The intricate world of off-road motorcycles requires a comprehensive understanding of their components and functionality. Whether you’re a seasoned rider or a newcomer to the sport, having access to a detailed guide can enhance your ability to perform essential upkeep and troubleshoot common issues.

In this section, we delve into the vital aspects of maintaining a high-performance motorcycle. Proper care not only extends the lifespan of the machine but also ensures optimal performance on various terrains. From engine inspections to suspension adjustments, each procedure is crucial for safe and enjoyable riding experiences.

Equipped with the right knowledge, you can confidently tackle routine maintenance tasks and minor repairs. This resource aims to provide you with clear instructions, enabling you to keep your motorcycle in top condition. With an emphasis on practical advice and hands-on techniques, you’ll be well-prepared to face any challenges that arise.

Overview

This section provides a comprehensive look at a high-performance dirt bike renowned for its agility, power, and advanced engineering. Designed for both competitive racing and recreational riding, this model stands out due to its cutting-edge features and rider-friendly design. Enthusiasts appreciate its balance of speed and control, making it a preferred choice among motocross riders.

Key Features

Highlighting the essential attributes, the following table summarizes the significant components that contribute to the bike’s superior performance:

| Feature | Description |

|---|---|

| Engine | Powerful, liquid-cooled engine designed for optimal torque and horsepower. |

| Suspension | Advanced suspension system that enhances stability and handling on various terrains. |

| Weight | Lightweight construction for improved maneuverability and agility. |

| Braking System | High-performance braking components ensuring quick and reliable stops. |

| Design | Aerodynamic design that minimizes drag and maximizes speed. |

Performance and Handling

The machine’s impressive handling capabilities are a result of meticulous engineering and thoughtful design choices. Riders benefit from a responsive throttle, allowing for precise control during acceleration and cornering. This results in an exhilarating riding experience, whether on the track or off-road.

Key Features of the Model

This section explores the distinctive attributes of a prominent off-road motorcycle, emphasizing its advanced design and performance capabilities. Understanding these characteristics is essential for enthusiasts and potential owners alike, providing insight into what makes this machine stand out in its class.

Performance and Handling

The motorcycle is engineered for exceptional performance, ensuring agility and stability on various terrains. Its lightweight frame and powerful engine contribute to an exhilarating riding experience, allowing riders to tackle challenging obstacles with ease.

Advanced Technology

Incorporating cutting-edge technology, this model features an efficient fuel injection system and adjustable suspension. These enhancements allow for optimal customization based on rider preference and riding conditions, making it a versatile choice for both amateur and seasoned riders.

| Feature | Description |

|---|---|

| Engine Type | High-performance four-stroke engine designed for maximum power output. |

| Frame | Lightweight aluminum frame for improved maneuverability. |

| Suspension | Fully adjustable suspension system for enhanced comfort and handling. |

| Braking System | High-performance braking components for reliable stopping power. |

| Fuel System | Advanced fuel injection for improved efficiency and responsiveness. |

Common Issues Faced by Owners

Motorcycle enthusiasts often encounter various challenges with their machines that can affect performance and overall enjoyment. Understanding these typical problems is essential for maintaining optimal functionality and ensuring a smooth riding experience.

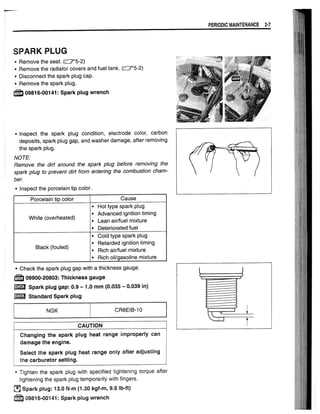

One frequent concern relates to engine performance. Owners may notice issues such as hesitation during acceleration or difficulty starting the engine. These symptoms can stem from factors like fuel quality, air filter condition, or ignition system malfunctions.

Another common problem involves the suspension system. Riders often report a harsh or uncomfortable ride, which can be attributed to worn components or improper setup. Regular inspection and maintenance of suspension parts are vital to prevent these issues from escalating.

Braking performance is also a significant aspect that owners must monitor. Symptoms such as spongy brakes or uneven wear on brake pads may indicate the need for adjustment or replacement. Ensuring the braking system is in top condition is crucial for rider safety.

Lastly, electrical system failures can be a nuisance. Problems such as flickering lights or a non-responsive starting system are often linked to battery issues or faulty wiring. Regular checks can help identify potential electrical problems before they lead to larger complications.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your off-road motorcycle. Regular attention to various components can ensure optimal performance and reduce the likelihood of unexpected breakdowns. By adopting a consistent maintenance routine, you can enhance the durability and efficiency of your machine.

Firstly, always keep the air filter clean and well-maintained. A clogged filter can restrict airflow and impact engine performance. Regularly inspect and clean the filter to promote better combustion and reduce wear on engine parts.

Next, ensure that the lubrication system is functioning effectively. Regular oil changes using high-quality fluids are crucial for minimizing friction and heat within the engine. Follow the manufacturer’s guidelines for oil change intervals to keep the engine running smoothly.

Additionally, pay attention to the chain and sprockets. A well-lubricated chain will not only provide smoother power transfer but also prolong the life of both the chain and sprockets. Regularly clean and lubricate these components to maintain optimal performance.

Lastly, check tire pressure and tread regularly. Properly inflated tires improve handling and traction, while adequate tread ensures safety on various terrains. Regular tire maintenance contributes to a better riding experience and reduces the risk of flats.

Tools Required for Repairs

Proper maintenance and servicing of your vehicle necessitate a selection of essential instruments. Having the right equipment at hand ensures efficient troubleshooting and effective resolution of issues that may arise during operation. This section outlines the key tools that facilitate various tasks associated with upkeep.

Basic Hand Tools

A good toolkit typically includes a variety of wrenches, pliers, and screwdrivers. These instruments are crucial for loosening and tightening bolts, adjusting components, and handling minor repairs. Make sure to have both metric and standard sizes available to accommodate different parts.

Specialized Equipment

In addition to standard tools, certain specialized devices may be necessary for specific tasks. This includes torque wrenches for precise fastening, diagnostic scanners for electronic assessments, and compression testers to evaluate engine performance. Investing in quality equipment will enhance your ability to conduct thorough examinations and repairs.

Step-by-Step Repair Procedures

This section outlines a comprehensive guide for addressing common issues in high-performance motorcycles. Following these detailed instructions will ensure that every component is thoroughly examined and restored to optimal functionality.

1. Preparation: Begin by gathering all necessary tools and components. Ensure that your workspace is clean and organized to facilitate an efficient workflow.

2. Inspection: Conduct a thorough examination of the vehicle. Look for any visible signs of wear or damage, paying special attention to critical areas such as the engine, suspension, and braking systems.

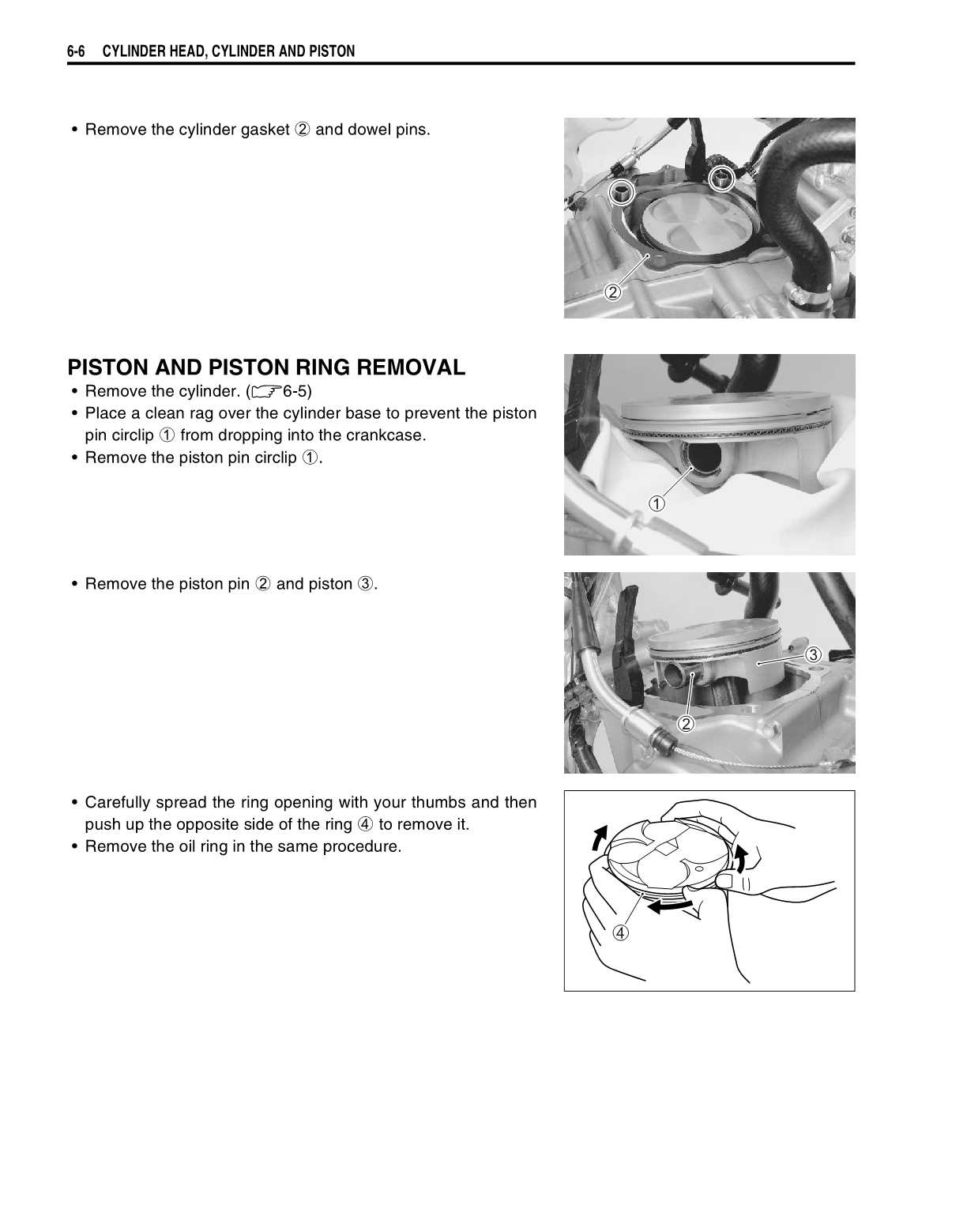

3. Disassembly: Carefully disassemble the parts that require attention. Take note of the order and orientation of each component, as this will simplify reassembly.

4. Cleaning: Clean all components using appropriate solvents. Remove any dirt, grime, or debris that may hinder performance or cause damage during operation.

5. Replacement: Replace any worn or damaged parts with high-quality alternatives. Always refer to specifications to ensure compatibility and performance standards.

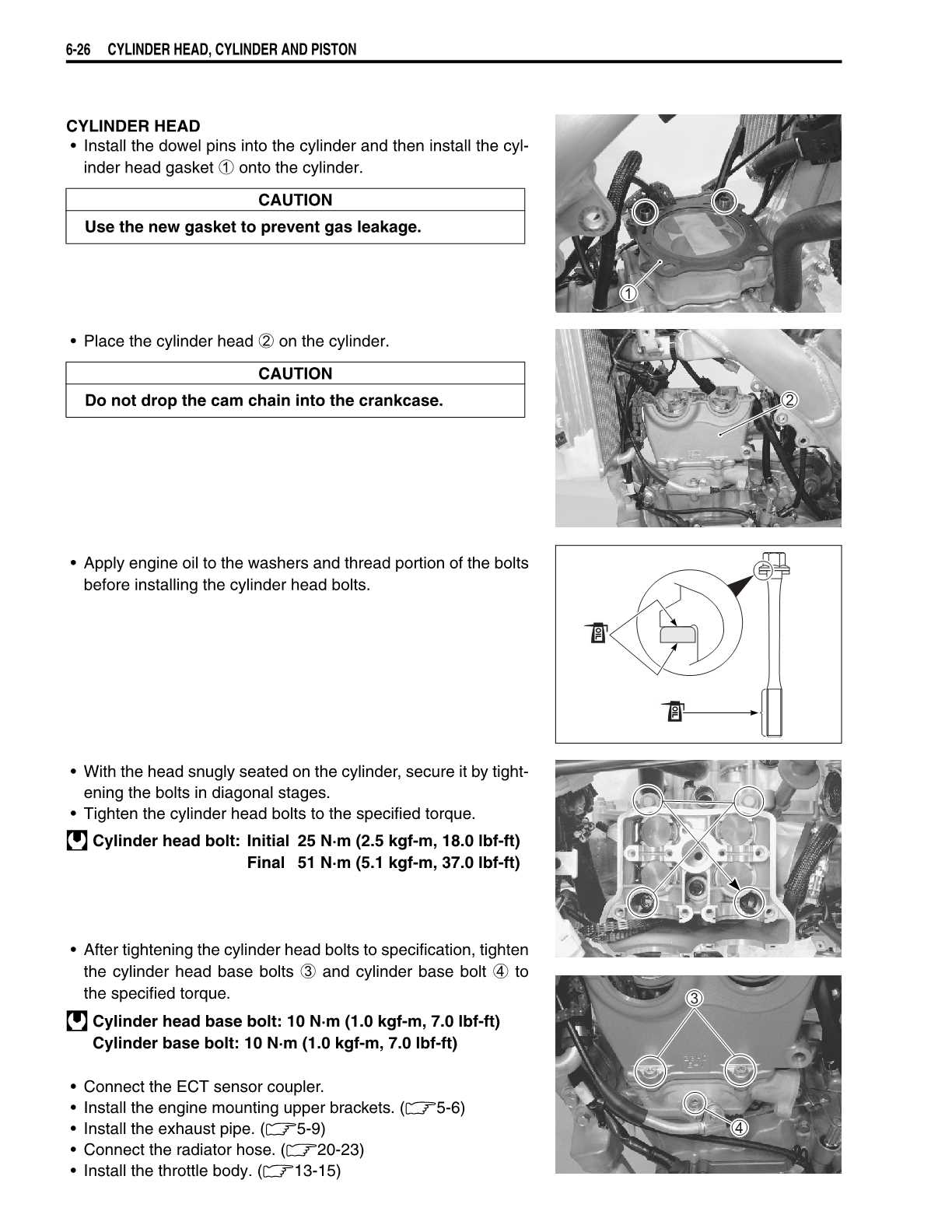

6. Reassembly: Reassemble the disassembled components in the reverse order of disassembly. Double-check each connection and alignment to avoid future issues.

7. Testing: Once reassembly is complete, perform a series of tests to verify that the vehicle operates smoothly. Pay attention to any unusual sounds or behaviors that may indicate lingering problems.

8. Final Checks: Conduct a final inspection to ensure all tools are removed from the workspace and that everything is secure. Document any changes made during the process for future reference.

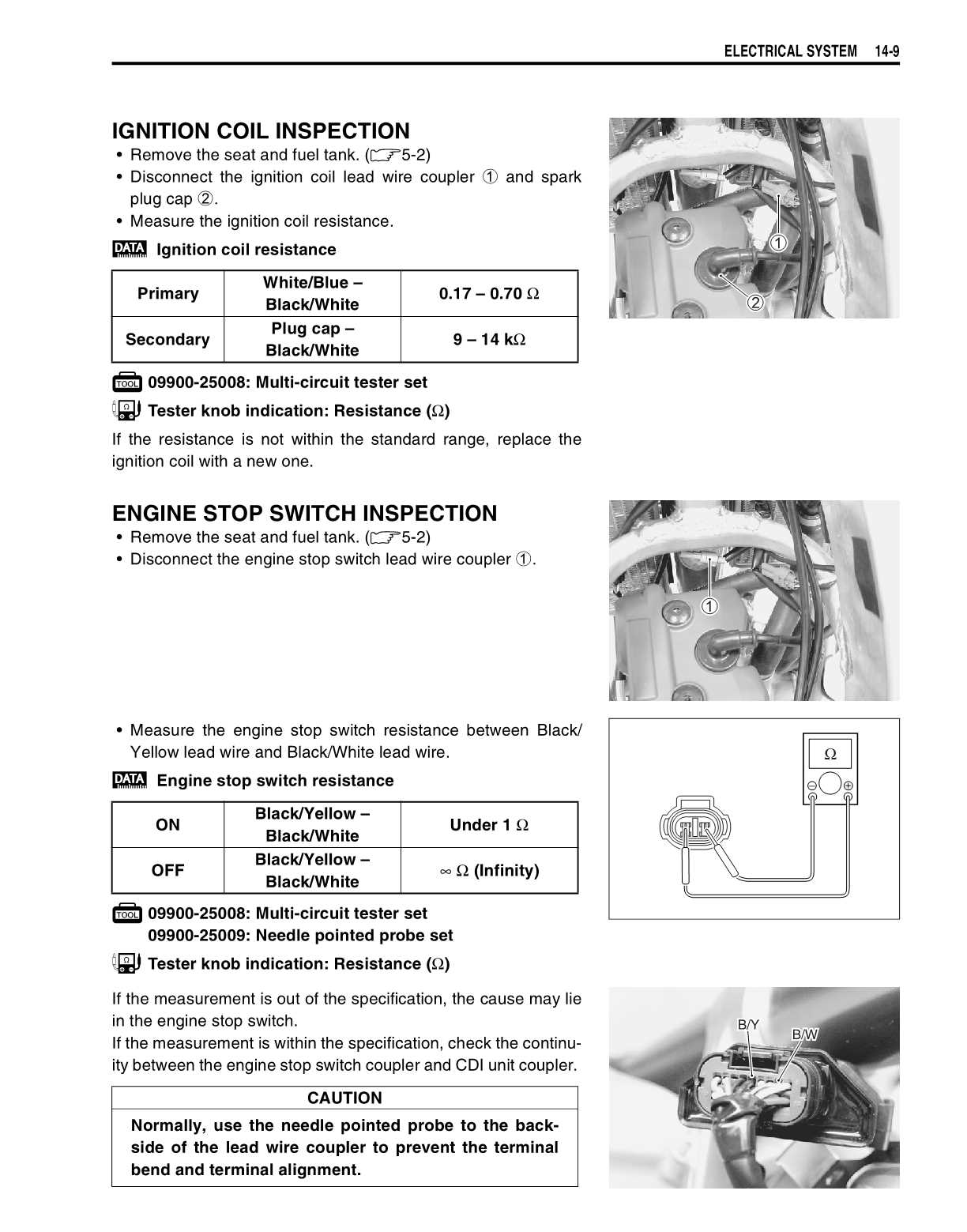

Electrical System Troubleshooting

The electrical system is crucial for the proper functioning of any vehicle, ensuring that all components operate smoothly. Identifying issues within this system can often be a challenging task, requiring a methodical approach to diagnostics. Understanding common problems and their symptoms is essential for effective resolution.

Common Symptoms: One of the most frequent indicators of electrical issues includes difficulty starting the engine. Additional signs may consist of flickering lights, unresponsive instruments, or unusual noises from the electrical components. Addressing these symptoms promptly can prevent more significant complications down the line.

Basic Steps for Diagnosis: Begin by inspecting the battery connections for corrosion or looseness, as these can lead to poor electrical flow. Check the fuses to ensure they are intact and replace any that are blown. Utilize a multimeter to measure voltage levels throughout the system, helping pinpoint any discrepancies.

Wiring Inspection: Examine the wiring harness for any signs of wear, fraying, or damage. Broken or shorted wires can create shorts that affect the overall performance of the electrical system. Replacing damaged wiring is often essential for restoring functionality.

Component Testing: After basic checks, focus on individual components such as the starter, alternator, and ignition system. Testing these parts can help identify faulty elements that may require replacement. A systematic approach will streamline the troubleshooting process and facilitate timely repairs.

Engine Rebuild Guidelines

Rebuilding an engine is a complex yet rewarding process that requires careful planning and attention to detail. This procedure not only enhances performance but also extends the lifespan of the machine. Understanding the essential steps involved in the overhaul can lead to successful outcomes and improved reliability.

Preparation: Before starting, gather all necessary tools and parts. A clean workspace is crucial to avoid contamination and misplacement of components. Review the specifications and requirements specific to the engine type to ensure compatibility with replacement parts.

Disassembly: Begin by systematically removing the engine from the frame. Document each step and keep track of all fasteners and components. Carefully disassemble the engine, noting any wear or damage that may indicate underlying issues.

Inspection: Thoroughly examine all parts for signs of wear, cracks, or deformation. Pay special attention to critical areas such as bearings, pistons, and cylinder walls. Replace any damaged components to ensure optimal performance post-rebuild.

Cleaning: Clean all components using appropriate solvents and tools. Remove carbon deposits, dirt, and old gaskets to prepare surfaces for reassembly. Ensuring cleanliness is vital to prevent future engine failures.

Reassembly: Follow the manufacturer’s guidelines for torque specifications and assembly order. Apply fresh gaskets and seals to prevent leaks. Be meticulous with each step, ensuring that all parts fit snugly and function as intended.

Testing: Once reassembled, conduct thorough tests to verify proper operation. Monitor for unusual noises or vibrations, and check fluid levels. This step is critical to confirm that the engine performs optimally before returning it to service.

Suspension Adjustments Explained

Proper tuning of the suspension system is crucial for enhancing overall performance and rider comfort. By understanding the various aspects of suspension settings, enthusiasts can optimize their vehicle’s handling characteristics for different terrains and riding styles.

Compression and Rebound Damping are essential factors to consider. Compression damping controls how quickly the suspension compresses under load, while rebound damping affects how fast it returns to its original position. Adjusting these settings can significantly impact traction and stability during rides.

Spring Preload is another critical adjustment that determines the initial tension on the springs. Increasing preload raises the ride height and can enhance cornering performance, whereas reducing it lowers the ride height, improving comfort over rough terrain.

Ride Height adjustments are equally important, as they influence the overall geometry of the vehicle. A higher ride height can provide better obstacle clearance, while a lower setting can improve handling and aerodynamics.

Fuel System Maintenance Strategies

Proper upkeep of the fuel system is crucial for optimal performance and longevity of the machine. Regular inspections and timely interventions can prevent potential issues that may arise from neglect. This section outlines effective techniques to ensure the fuel delivery components function smoothly and efficiently.

Begin with routine checks of fuel filters, replacing them as needed to prevent clogging that can hinder flow. Additionally, it is essential to inspect fuel lines for signs of wear or leakage, ensuring connections are secure. Using high-quality fuel and additives can help maintain cleanliness within the system, minimizing deposits that could impact performance.

Periodically cleaning or replacing injectors is also advisable, as this promotes proper atomization and combustion. Moreover, maintaining appropriate fuel levels and avoiding prolonged storage of old fuel can enhance the overall functionality of the system. Adhering to these strategies will significantly contribute to the reliable operation of the vehicle.

Recommended Oils and Fluids

Choosing the right lubricants and fluids is crucial for maintaining optimal performance and longevity of your motorcycle. High-quality products ensure efficient operation and protect the engine and other vital components from wear and tear.

| Type | Recommended Product | Specification |

|---|---|---|

| Engine Oil | Premium Synthetic Oil | 10W-40 |

| Transmission Oil | High-Performance Gear Oil | 80W-90 |

| Coolant | Organic Acid Technology (OAT) Coolant | 50/50 Mix with Water |

| Brake Fluid | DOT 4 Brake Fluid | High-Temperature Formula |

| Fuel Additive | High-Performance Fuel Stabilizer | As Recommended |

Using the recommended oils and fluids not only enhances the motorcycle’s performance but also extends its lifespan. Always consult the owner’s guidelines to ensure compatibility and follow proper maintenance intervals for optimal results.

Parts Replacement Procedures

This section outlines essential steps for substituting components within the vehicle. Proper techniques ensure longevity and optimal performance. Familiarity with specific tools and practices is crucial for success in these tasks.

Preparation Steps

- Gather necessary tools and replacement parts.

- Ensure the workspace is clean and organized.

- Consult relevant documentation for specific procedures related to the component.

Replacement Process

- Turn off the engine and disconnect the battery to prevent any electrical issues.

- Carefully remove the damaged or worn part, taking note of any fasteners and connections.

- Install the new component, ensuring it is aligned correctly and secured properly.

- Reconnect any electrical connections and reattach the battery.

- Perform a functionality check to confirm the new part is operating as intended.

Upgrades for Enhanced Performance

Improving the capabilities of your two-wheeler can significantly elevate your riding experience. By focusing on key modifications, you can boost power, handling, and overall efficiency. This section explores various enhancements that can transform your machine into a more dynamic and responsive vehicle.

Engine Modifications

One of the most impactful areas for improvement lies within the powerplant. Upgrading the exhaust system can enhance airflow, leading to better performance and a more aggressive sound. Additionally, tuning the fuel management system can optimize the air-fuel mixture, resulting in increased horsepower and torque. These adjustments not only improve acceleration but also contribute to a smoother ride.

Suspension and Handling Enhancements

To maximize handling, consider investing in a high-quality suspension setup. Upgrading the forks and rear shock absorber can significantly improve stability and comfort, allowing for better control over rough terrain. Furthermore, adjusting the geometry of the bike through new triple clamps can enhance cornering capabilities, making your rides more enjoyable and precise.