Ensuring the longevity and optimal performance of a vehicle requires a thorough understanding of its components and systems. This section offers insights into essential practices and techniques that every owner should be aware of when it comes to their automobile. By familiarizing oneself with various aspects of maintenance, drivers can enhance their driving experience and avoid unnecessary issues.

Understanding your vehicle is crucial for tackling common challenges that arise during ownership. From regular checks to troubleshooting minor problems, having access to detailed information can make a significant difference. This resource aims to provide valuable guidance, enabling individuals to navigate their vehicle’s intricacies with confidence.

Additionally, learning about the specific features and functions of your automobile can lead to more informed decisions regarding care and upgrades. Whether addressing wear and tear or enhancing performance, this guide serves as a vital tool for those looking to maximize their vehicle’s potential.

Comprehensive Guide for Tacoma Owners

This section offers valuable insights for individuals who own a versatile compact vehicle, emphasizing maintenance, troubleshooting, and enhancing performance. Understanding the intricacies of your vehicle can lead to a more satisfying ownership experience.

To ensure longevity and reliability, consider the following essential aspects:

- Regular Maintenance: Schedule routine checks to monitor fluid levels, tire pressure, and brake condition.

- Performance Enhancements: Explore upgrades such as improved exhaust systems or air filters for better efficiency.

- Common Issues: Familiarize yourself with typical problems that may arise, such as electrical issues or suspension wear.

By staying informed and proactive, you can keep your vehicle in optimal condition, ensuring that it serves you well for years to come.

Understanding Your Vehicle’s Specifications

Grasping the intricacies of your automobile’s specifications is essential for optimizing its performance and ensuring longevity. These details encompass various aspects, from engine capabilities to dimensions, contributing to the overall functionality and efficiency of the vehicle.

Key Components to Consider

Focusing on critical elements such as engine type, horsepower, and torque ratings can provide insight into how your vehicle performs under different conditions. Additionally, understanding the drivetrain layout and suspension system plays a significant role in handling and ride comfort.

The Importance of Maintenance

Regular upkeep based on the manufacturer’s recommendations helps maintain the integrity of these specifications. Following the guidelines ensures that your vehicle operates at peak performance, enhancing both safety and driving experience.

Common Issues with the 1998 Model

Throughout its years of service, this particular vehicle has been known to present several challenges that owners often encounter. Understanding these typical problems can help in maintaining performance and ensuring longevity.

Engine Performance Problems often arise, including issues related to rough idling or stalling. These symptoms can be linked to various factors such as fuel delivery or ignition system failures.

Transmission Difficulties are also frequently reported. Drivers may experience hesitations during shifts or slipping sensations, indicating potential issues with the transmission fluid or internal components.

Suspension and Steering Concerns might manifest as uneven tire wear or difficulty in handling. Regular inspections of the suspension components can prevent further complications.

Electrical System Malfunctions can lead to a variety of inconveniences, from flickering lights to battery drainage. Routine checks of the wiring and connections can mitigate these problems.

Essential Tools for Repairs

When embarking on maintenance tasks, having the right equipment is crucial for efficiency and effectiveness. A well-equipped workspace not only enhances the quality of work but also ensures safety and convenience during various procedures.

Below is a list of fundamental instruments that are beneficial for anyone undertaking vehicle maintenance:

- Socket Set: A comprehensive socket set is vital for loosening and tightening bolts of different sizes.

- Wrenches: Both open-end and adjustable wrenches provide versatility for various fasteners.

- Screwdrivers: A selection of flathead and Phillips screwdrivers is essential for accessing and securing components.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, bending, and cutting tasks.

- Jack and Jack Stands: These tools are necessary for lifting the vehicle safely for undercarriage work.

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

Equipping yourself with these basic tools will significantly enhance your ability to perform various maintenance and service tasks with confidence and precision.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. Following a structured approach to maintenance tasks not only enhances safety but also improves efficiency and reliability. Below are detailed steps for common procedures to keep your vehicle in excellent condition.

Routine Checks

- Inspect fluid levels including oil, coolant, and brake fluid.

- Examine tire pressure and tread depth regularly.

- Check the condition of belts and hoses for wear or damage.

Scheduled Maintenance Tasks

- Oil Change: Replace the engine oil and filter every 3,000 to 5,000 miles.

- Brake Inspection: Evaluate brake pads and discs for signs of wear during each service.

- Battery Maintenance: Clean terminals and check for corrosion; ensure secure connections.

Engine Troubleshooting Techniques

Effective diagnostics are essential for maintaining optimal performance and longevity of an automobile’s powertrain. Understanding common issues and their symptoms allows for timely interventions, which can prevent more significant complications down the line.

Identifying Symptoms

Recognizing unusual sounds, vibrations, or performance changes is the first step in addressing engine concerns. These signs often indicate underlying problems, ranging from minor adjustments to serious mechanical failures. Regular monitoring can aid in early detection.

Diagnostic Tools and Methods

Utilizing diagnostic equipment, such as OBD-II scanners, can provide valuable insights into the engine’s functioning. These tools help pinpoint error codes that correspond to specific issues. Additionally, visual inspections and physical tests, such as compression checks, are critical for a comprehensive assessment.

Transmission Care and Solutions

Maintaining the functionality of a vehicle’s transmission is essential for optimal performance and longevity. Regular care can prevent common issues, ensuring smooth operation and enhancing overall driving experience.

Routine Maintenance Practices

Consistent upkeep of the transmission system involves various practices that contribute to its health. Checking fluid levels and quality is crucial, as proper lubrication minimizes wear and tear. Additionally, regular inspections can identify potential leaks and other abnormalities early on.

Troubleshooting Common Issues

When transmission problems arise, prompt action is necessary to mitigate damage. Some frequent symptoms include slipping gears, delayed engagement, or unusual noises. Diagnosing these issues quickly can lead to effective solutions and prevent extensive repairs.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Slipping gears | Low fluid level or contamination | Check and replace fluid as needed |

| Delayed engagement | Worn clutch or faulty solenoid | Inspect components and replace if necessary |

| Unusual noises | Internal wear or damage | Consult a professional for evaluation |

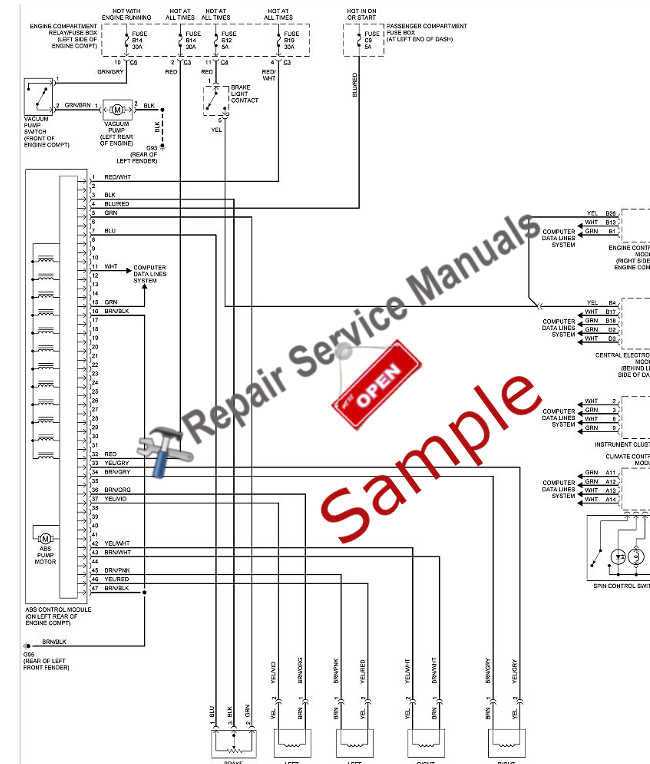

Electrical System Diagnostics

Understanding the intricacies of an automotive electrical system is essential for effective troubleshooting. This section aims to explore various diagnostic techniques and tools that can aid in identifying and resolving issues within the circuitry.

To begin with, it is crucial to familiarize oneself with the components involved in the electrical system. A systematic approach helps in pinpointing the root cause of any malfunction.

| Component | Common Issues | Diagnostic Tools |

|---|---|---|

| Battery | Weak charge, corrosion | Multimeter, Load tester |

| Alternator | Overcharging, undercharging | Voltmeter, Oscilloscope |

| Starter | Non-start, clicking sound | Test light, Relay tester |

| Wiring | Fraying, shorts | Wiring diagram, Continuity tester |

Employing the right tools and understanding the common problems associated with each component can significantly streamline the diagnostic process. Thorough checks and careful analysis will ensure optimal performance of the vehicle’s electrical functions.

Suspension and Steering Components

The effective functioning of a vehicle relies significantly on its suspension and steering systems. These components play a crucial role in ensuring stability, control, and comfort while driving. Understanding their design and maintenance can greatly enhance performance and safety on the road.

Overview of Suspension Parts

The suspension system comprises various elements that work together to absorb shocks and maintain tire contact with the road surface. Key components include springs, shock absorbers, and control arms, each contributing to the overall ride quality and handling characteristics. Regular inspections and timely replacements of worn parts are essential to preserve optimal performance.

Steering Mechanism Insights

The steering system enables drivers to maneuver the vehicle with precision. It includes elements such as the steering wheel, column, and linkage. Proper alignment and functionality of these parts are vital for responsive handling and safety. Addressing any issues promptly can prevent further complications and ensure a smooth driving experience.

Braking System Maintenance Tips

Ensuring the longevity and efficiency of your vehicle’s stopping mechanisms is crucial for safe driving. Regular upkeep can help prevent issues that may compromise performance and safety. Below are some essential practices to keep in mind.

Regular Inspections are vital. Frequently check brake pads and rotors for wear and tear. Look for any unusual sounds or vibrations during braking, which may indicate a need for attention.

Fluid Levels should be monitored consistently. Maintaining the proper hydraulic fluid level ensures optimal functioning. If you notice any leaks, address them immediately to avoid further complications.

Brake Pad Replacement is necessary when they become too thin. Ignoring this can lead to damage to the rotors and other components, resulting in costly repairs.

Cleaning Components helps prevent debris buildup that can hinder performance. Regularly clean the calipers and other parts to ensure smooth operation.

By following these maintenance tips, you can enhance the reliability of your vehicle’s braking system and promote safer driving experiences.

Fluid Change Recommendations

Maintaining optimal performance of a vehicle requires regular attention to various fluids essential for its operation. Proper fluid management not only enhances the lifespan of components but also ensures safety and efficiency. Understanding when and how to replace these vital substances is key to effective vehicle upkeep.

For engine oil, it is advisable to change it approximately every 5,000 to 7,500 miles, depending on driving conditions. Using high-quality oil that meets specifications can significantly improve engine longevity.

Transmission fluid should also be monitored regularly, with changes recommended every 30,000 to 60,000 miles. This interval helps maintain smooth shifting and reduces wear on transmission components.

Coolant replacement is crucial for preventing overheating and corrosion within the cooling system. A typical guideline suggests replacing coolant every two to three years, but checking levels and condition annually is wise.

Brake fluid must not be overlooked, as it can absorb moisture over time, compromising braking efficiency. It is generally recommended to change brake fluid every two years to ensure responsive braking performance.

Lastly, differential fluid changes should be considered every 30,000 to 50,000 miles. This maintenance helps protect gear systems from wear and ensures smooth operation.

Aftermarket Parts and Upgrades

Exploring alternatives and enhancements for vehicles can significantly elevate performance and aesthetics. Aftermarket components provide enthusiasts with opportunities to personalize their rides, improve functionality, and achieve specific goals, whether it’s enhanced power, better handling, or visual appeal.

Upgrading key elements such as suspension systems, exhausts, and intake systems can lead to noticeable improvements in driving experience. Additionally, aesthetic modifications like custom wheels and lighting can transform the overall look, reflecting individual style. Selecting the right parts and ensuring compatibility with existing systems is crucial for optimal results.

Moreover, the aftermarket industry offers a wealth of options, from high-performance brands to budget-friendly solutions. Researching reputable suppliers and reading reviews can guide choices, ensuring reliable enhancements that meet expectations. Engaging with fellow enthusiasts through forums or local clubs can also provide valuable insights and recommendations.

Safety Precautions During Repairs

Ensuring a secure environment is essential when performing maintenance tasks on vehicles. By adhering to specific guidelines, individuals can minimize risks and enhance safety while working. Awareness of potential hazards is crucial for a successful and injury-free experience.

Personal Protective Equipment (PPE) is vital when engaging in any maintenance activity. This includes wearing gloves, safety goggles, and durable footwear to protect against potential injuries. Using the right gear not only safeguards the individual but also promotes a focused work atmosphere.

Proper Ventilation is equally important. When working in enclosed spaces, ensuring adequate airflow can prevent the buildup of harmful fumes or gases. Opening doors and windows or utilizing exhaust fans can significantly improve air quality and reduce health risks.

Tool Management plays a significant role in maintaining safety. Keeping tools organized and in good condition helps prevent accidents. Regularly inspecting equipment ensures they function correctly and reduces the likelihood of malfunctions during tasks.

Lastly, being aware of one’s surroundings is essential. Keeping the workspace tidy and free from clutter allows for easier movement and reduces the chances of accidents. By following these guidelines, individuals can create a safer environment while undertaking vehicle maintenance.