Understanding the intricacies of engine upkeep is essential for maximizing performance and longevity. This guide serves as a valuable resource for enthusiasts and professionals alike, providing insights into troubleshooting, servicing, and enhancing the efficiency of various engine types. From routine checks to advanced adjustments, mastering these techniques can lead to significant improvements in operation.

Every engine comes with its unique set of specifications and requirements, making it crucial to familiarize oneself with specific characteristics and common issues. This compilation aims to simplify the process by offering detailed information tailored to a wide range of engine variants. Whether you’re dealing with a minor malfunction or undertaking significant enhancements, this resource will equip you with the necessary knowledge.

By focusing on best practices and practical solutions, this guide empowers users to take control of their machinery. With the right approach and understanding, even the most complex challenges can be addressed effectively. Dive into the essential techniques and become adept at ensuring optimal performance, regardless of the engine in question.

Understanding Briggs & Stratton Engines

Engines from this renowned manufacturer are celebrated for their durability and efficiency, playing a vital role in various outdoor equipment. With a legacy of reliability, these power units have become a preferred choice for homeowners and professionals alike, ensuring that tasks are completed effectively and with minimal downtime.

Key Features of These Power Units

The engines are designed with several standout characteristics that enhance performance. Longevity is one of the primary benefits, as they are constructed with high-quality materials and precision engineering. Additionally, easy maintenance options make it simpler for users to keep their machines running smoothly, promoting a longer lifespan.

Types of Applications

These power sources find use in a variety of applications, ranging from lawn mowers to generators. Their versatility ensures that whether for residential or commercial use, they can handle diverse tasks efficiently. As a result, understanding the specific requirements and features of these engines can greatly enhance the user experience and overall satisfaction.

Common Issues with Small Engines

Small engines are widely used in various applications, from lawn mowers to generators. Despite their utility, these engines can experience a range of problems that affect performance and reliability. Understanding these issues is crucial for effective maintenance and troubleshooting.

Typical Problems

Several common challenges arise with small engines. Identifying these early can save time and resources in repairs. Below is a summary of frequently encountered issues:

| Issue | Description |

|---|---|

| Starting Difficulties | Engines may struggle to start due to fuel delivery problems or ignition system failures. |

| Inefficient Fuel Consumption | High fuel usage can indicate carburetor malfunctions or air leaks. |

| Overheating | Excessive heat often results from insufficient lubrication or cooling system failures. |

| Loss of Power | Reduced power output may be caused by clogged filters or internal wear. |

Preventive Measures

Regular maintenance is essential for minimizing issues. Simple tasks, such as changing the oil and cleaning air filters, can significantly enhance engine longevity and performance. Keeping components in good condition ensures optimal functionality and reduces the likelihood of breakdowns.

Essential Tools for Engine Repair

When it comes to maintaining and fixing small engines, having the right set of tools is crucial for achieving optimal performance. Each task requires specific instruments to ensure efficiency and accuracy. Understanding which tools are necessary can save both time and effort during the process.

Here is a list of essential instruments that every engine enthusiast should consider having in their toolkit:

| Tool | Description |

|---|---|

| Socket Set | A collection of sockets in various sizes to fit different bolts and nuts, essential for loosening and tightening fasteners. |

| Wrench Set | Adjustable and fixed wrenches help in gripping and turning nuts and bolts in tight spaces. |

| Screwdriver Set | Includes both flathead and Phillips screwdrivers for assembling and disassembling components. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening. |

| Pliers | Useful for gripping, twisting, and cutting wires or other materials in small engine assemblies. |

| Fuel Line Pliers | Specifically designed to handle fuel lines safely and efficiently, minimizing the risk of spills. |

| Feeler Gauges | Used to measure gap widths, particularly for spark plugs and valve clearances. |

| Multimeter | Essential for diagnosing electrical issues, allowing you to measure voltage, current, and resistance. |

Having these tools readily available will empower you to tackle a variety of engine-related tasks effectively. Proper maintenance not only prolongs the life of the equipment but also enhances performance and reliability.

Step-by-Step Maintenance Guide

Proper upkeep is essential for ensuring the longevity and optimal performance of your outdoor power equipment. Regular attention to key components can prevent costly repairs and enhance efficiency. This guide provides a structured approach to maintaining your machinery effectively.

1. Safety First: Before starting any maintenance task, ensure the equipment is turned off and disconnected from any power source. Wear appropriate safety gear, including gloves and goggles.

2. Clean the Exterior: Begin by removing dirt and debris from the outer surfaces. Use a brush or cloth to wipe down the machine, paying attention to air vents and cooling fins. A clean exterior promotes better airflow and cooling.

3. Check Oil Levels: Regularly inspect the oil levels. If low, replenish with the recommended type of lubricant. Consider changing the oil at least once per season to maintain optimal engine health.

4. Air Filter Inspection: Examine the air filter for dirt or blockages. A clean filter ensures proper airflow, which is crucial for engine efficiency. Replace or clean the filter as necessary.

5. Spark Plug Condition: Inspect the spark plug for wear and carbon buildup. If damaged, replace it to ensure reliable starting and smooth operation. Regular checks can prevent ignition issues.

6. Fuel System Maintenance: Check fuel lines for cracks or leaks. Use fresh fuel, as stale fuel can lead to performance problems. Consider adding a fuel stabilizer to prolong fuel life during storage.

7. Blade Care: For cutting equipment, sharpen or replace blades regularly. Dull blades can strain the engine and reduce cutting efficiency. Ensure blades are securely attached after maintenance.

8. Storage Practices: At the end of the season, prepare the equipment for storage. Drain fuel, clean all parts, and store in a dry, sheltered area to prevent rust and damage.

By following these systematic steps, you can ensure that your machinery remains in peak condition, ready to tackle any task efficiently.

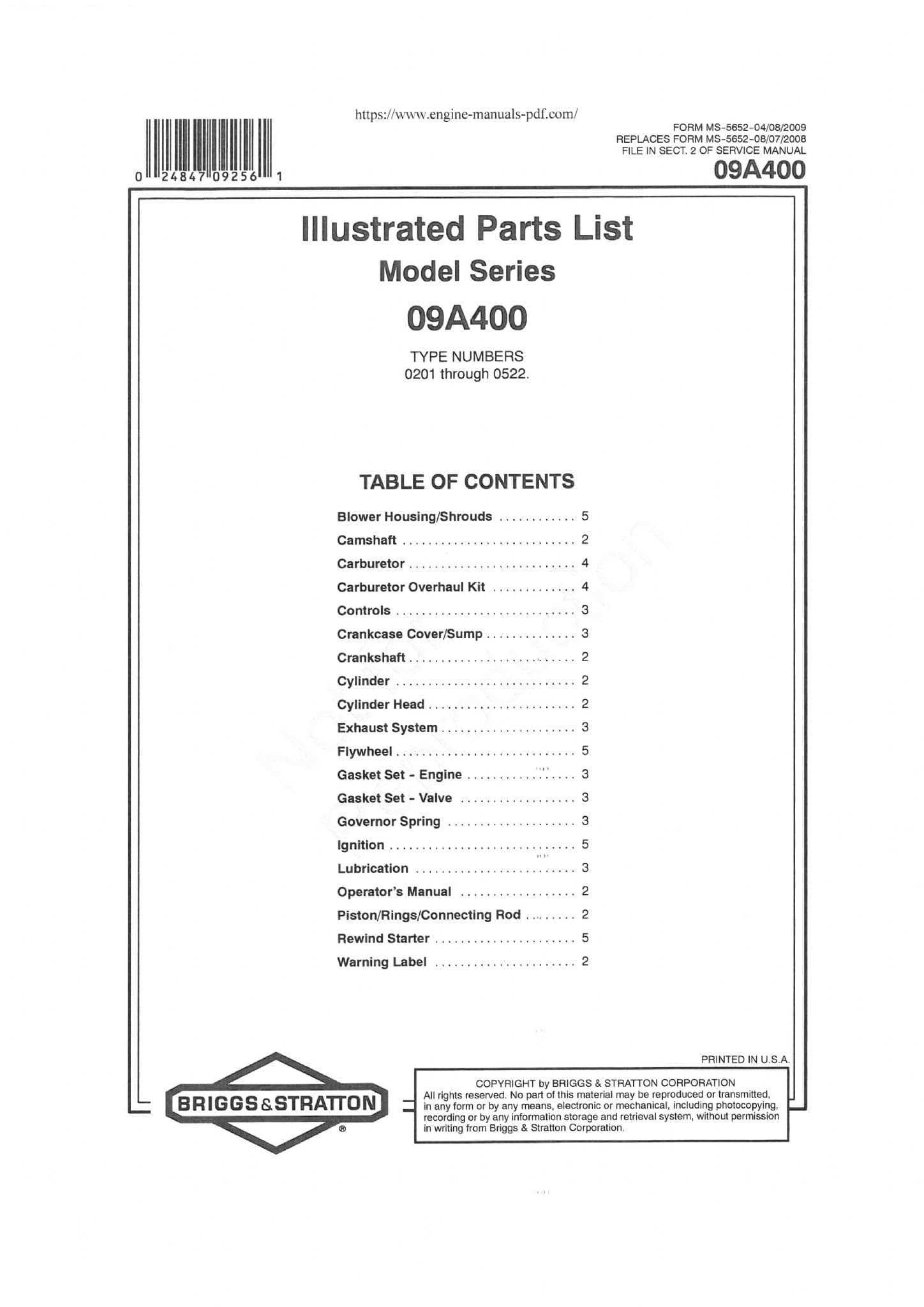

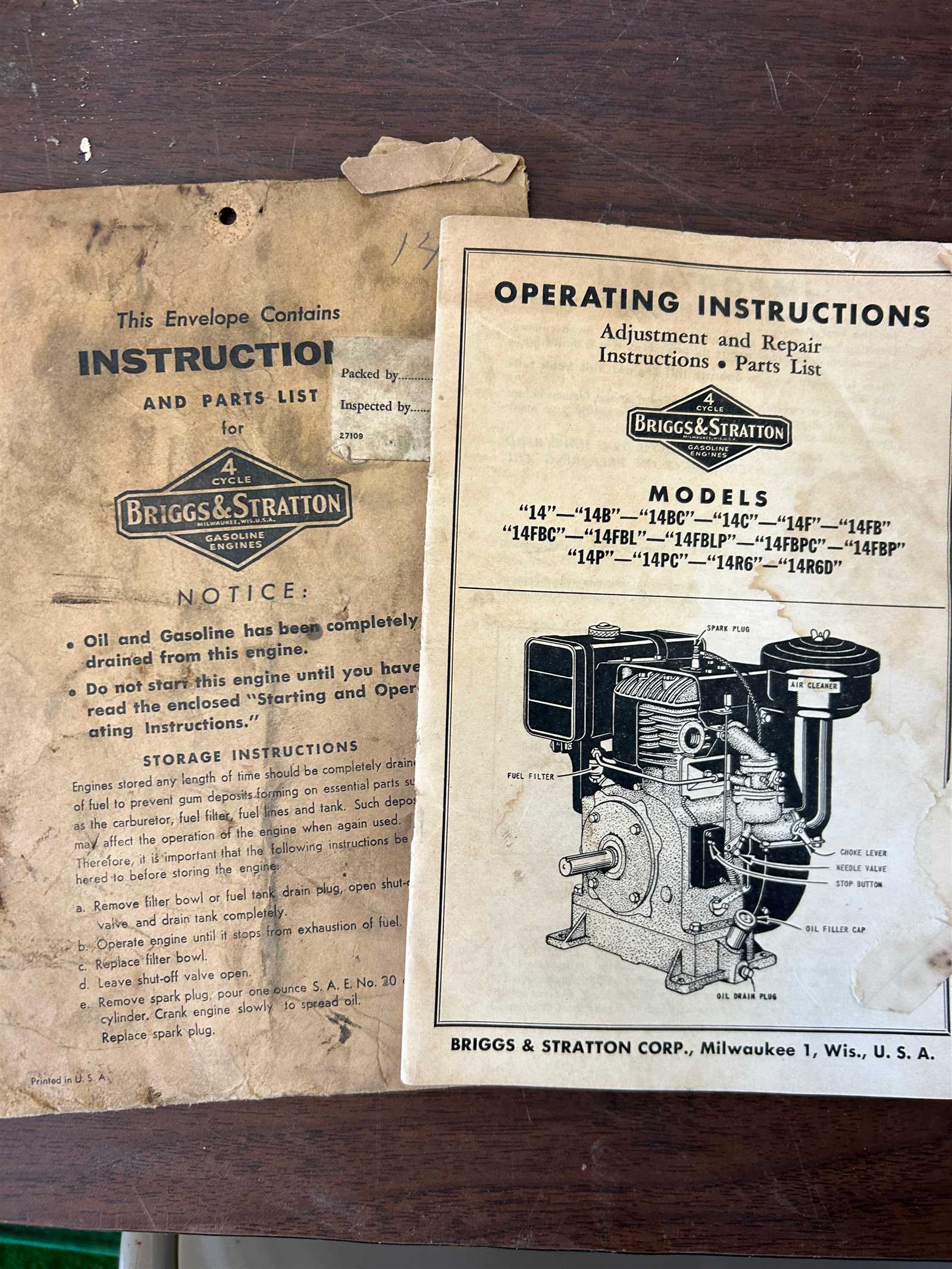

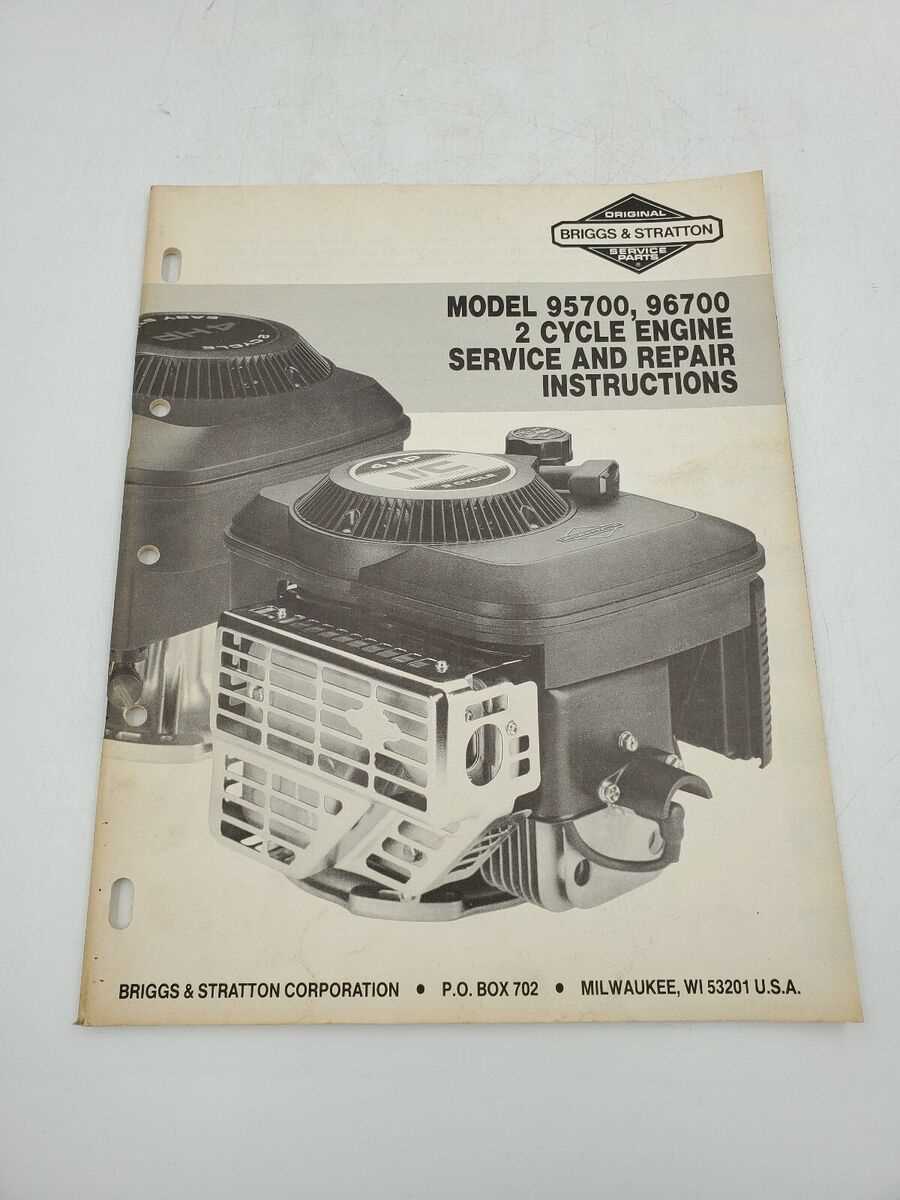

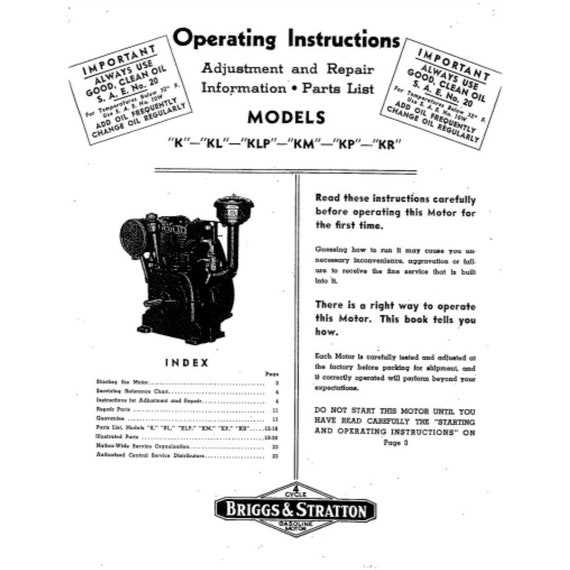

Identifying Engine Model Types

Understanding the various types of engines is essential for effective maintenance and troubleshooting. Each engine type comes with unique characteristics, which can significantly impact performance and repair processes. By identifying the specific type, users can access relevant resources and support, ensuring optimal care for their equipment.

Key Features to Look For

- Engine Number: This is typically stamped on the engine itself and serves as a primary identifier.

- Model Name: Often found on the engine cover or casing, this can provide immediate insights into the type.

- Power Output: Different models are designed for varying power requirements, which can help narrow down the options.

- Type of Fuel: Whether it runs on gasoline, diesel, or alternative fuels can also indicate the engine category.

Common Engine Categories

- Single Cylinder: Typically found in smaller machines, these are straightforward and easy to identify.

- V-Twin: Known for their power, these engines have two cylinders arranged in a V configuration.

- Four-Cycle: Common in many applications, these engines operate on a four-stroke cycle for improved efficiency.

- Two-Cycle: Generally lighter and simpler, these engines are often used in handheld equipment.

By familiarizing yourself with these aspects, you can effectively identify engine types, paving the way for better maintenance practices and troubleshooting approaches.

Fuel System Troubleshooting Tips

Maintaining the optimal performance of your engine often hinges on the fuel delivery system. Identifying and resolving issues within this system can significantly enhance efficiency and longevity. Here are some effective strategies to diagnose and fix common problems.

Common Symptoms and Their Causes

- Engine Won’t Start: This may indicate a clogged fuel line, a malfunctioning fuel pump, or an empty tank.

- Poor Acceleration: Potential issues include contaminated fuel, a dirty air filter, or a malfunctioning carburetor.

- Fuel Leaks: Check for damaged hoses, loose fittings, or cracks in the fuel tank.

- Unusual Engine Noise: This can be a sign of air entering the fuel system or issues with fuel mixture.

Troubleshooting Steps

- Examine the fuel tank for debris and ensure it contains an adequate amount of fuel.

- Inspect fuel lines for blockages or leaks, replacing any damaged sections.

- Test the fuel pump’s functionality and replace it if necessary.

- Clean or replace the fuel filter to ensure unobstructed fuel flow.

- Check the carburetor for clogs, and adjust or clean as needed to restore proper operation.

By following these guidelines, you can effectively diagnose and resolve fuel system issues, ensuring your engine runs smoothly and efficiently.

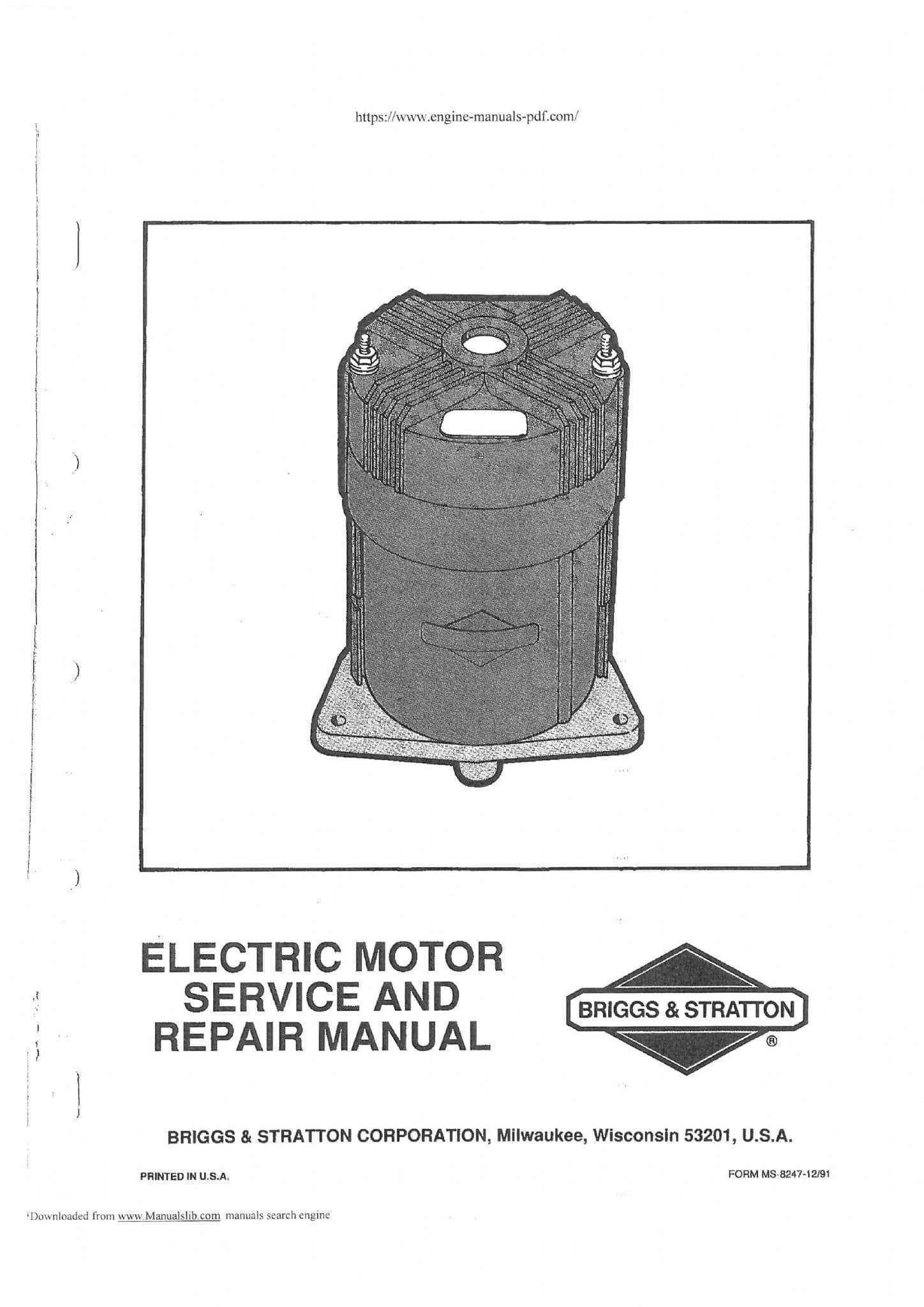

Electrical Components and Repairs

This section delves into the intricate world of electrical systems in small engines, emphasizing their crucial role in performance and functionality. Understanding these components is essential for effective maintenance and troubleshooting.

Key electrical parts include:

- Ignition Coil

- Starter Motor

- Battery

- Wiring Harness

- Magneto

Each component plays a significant role in the overall operation. For instance, the ignition coil generates the spark necessary for combustion, while the starter motor initiates engine operation. A well-maintained battery ensures reliable power supply, and a properly functioning wiring harness facilitates communication between different parts.

Common issues may arise, including:

- Weak spark or no ignition

- Starter not engaging

- Battery not holding charge

- Damaged wiring

To address these problems, consider the following troubleshooting steps:

- Check connections and clean terminals.

- Test the ignition coil with a multimeter.

- Inspect the starter motor for wear and functionality.

- Replace faulty components as needed.

Regular inspection and timely attention to electrical components can significantly enhance the longevity and efficiency of the engine. Familiarity with these systems not only aids in resolving issues but also contributes to optimal performance.

Importance of Regular Oil Changes

Routine oil replacements are crucial for maintaining the longevity and efficiency of small engines. Fresh oil ensures that all moving components are adequately lubricated, reducing friction and wear. This practice not only enhances performance but also prevents costly damage that can arise from neglect.

Enhancing Engine Performance: Clean oil plays a vital role in engine functionality. It helps in removing impurities and debris, allowing the engine to operate smoothly. This can lead to better fuel efficiency and increased power output.

Extending Lifespan: Regularly changing the oil can significantly extend the life of an engine. Contaminated oil can lead to overheating and corrosion, which can ultimately shorten the engine’s lifespan. By ensuring that the oil is changed consistently, users can avoid premature wear and maintain optimal performance.

Cost-Effective Maintenance: Investing time in routine oil changes can save money in the long run. The cost of new oil is minimal compared to the potential expenses of major repairs caused by neglect. Preventative maintenance through regular oil changes is a smart strategy for any engine owner.

In conclusion, prioritizing frequent oil changes is essential for anyone looking to maximize the performance and durability of their equipment.

Cleaning and Replacing Air Filters

Maintaining optimal engine performance requires regular attention to air intake components. Air filters play a crucial role in ensuring that clean air reaches the combustion chamber, thus enhancing efficiency and prolonging engine life. Neglecting these filters can lead to reduced power output and increased fuel consumption.

Importance of Clean Air Filters

Dirty or clogged filters can restrict airflow, which negatively impacts engine performance. A clean filter allows for better combustion and can significantly improve fuel efficiency. Regular inspection and replacement of these components are essential for maintaining equipment functionality.

Steps for Cleaning and Replacement

To clean an air filter, first remove it from the engine. Use compressed air or a soft brush to gently remove dust and debris. For foam filters, wash them in warm, soapy water, rinse thoroughly, and allow to dry completely before reinstallation. If the filter is damaged or excessively dirty, replacing it is the best option. Ensure you install a new filter that meets the manufacturer’s specifications for optimal performance.

Regular maintenance of air intake systems not only enhances efficiency but also helps prevent potential engine issues down the line. Prioritizing this task can lead to a smoother operation and a longer lifespan for your equipment.

How to Diagnose Engine Noises

Identifying unusual sounds emanating from an engine is crucial for maintaining optimal performance. Such noises can indicate underlying issues that, if left unchecked, may lead to more severe problems. By systematically evaluating these sounds, you can pinpoint potential malfunctions and take appropriate action.

Common Engine Noises and Their Causes

| Noise Type | Possible Cause |

|---|---|

| Knocking | Poor fuel quality or ignition timing issues |

| Hissing | Leaks in the intake manifold or exhaust system |

| Rattling | Loose components or failing bearings |

| Grinding | Worn gears or insufficient lubrication |

| Ticking | Valve clearance issues or low oil levels |

Steps for Effective Diagnosis

To effectively diagnose engine sounds, start by isolating the noise source. Listen closely during idle and while revving the engine. Use a mechanic’s stethoscope for better clarity. Once identified, compare the sound with the common types listed above, and investigate further based on the potential causes. Regular maintenance and timely interventions can prevent minor issues from escalating into major repairs.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is paramount. Proper precautions can significantly reduce the risk of accidents and injuries. By following specific guidelines, individuals can create a safer working environment while addressing mechanical issues.

1. Personal Protective Equipment: Always wear appropriate gear, including gloves, goggles, and ear protection. This equipment shields against potential hazards, such as sharp objects and loud noises.

2. Workspace Organization: Keep the area tidy and free of clutter. A clean workspace minimizes the risk of tripping or misplacing tools, ensuring a more efficient process.

3. Disconnect Power Sources: Before starting any task, ensure that all power sources are disconnected. This step prevents unexpected start-ups that could lead to serious injuries.

4. Proper Tool Usage: Utilize the right tools for each specific task. Using incorrect tools can lead to accidents and damage to the equipment.

5. Read Instructions Carefully: Familiarize yourself with any guidelines related to the equipment. Understanding how it operates aids in performing tasks safely and effectively.

6. Avoid Working Alone: Whenever possible, have someone nearby during maintenance. In case of an emergency, having assistance can be crucial.

By adhering to these fundamental safety measures, individuals can protect themselves and ensure a smoother process while addressing mechanical concerns.

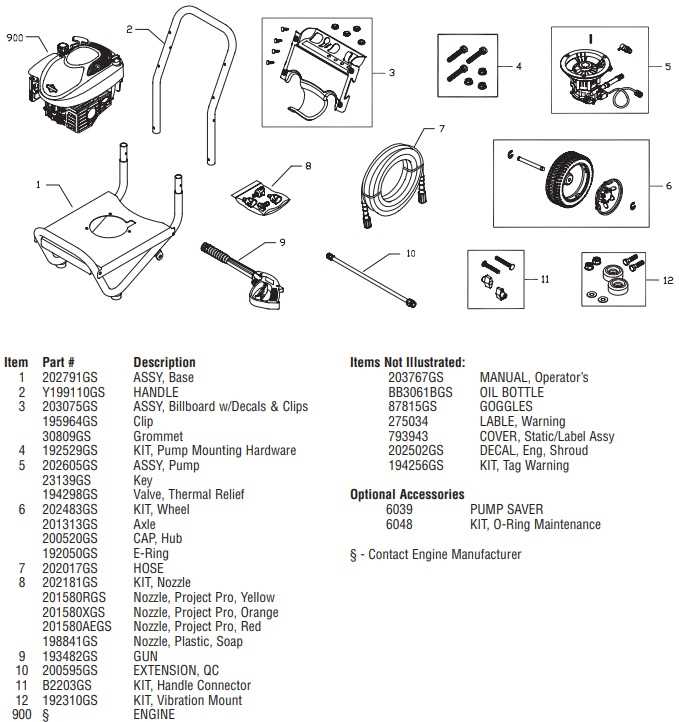

Finding Replacement Parts Effectively

Locating suitable components for machinery can be a straightforward process if approached with the right strategies. Understanding the necessary steps will ensure you obtain the correct items, saving both time and effort.

Identify Required Components

Before seeking new parts, it’s crucial to determine exactly what you need. This involves:

- Assessing the condition of existing parts

- Consulting any available documentation for specifications

- Taking note of part numbers or models when possible

Where to Look for Parts

Once you know what you need, various sources can provide the required components:

- Local hardware or specialty stores

- Online marketplaces and dedicated websites

- Authorized dealers for specific brands

- Salvage yards or second-hand shops

By following these guidelines, you can streamline the process of finding the right components, ensuring your equipment functions smoothly and efficiently.

Resources for Further Learning

Expanding your knowledge and skills related to small engine maintenance can greatly enhance your understanding and proficiency. There are various resources available to help you delve deeper into the intricacies of engine care, troubleshooting, and overall performance improvement. Whether you prefer books, online tutorials, or hands-on workshops, these tools can aid in developing a well-rounded skill set.

Books and Guides

Several comprehensive books provide insights into engine mechanics, troubleshooting techniques, and maintenance best practices. Here are a few notable titles:

| Title | Author | Focus Area |

|---|---|---|

| Small Engine Repair | Mark Smith | General Maintenance |

| The Complete Guide to Engine Repair | Jane Doe | Advanced Troubleshooting |

| DIY Engine Projects | John Appleseed | Hands-On Techniques |

Online Resources

The internet offers a plethora of platforms for learning. Websites, video tutorials, and forums can provide invaluable support and advice from fellow enthusiasts and experts. Consider exploring the following options:

- Educational YouTube Channels

- Online Courses on Engine Mechanics

- Forums dedicated to Engine Enthusiasts