Owning a robust automobile brings immense joy and utility, but it also requires a commitment to upkeep. Understanding how to manage and address common issues can significantly enhance the longevity and performance of your vehicle. This section aims to provide essential insights into maintenance practices and troubleshooting techniques.

Essential knowledge is paramount for any car enthusiast or everyday driver looking to ensure their vehicle remains in optimal condition. Familiarity with key components, systems, and potential problems can empower owners to tackle minor repairs and recognize when professional help is needed.

Furthermore, having access to a detailed resource can serve as the ultimate guide in navigating the intricacies of vehicle care. By delving into specific processes, this article will equip readers with practical skills and confidence in managing their automobile’s health.

Essential Maintenance Tips for Your Cruiser

Regular upkeep is vital to ensure the longevity and performance of your vehicle. By following some key practices, you can maintain its efficiency and reliability over time. This section highlights essential tips to keep your ride in top shape.

Routine Inspections

Conducting frequent checks on critical components is crucial. Focus on the following:

- Fluids: Regularly check oil, coolant, brake fluid, and transmission fluid levels.

- Tires: Monitor tire pressure and tread depth to enhance safety and fuel efficiency.

- Brakes: Inspect brake pads and rotors for wear to ensure optimal stopping power.

Scheduled Servicing

Adhering to a consistent servicing schedule can prevent major issues. Consider the following:

- Oil Changes: Change engine oil and filter every 3,000 to 5,000 miles, depending on usage.

- Air Filters: Replace air filters every 15,000 to 30,000 miles to improve engine performance.

- Belt and Hose Checks: Inspect and replace belts and hoses as needed to avoid breakdowns.

By implementing these essential practices, you can ensure your vehicle remains dependable and ready for any adventure.

Common Issues with the 1996 Model

The vehicle from this era is known for its durability and performance, yet like any machinery, it has its share of challenges. Owners often report specific concerns that can arise with age and wear, impacting overall functionality and driving experience. Understanding these common problems can help in maintaining optimal condition and ensuring longevity.

Engine Performance

One frequent issue relates to engine efficiency. Many users experience symptoms such as rough idling, decreased power, or unusual noises. These may be attributed to worn spark plugs, fuel injectors, or air filters. Regular maintenance and timely replacements can alleviate these concerns, enhancing the vehicle’s performance.

Transmission Troubles

Transmission problems can also surface, often characterized by slipping gears or difficulty in shifting. These symptoms might indicate low fluid levels or a need for a complete fluid change. It’s crucial to address these signs promptly, as neglect can lead to more severe damage and costly repairs.

In conclusion, while this model boasts reliability, being aware of its potential pitfalls can empower owners to take proactive measures. Regular inspections and maintenance routines are key to ensuring a smooth and enjoyable driving experience.

Step-by-Step Repair Procedures Explained

This section delves into the structured methodologies essential for conducting maintenance and troubleshooting on your vehicle. Clear and concise guidelines will enable you to navigate through various tasks effectively, ensuring that every procedure is completed with precision. By following systematic steps, you can minimize errors and enhance the overall performance of your automobile.

Below is a detailed breakdown of the fundamental processes involved in vehicle maintenance:

| Procedure | Description | Tools Required |

|---|---|---|

| Inspection | Conduct a thorough examination of all critical components to identify any signs of wear or damage. | Flashlight, Inspection mirror |

| Fluid Checks | Ensure all fluids, including oil, coolant, and brake fluid, are at appropriate levels and free of contaminants. | Dipstick, Funnel |

| Filter Replacement | Replace air and oil filters to maintain optimal engine performance and efficiency. | Wrench set, Oil catch pan |

| Brake Maintenance | Inspect and replace brake pads and rotors as necessary to ensure safety during operation. | Jack, Jack stands, Brake tool kit |

| Tire Rotation | Rotate tires to promote even wear and extend their lifespan. | Tire iron, Torque wrench |

Adhering to these procedures will not only extend the longevity of your vehicle but also enhance your overall driving experience. Each task, when executed properly, contributes to a well-maintained machine ready to tackle any road ahead.

Tools Needed for Efficient Repairs

Having the right equipment at your disposal is crucial for achieving effective maintenance and troubleshooting. Whether tackling minor adjustments or more extensive projects, the proper tools can streamline the process, enhance precision, and ultimately lead to successful outcomes. Below are essential implements that every enthusiast should consider for their toolkit.

Basic Hand Tools

- Wrenches: A variety of sizes for different bolts.

- Screwdrivers: Both flathead and Phillips for versatile use.

- Pliers: For gripping and twisting tasks.

- Socket Set: Ideal for working with fasteners in tight spaces.

Specialized Equipment

- Torque Wrench: Ensures bolts are tightened to manufacturer specifications.

- Jack and Stands: Necessary for lifting and supporting the vehicle safely.

- Multimeter: Useful for diagnosing electrical issues.

- Diagnostic Scanner: Helps in identifying trouble codes for electronic systems.

Equipping your workspace with these essential tools not only facilitates smoother workflows but also fosters confidence in handling various tasks effectively.

Understanding the Engine Specifications

Grasping the intricacies of an automotive power unit is essential for both enthusiasts and professionals. Knowledge of the various components and their performance metrics can significantly enhance maintenance practices and troubleshooting efforts. This section delves into the essential characteristics that define the engine’s functionality and efficiency.

Key Performance Metrics

The performance of a vehicle’s engine is often evaluated based on several critical parameters. These metrics help in understanding the overall capability and reliability of the engine. Below are the primary specifications to consider:

| Specification | Value |

|---|---|

| Cylinder Configuration | V6 |

| Displacement | 4.5 L |

| Horsepower | 215 hp |

| Torque | 300 lb-ft |

| Fuel System | Multi-Point Fuel Injection |

| Compression Ratio | 9.5:1 |

Understanding Fuel Efficiency

Another crucial aspect of engine specifications is fuel efficiency, which directly impacts operational costs and environmental footprint. The balance between power output and fuel consumption is vital for optimal performance. Knowing the estimated miles per gallon can assist owners in making informed decisions about usage and maintenance strategies.

Electrical System Troubleshooting Guide

The electrical system in a vehicle is vital for its overall functionality and performance. Proper diagnosis of issues can save time and reduce repair costs. This section outlines key strategies for identifying and resolving common electrical problems that may arise.

Step 1: Initial Inspection

Begin by conducting a thorough visual examination of the wiring harnesses, connectors, and fuses. Look for signs of wear, corrosion, or loose connections that may lead to intermittent failures.

Step 2: Battery Check

Ensure the battery is fully charged and in good condition. A weak or dead battery can cause numerous electrical faults. Use a multimeter to measure the voltage; a reading below 12.4 volts indicates a need for charging or replacement.

Step 3: Fuse Assessment

Inspect all fuses related to the electrical components in question. Replace any blown fuses with the appropriate amperage rating. Consult the vehicle’s documentation for fuse location and specifications.

Step 4: Component Testing

For specific components like lights, starter motors, or sensors, utilize a multimeter to test for continuity and proper voltage levels. Ensure each part receives the correct electrical supply as per its design requirements.

Step 5: Wiring Integrity

Trace the wiring from the battery to the components, checking for any damage or shorts. Repair or replace any faulty wiring to ensure a reliable connection throughout the system.

Step 6: Consult Diagnostic Tools

If issues persist, consider using specialized diagnostic tools such as scanners or oscilloscopes. These devices can provide deeper insights into the electrical system’s performance and help pinpoint complex issues.

By following these systematic steps, troubleshooting electrical issues can become more manageable, leading to efficient resolutions and improved vehicle reliability.

Best Practices for Brake System Care

Ensuring the optimal performance of a vehicle’s braking mechanism is crucial for safety and longevity. Regular maintenance and attention to specific components can significantly enhance the reliability of the entire system. Following best practices not only prolongs the life of the brakes but also provides a smoother and more secure driving experience.

Regular Inspection

Frequent checks of the braking system are essential. Look for wear signs, leaks, and unusual noises. Catching issues early can prevent costly repairs and ensure a safer ride.

Proper Fluid Maintenance

The hydraulic fluid plays a vital role in brake function. Regularly check the fluid level and quality, replacing it as necessary. Contaminated fluid can lead to brake failure, making timely changes essential.

| Component | Inspection Frequency | Notes |

|---|---|---|

| Brake Pads | Every 6,000 miles | Replace if worn down to 1/8 inch |

| Brake Rotors | Every 12,000 miles | Check for scoring and warping |

| Brake Lines | Annually | Look for cracks and leaks |

| Brake Fluid | Every 2 years | Change if contaminated or discolored |

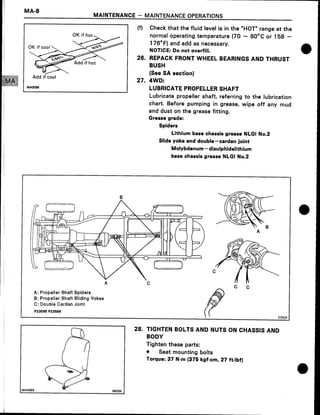

Transmission and Drivetrain Insights

This section delves into the intricacies of the power transfer mechanisms and their vital role in vehicle performance. Understanding these components is essential for maintaining optimal functionality and ensuring a smooth driving experience. Proper care and knowledge about the elements involved can greatly enhance longevity and reliability.

Understanding Gear Systems

At the heart of the drivetrain are the gear systems, responsible for regulating power distribution from the engine to the wheels. These systems can be automatic or manual, each with its own advantages. Automatic transmissions offer ease of use and convenience, while manual options provide greater driver control and engagement. Regular maintenance of these systems is crucial, as fluid changes and component inspections can prevent potential failures.

Transfer Case Functionality

The transfer case plays a pivotal role in managing power distribution between different axles, especially in four-wheel-drive setups. It enables smooth transitions between driving modes, ensuring that traction is optimized based on road conditions. Understanding the signs of wear or malfunction in this component is essential for maintaining performance and safety. Regular checks and fluid assessments can help in early detection of issues, thereby prolonging the lifespan of the drivetrain.

Preventative Measures for Longevity

Ensuring the durability and optimal performance of your vehicle requires a proactive approach. Regular maintenance and careful attention to various components can significantly extend the lifespan and efficiency of the machinery. By adopting specific practices, owners can mitigate potential issues before they escalate, saving both time and resources in the long run.

Routine Inspections: Conducting frequent assessments of critical systems, such as the engine, transmission, and brakes, is essential. Look for signs of wear and tear, and address any irregularities promptly to prevent major failures.

Fluid Changes: Keeping all fluids, including oil, coolant, and transmission fluid, at optimal levels is vital. Regularly replacing these fluids according to the manufacturer’s recommendations can help maintain performance and prevent corrosion.

Tire Care: Maintaining proper tire pressure and regularly rotating tires can enhance traction and extend their life. Also, inspect the tread depth to ensure safety and efficiency.

Battery Maintenance: A well-maintained battery is crucial for reliable starts. Clean terminals and check the charge level periodically to avoid unexpected breakdowns.

Driving Habits: Adopting smooth driving techniques, such as gentle acceleration and braking, can reduce stress on the vehicle’s components. Avoiding sudden stops and excessive speeds can contribute to a longer lifespan.

Incorporating these preventative measures into your routine will not only enhance the reliability of your vehicle but also improve overall satisfaction with its performance.

Aftermarket Parts: What to Consider

When enhancing or maintaining your vehicle, selecting the right components can significantly influence performance, durability, and overall driving experience. Aftermarket options present a vast array of choices, but not all are created equal. Understanding the key factors involved in this decision-making process is crucial for ensuring optimal functionality and longevity.

Quality and Compatibility

Prioritize the quality of aftermarket components. Research reputable manufacturers known for their reliability and durability. Additionally, ensure that the parts are compatible with your specific model; mismatched components can lead to inefficiencies or damage.

Cost vs. Value

While it may be tempting to opt for cheaper alternatives, consider the long-term value over initial savings. Investing in high-quality parts often results in better performance and reduced maintenance costs, making them a more economical choice over time.