In the realm of household appliances, ensuring optimal functionality is essential for a seamless experience. This section delves into the intricacies of a specific washing machine model, offering insights into its components and common issues users may encounter. By familiarizing oneself with the inner workings and potential pitfalls, owners can maintain efficiency and prolong the lifespan of their equipment.

Throughout this guide, you will discover valuable information tailored to assist you in troubleshooting and resolving typical challenges. Whether it’s addressing minor malfunctions or understanding operational features, having a detailed reference at your disposal can make a significant difference. Knowledge empowers users to tackle concerns confidently, ensuring their laundry tasks proceed smoothly.

As we explore the various aspects of this appliance, you will gain a deeper appreciation for its design and functionality. Emphasizing preventive care and routine maintenance, this guide aims to equip you with the tools necessary for effective management of your appliance, ultimately enhancing your laundry experience.

Overview of Maytag Lav3600aww

This section provides a comprehensive look at a popular appliance known for its reliability and efficiency in laundry care. Designed to meet the needs of modern households, this machine combines innovative technology with user-friendly features, ensuring optimal performance for a variety of fabric types.

The appliance is equipped with multiple settings that cater to different washing requirements, allowing users to customize cycles based on their laundry needs. With its robust construction, it is built to withstand regular use while maintaining high standards of cleanliness and care for garments.

Additionally, energy efficiency is a key highlight, making it an eco-friendly choice for consumers looking to reduce their environmental impact while managing household chores. Overall, this model represents a blend of practicality and advanced engineering, making it a valuable addition to any laundry room.

Common Issues with Maytag Washers

Washing machines are essential appliances in many households, yet they can encounter various challenges over time. Understanding the typical problems can help users maintain optimal performance and extend the lifespan of their devices. This section outlines frequent malfunctions that might occur in these types of laundry machines.

Noise During Operation: Excessive or unusual sounds during a wash cycle can indicate issues with the drum, motor, or other components. Users should investigate any grinding, squeaking, or rattling noises to determine the source.

Water Leakage: One of the more common issues is water escaping from the machine. This can stem from worn-out door seals, damaged hoses, or improper loading. Regular inspection of these areas can help prevent significant water damage.

Failure to Drain: If the appliance fails to drain properly, it may be due to a clogged pump or hose. This issue often leads to standing water, which can become a breeding ground for mold and bacteria.

Cycle Interruption: Machines may unexpectedly halt during a cycle. This could be a result of electrical issues, door latch problems, or a malfunctioning control board. Identifying the cause early can prevent further complications.

Inconsistent Cleaning Results: If clothes come out still dirty, it may indicate that the detergent is not being dispensed correctly, or the load is unbalanced. Users should ensure that they are using the right amount of detergent and loading the machine evenly.

By familiarizing oneself with these potential issues, users can take proactive steps to address them, ensuring their laundry machines operate smoothly and efficiently.

Essential Tools for Repairs

When tackling maintenance tasks, having the right instruments can make all the difference in achieving successful outcomes. Equipping yourself with essential tools not only streamlines the process but also enhances your confidence in handling various issues that may arise. This section outlines the must-have devices that will aid you in any undertaking.

Basic Hand Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers in various sizes.

- Wrenches: Adjustable and socket wrenches for dealing with nuts and bolts.

- Pliers: Needle-nose, slip-joint, and cutting pliers for gripping and cutting tasks.

Specialized Instruments

- Multimeter: For measuring electrical properties and diagnosing issues.

- Level: To ensure components are aligned properly during installation.

- Torque Wrench: Essential for applying the correct amount of force to fasteners.

Having these tools readily available not only simplifies your efforts but also equips you to tackle a wide range of challenges effectively.

Step-by-Step Troubleshooting Guide

This section provides a structured approach to identifying and resolving common issues that may arise with your appliance. By following these systematic steps, you can effectively diagnose problems and take appropriate actions to restore functionality. Each step is designed to guide you through the process, ensuring that no potential cause is overlooked.

Start by observing the behavior of the unit. Is it making unusual noises, failing to start, or displaying error codes? Take note of any symptoms, as this information will be crucial in narrowing down the possible issues. After that, check the power supply. Ensure that the appliance is properly plugged in and that there are no blown fuses or tripped circuit breakers.

If the power supply is intact, examine the water supply for any interruptions. Make sure the valves are open and that there are no kinks in the hoses. Next, inspect the drain system to confirm that it is not clogged, which can impede performance. Cleaning any blockages may resolve drainage issues.

Moving on, assess the internal components. Look for any visible signs of wear or damage, such as frayed wires or broken parts. If necessary, consult the technical specifications to identify any specific components that may need inspection or replacement.

Finally, if problems persist after these checks, consider consulting troubleshooting resources or seeking professional assistance. Documenting your findings throughout this process can help pinpoint recurring issues and facilitate future maintenance.

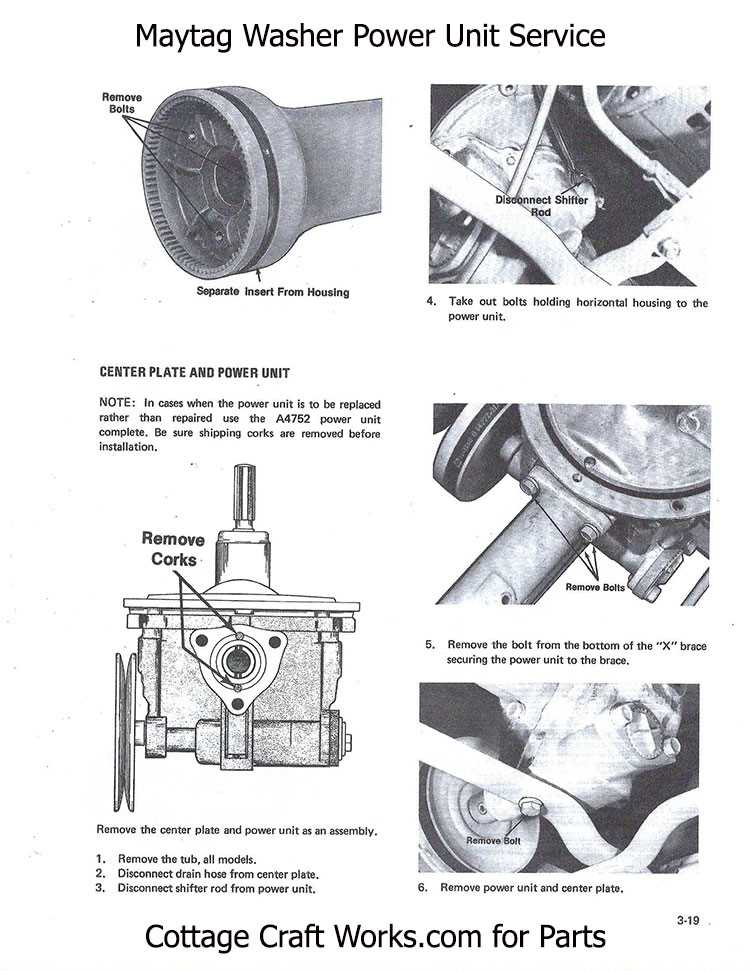

How to Access the Washer Components

Gaining entry to the internal elements of a washing machine is essential for maintenance and troubleshooting. Understanding the layout and functionality of these parts allows for effective diagnosis and repair, ensuring optimal performance.

Safety Precautions

Before beginning, ensure the appliance is unplugged. This prevents electrical hazards and protects the user from potential injuries. Additionally, wear safety gloves to safeguard your hands while working.

Steps to Access Internal Parts

Follow these guidelines to reach the key components:

| Step | Description |

|---|---|

| 1 | Remove the control panel screws and detach it carefully. |

| 2 | Take off the front panel by unscrewing the fasteners at the bottom. |

| 3 | Lift the lid to access the drum and its associated mechanisms. |

| 4 | Check all wiring and connections for any signs of wear or damage. |

Following these steps will facilitate access to the machine’s components, allowing for thorough inspection and maintenance as needed.

Replacing the Door Seal

The door seal is a crucial component that prevents leaks and ensures optimal performance. Over time, this part may wear out or become damaged, leading to potential water escape and efficiency issues. Replacing it is a straightforward task that can significantly enhance the functionality of your appliance.

Follow these steps to effectively replace the door seal:

- Gather Tools and Materials:

- New door seal

- Screwdriver

- Cleaning cloth

- Silicone lubricant (optional)

- Unplug the Appliance: Always ensure the unit is disconnected from the power source to avoid any electrical hazards.

- Remove the Old Seal:

- Locate the screws or clips securing the seal.

- Carefully detach the old seal from the door, taking note of how it was installed.

- Clean the Surface: Use a cleaning cloth to remove any debris or residue from the door’s edge.

- Install the New Seal:

- Align the new seal with the door edge, ensuring it fits snugly.

- Secure it with screws or clips, as needed.

- Test for Leaks: After installation, run a cycle and check for any signs of water escaping.

By following these simple steps, you can ensure that your appliance operates efficiently and effectively, extending its lifespan and enhancing its performance.

Fixing Drainage Problems

Addressing drainage issues is crucial for maintaining optimal performance in household appliances. These complications can lead to inefficient operation and even potential damage. Understanding common causes and solutions can help restore functionality.

- Clogged Hoses: Inspect hoses for blockages.

- Pump Malfunction: Check if the drainage pump is functioning properly.

- Improper Installation: Ensure that all components are installed correctly.

- Dirty Filters: Clean any filters that may be obstructed.

By taking these steps, users can effectively resolve drainage issues and enhance the efficiency of their appliances.

Addressing Electrical Malfunctions

Electrical issues can disrupt the normal functioning of household appliances, leading to inconvenience and frustration. Identifying and resolving these problems is crucial for restoring efficiency and safety. This section focuses on common electrical disturbances, providing guidance on troubleshooting and possible solutions.

Identifying Common Symptoms

Recognizing the signs of electrical problems is the first step toward resolution. Common symptoms include inconsistent power supply, where the appliance may intermittently turn on and off, or complete failure to start. Other indicators can include unusual noises, such as buzzing or clicking sounds, and the presence of burnt smells, which may suggest overheating or short circuits.

Troubleshooting Steps

To effectively address these issues, follow a systematic approach. First, ensure that the appliance is properly plugged in and that the outlet is functioning. You can test the outlet with a multimeter or by plugging in another device. If the outlet is operational, inspect the power cord for any visible damage. Next, check the circuit breaker to see if it has tripped; resetting it may resolve the issue. If problems persist, examining internal components such as fuses and relays may be necessary. Consult relevant documentation for specific guidance on accessing these parts safely.

In some cases, professional assistance may be required, especially if the electrical malfunction involves complex wiring or potential hazards. Regular maintenance can also help prevent future electrical disturbances, ensuring the longevity and reliability of your appliances.

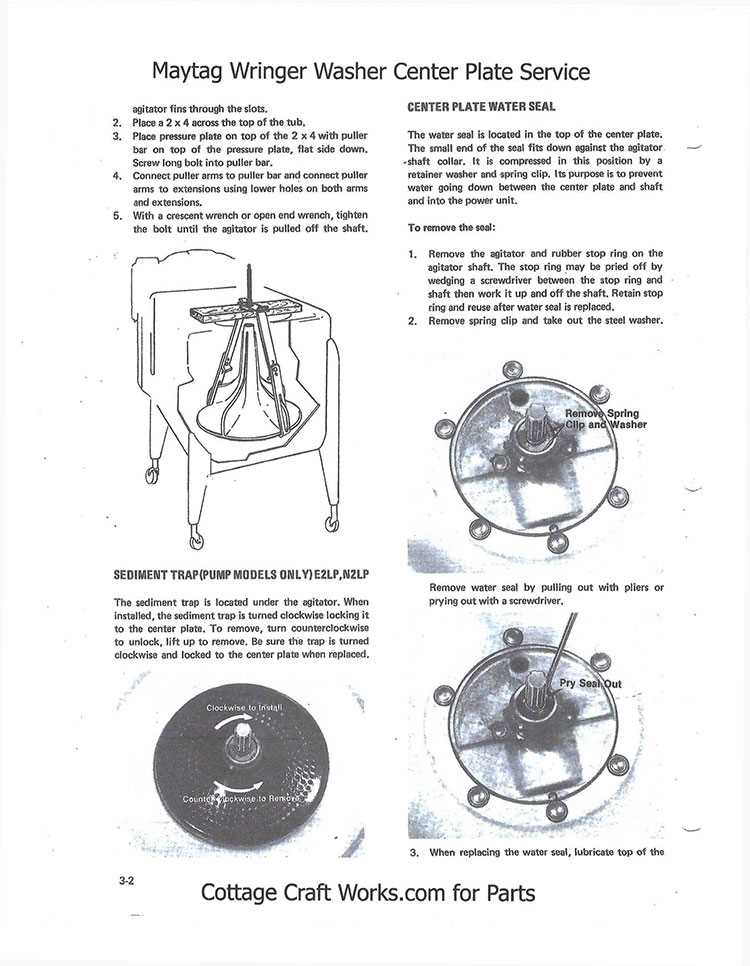

Cleaning the Pump Filter

Maintaining the cleanliness of the pump filter is essential for ensuring optimal performance and longevity of your appliance. Over time, debris and lint can accumulate, leading to potential blockages that may hinder the efficiency of the washing cycle. Regularly checking and cleaning this component helps prevent malfunctions and keeps the appliance running smoothly.

To access the filter, locate the panel or cover, which is typically found at the front or bottom of the machine. After removing it, you may need to place a towel or shallow container beneath to catch any residual water. Carefully unscrew or pull out the filter, and inspect it for any visible obstructions. Rinse it under warm water to eliminate any trapped particles, ensuring that all openings are clear.

Once cleaned, reinsert the filter securely and replace the cover. Regular maintenance of this part not only enhances performance but also contributes to the overall hygiene of your laundry. Make it a habit to check the filter periodically, especially after heavy use or washing items that shed lint easily.

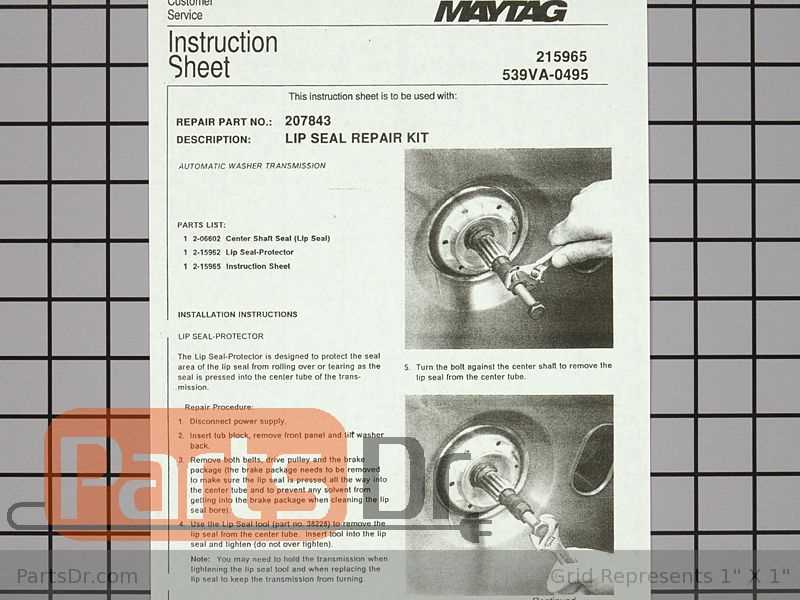

Replacing the Agitator Assembly

Replacing the agitator assembly is a crucial task when addressing issues with the washing performance of your appliance. Over time, wear and tear can lead to reduced efficiency, uneven washing, or complete failure of the component. This guide provides a step-by-step approach to assist you in performing this task effectively.

Before you begin, ensure you have the necessary tools and replacement parts ready. Here’s what you’ll need:

- Screwdriver set

- Socket wrench

- Replacement agitator assembly

- Towels for any spills

Follow these steps to successfully replace the agitator assembly:

- Disconnect the Power: Always unplug the appliance from the electrical outlet to ensure safety during the process.

- Remove the Agitator Cap: Use a screwdriver to pry off the cap located at the top of the agitator.

- Unscrew the Bolt: Locate and remove the central bolt that secures the agitator in place using the socket wrench.

- Lift the Agitator Out: Carefully pull the agitator assembly out of the tub. You may need to wiggle it gently to free it.

- Install the New Agitator: Position the new assembly into the tub, ensuring it fits snugly.

- Reattach the Bolt: Secure the agitator with the bolt you removed earlier, tightening it adequately.

- Replace the Cap: Snap the cap back onto the top of the agitator to complete the installation.

- Reconnect the Power: Plug the appliance back in and perform a test cycle to ensure everything functions correctly.

By following these straightforward steps, you can restore the washing capabilities of your appliance and ensure it operates smoothly for years to come.

Understanding Error Codes

Error codes serve as vital indicators that help identify issues within appliances. By decoding these signals, users can diagnose problems more efficiently, leading to quicker solutions and improved functionality. Recognizing the meaning behind these codes is essential for effective troubleshooting and maintaining optimal performance.

Each device has its own set of error indicators, which can vary in format and meaning. Below is a table summarizing some common error codes and their possible interpretations:

| Error Code | Possible Meaning |

|---|---|

| E1 | Water supply issue |

| E2 | Drainage problem |

| E3 | Overheating detected |

| E4 | Unbalanced load |

| E5 | Sensor malfunction |

Understanding these codes empowers users to take appropriate actions, whether that involves simple adjustments or seeking professional assistance. A proactive approach can prolong the lifespan of the appliance and ensure its reliable operation.

Maintaining Your Washer for Longevity

Proper care and regular maintenance are essential for extending the life of your laundry appliance. By following a few simple practices, you can ensure it operates efficiently and effectively for many years. Regular attention to the machine not only enhances its performance but also helps in preventing common issues that may arise over time.

Routine Cleaning

One of the most crucial aspects of upkeep is cleaning. Make it a habit to wipe down the exterior and clean the detergent dispenser regularly. Over time, residues can build up, affecting the wash quality. Additionally, running a maintenance cycle with a washing machine cleaner can eliminate odors and buildup inside the drum.

Checking Hoses and Connections

Inspecting hoses and connections periodically is vital to prevent leaks and other water-related issues. Ensure that hoses are not kinked or damaged and that connections are secure. Replacing worn-out hoses promptly can save you from potential flooding and costly repairs.

By integrating these maintenance practices into your routine, you can significantly improve the lifespan and functionality of your laundry appliance.

When to Call a Professional Technician

There are times when tackling an issue on your own may not be the best approach. Recognizing these moments can save you both time and further complications. If a situation escalates beyond basic troubleshooting, seeking the expertise of a trained specialist is essential.

Signs You Need Professional Help

Several indicators suggest that it’s time to reach out for professional assistance. If you encounter persistent problems despite following basic troubleshooting steps, or if you notice unusual noises or leaks, it’s wise to consult an expert.

| Signs | Action |

|---|---|

| Persistent issues | Contact a technician |

| Unusual sounds | Seek expert evaluation |

| Visible leaks | Immediate professional service |

| Burning smells | Emergency technician visit |

Complex Repairs

Some repairs require specialized knowledge and tools. If the task involves electrical components or intricate mechanical parts, it’s prudent to leave it to those who have the appropriate training. This not only ensures safety but also improves the chances of a successful fix.