In the realm of advanced aviation engineering, maintaining the integrity and durability of critical components is essential. This guide delves into the extensive methods and detailed processes designed to ensure the continued reliability of complex airborne structures. By understanding each phase and step of these methods, technicians can sustain the highest standards of safety and performance.

The information provided here covers a wide array of techniques for addressing potential issues in core airframe components. Whether dealing with routine upkeep or more intricate reconditioning, these guidelines are tailored to offer clarity on handling intricate systems with precision and care. This guide aims to empower skilled personnel to make informed decisions, using best practices that prioritize longevity and resilience in every task.

Precision and attention to detail are at the heart of each process presented here. With a focus on both preventative and corrective measures, this guide is a valuable resource for those tasked with the upkeep of essential aviation systems. Through consistent adherence to these protocols, each inspection and adjustment can help to uphold structural soundness and operational efficiency.

Understanding the A320 Structural Repair Guide

In this section, we explore the essential resource for technicians and engineers tasked with restoring the integrity of various aircraft components. This reference provides comprehensive instructions and techniques for addressing physical wear or unanticipated damage to ensure continued safety and operational efficiency.

Key Contents of the Resource

Each chapter covers specific areas of the airframe, offering step-by-step guidance on assessing, preparing, and implementing fixes. Clear diagrams and technical notes support the methods, making complex tasks more manageable.

Critical Reference for Aviation Technicians

With detailed explanations for each type of repair, this guide enables maintenance teams to confidently approach any situation, equipped with instructions tailored to individual sections of the aircraft’s framework.

Guidance for Safe Restoration Practices

Beyond technical steps, the resource emphasizes safe practices and compliance standards. Each repair strategy includes reminders to adhere to regulations, ensuring not only a secure restoration but also regulatory approval.

Critical Components in A320 Maintenance

Ensuring optimal condition of vital parts is essential to maintaining the overall reliability and safety of modern passenger aircraft. These critical elements, integral to the aircraft’s operation, require consistent monitoring and precise handling during routine and specialized upkeep procedures. Each component demands a unique approach due to its role and the stresses it undergoes, making focused maintenance indispensable for efficient service life and safety.

Wing Structure and Fastenings

Among the most crucial sections are the wings and their connection points. These areas not only bear aerodynamic loads but also support weight distribution during different flight phases. Regular inspections for fatigue and adjustments to fastenings help prevent potential weaknesses, ensuring stability.

Landing Gear Mechanisms

Landing assemblies undergo substantial stress during takeoffs, landings, and taxiing. Maintenance of these systems involves detailed assessment of shock absorbers, brakes, and struts. Paying close attention to hydraulic lines and tire integrity is necessary to maintain operational readiness and ground control.

Flight Control Surfaces

Elements such as ailerons, elevators, and rudders are essential for maneuvering and stabilization. Continuous assessments ensure that these controls remain responsive and free from wear that could affect movement precision. Proper alignment and adjustment are key in avoiding imbalances during flight.

Powerplant and Engine Mountings

Engines, being power sources, rely on secure mountings and intact connection points. E

Types of Structural Repairs on the A320

Aircraft often require various forms of maintenance to address wear, minor damage, or more substantial issues encountered over time. These corrective actions are essential for ensuring both the longevity and safety of the plane’s operation. Depending on the location, depth, and complexity of the issue, different methods are utilized to restore the component’s full functionality.

- Preventive Measures: Involves regular inspections and minor adjustments to prevent the progression of early-stage wear. These steps focus on minor refinements, such as treating surface irregularities.

- Minor Surface Restoration: Targets smaller impacts or abrasions that may arise from regular operations. Typically includes filling, sanding, and sealing to restore smoothness and protect against corrosion.

- Component Reinforcement: Applies additional support to areas experiencing increased load or stress. This may include installing extra fittings or materials to maintain balance and structural strength.

- Complete Component Replacement: For areas with extensive issues, swapping out affected parts entirely may be required. This approach ensures that the affected areas meet strict safety and performance standards.

Each method is selected based on the extent of the damage, ensuring that repairs are not only effective but also efficient, maintaining the plane’s operational integrity and minimizing

Evaluating Damage Levels for Safety

In the assessment of airframe wear and impacts, understanding the degree and nature of physical harm is crucial for maintaining operational safety. By categorizing the extent of wear or deformation, teams can prioritize actions to ensure enduring reliability. This section outlines methods for examining harm intensities, helping in the timely identification of necessary actions to restore function and integrity.

Types of Damage Categories

Damage is typically classified into levels that range from minor, surface-level imperfections to more severe compromises impacting core structure and function. Each level requires distinct considerations and approaches, from immediate actions to periodic monitoring. Recognizing these levels helps allocate resources efficiently and prevent unnecessary downtime.

Inspection Guidelines and Criteria

Accurate assessment involves specific criteria for each damage type. Key factors include the location of the impact, its size, and any observable distortion or surface cracks. Documenting these aspects according to established guidelines aids in comparing findings and maintaining consistency across evaluations.

| Damage Level | Description | Suggested Action | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Minor | Superficial marks or scratches with no deep penetration | Routine monitoring and minor surface treatment if needed | ||||||||||||||||||||||||||||

| Moderate |

| Document Type | Description |

|---|---|

| Modification Approval | Official authorization for the proposed changes, verifying that they meet regulatory standards. |

| Inspection Reports | Detailed accounts of evaluations conducted before and after the modifications, ensuring integrity and compliance. |

| Material Certifications | Proof that all materials used meet specified quality and safety standards. |

| Work Instructions | Step-by-step guidelines that detail the procedures followed during the modification process. |

Retention and Accessibility

All documentation must be securely stored and readily accessible for future reference. This practice not only supports compliance during audits but also facilitates the tracking of historical data related to modifications.

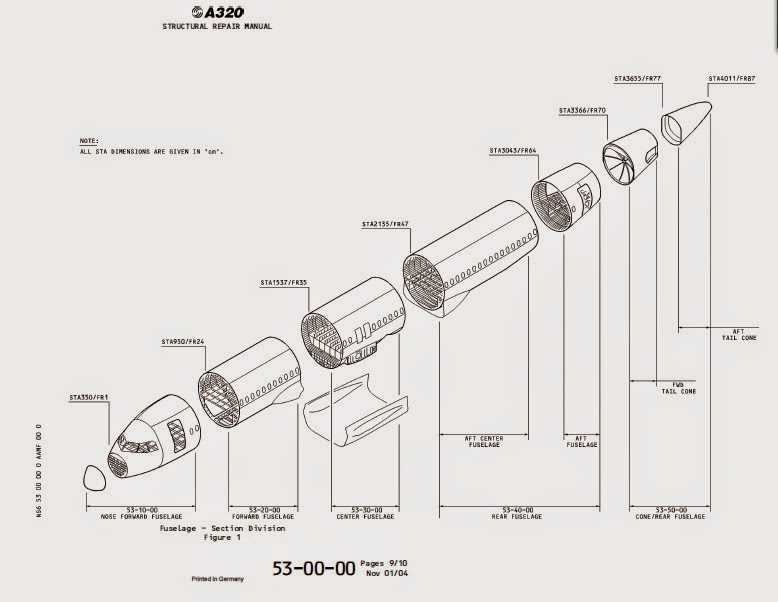

Using Diagrams in A320 Repair Work

Visual representations play a crucial role in the maintenance and restoration of aviation structures. These illustrations assist technicians in understanding complex components and facilitate efficient procedures. By relying on accurate depictions, professionals can ensure precision in their tasks, leading to enhanced safety and reliability.

Benefits of Utilizing Visual Aids

Employing diagrams offers several advantages, including improved comprehension of intricate systems and streamlined workflows. Technicians can quickly locate relevant information, reducing the time spent deciphering written instructions.

Types of Illustrations Commonly Used

| Type | Description |

|---|---|

| Flowcharts | Show sequential steps in processes, making procedures easier to follow. |

| Exploded Views | Depict components separated from their assembly to highlight relationships. |

| Detail Drawings | Provide close-up views of specific parts, emphasizing critical measurements. |

Common Challenges in Structural Repair

Addressing issues related to the integrity of aircraft components involves navigating a range of difficulties that can arise during the restoration process. These obstacles can stem from various factors, including material properties, environmental conditions, and the need for precision in execution. Each situation presents unique demands that require careful consideration and expertise.

Material Limitations

One significant challenge lies in the characteristics of the materials used. Different substances exhibit varying levels of strength, flexibility, and resistance to environmental factors. Understanding these properties is crucial, as they influence the approach taken for remediation and affect the overall durability of the components.

Precision and Quality Control

Another critical aspect is maintaining high standards of accuracy throughout the process. Ensuring that every measurement and application adheres to specified guidelines is vital for achieving optimal results. Any deviation can lead to compromised safety and performance, making meticulous attention to detail indispensable.

Future Updates in Structural Repair Manuals

The continuous evolution in aerospace technology necessitates regular enhancements in documentation related to aircraft maintenance. These updates aim to ensure compliance with current regulations and reflect advancements in materials and methodologies used in aviation.

Technological Advancements

Emerging technologies, such as augmented reality and artificial intelligence, are anticipated to play a significant role in future revisions. These innovations can streamline the maintenance process and improve accuracy in following procedures.

Regulatory Changes

As aviation safety standards evolve, updates will incorporate new regulations from governing bodies. This ensures that maintenance practices remain aligned with safety requirements and best practices within the industry.

| Update Type | Description | Impact |

|---|---|---|

| Technological | Integration of AI and AR tools | Improved accuracy and efficiency |

| Regulatory | New safety standards | Enhanced compliance and safety |

| Material | Introduction of new composites | Better durability and performance |