In the world of machinery, ensuring optimal performance is crucial for efficiency and longevity. This section provides essential insights into the upkeep and troubleshooting of specific models, allowing users to maximize their equipment’s potential. By understanding key aspects of functionality, operators can address common issues effectively.

Regular maintenance plays a vital role in preserving the integrity of your machinery. Familiarizing oneself with operational principles not only enhances productivity but also extends the lifespan of the unit. This guidance offers practical tips and techniques tailored to facilitate a seamless maintenance experience.

By engaging with this resource, users can confidently navigate various challenges that may arise during operation. Whether it’s routine checks or addressing unexpected malfunctions, the information presented here serves as a valuable companion in your journey toward reliable performance.

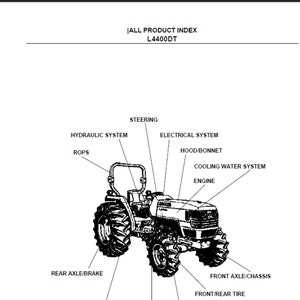

This section will provide a comprehensive introduction to the agricultural machinery model, highlighting its key features and specifications. Understanding the fundamentals of this equipment is crucial for effective usage and maintenance.

| Feature | Details |

|---|---|

| Engine Type | Four-stroke, liquid-cooled |

| Horsepower | Approx. 44 HP |

| Transmission | Gear-driven |

| Weight | About 1,800 lbs |

| Drive Type | 4WD |

By exploring these elements, users can gain a clearer understanding of the machine’s capabilities and operational characteristics, paving the way for effective utilization and upkeep strategies.

Common Issues with Kubota L4400

When operating agricultural machinery, certain challenges may arise that can affect performance and efficiency. Understanding these frequent problems can help users maintain their equipment effectively and ensure its longevity.

1. Engine Performance Problems: One of the most common concerns involves engine difficulties. These may manifest as poor starting, irregular idling, or a noticeable loss of power. Regular maintenance, such as checking fuel filters and air intake, can mitigate these issues.

2. Hydraulic System Failures: Hydraulic components are essential for the smooth operation of various functions. Users often experience leaks or unresponsive controls, which can stem from worn seals or low fluid levels. Regular inspections of the hydraulic system can help identify potential issues early.

3. Transmission Troubles: Shifting problems may occur, leading to difficulty in changing gears. This could be due to low transmission fluid or worn components. Regularly checking fluid levels and ensuring proper maintenance can alleviate these concerns.

4. Electrical System Glitches: Electrical failures can result in lights not functioning or starting issues. These may arise from battery problems or faulty wiring. Regular battery checks and ensuring connections are secure can help prevent these complications.

Being proactive about these common challenges can significantly enhance the operation and durability of agricultural equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your agricultural machinery operates at its best. Implementing a consistent maintenance routine not only enhances efficiency but also prolongs the lifespan of the equipment. Below are key strategies to consider for optimal functioning.

Routine Checks

- Inspect fluid levels, including oil, coolant, and fuel, to ensure they are within recommended limits.

- Examine filters regularly; clean or replace them as needed to maintain air and fluid quality.

- Check the condition of belts and hoses for signs of wear or damage, replacing them promptly.

Seasonal Maintenance

- Before the start of each season, perform a thorough inspection to identify any necessary repairs or adjustments.

- Sharpen blades and other cutting components to ensure optimal performance during use.

- Store equipment in a dry, covered area to protect it from harsh weather conditions and environmental factors.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and restoring machinery effectively. This section outlines the fundamental instruments that will facilitate efficient troubleshooting and ensure optimal performance.

- Wrenches: Various sizes are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are essential for accessing different components.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Socket Set: A comprehensive set helps in removing and securing nuts in tight spaces.

- Torque Wrench: Ensures that fasteners are tightened to the specified settings.

- Diagnostic Tools: Equipment to assess the machine’s performance and identify issues.

In addition to these primary tools, having a sturdy workbench, safety equipment, and proper lighting can enhance the repair process and promote a safer work environment.

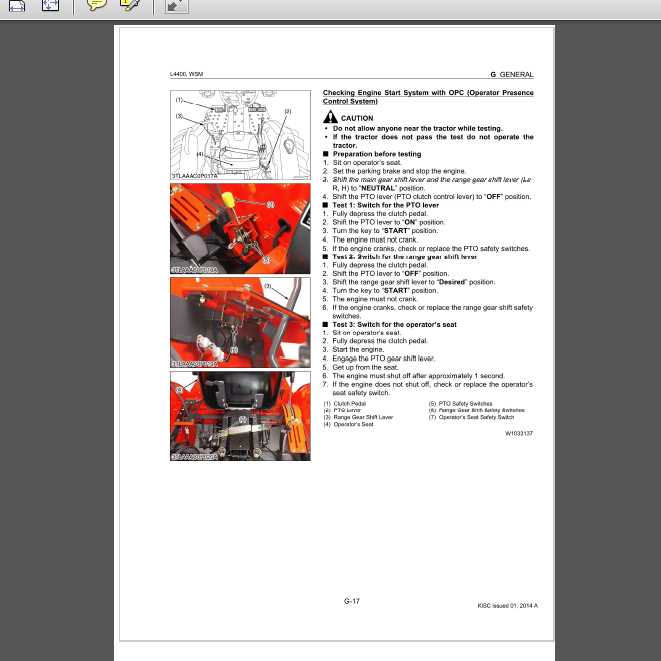

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to resolving common issues that may arise with your machinery. By following detailed guidelines, you can effectively troubleshoot and fix various problems, ensuring optimal performance and longevity.

1. Diagnosis: Begin by identifying the specific issue. Observe the symptoms and note any unusual sounds or behaviors. Utilize diagnostic tools if necessary to pinpoint the problem accurately.

2. Preparation: Gather all essential tools and replacement parts before starting the procedure. Ensure your workspace is organized and safe to facilitate an efficient workflow.

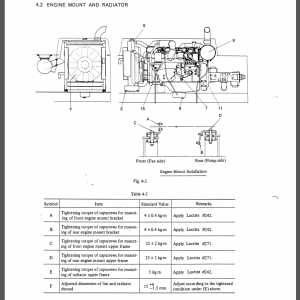

3. Disassembly: Carefully disassemble the relevant components. Follow the sequence outlined in your guidance documentation to avoid confusion. Keep track of all fasteners and parts to ensure smooth reassembly.

4. Inspection: Thoroughly examine each part for wear and damage. Look for cracks, corrosion, or any signs of failure. Take notes on any components that require replacement or repair.

5. Repair or Replacement: Address any issues identified during the inspection. Repair minor damage or replace faulty components as necessary, ensuring that all replacements meet the specified standards.

6. Reassembly: Carefully reassemble the machinery in reverse order of disassembly. Ensure that all connections are secure and that parts are aligned correctly to prevent future issues.

7. Testing: After reassembly, conduct thorough testing to verify that the issue has been resolved. Monitor the performance closely and listen for any unusual sounds during operation.

By adhering to these structured procedures, you can effectively manage and resolve common challenges, leading to enhanced functionality and extended service life of your equipment.

Engine Troubleshooting Techniques

Identifying and resolving issues in a power unit is crucial for maintaining optimal performance. This section outlines essential methods to diagnose problems effectively, ensuring that the engine operates smoothly and efficiently.

- Visual Inspection: Begin with a thorough examination of the engine components. Look for signs of wear, leaks, or loose connections that may indicate potential issues.

- Listen for Unusual Noises: Pay attention to any abnormal sounds during operation. Knocking, grinding, or hissing can signal underlying mechanical problems.

- Check Fluid Levels: Regularly monitor oil, coolant, and fuel levels. Low or contaminated fluids can lead to significant performance issues.

- Use Diagnostic Tools: Implement diagnostic equipment to retrieve error codes and assess engine performance metrics. These tools can provide valuable insights into specific malfunctions.

By applying these techniques systematically, operators can effectively pinpoint issues and implement appropriate solutions, prolonging the lifespan of the machinery.

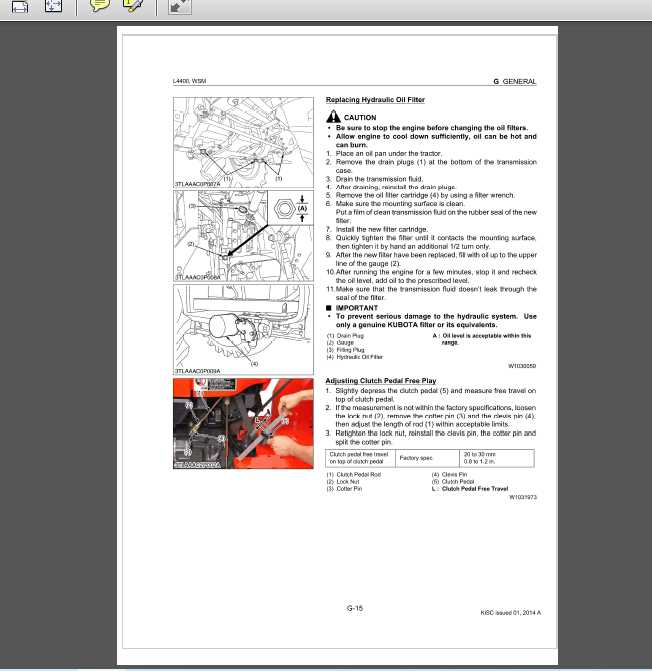

Hydraulic System Maintenance

Regular upkeep of the hydraulic system is essential for ensuring optimal performance and longevity of the machinery. This involves a series of tasks aimed at maintaining fluid integrity, checking for leaks, and ensuring all components operate smoothly. Proper maintenance not only enhances efficiency but also prevents costly repairs in the long run.

Start by regularly inspecting the hydraulic fluid level and quality. It is crucial to keep the fluid clean and free from contaminants, as dirty fluid can lead to component wear and system failures. Replace the hydraulic fluid as recommended by the manufacturer to maintain system integrity.

Next, examine the hoses and fittings for signs of wear or damage. Look for cracks, leaks, or bulges that could indicate a potential failure. Replacing damaged hoses promptly is vital to avoid system malfunctions. Additionally, check all connections to ensure they are tight and secure.

It is also important to inspect the hydraulic filters regularly. Clogged filters can restrict fluid flow and lead to overheating or other performance issues. Clean or replace filters according to the maintenance schedule to ensure the system operates efficiently.

Finally, regularly testing the hydraulic system’s pressure is essential. Monitoring pressure levels can help identify any irregularities or potential issues early, allowing for timely intervention. Maintaining the hydraulic system through these practices will promote reliability and extend the lifespan of the equipment.

Transmission Issues and Solutions

The transmission system is crucial for the smooth operation of any agricultural machine. Various challenges can arise that hinder performance, leading to decreased efficiency. Identifying these issues promptly can prevent further complications and costly repairs.

Common Problems

- Slipping Gears: A frequent issue where the vehicle unexpectedly changes gears.

- Unresponsive Shifting: Difficulty in changing gears, which can lead to operational delays.

- Fluid Leaks: Visible drips or puddles under the machine indicating potential fluid loss.

- Overheating: Excessive heat can damage components and lead to malfunction.

Recommended Solutions

- Regular Maintenance: Schedule routine inspections to check for wear and tear.

- Fluid Checks: Monitor transmission fluid levels and quality to ensure proper function.

- Adjust Linkages: Ensure that shift linkages are properly adjusted for accurate gear selection.

- Consult Professionals: If problems persist, seek assistance from qualified technicians to diagnose and resolve issues.

Electrical System Diagnostics

Effective analysis of the electrical framework in agricultural machinery is crucial for ensuring optimal performance and preventing operational failures. This section outlines key methods for evaluating the electrical components, focusing on systematic troubleshooting techniques.

To accurately diagnose issues, it is important to understand the various elements involved in the electrical system. Regular checks can help identify irregularities before they escalate into significant problems. Here are some common diagnostic procedures:

| Component | Diagnostic Method | Expected Result |

|---|---|---|

| Battery | Check voltage levels using a multimeter | 12.6V or higher indicates a fully charged battery |

| Wiring | Inspect for corrosion or wear | All connections should be secure and free from damage |

| Fuses | Examine for continuity with a multimeter | Functional fuses will show no breaks in the filament |

| Alternator | Measure output voltage under load | Should be between 13.5V and 14.5V when operational |

Utilizing these methods will assist in maintaining the reliability of the electrical system, ultimately enhancing the longevity and efficiency of the equipment.

Preventive Measures for Longevity

Ensuring the extended lifespan of machinery involves implementing a series of proactive strategies. These practices not only enhance performance but also minimize the risk of breakdowns and costly repairs. By adhering to simple yet effective measures, users can significantly prolong the operational life of their equipment.

- Regular Inspections: Conduct periodic checks to identify any signs of wear and tear.

- Routine Maintenance: Follow a consistent maintenance schedule, including oil changes and filter replacements.

- Proper Storage: Store equipment in a dry, sheltered location to protect it from environmental damage.

- Cleanliness: Keep all parts free from dirt and debris to prevent contamination and enhance functionality.

- Training: Ensure that operators are well-trained in the correct use and handling of the equipment.

By integrating these preventive measures into regular practices, users can enjoy a more reliable and efficient performance from their machinery, ultimately leading to reduced downtime and enhanced productivity.

Finding Replacement Parts Easily

Locating suitable components for machinery can be a straightforward process if approached methodically. Understanding where to search and how to identify necessary items is key to maintaining equipment efficiently.

Here are several effective strategies for sourcing parts:

- Check local dealerships that specialize in machinery; they often have a range of items in stock.

- Utilize online retailers that focus on agricultural equipment; they provide detailed catalogs for easy browsing.

- Visit salvage yards or surplus stores; these places may have used components at a fraction of the cost.

When searching, ensure to have the model number and specifications on hand to facilitate the process.

In addition to these options, consider joining forums or groups dedicated to equipment enthusiasts. Members often share tips on where to find rare or hard-to-source parts.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Adhering to proper guidelines not only protects the individual performing the work but also extends the life of the equipment. This section outlines essential safety measures that should be followed while conducting any servicing activities.

Before commencing work, it is vital to assess the work area and equip oneself with appropriate protective gear. The following table summarizes key safety measures:

| Safety Measure | Description |

|---|---|

| Wear Personal Protective Equipment (PPE) | Always use gloves, goggles, and helmets to shield against potential hazards. |

| Ensure Proper Ventilation | Work in well-ventilated spaces to avoid inhaling harmful fumes and gases. |

| Disconnect Power Sources | Before beginning any work, make sure to turn off and disconnect all power sources to prevent accidental starts. |

| Use Tools Correctly | Employ tools as intended and ensure they are in good condition to avoid malfunctions. |

| Keep Workspace Organized | Maintain a tidy work area to minimize the risk of tripping and other accidents. |

By following these essential precautions, individuals can significantly reduce the likelihood of accidents and ensure a safer working environment during any maintenance operations.