Owning a full-size sport utility vehicle comes with a unique set of responsibilities, particularly when it comes to maintenance and troubleshooting. Understanding the intricacies of your vehicle not only enhances its longevity but also ensures optimal performance on the road. This section serves as a crucial resource for any enthusiast or owner seeking to delve deeper into the essential upkeep of their automobile.

Whether you’re facing minor issues or planning a major overhaul, having access to detailed information can make all the difference. This guide aims to equip you with the necessary insights and procedures to tackle various challenges that may arise during ownership. From basic upkeep to more complex repairs, you’ll find valuable tips and techniques designed to simplify the process.

With a focus on practical advice and thorough explanations, this resource is tailored to empower you. By familiarizing yourself with the inner workings of your vehicle, you can confidently address concerns as they arise and ultimately enhance your driving experience.

Overview of the 2002 GMC Yukon XL

This section provides a comprehensive insight into a full-size SUV known for its spaciousness, robust performance, and versatile features. Ideal for families and adventurers alike, it balances comfort with functionality, making it a popular choice among large vehicle enthusiasts.

Equipped with powerful engine options and advanced technology, this model year emphasizes safety and reliability, ensuring peace of mind for drivers and passengers. Its design allows for ample cargo space, making it suitable for various activities, from road trips to daily commutes.

| Feature | Description |

|---|---|

| Seating Capacity | Accommodates up to nine passengers, providing generous legroom. |

| Engine Options | Available with V8 engines, offering a balance of power and efficiency. |

| Towing Capacity | Designed for heavy towing, making it ideal for trailers and boats. |

| Technology Features | Includes options for navigation systems and premium audio systems. |

| Safety Ratings | High safety ratings with various features to enhance driver and passenger protection. |

Common Issues and Troubleshooting Tips

When it comes to maintaining a large SUV, various challenges may arise that can affect performance and comfort. Understanding typical problems can help owners diagnose issues quickly and effectively. This section provides insights into frequent malfunctions and practical advice for addressing them.

Engine Performance Problems

One of the most common concerns involves engine performance, which may manifest as rough idling, decreased power, or unusual noises. Regularly checking the air filter, spark plugs, and fuel injectors can help ensure optimal operation. Additionally, paying attention to warning lights on the dashboard can prevent minor issues from escalating into major repairs.

Electrical System Failures

Electrical components can also pose significant challenges, including issues with the battery, alternator, or wiring. Symptoms such as dimming lights or difficulty starting the vehicle are indicators of potential electrical problems. Conducting routine checks on battery connections and ensuring that fuses are intact can often resolve these issues without extensive intervention.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right set of instruments is crucial for efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also enhances safety and accuracy. Understanding the essential implements required for various tasks can significantly improve the overall experience of vehicle upkeep.

Basic Hand Tools

Hand tools form the backbone of any maintenance toolkit. These items are fundamental for performing a wide range of tasks, from simple adjustments to more intricate repairs. Below is a list of key hand tools:

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for driving screws in and out of various components. |

| Pliers | Useful for gripping, twisting, and cutting wire or other materials. |

| Hammer | For driving nails and tapping parts into place. |

| Socket Set | Ideal for reaching fasteners in tight spaces. |

Power Tools

Power tools are invaluable for more demanding tasks. These instruments can significantly reduce the time and effort required to complete various jobs. Here are some commonly used power tools:

| Tool | Purpose |

|---|---|

| Impact Wrench | Great for loosening stubborn bolts with minimal effort. |

| Drill | Used for making holes or driving screws quickly. |

| Angle Grinder | Effective for cutting and grinding metal components. |

| Electric Ratchet | Speeds up the process of fastening and loosening nuts and bolts. |

| Air Compressor | Powers pneumatic tools and inflates tires. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle. Following systematic procedures not only enhances safety but also helps in identifying potential issues before they escalate. This section outlines crucial maintenance tasks that can be performed to keep your automobile running smoothly.

Essential Maintenance Tasks

- Check and change engine oil and filter regularly.

- Inspect and replace air filters as needed.

- Examine brake pads and rotors for wear.

- Inspect tire pressure and tread depth; rotate tires every 5,000 miles.

- Flush and replace coolant to prevent overheating.

Detailed Procedure for Oil Change

- Gather necessary tools: wrench, oil filter wrench, drain pan, funnel, and new oil.

- Warm up the engine for a few minutes to thin the oil, making it easier to drain.

- Turn off the engine and secure the vehicle on a flat surface.

- Place the drain pan under the oil pan and remove the drain plug, allowing old oil to fully drain.

- Replace the oil filter using the oil filter wrench.

- Reinstall the drain plug and fill the engine with new oil using a funnel.

- Start the engine and let it run for a minute, checking for leaks.

- Dispose of old oil and filter responsibly.

Understanding the Engine Specifications

Comprehending the specifications of a vehicle’s powertrain is essential for optimal performance and maintenance. Each engine is designed with specific characteristics that influence efficiency, output, and overall functionality. This section delves into the key elements that define engine specifications, allowing for informed decisions regarding upgrades, repairs, and enhancements.

Key Components and Features

Engines consist of various components, each playing a crucial role in the overall performance. The displacement refers to the total volume of the cylinders, directly impacting power generation. Additionally, compression ratio affects efficiency and fuel consumption. Understanding these attributes can help in assessing engine capabilities and suitability for specific needs.

Performance Metrics

Evaluating performance metrics such as horsepower and torque provides insight into the engine’s potential. Horsepower is a measure of how quickly work is done, while torque represents the rotational force available. These figures are vital for understanding acceleration, towing capacity, and overall driving experience, enabling users to match their vehicle’s capabilities with their requirements.

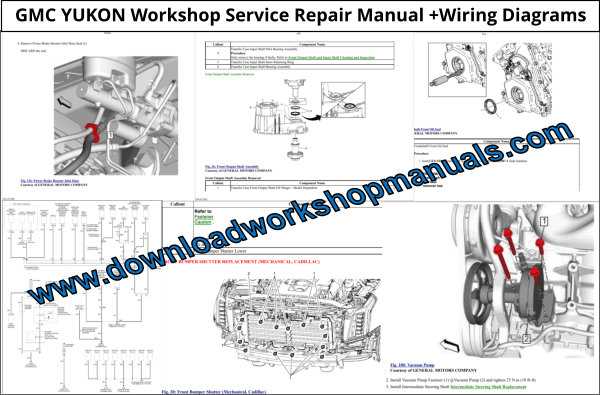

Electrical System and Wiring Diagrams

The electrical system of a vehicle plays a crucial role in its overall functionality, encompassing everything from the battery and alternator to various sensors and control modules. Understanding this intricate network is essential for diagnosing issues and ensuring optimal performance. Wiring diagrams serve as invaluable tools, providing a visual representation of the connections and pathways that power the vehicle’s components.

Overview of the Electrical System

The electrical architecture consists of multiple interconnected parts, including power distribution systems, lighting, and control circuits. Each component relies on precise wiring to communicate effectively. Analyzing the layout allows for quick identification of potential faults, making troubleshooting more efficient. Additionally, familiarity with the terminology used in electrical diagrams is vital for interpreting the information accurately.

Wiring Diagrams Explained

Wiring diagrams illustrate the arrangement of wires and their respective connections to various components. These diagrams often use symbols to represent different elements, such as switches, fuses, and connectors. By understanding these symbols and their meanings, one can effectively follow the circuit paths and pinpoint areas that may require attention. Regular reference to these diagrams can enhance maintenance practices and prolong the lifespan of the electrical system.

Brake System Repairs and Upgrades

The braking system is a critical component of any vehicle, ensuring safety and performance. Regular maintenance and timely enhancements can significantly improve responsiveness and durability. This section discusses essential interventions and potential modifications to optimize braking efficiency.

Inspection and Maintenance

Routine checks of the braking system can prevent costly failures. Key areas to examine include the brake pads, rotors, and fluid levels. Worn pads can lead to decreased stopping power, while warped rotors may cause vibrations during braking. Regularly flushing and replacing brake fluid is crucial to maintaining hydraulic performance.

Upgrading Components

Upgrading to high-performance brake pads can enhance stopping ability, especially under demanding conditions. Additionally, vented rotors or slotted designs can improve heat dissipation, reducing the risk of brake fade. Investing in braided stainless steel brake lines can also improve pedal feel and responsiveness, providing a more direct connection between the driver and the braking system.

Advanced Technologies

Consider incorporating advanced braking technologies such as anti-lock braking systems (ABS) or electronic brake-force distribution (EBD). These systems offer improved stability and control, particularly in emergency situations. Upgrading to performance calipers can also enhance braking force and reduce stopping distances.

In conclusion, proactive maintenance and thoughtful upgrades can greatly enhance the effectiveness of the braking system. By prioritizing these aspects, drivers can ensure a safer and more enjoyable driving experience.

Suspension and Steering Maintenance Guide

Proper upkeep of the suspension and steering systems is essential for ensuring a smooth and safe driving experience. These components work in tandem to provide stability, control, and comfort while navigating various road conditions. Regular inspections and timely maintenance can prevent costly repairs and enhance vehicle performance.

Inspection Procedures

Routine checks are vital to identify wear and tear in critical components such as shock absorbers, struts, and control arms. Look for signs of leaks, unusual noises, or uneven tire wear. Pay close attention to the steering linkage and joints, as any play or looseness can indicate a need for immediate attention. It is recommended to perform these inspections every few months or before long trips.

Maintenance Tips

To maintain optimal performance, consider lubricating moving parts and replacing worn-out components promptly. Ensure that the wheel alignment is adjusted as needed to prevent uneven tire wear and improve handling. Regularly checking fluid levels in power steering systems can also enhance responsiveness and prolong component life. Following these guidelines will help maintain the integrity of the suspension and steering systems for a safer driving experience.

Transmission Problems and Solutions

Issues with gear shifting can significantly affect vehicle performance and safety. Recognizing common symptoms early can help in diagnosing and resolving complications effectively. This section explores prevalent transmission challenges and their respective solutions.

Common Transmission Issues

| Issue | Description |

|---|---|

| Slipping Gears | The transmission unexpectedly changes gears or loses power. |

| Delayed Engagement | There is a noticeable lag when shifting from park to drive. |

| Fluid Leaks | Transmission fluid leaks under the vehicle, indicating a seal or gasket issue. |

| Unusual Noises | Grinding, whining, or clunking sounds when changing gears. |

Solutions and Preventative Measures

Addressing transmission problems promptly is crucial to avoid costly repairs. Regular maintenance, including fluid checks and changes, can prevent many issues. If symptoms arise, consider the following actions:

- For slipping gears, inspect and replace the transmission fluid or check for leaks.

- To resolve delayed engagement, assess the transmission filter and fluid levels.

- For fluid leaks, identify the source and replace damaged seals or gaskets.

- If unusual noises occur, consult a professional for a thorough inspection and repair.

Safety Features and Inspection Checklist

Ensuring the safety of your vehicle is paramount for both the driver and passengers. A thorough examination of safety elements can prevent accidents and enhance overall performance. This section outlines essential features and a systematic checklist to evaluate the condition and functionality of these safety components.

Key Safety Features

Modern vehicles are equipped with a variety of safety technologies designed to protect occupants in the event of a collision. Common features include airbags, anti-lock braking systems (ABS), traction control, and electronic stability control. Regular checks of these systems are crucial for maintaining optimal functionality.

Inspection Checklist

- Airbags: Verify that the airbag warning light illuminates when starting the engine and turns off after a few seconds.

- Brakes: Assess brake responsiveness and check for unusual noises or vibrations during operation.

- Tires: Inspect tire tread depth and ensure even wear; check for proper inflation.

- Lights: Test all exterior and interior lights, including headlights, brake lights, and turn signals.

- Seatbelts: Ensure all seatbelts are functioning correctly, retract smoothly, and show no signs of wear or fraying.

- Wipers: Confirm that windshield wipers operate effectively and that wiper blades are in good condition.

- Mirrors: Check that all mirrors are properly adjusted and free of cracks or obstructions.

By adhering to this checklist and routinely inspecting these critical features, vehicle owners can enhance safety, reduce the risk of incidents, and promote a secure driving environment.

Aftermarket Parts and Modifications

Enhancing vehicle performance and aesthetics through aftermarket components and alterations has become a popular practice among enthusiasts. These upgrades can significantly improve handling, power, and overall functionality, offering drivers a personalized experience tailored to their specific needs and preferences.

When considering modifications, it is essential to evaluate both the benefits and potential drawbacks. Aftermarket parts can range from performance enhancements such as exhaust systems and cold air intakes to visual upgrades like custom lighting and body kits. Each addition can bring distinct advantages, yet compatibility and installation quality should always be prioritized.

Moreover, modifications can also affect the vehicle’s warranty and insurance coverage. Understanding the implications of changes made to the original design is crucial to ensure compliance with local regulations and to maintain safety standards. Ultimately, the right choices can lead to a uniquely personalized vehicle that reflects the owner’s style and driving preferences.