to keep their tools in top condition.

The following guidance provides detailed insights into troubleshooting various challenges that may arise during operation. From examining essential parts to implementing effective solutions, this resource aims to empower users with the knowledge needed for successful upkeep. Whether dealing with minor adjustments or more complex issues, having a clear understanding of the mechanics involved can significantly enhance the user experience.

By equipping oneself with the right information, individuals can confidently approach maintenance tasks. This not only enhances the effectiveness of the equipment but also promotes a safer and more enjoyable outdoor experience. As we explore the steps involved in servicing these vital tools, readers will gain valuable skills that contribute to their gardening endeavors.

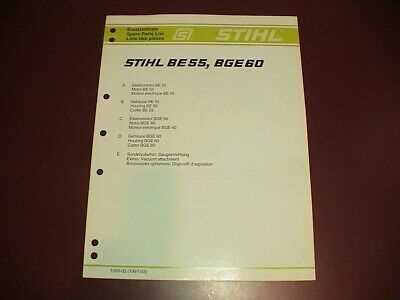

Understanding Stihl Leaf Blower Models

When selecting equipment for outdoor maintenance, it’s essential to recognize the various models available in the market. Each variant serves distinct purposes and offers unique features, making it crucial to understand their differences and advantages. This knowledge can significantly impact efficiency and overall satisfaction during usage.

Categories of Equipment

The devices are typically categorized based on their power source and design. Users can choose between handheld and backpack configurations, each tailored to specific tasks. Handheld options are often lighter and more maneuverable, while backpack styles provide increased power and extended runtime, making them suitable for larger areas.

Key Features to Consider

When evaluating different models, several features should be considered. Weight plays a vital role in user comfort during prolonged use. Additionally, airflow capacity is critical for effectiveness, influencing how quickly debris can be cleared. Other aspects, such as noise levels and ease of maintenance, also contribute to the overall user experience.

Understanding these distinctions not only aids in selecting the right tool but also enhances performance and productivity in outdoor tasks.

Common Issues with Leaf Blowers

When operating outdoor cleaning devices, users may encounter several frequent problems that can hinder performance and efficiency. Understanding these issues can help in maintaining optimal function and extending the lifespan of the equipment.

Frequent Problems

- Insufficient airflow: This can occur due to clogged filters or obstructions in the air intake.

- Starting difficulties: Engines may fail to start or run inconsistently, often caused by fuel issues or ignition failures.

- Unusual noises: Uncommon sounds may indicate mechanical failures or loose components.

- Vibration: Excessive shaking during operation can be a sign of unbalanced parts or wear.

Troubleshooting Tips

- Check and clean air filters regularly to prevent blockages.

- Ensure proper fuel mixture and inspect the fuel lines for leaks.

- Examine spark plugs and ignition components for wear or damage.

- Regularly inspect all screws and bolts to ensure they are tight.

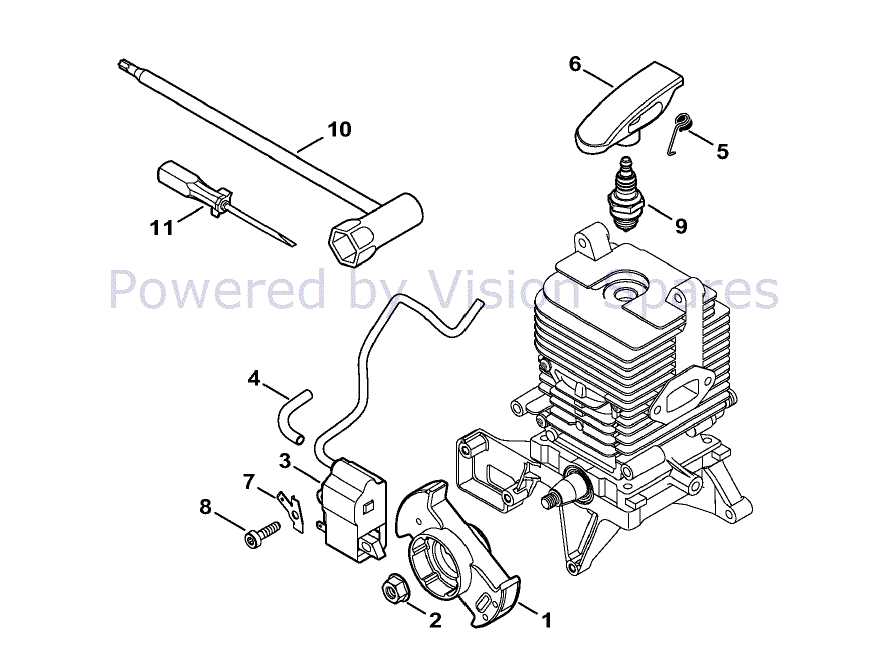

Essential Tools for Repairs

Having the right instruments on hand is crucial for maintaining and restoring equipment. These implements facilitate effective troubleshooting and ensure that tasks are carried out efficiently. By using suitable tools, individuals can enhance their skills and address various issues with ease.

Wrenches are vital for loosening and tightening bolts, providing the necessary grip to manage different fasteners. Screwdrivers, both flathead and Phillips, are essential for accessing internal components and securing them properly. Additionally, a multimeter is invaluable for diagnosing electrical problems, allowing users to measure voltage, current, and resistance.

Another important item is a toolbox to keep everything organized. A well-stocked toolbox can include pliers for gripping and bending wires, cutters for trimming excess material, and lubricants to ensure smooth operation of moving parts. By equipping oneself with these necessary implements, maintenance tasks become more manageable and successful.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues that may arise with your equipment. Following a systematic method will help identify the underlying problems and facilitate effective solutions, ensuring optimal performance.

Common Symptoms and Their Solutions

Begin by observing the symptoms your device exhibits. Common issues may include insufficient power, unusual noises, or failure to start. For instance, if the device struggles to function at full capacity, consider checking the fuel levels, air filters, and spark plugs. Cleaning or replacing these components can often resolve performance issues.

Safety Precautions

Always prioritize safety during troubleshooting. Before inspecting or servicing the unit, ensure it is powered down and disconnected from any power source. Wear appropriate protective gear, such as gloves and goggles, to prevent injury. By maintaining a safe working environment, you can effectively address any issues with confidence.

Cleaning the Air Filter

Maintaining optimal airflow is crucial for the efficient functioning of your outdoor equipment. A clean filtration system ensures that the engine operates smoothly and effectively, preventing potential issues caused by dirt and debris accumulation. Regular cleaning of the filtration component is a straightforward yet essential task that can significantly enhance performance.

Step 1: Begin by removing the filtration element from its housing. Ensure that the engine is turned off and cooled down to prevent any accidents. Carefully detach any securing mechanisms, if applicable.

Step 2: Gently tap the filter to dislodge loose particles. For a more thorough cleaning, consider using compressed air to blow out trapped debris. This method is particularly effective for foam or paper filters.

Step 3: If the filter is heavily soiled, wash it with warm, soapy water. Rinse thoroughly and allow it to dry completely before reinstalling. Ensure that no moisture remains, as this can lead to engine issues.

Step 4: Once dry, reinsert the filtration element into its housing, securing it properly. Regularly check the filtration component as part of routine maintenance to keep your equipment operating at its best.

Inspecting Fuel and Oil Levels

Regular examination of liquid levels is essential for optimal performance and longevity of your equipment. Ensuring that the correct amounts of fuel and lubricant are present can prevent operational issues and enhance efficiency. This process involves checking both types of fluids to maintain a smooth running experience.

Start by locating the fuel reservoir. It is typically marked and accessible, allowing you to visually assess the amount of fuel remaining. If the level appears low, it is advisable to refill with the recommended type of fuel to avoid performance degradation.

Next, inspect the lubricant. This vital fluid ensures that moving parts function correctly and reduces friction. Look for the oil reservoir, which may also have a visibility window or dipstick to help you determine the current level. If the oil appears dirty or is below the recommended level, replacing it will help maintain the unit’s functionality.

In conclusion, consistently monitoring these essential fluids will not only prolong the life of your equipment but also ensure its reliability during use. Proper maintenance leads to a more enjoyable experience and minimizes the risk of breakdowns.

Replacing the Spark Plug

Ensuring optimal performance of your equipment often requires attention to the ignition component. A faulty spark initiator can lead to starting difficulties and inefficient operation. Regularly checking and replacing this vital part is essential for maintaining smooth functionality.

Before you begin, gather the necessary tools: a socket wrench, a replacement initiator, and a gap gauge. First, ensure the device is turned off and cool to the touch. Remove any coverings to access the ignition area easily.

Using the socket wrench, carefully detach the existing initiator from its socket. Inspect the removed part for any signs of wear or carbon buildup. If the old component appears damaged, it is crucial to replace it with a new one.

When installing the new initiator, ensure it is properly aligned and securely fastened. Utilize the gap gauge to verify the appropriate distance between the electrodes. This adjustment is vital for efficient combustion and overall performance.

After replacing the initiator, reassemble any coverings and test the equipment to ensure it operates smoothly. Regular maintenance of this component will contribute significantly to the longevity and reliability of your machinery.

Fixing Electrical Components

When addressing issues with electrical elements in outdoor equipment, it’s essential to systematically diagnose and resolve any problems. Understanding the fundamental operations of these components can greatly assist in troubleshooting and ensuring optimal performance.

Start by checking for visible signs of damage, such as frayed wires or burnt connections. Ensure that all connections are secure and free from corrosion. Using a multimeter can help identify faulty circuits or short circuits within the system.

If a component is not functioning as expected, it may require replacement. Always refer to specifications for compatible parts, ensuring proper fit and functionality. When replacing any part, take care to follow the manufacturer’s guidelines to avoid further issues.

Regular maintenance can prevent electrical failures. Keep connections clean and perform routine inspections to identify wear before it leads to more significant problems. By staying proactive, you can extend the lifespan of the equipment and maintain its efficiency.

Maintenance for Optimal Performance

Regular upkeep is essential to ensure your equipment operates efficiently and reliably. By adhering to a systematic approach, you can prolong the lifespan of your device and maintain its peak functionality. This section outlines key practices that will help you achieve optimal results during usage.

Routine Checks

Conducting frequent inspections is vital for identifying potential issues before they escalate. Pay attention to the air intake and filter; keeping these components clean enhances airflow and overall efficiency. Additionally, regularly examining fuel lines and connections helps prevent leaks that can disrupt performance.

Component Care

Each part of your apparatus requires specific attention to function properly. Ensure the spark plug is in good condition and replace it as needed. Lubrication of moving parts is equally important; using appropriate oils can minimize wear and tear, contributing to smoother operation. Proper maintenance not only boosts performance but also ensures safety during operation.

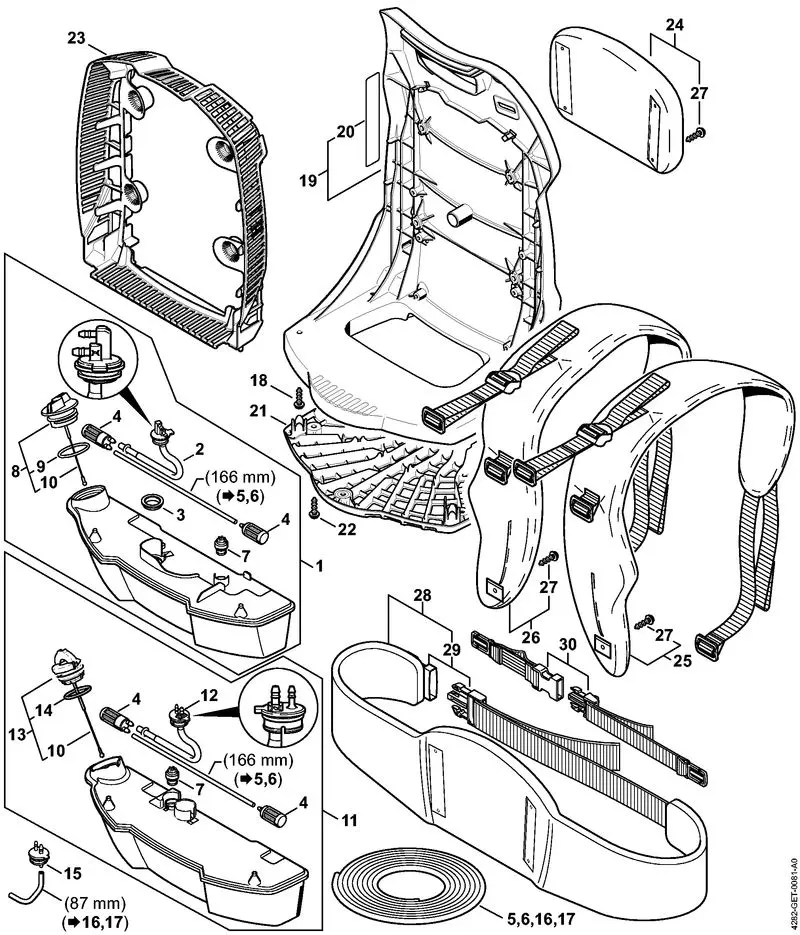

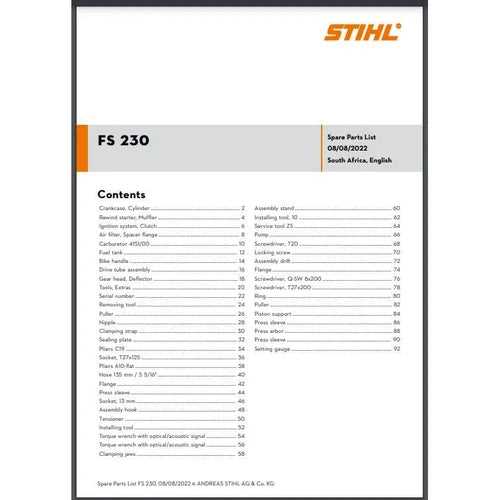

Parts Replacement Process Explained

Replacing components in any device is essential for maintaining optimal performance and longevity. Understanding the systematic approach to this task ensures that individuals can efficiently restore functionality while minimizing potential issues. This section outlines the key steps involved in the process of exchanging various elements within your equipment.

Step-by-Step Guide

The process generally involves a few crucial steps to ensure a successful replacement:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement components to ensure everything is at hand. |

| 2 | Carefully disassemble the unit, taking note of the arrangement of parts for easy reassembly. |

| 3 | Remove the faulty component, checking for any additional wear or damage in surrounding areas. |

| 4 | Install the new part, ensuring it fits properly and is secured according to specifications. |

| 5 | Reassemble the unit, referring to your notes to maintain the original configuration. |

| 6 | Test the device to confirm that the new part functions correctly and the overall performance is restored. |

Tips for Successful Replacement

To enhance the effectiveness of the replacement process, consider the following tips:

- Always refer to the specific guidelines for the model you are working with.

- Keep a clean workspace to avoid misplacing small components.

- Take your time to ensure each step is completed accurately, reducing the likelihood of errors.

Safety Precautions During Repairs

When conducting maintenance on outdoor equipment, it is crucial to prioritize safety to prevent accidents and injuries. Adopting appropriate safety measures ensures a secure working environment and protects both the user and the equipment.

Before beginning any maintenance tasks, it is essential to prepare adequately. This involves wearing suitable protective gear and ensuring that the workspace is organized and free of hazards.

| Safety Measure | Description |

|---|---|

| Protective Gear | Always wear safety goggles, gloves, and ear protection to shield against debris and noise. |

| Workspace | Keep the area tidy and well-lit to avoid tripping hazards and ensure visibility. |

| Power Source | Disconnect the power supply before starting any work to prevent accidental activation. |

| Tools | Use the correct tools for the task to minimize the risk of injury and equipment damage. |

| Follow Instructions | Adhere to guidelines and manuals specific to the equipment to ensure proper handling. |

By observing these precautions, individuals can effectively minimize risks and enhance safety during maintenance activities.

Finding Genuine Replacement Parts

Locating authentic components for your outdoor equipment is crucial for ensuring optimal performance and longevity. Using original pieces guarantees compatibility and reliability, which are essential for maintaining the functionality of your device.

When searching for replacements, it’s important to identify trusted sources that provide verified products. Below are some recommended avenues to consider:

| Source | Description |

|---|---|

| Authorized Dealers | These establishments are licensed to sell original components and often have knowledgeable staff to assist with your needs. |

| Manufacturer’s Website | The official site usually offers a selection of parts and provides detailed specifications to ensure you find the right fit. |

| Reputable Online Retailers | Many established e-commerce platforms specialize in outdoor equipment parts, offering a range of genuine options. |

| Local Repair Shops | These businesses often have access to authentic parts and can provide installation assistance if needed. |

By prioritizing original components, you enhance the efficiency of your equipment and reduce the risk of future issues. Investing time in sourcing the right parts pays off in the long run.

Tips for Preventing Future Problems

Maintaining equipment in optimal condition is essential to avoid complications down the line. Implementing a few proactive strategies can significantly enhance longevity and performance. By following some simple guidelines, users can reduce the likelihood of encountering issues during operation.

Regular Maintenance Checks

Frequent inspections are crucial. Ensure that all components are clean and free from debris. Pay special attention to filters and air intakes, as blockages can lead to overheating and reduced efficiency. Keeping an organized schedule for routine maintenance will help identify potential issues before they escalate.

Proper Storage Techniques

How you store your equipment can greatly influence its durability. Always store in a dry, protected environment to prevent rust and corrosion. Additionally, using protective covers can shield from dust and moisture. Fuel management is also important; consider using stabilizers if the equipment will be unused for an extended period.