In the world of air firearms, proper upkeep is essential for ensuring optimal performance and longevity. Whether for recreational shooting or competitive events, maintaining the functionality of these devices can greatly enhance the shooting experience. Understanding the intricacies of these mechanisms allows enthusiasts to address issues effectively and keep their equipment in prime condition.

The following sections provide a comprehensive overview of common challenges faced by users and offer practical advice on troubleshooting and enhancing the reliability of air firearms. By familiarizing oneself with essential procedures and techniques, shooters can not only preserve their equipment but also improve their skills.

From routine checks to more involved adjustments, this guide aims to empower users with the knowledge needed to manage their airgun’s care. Emphasizing safety and efficiency, the insights provided here will aid in maintaining high standards of operation and enjoyment.

Guide for Maintenance and Troubleshooting

This section provides essential information on how to maintain and troubleshoot a specific air-powered device, ensuring its longevity and optimal performance. Understanding the various components and their functions will assist users in resolving common issues and performing routine upkeep effectively.

Common Issues and Solutions

Users may encounter a range of problems with their air-powered devices. Here are some frequent issues along with recommended solutions:

| Issue | Solution |

|---|---|

| Loss of pressure | Check seals and connections for wear or damage. |

| Inconsistent firing | Inspect the trigger mechanism and clean as necessary. |

| Difficulty loading | Ensure that the loading mechanism is clear of debris. |

Maintenance Tips

Regular maintenance is crucial for the efficient operation of the device. Consider the following tips:

- Clean all components regularly to prevent buildup.

- Lubricate moving parts as needed to ensure smooth operation.

- Store in a cool, dry place to avoid damage from moisture.

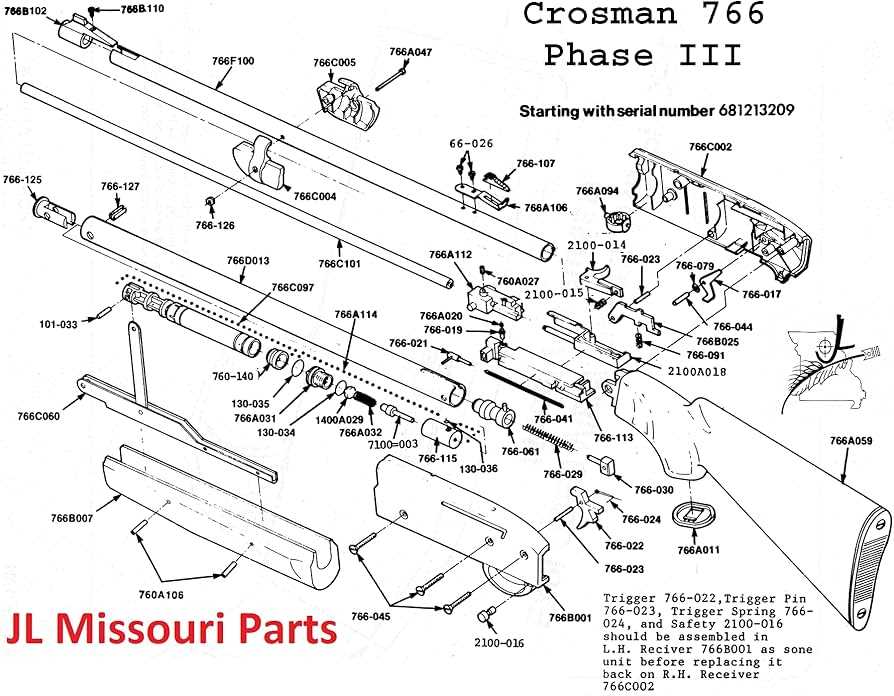

Understanding Crosman 766 Components

This section explores the various elements that make up a specific type of air gun. Each component plays a vital role in the overall function and performance of the device, and understanding these parts can enhance the user’s experience and maintenance knowledge.

Key Elements of the Air Gun

The main parts of the air gun include the barrel, action, and stock. The barrel is responsible for directing the projectile, while the action mechanism facilitates the loading and firing processes. The stock provides stability and support, allowing for better aim and control.

Importance of Each Component

Every element has a unique function that contributes to the air gun’s efficiency. For instance, a well-maintained barrel can improve accuracy, while a properly functioning action ensures reliable firing. Understanding the importance of these components enables users to perform better maintenance and troubleshoot issues effectively.

Common Issues and Symptoms

This section highlights typical problems and their corresponding indicators that users may encounter with air-powered devices. Recognizing these signs early can help prevent further complications and ensure proper functioning.

Decreased Power and Accuracy

A noticeable decline in performance can manifest as reduced power in shots or poor accuracy. This may result from various factors, including wear and tear of internal components or insufficient maintenance. Users should pay attention to the distance and precision of shots to identify if this issue arises.

Unusual Noises and Leaks

Strange sounds during operation or any signs of air escaping can indicate mechanical issues. These symptoms may suggest that seals or gaskets are damaged, leading to inefficiency. Regular inspection and timely intervention are essential to address these concerns and maintain optimal performance.

Tools Needed for Repairs

When undertaking maintenance on your equipment, having the right tools at your disposal is essential for achieving effective results. A well-equipped workspace can significantly enhance the repair process, making it smoother and more efficient.

Gathering essential instruments such as screwdrivers, wrenches, and pliers is vital. These tools allow you to easily access and adjust various components. Additionally, a quality set of replacement parts can help ensure that any damaged elements are promptly addressed, restoring functionality.

It’s also beneficial to have lubricants and cleaning supplies on hand. Regular maintenance can prevent future issues, so keeping your tools organized and your workspace clean will contribute to long-lasting performance. Proper preparation will ultimately lead to a more satisfying and effective repair experience.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to carefully dismantling your airgun. Following the correct procedures ensures that each component is accessible for maintenance or repair, facilitating a smoother reassembly process later on.

Required Tools

- Flathead screwdriver

- Phillips screwdriver

- Pliers

- Cleaning cloth

- Small container for screws

Disassembly Steps

- Ensure the airgun is unloaded and free from any ammunition.

- Use the appropriate screwdriver to remove the screws securing the stock to the main body.

- Gently pull the stock away from the body, being cautious of any attached components.

- Locate and remove any screws holding the barrel assembly in place.

- Carefully detach the barrel from the main body, taking note of any springs or seals that may be present.

- Remove additional screws that secure the trigger assembly, then extract the assembly gently.

- Inspect each component as you remove it, cleaning any dirt or debris with a cloth.

- Store all removed parts and screws in a container to avoid misplacement during the process.

Identifying and Replacing Parts

Understanding how to recognize and substitute components in your air gun can significantly enhance its performance and longevity. This process involves careful observation and a basic knowledge of the system’s layout. By familiarizing yourself with each part’s function, you can effectively troubleshoot issues and implement necessary changes.

To begin with, it is essential to identify the specific components that may require attention. Common areas to inspect include the trigger mechanism, valve assembly, and seals. Each of these parts plays a critical role in the overall functionality of the device. Using a diagram or a detailed guide can be immensely helpful in pinpointing the exact location and appearance of each piece.

Once you have identified the parts that need replacement, the next step is to locate suitable substitutes. Ensure that any new components are compatible with your specific model. It is advisable to consult reputable sources or suppliers who specialize in air gun parts to find high-quality replacements. When installing new components, take care to follow proper procedures to avoid damage and ensure optimal performance. Regular maintenance and timely replacements can lead to a more enjoyable shooting experience.

Reassembly Tips and Tricks

Putting a device back together after disassembly can be a meticulous process that requires careful attention to detail. Proper reassembly ensures that all components function correctly and enhances the longevity of the item. Following a systematic approach can make this task more manageable and efficient.

Before starting, organize all parts and tools needed for the reassembly. Keeping components sorted can prevent confusion and make the process smoother. It is also beneficial to refer to a visual guide or documentation that outlines the correct order of assembly.

As you reassemble, pay attention to any alignment markers or guide pins that help in positioning parts correctly. Applying a small amount of lubricant to moving components can improve performance and reduce wear. Additionally, hand-tightening screws and fasteners initially allows for adjustments before fully securing them.

Finally, once the item is reassembled, perform a thorough inspection to ensure everything is in place. Conducting a few test runs can help identify any issues that may need addressing before regular use. This careful approach will lead to successful reassembly and optimal performance.

Maintenance Procedures for Longevity

Regular upkeep is essential for ensuring the extended functionality of your equipment. By implementing a systematic maintenance routine, you can significantly enhance its performance and lifespan. This section outlines key practices that will help in preserving the integrity of your device.

Cleaning: Frequent cleaning is vital to remove debris and prevent corrosion. Use a soft cloth and suitable cleaning solutions to maintain surfaces and mechanisms. Pay particular attention to areas prone to residue buildup.

Lubrication: Applying the appropriate lubricants to moving parts reduces friction and wear. Ensure that only recommended substances are used to avoid damage to internal components.

Inspection: Conducting regular inspections allows for early detection of wear or malfunction. Look for signs of damage, loose components, or irregularities in performance. Addressing these issues promptly can prevent further complications.

Storage: Proper storage conditions play a significant role in maintaining equipment health. Store in a cool, dry place away from direct sunlight and extreme temperatures to prevent deterioration.

By following these guidelines, you can help ensure that your device remains in optimal condition for years to come.

Troubleshooting Firing Problems

When facing issues with launching projectiles, it is important to identify potential causes and solutions. Various factors can contribute to firing malfunctions, ranging from mechanical failures to improper handling. This section will guide you through common problems and how to address them effectively.

Common Issues

- Inconsistent firing or no action at all

- Weak or reduced power during discharge

- Unusual noise during operation

Steps to Diagnose

- Check the Air Source: Ensure that the air reservoir is adequately filled and properly connected.

- Inspect the Seals: Look for any wear or damage on seals that may lead to air leaks.

- Examine the Trigger Mechanism: Ensure that the trigger is functioning smoothly without obstruction.

- Review the Barrel: Make sure the barrel is clear of debris or obstructions that could affect performance.

- Test with Different Projectiles: Sometimes, using incompatible or damaged projectiles can cause firing issues.

By following these troubleshooting steps, you can identify and resolve common issues that affect launching efficiency. Regular maintenance and attention to detail will enhance overall performance.

Fixing Leaks in the System

Addressing leaks within a pressurized system is crucial for maintaining its efficiency and functionality. Identifying the source of the leak can often be the first step towards resolving the issue. Common leak points include seals, joints, and connectors, which may wear over time or become damaged due to external factors.

Identifying the Source of the Leak

To pinpoint the location of the leak, it is advisable to conduct a thorough inspection of the entire system. Look for any signs of moisture or air escaping from connections. Utilizing a soapy water solution can help reveal small leaks; bubbles will form at the site of any escaping air. Once identified, proceed to assess whether the affected areas require tightening, resealing, or complete replacement of parts.

Repairing Leaks

After determining the source, repairs can be implemented. For minor leaks, applying a suitable sealant or tape can often suffice. In cases where components are damaged, replacing them is essential to ensure the integrity of the system. Always ensure that the replacement parts are compatible with the existing setup to avoid future complications. Regular maintenance checks can also help prevent leaks from developing in the first place.

Adjusting the Trigger Mechanism

Fine-tuning the trigger assembly is essential for enhancing performance and ensuring a smoother shooting experience. Proper adjustments can lead to improved accuracy and responsiveness, making it easier to achieve consistent results.

Tools Needed

- Small screwdriver

- Allen wrench

- Lubricant

Adjustment Process

- Remove the stock from the body to access the trigger components.

- Locate the adjustment screws, typically found near the trigger pivot point.

- Using the small screwdriver, turn the screws clockwise to increase resistance or counterclockwise to decrease it.

- Test the trigger pull after each adjustment to find the optimal setting.

- Once satisfied, reassemble the components and test for functionality.

Regular maintenance of the trigger mechanism will prolong its lifespan and enhance the overall shooting experience. Always consult a reliable resource for specific guidelines related to your particular model.

Cleaning and Lubrication Techniques

Maintaining optimal performance of your air-powered device involves regular cleaning and appropriate lubrication. These practices not only enhance functionality but also prolong the lifespan of the equipment. Understanding the right techniques and products is essential for effective maintenance.

Cleaning Procedures

Proper cleaning involves several steps to ensure that all components function smoothly:

- Disassemble the unit carefully, following the manufacturer’s guidelines.

- Use a soft cloth or brush to remove dust and debris from all surfaces.

- For stubborn residue, consider using a mild solvent that is safe for the materials.

- Inspect seals and gaskets for wear or damage and replace if necessary.

Lubrication Techniques

Effective lubrication is crucial for reducing friction and preventing wear:

- Select a lubricant suitable for the specific materials of the device.

- Apply lubricant sparingly to moving parts, ensuring even coverage.

- Avoid over-lubrication, as excess can attract dirt and grime.

- Regularly check lubrication levels and reapply as needed to maintain optimal performance.

When to Seek Professional Help

Knowing when to turn to an expert can save time and prevent further complications. While many issues can be addressed at home, some situations require specialized knowledge and tools. It is essential to recognize the signs indicating that assistance from a trained technician is necessary.

If you encounter persistent malfunctions that do not improve with basic troubleshooting, it may be time to seek help. Additionally, if you notice unusual sounds, leaks, or performance issues that impact safety, professional evaluation is advisable. These symptoms often suggest underlying problems that need expert attention.

Furthermore, if you’re unsure about how to disassemble or reassemble components safely, enlisting a professional can prevent damage and ensure proper functioning. Relying on trained individuals can also provide peace of mind, knowing that your equipment is in capable hands.

Ultimately, prioritizing safety and functionality should guide your decision. If you ever feel out of your depth, it’s best to consult with someone who has the expertise to handle such matters.