Understanding the intricacies of engine maintenance and repair is essential for any mechanic or enthusiast. This section delves into the various procedures and best practices for ensuring optimal performance of heavy-duty engines. By exploring detailed techniques and troubleshooting methods, readers will gain valuable insights into enhancing engine reliability and longevity.

Through a systematic approach, individuals can familiarize themselves with essential components, common issues, and effective solutions. Whether you are a seasoned professional or a novice, the information presented here will serve as a vital resource for enhancing your knowledge and skills in engine care.

Effective maintenance not only prolongs the lifespan of an engine but also improves fuel efficiency and reduces operational costs. By applying the strategies outlined in this guide, users can confidently tackle various challenges, ensuring their machinery operates at peak performance.

This section delves into the essential characteristics of a specific diesel power unit, renowned for its robustness and efficiency. Understanding these features is crucial for anyone seeking to maximize performance and maintain longevity. This overview will cover various aspects, from structural components to operational capabilities, highlighting what sets this engine apart in the field of heavy machinery.

Key Components of the Engine

The engine comprises several vital elements that contribute to its functionality and reliability. Each component plays a significant role in ensuring optimal performance under varying conditions.

| Component | Description |

|---|---|

| Cylinder Block | The main body housing the cylinders and supporting various engine parts. |

| Crankshaft | Converts linear motion from the pistons into rotational motion. |

| Fuel System | Manages the delivery and injection of fuel into the combustion chamber. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

Operational Advantages

This power unit is designed to deliver impressive torque and horsepower, making it suitable for various applications. Its fuel efficiency and durability make it a preferred choice for many operators. Additionally, the engine’s ability to perform well in challenging environments enhances its appeal.

Common Issues in 4BT Engines

Engines of this type often encounter various challenges that can impact their performance and longevity. Understanding these common issues is crucial for maintaining optimal operation and preventing more significant problems in the future.

Overheating is one of the frequent concerns. This can stem from inadequate cooling system maintenance, such as low coolant levels or a malfunctioning thermostat. Regular checks of the cooling system components can help prevent this issue.

Another prevalent problem is fuel injector failure. When injectors become clogged or worn out, they can lead to poor fuel atomization, resulting in reduced engine efficiency and increased emissions. Keeping the fuel system clean and using quality fuel can mitigate this risk.

Oil leaks are also a common sight. These can originate from various points, including gaskets and seals. Regular inspections and timely replacements of worn components can help maintain oil integrity and engine health.

Lastly, starting difficulties may arise, often related to issues with the battery or starter motor. Ensuring that these electrical components are in good condition can significantly enhance reliability during start-up.

Essential Tools for Repairs

When working on engine maintenance and restoration, having the right equipment is crucial for achieving effective results. A well-equipped toolkit can make a significant difference in the efficiency and quality of the work performed.

- Wrenches: Various sizes of wrenches are essential for loosening and tightening bolts and nuts.

- Screwdrivers: A set of screwdrivers, including both flathead and Phillips, is necessary for different types of fasteners.

- Socket Set: A comprehensive socket set allows for easy access to hard-to-reach bolts, making assembly and disassembly smoother.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-torquing.

In addition to these basics, consider including specialized tools tailored to specific tasks.

- Pliers: Useful for gripping and manipulating components during work.

- Oil Filter Wrench: Aids in removing stubborn oil filters.

- Compression Tester: Important for checking the health of the engine’s cylinders.

- Multimeter: Essential for diagnosing electrical issues within the system.

Investing in quality tools not only improves the ease of work but also enhances the longevity of the equipment being serviced.

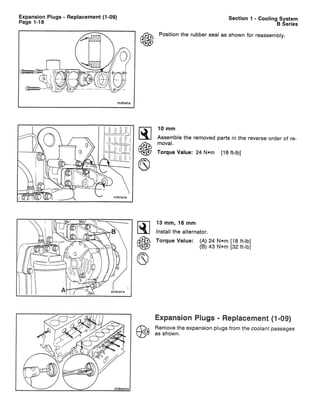

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your engine. Following a systematic approach not only enhances efficiency but also helps in identifying potential issues before they escalate. This section outlines the fundamental steps necessary for effective maintenance.

1. Initial Inspection: Begin with a thorough visual examination of the engine components. Check for any signs of leaks, unusual wear, or corrosion. Ensure all connections are secure and that there are no loose parts.

2. Fluid Checks: Regularly monitor fluid levels, including oil, coolant, and fuel. Maintain the appropriate levels as specified in the specifications. Replace fluids that appear dirty or contaminated.

3. Filter Replacement: Change the oil and air filters at regular intervals to ensure optimal airflow and lubrication. Dirty filters can lead to decreased performance and increased wear on the engine components.

4. Belt and Hose Inspection: Examine belts for cracks, fraying, or excessive wear. Inspect hoses for signs of swelling or leaks. Replace any components that show signs of damage.

5. Electrical System Check: Test the battery and electrical connections for proper function. Clean terminals to prevent corrosion and ensure reliable starts.

6. Performance Testing: After completing the maintenance procedures, conduct a performance test to verify that the engine operates smoothly. Monitor for any unusual noises or vibrations during operation.

Implementing these procedures regularly will help maintain the efficiency and reliability of your engine, ensuring it continues to perform at its best.

Diagnosing Engine Performance Problems

Identifying issues related to engine efficiency is crucial for maintaining optimal functionality. Various factors can affect performance, ranging from mechanical wear to improper fuel delivery. Understanding the symptoms and conducting thorough evaluations are essential steps in resolving these challenges.

Common Symptoms of Performance Issues

Engines may exhibit a range of symptoms indicating performance problems. Common signs include irregular acceleration, reduced power output, or unusual noises. Observing these indicators can help pinpoint underlying issues that require attention. In many cases, visual inspections and diagnostic tools can provide valuable insights into the root causes of these symptoms.

Diagnostic Steps and Tools

Effective diagnosis often involves a systematic approach. Start by checking the fuel system, as poor fuel quality or delivery issues can significantly impact performance. Utilize diagnostic equipment to monitor engine parameters and detect anomalies. Regular maintenance and timely interventions can prevent minor issues from escalating into major repairs, ensuring long-term reliability.

Replacing Key Engine Components

Maintaining the functionality of vital engine parts is essential for optimal performance and longevity. This section outlines the process and considerations involved in replacing critical components to ensure reliable operation.

Essential Parts to Consider

- Pistons

- Crankshaft

- Timing belt

- Oil pump

Steps for Component Replacement

- Assess the condition of the components and identify any that require replacement.

- Gather the necessary tools and replacement parts.

- Carefully disassemble the engine, taking note of the order of parts.

- Install the new components, ensuring proper alignment and fit.

- Reassemble the engine, following the manufacturer’s guidelines for torque specifications.

- Perform a thorough inspection and test run to confirm functionality.

Upgrading Your 4BT Engine

Enhancing the performance of your engine can lead to significant improvements in efficiency and power output. By implementing various modifications, you can optimize various aspects such as fuel consumption, torque, and overall responsiveness.

Engine Components play a crucial role in upgrading your system. Consider replacing the stock components with high-performance alternatives. Upgraded fuel injectors and turbochargers can greatly enhance power delivery and efficiency. Ensure that the new components are compatible with your existing setup.

Cooling Systems are essential for maintaining optimal operating temperatures. Installing a high-capacity intercooler or upgrading the radiator can prevent overheating during demanding conditions. This helps maintain performance and extends the lifespan of your engine.

Tuning and Calibration are vital steps after making hardware modifications. Adjusting the engine’s control unit can maximize the benefits of the upgrades. A proper tune can improve throttle response and fuel mapping, resulting in a smoother driving experience.

Finally, don’t overlook maintenance. Regularly inspecting and servicing upgraded components ensures that they perform at their best. Staying proactive can help avoid costly repairs and keep your engine running efficiently.

Safety Tips During Engine Repairs

When working on automotive engines, ensuring safety is paramount. Proper precautions can help prevent accidents and injuries, creating a secure environment for both the technician and the equipment. Understanding potential hazards and taking appropriate measures is essential for successful maintenance tasks.

Before starting any work, it is crucial to wear appropriate personal protective equipment, including gloves, safety goggles, and steel-toed boots. This gear can shield you from sharp edges, hot components, and harmful substances. Additionally, working in a well-ventilated area helps minimize exposure to fumes and vapors released during the process.

Always disconnect the battery before beginning any disassembly to prevent electrical shocks or short circuits. Make sure to keep tools organized and within reach to avoid unnecessary movements that could lead to accidents. Furthermore, using the correct tools for each task reduces the risk of injuries and ensures efficient work.

Lastly, it’s important to have a clear understanding of the engine’s components and systems. Familiarizing yourself with the machinery not only aids in identifying issues but also enhances safety by minimizing mistakes. Taking the time to plan your work and follow safety protocols will lead to a more effective and secure repair process.

Preventive Measures for Longevity

Ensuring the extended lifespan of an engine requires a proactive approach to maintenance and care. By implementing a series of preventive strategies, operators can enhance performance and mitigate potential issues before they arise. Regular attention to key components and systems plays a crucial role in achieving optimal reliability.

Regular Maintenance Checks

Conducting frequent inspections is essential for identifying wear and tear. Schedule routine evaluations of fluid levels, filters, and belts to ensure everything operates smoothly. Addressing minor issues promptly can prevent them from escalating into significant problems.

Quality Fuel and Lubricants

Utilizing high-grade fuel and lubricants is vital for engine health. Quality products reduce deposits and wear, promoting efficient operation. Always adhere to manufacturer recommendations regarding specifications to ensure compatibility and performance.

Resources for Further Information

This section provides valuable materials and references for those seeking in-depth knowledge and guidance related to engine maintenance and troubleshooting. By utilizing these resources, individuals can enhance their understanding and skills in handling various engine-related tasks.

Online Platforms

Numerous online platforms offer comprehensive insights, forums, and discussions related to engine services. Engaging with these communities can lead to valuable advice and shared experiences from fellow enthusiasts and professionals.

Books and Publications

A variety of books and technical publications are available that cover fundamental principles and advanced techniques for engine upkeep. These materials can serve as excellent references for both beginners and experienced users.

| Resource Type | Examples |

|---|---|

| Online Forums | Engine Forum, Auto Repair Forum |

| Technical Books | Engine Repair Basics, Advanced Engine Troubleshooting |

| Video Tutorials | YouTube Engine Maintenance Channels |