In the world of automotive engineering, understanding the intricacies of vehicle upkeep is essential for every enthusiast and owner. A thorough exploration of the various components and systems within a sophisticated machine not only enhances performance but also extends its lifespan. This resource aims to provide valuable insights into the maintenance practices and troubleshooting techniques necessary for optimal functionality.

Whether you are facing minor inconveniences or significant issues, being well-informed can empower you to take charge of your vehicle’s health. This guide serves as a go-to resource, offering detailed explanations and step-by-step procedures for a range of tasks. From routine inspections to complex repairs, mastering these skills will ensure your ride remains in peak condition.

Furthermore, embracing self-sufficiency in vehicle care fosters a deeper connection with your automobile. Understanding its mechanics allows for informed decisions and preventative measures, ultimately leading to a smoother driving experience. As you delve into this guide, you will discover practical tips and expert advice tailored to help you navigate the challenges of automotive maintenance with confidence.

Audi A5 Repair Manual Overview

This section provides a comprehensive insight into the essential guidance and resources for maintaining and servicing a specific luxury vehicle. It highlights the importance of understanding the intricacies of the automobile, ensuring optimal performance, safety, and longevity. Various aspects of vehicle upkeep are detailed, empowering owners with the knowledge to tackle common issues effectively.

Key Features

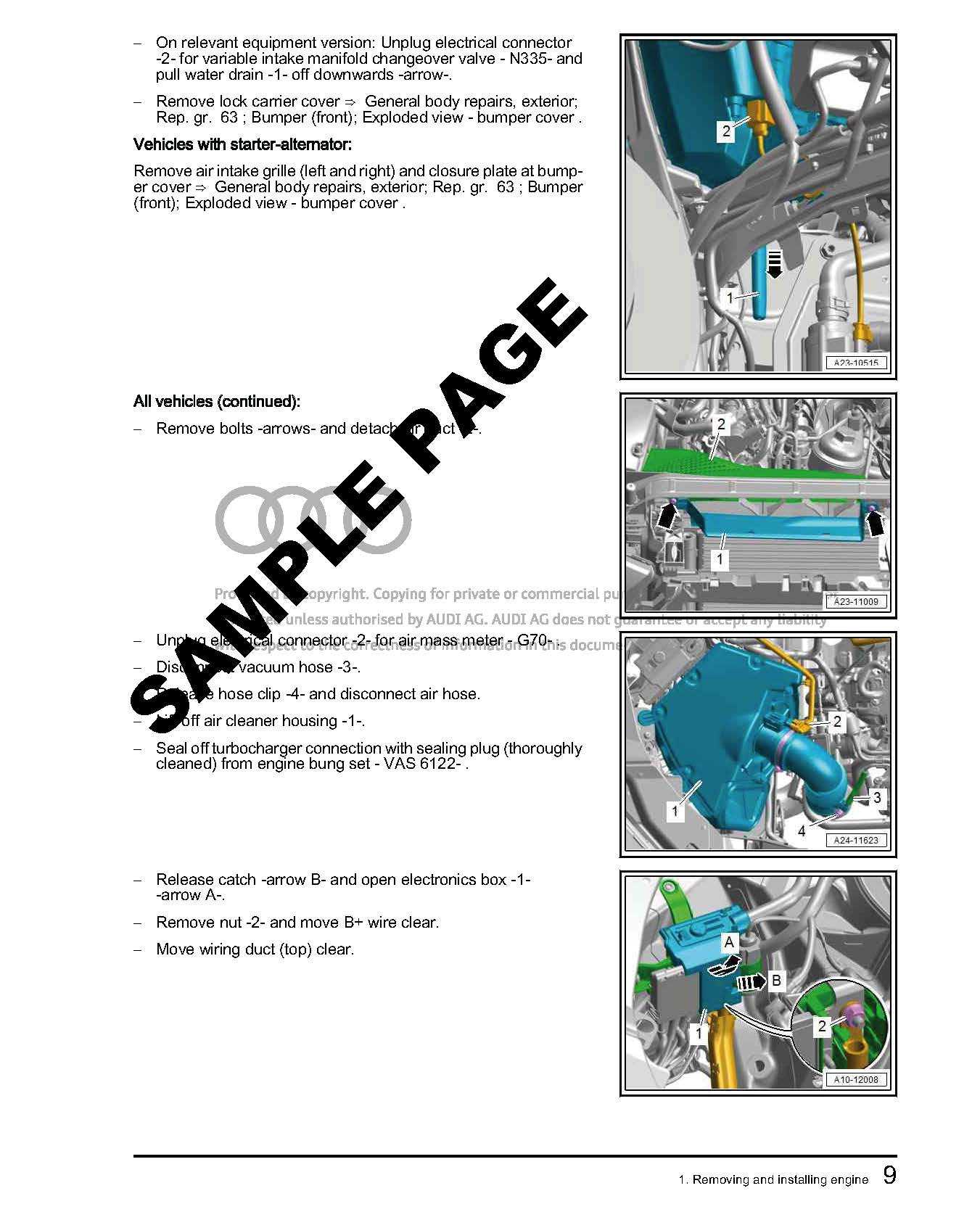

- Step-by-step instructions for routine maintenance tasks

- Detailed troubleshooting guides for common problems

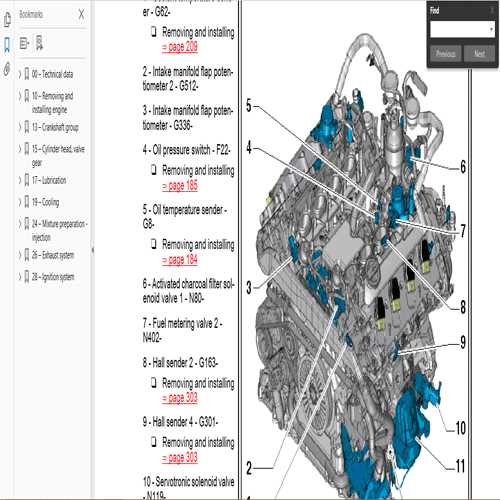

- Diagrams and illustrations for enhanced understanding

- Specifications for parts and components

Benefits of Using the Guide

- Improved vehicle reliability through regular upkeep

- Cost savings by performing minor repairs independently

- Increased understanding of the vehicle’s systems

- Enhanced safety for drivers and passengers

Essential Tools for Audi A5 Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of vehicles. For those looking to work on their cars, understanding the essential tools can make all the difference in achieving successful outcomes.

Here are the fundamental tools you should consider having on hand:

- Socket Set: A comprehensive socket set is vital for loosening and tightening bolts in various sizes.

- Wrench Set: An adjustable wrench set helps access hard-to-reach areas and provides versatility.

- Screwdrivers: Both flat-head and Phillips screwdrivers are necessary for multiple tasks, including panel removal.

- Torque Wrench: This tool ensures that nuts and bolts are tightened to the manufacturer’s specifications.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating wires and small components.

In addition to these basics, consider the following specialized tools:

- Diagnostic Scanner: A diagnostic tool can read error codes and help identify issues in the vehicle’s systems.

- Jack and Jack Stands: Essential for lifting the vehicle safely during maintenance tasks.

- Oil Filter Wrench: This specialized wrench makes changing the oil filter easier and less messy.

- Multimeter: Useful for diagnosing electrical problems and checking battery health.

Equipping yourself with these essential items not only streamlines the process but also enhances safety and efficiency while working on your vehicle.

Common Audi A5 Issues and Solutions

Every vehicle has its own set of challenges, and this model is no exception. Understanding the frequent problems that can arise, along with their respective fixes, can significantly enhance the ownership experience. Here, we explore typical concerns faced by owners and offer effective remedies.

1. Electrical Problems

Many drivers report issues with the electrical system, such as malfunctioning lights or erratic dashboard indicators. Regularly checking battery connections and ensuring that fuses are intact can prevent these annoyances. If problems persist, professional diagnostics may be necessary to identify deeper faults.

2. Suspension Wear

Suspension components can degrade over time, leading to a bumpy ride or unusual noises. Inspecting shock absorbers and bushings periodically can help maintain comfort. Replacing worn parts promptly ensures optimal handling and safety.

3. Engine Performance

Occasional performance issues, such as decreased power or increased fuel consumption, can arise. Regular maintenance, including timely oil changes and air filter replacements, plays a crucial role in sustaining engine efficiency. Utilizing high-quality fluids can also make a difference.

4. Transmission Concerns

Some owners may experience shifting problems or delays when changing gears. Keeping the transmission fluid at the appropriate level and replacing it according to the schedule can help avoid serious issues. If difficulties continue, seeking professional assistance is advisable.

5. Cooling System Leaks

Leaks in the cooling system can lead to overheating and engine damage. Regularly inspecting hoses and the radiator for signs of wear or cracks is essential. Addressing any leaks immediately can save time and prevent costly repairs.

By being aware of these common challenges and their solutions, owners can ensure a more reliable and enjoyable driving experience.

Engine Maintenance Guidelines for Audi A5

Proper upkeep of the engine is crucial for ensuring optimal performance and longevity of your vehicle. Following a set of guidelines can help you maintain the health of your powertrain, reducing the risk of costly issues down the line.

Regular Checks and Fluid Maintenance

- Oil Change: Replace engine oil and filter every 5,000 to 10,000 miles, depending on driving conditions.

- Coolant Levels: Check and top up the coolant regularly to prevent overheating.

- Transmission Fluid: Inspect the transmission fluid every 30,000 miles and change it as needed.

- Brake Fluid: Change brake fluid every two years to ensure optimal braking performance.

Inspection of Key Components

- Belt and Hose Inspection: Regularly examine belts and hoses for signs of wear or cracking.

- Air Filter Replacement: Change the air filter every 15,000 to 30,000 miles to maintain airflow.

- Spark Plug Replacement: Replace spark plugs every 60,000 miles to ensure efficient combustion.

- Battery Maintenance: Inspect battery terminals and connections for corrosion, and replace the battery as needed.

By adhering to these guidelines, you can enhance the reliability and efficiency of your engine, ultimately contributing to a smoother driving experience.

Transmission Care for Audi A5 Models

Proper maintenance of the transmission system is essential for ensuring optimal performance and longevity of your vehicle. A well-functioning transmission not only enhances driving experience but also prevents costly repairs in the future.

To maintain the transmission in peak condition, consider the following essential practices:

- Regular Fluid Checks: Monitor the transmission fluid level and quality. Low or dirty fluid can lead to overheating and poor shifting performance.

- Fluid Change Intervals: Follow the manufacturer’s guidelines for fluid replacement. Typically, changing the fluid every 30,000 to 60,000 miles is recommended.

- Inspect Seals and Gaskets: Regularly check for any signs of leaks around the transmission seals and gaskets to prevent fluid loss.

Additionally, proper driving habits can significantly influence transmission health:

- Avoid aggressive acceleration and sudden stops, which can put extra strain on the transmission.

- Utilize the appropriate gear settings for varying driving conditions, especially when towing or driving uphill.

- Be mindful of engine performance; any unusual noises or warning lights should be addressed immediately.

By following these guidelines, you can help ensure the reliability and efficiency of the transmission system, ultimately enhancing your driving experience and reducing the likelihood of future issues.

Electrical Systems Troubleshooting Tips

Effective diagnostics of electrical components is crucial for maintaining vehicle performance. Understanding common issues and systematic approaches can save time and enhance reliability. Below are valuable insights to help identify and resolve electrical problems efficiently.

| Issue | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Dead Battery | Corroded terminals or faulty alternator | Inspect battery connections for corrosion; test voltage with a multimeter. |

| Flickering Lights | Loose connections or failing bulbs | Check for loose wiring; replace any faulty bulbs. |

| Non-Functional Accessories | Blown fuses or damaged wiring | Inspect fuse box; replace any blown fuses and check wiring integrity. |

| Intermittent Start Issues | Faulty ignition switch or starter | Test the ignition switch and starter functionality with appropriate tools. |

| Dashboard Warning Lights | Sensor failure or electrical short | Use a diagnostic scanner to read error codes; address issues accordingly. |

By following these guidelines, identifying and fixing electrical issues can become a more manageable task, ensuring optimal operation of the vehicle’s systems.

Brake System Inspection and Repair

The braking mechanism of a vehicle is crucial for safety and performance. Regular evaluation and maintenance are essential to ensure optimal functionality and to prevent potential failures. This section outlines key procedures for examining and addressing issues within the braking system.

Inspection should begin with a visual assessment of all components. Look for signs of wear, leaks, or corrosion, and pay special attention to pads, rotors, and lines. Ensuring that each part is in good condition is vital for effective stopping power.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Brake Pads | Thin material, cracking, uneven wear | Replace if below minimum thickness |

| Brake Rotors | Grooves, warping, discoloration | Machine or replace as necessary |

| Brake Lines | Leaks, fraying, rust | Replace damaged lines immediately |

| Fluid Level | Low fluid level, discoloration | Top up or replace fluid |

After visual inspection, a thorough test of the braking system is required. This includes checking for responsiveness, unusual noises, and vibrations during operation. Addressing any abnormalities promptly will enhance safety and prolong the lifespan of the braking components.

Regular maintenance, including pad replacement and fluid changes, is necessary to maintain high performance. Following the recommended service intervals ensures the system remains in peak condition and reduces the risk of unexpected failures.

Suspension and Steering Adjustments

Maintaining optimal performance in your vehicle’s handling and comfort requires careful attention to the suspension and steering systems. Proper adjustments can enhance stability, improve ride quality, and ensure safety during driving. This section outlines essential considerations and procedures for achieving precise alignment and functionality.

Key Components

The main elements that influence suspension and steering performance include shock absorbers, struts, control arms, and tie rods. Understanding how each component interacts can help identify the need for adjustments. Regular checks can prevent uneven tire wear and maintain responsive steering.

Adjustment Procedures

Follow these steps for effective alignment and tuning:

| Step | Description |

|---|---|

| 1 | Inspect all components for wear or damage. |

| 2 | Adjust the toe settings to ensure straight-line tracking. |

| 3 | Align camber angles for optimal tire contact. |

| 4 | Check caster angles for enhanced steering stability. |

| 5 | Test drive to verify adjustments and make necessary refinements. |

By following these guidelines, you can ensure that your vehicle’s suspension and steering systems perform at their best, providing a smooth and controlled driving experience.

Fluid Change Intervals Explained

Maintaining the optimal performance of a vehicle involves regular updates to various fluids. Understanding the appropriate intervals for these changes is crucial for longevity and efficiency. This section delves into the recommended timelines for fluid replacement and the factors that influence them.

Different types of fluids require distinct attention and care. Below are the main categories:

- Engine Oil: Typically recommended for change every 5,000 to 7,500 miles, depending on driving conditions and oil type.

- Transmission Fluid: Generally advised to replace every 30,000 to 60,000 miles, although some vehicles may have longer intervals.

- Coolant: Usually suggested to be changed every 30,000 to 50,000 miles to prevent overheating and corrosion.

- Brake Fluid: Should be replaced every 2 years, regardless of mileage, to maintain braking performance.

- Power Steering Fluid: Often needs changing every 50,000 to 75,000 miles, as it can degrade over time.

Factors that influence these intervals include:

- Driving Conditions: Frequent stop-and-go traffic, towing, or harsh weather can necessitate more frequent changes.

- Fluid Quality: Synthetic fluids often have longer life spans compared to conventional options.

- Vehicle Age: Older models may require more frequent servicing due to wear and tear.

Regularly monitoring and adhering to these intervals ensures optimal performance, safety, and reliability of the vehicle.

Bodywork and Paint Repair Techniques

Maintaining the exterior of a vehicle is essential for both aesthetic appeal and long-term durability. Various methods exist for addressing imperfections in body panels and restoring the finish to its original luster. Understanding these techniques can help ensure a professional outcome.

Common issues that may require attention include dents, scratches, and rust. Each of these problems can be approached using specific strategies:

- Dent Removal:

- Using a suction tool to pull out minor dents.

- Applying heat followed by a rapid cooling technique to restore panel shape.

- Utilizing specialized tools for more complex dents.

- Scratch Repair:

- Cleaning the area thoroughly before assessment.

- Using touch-up paint for minor scratches.

- Buffing and polishing to blend the repaired area with the surrounding surface.

- Rust Treatment:

- Identifying and addressing the source of corrosion.

- Using sandpaper to remove rust from affected areas.

- Applying a rust-inhibiting primer before repainting.

By employing these techniques, individuals can significantly enhance the longevity and visual appeal of their vehicle’s exterior. Consistent care and timely intervention will lead to a well-maintained appearance and preserve the overall value.

Utilizing Diagnostic Tools Effectively

Effective troubleshooting requires a comprehensive understanding of the systems at play. Leveraging advanced diagnostic instruments not only enhances the accuracy of assessments but also streamlines the entire troubleshooting process. This section aims to provide insights into maximizing the benefits of these tools for optimal performance analysis.

Understanding Diagnostic Instruments

Diagnostic tools encompass a range of devices designed to identify malfunctions within various systems. By utilizing these instruments, one can gain valuable insights into performance issues, thereby facilitating timely interventions. Familiarity with the features and functions of these tools is essential for accurate diagnostics.

Best Practices for Effective Utilization

To harness the full potential of diagnostic equipment, it is crucial to adhere to certain best practices. First, ensure that all tools are regularly calibrated and maintained. This guarantees that readings are reliable. Second, when interpreting data, consider the broader context of the vehicle’s operation. Utilizing historical data alongside real-time analysis can lead to more informed decisions. Lastly, always document findings meticulously, as this creates a valuable resource for future diagnostics.

In conclusion, mastering the use of diagnostic instruments is vital for efficient problem-solving. By adhering to best practices, one can enhance the reliability of assessments and ensure effective performance management.

Safety Precautions During Repairs

When engaging in mechanical tasks, ensuring a secure environment is paramount. Adhering to proper guidelines not only protects the individual performing the work but also safeguards the surrounding area and equipment. Awareness of potential hazards and taking proactive measures can significantly reduce the risk of accidents.

Personal Protective Equipment (PPE) is essential in maintaining safety. Always wear gloves, goggles, and sturdy footwear to shield against injuries from sharp objects and heavy components. Additionally, consider using ear protection when working in noisy environments.

Before beginning any project, ensure that the workspace is clean and organized. Remove unnecessary items that could lead to trips or falls. Adequate lighting is also crucial; poor visibility can contribute to mistakes and accidents.

It is advisable to familiarize yourself with the tools being used. Understanding their functions and potential dangers can prevent misuse and injuries. Furthermore, always follow the manufacturer’s instructions for any devices or components involved in the task.

Proper Ventilation is necessary when working with chemicals or materials that emit fumes. Ensure that the workspace has adequate airflow to minimize inhalation risks. In some cases, using a respirator may be beneficial.

Lastly, keep a first aid kit readily accessible. In the event of an accident, having immediate access to basic medical supplies can make a significant difference in response time and treatment effectiveness.

Finding Quality Replacement Parts

When it comes to maintaining your vehicle’s performance, sourcing high-quality components is essential. The right parts not only enhance longevity but also ensure optimal functionality. It’s crucial to navigate the market wisely to avoid inferior alternatives that may compromise your vehicle’s integrity.

Here are some key factors to consider when searching for top-notch components:

| Criteria | Description |

|---|---|

| Authenticity | Choose original equipment manufacturer (OEM) parts for guaranteed quality and compatibility. |

| Reputation | Research suppliers and read customer reviews to ensure reliability and service standards. |

| Warranty | Opt for parts that come with a warranty, providing you peace of mind regarding their durability. |

| Price | While affordability is important, prioritize quality over low-cost options to avoid future expenses. |

| Compatibility | Verify that parts are specifically designed for your vehicle’s make and model to ensure proper fit and function. |

By considering these aspects, you can make informed decisions and maintain your vehicle in prime condition.