The upkeep of outdoor machinery is crucial for ensuring optimal performance and longevity. Understanding the intricacies of these machines can greatly enhance their functionality and efficiency. This section delves into various aspects of servicing and troubleshooting, providing essential insights for users.

Whether it’s addressing common issues or implementing preventive measures, having a comprehensive understanding of the equipment’s components and operations is invaluable. Proper care not only extends the lifespan of the machinery but also ensures a smoother operation during use.

In this guide, you will find practical advice and detailed procedures that can assist in maintaining your lawn equipment. Emphasizing the importance of regular checks and timely interventions, this section aims to empower users with the knowledge needed to tackle challenges confidently.

This section aims to provide an overview of a specific model of lawn tractors, focusing on its features, specifications, and performance. Understanding the intricacies of this machine is essential for effective maintenance and troubleshooting.

Key Features of the Model

- Powerful engine designed for efficiency

- Ergonomic design for user comfort

- Advanced cutting technology for a clean finish

Specifications Overview

- Engine type: V-twin

- Cutting deck size: 48 inches

- Transmission: Hydrostatic

By familiarizing yourself with these characteristics, you will enhance your ability to operate and care for the machine effectively.

Common Issues with Lawn Tractors

Lawn tractors are essential for maintaining a well-kept yard, but they can encounter various problems over time. Understanding these issues can help owners troubleshoot and maintain their equipment effectively.

- Engine Problems: Difficulties starting the engine or unusual noises can indicate underlying issues.

- Battery Failure: A dead or weak battery may result in starting troubles, often requiring replacement.

- Blades Not Engaging: If the cutting blades do not engage properly, it may be due to a faulty switch or worn-out components.

- Overheating: Engines can overheat if they lack proper oil levels or if the cooling system is obstructed.

- Transmission Issues: Problems with shifting gears or lack of movement can signal transmission malfunctions.

Regular maintenance and early detection of these common issues can enhance the longevity and performance of lawn tractors.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right instruments is crucial. These essential implements not only streamline the process but also enhance efficiency and effectiveness. Understanding the tools needed can greatly simplify the tasks at hand, ensuring that every job is completed successfully.

Basic Hand Tools

Every repair task begins with fundamental hand tools. A reliable set of wrenches, screwdrivers, and pliers forms the backbone of any toolkit. These items are indispensable for loosening or tightening components, making adjustments, and performing regular upkeep. Investing in high-quality hand tools can significantly impact the ease of any maintenance endeavor.

Specialized Equipment

In addition to standard tools, specialized equipment plays a vital role in more complex repairs. Items such as torque wrenches, diagnostic tools, and lubricants can make a substantial difference. These tools are designed to address specific challenges and ensure that machinery operates at its best. Utilizing the right specialized gear not only enhances repair quality but also extends the lifespan of the equipment.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your lawn care equipment. Regular upkeep not only enhances efficiency but also minimizes potential issues.

Follow these essential steps for effective maintenance:

- Check the Oil Level:

- Ensure the engine is cool before checking.

- Remove the dipstick, wipe it clean, and reinsert to check the level.

- Add oil if necessary to reach the recommended level.

- Inspect the Air Filter:

- Remove the air filter cover.

- Check for dirt and debris; clean or replace as needed.

- Sharpen the Blades:

- Remove the blades carefully using the appropriate tools.

- Sharpen using a file or grinder, ensuring a smooth edge.

- Reattach securely to the mower.

- Clean the Undercarriage:

- Scrape off grass clippings and debris after each use.

- Use a pressure washer for a thorough cleaning periodically.

- Check Tire Pressure:

- Inspect each tire for proper inflation.

- Inflate to the recommended pressure if necessary.

By following these maintenance steps regularly, you can enhance the reliability and efficiency of your equipment, ensuring a well-maintained performance season after season.

Replacing the Blades Effectively

Maintaining the sharpness and functionality of cutting implements is essential for optimal performance in lawn care. Over time, wear and tear can diminish the effectiveness of these components, making timely replacements crucial for achieving a clean and efficient cut.

To begin the replacement process, ensure the machine is turned off and disconnected from any power source. This safety precaution is vital to prevent accidental engagement during maintenance. Gather the necessary tools, such as a socket wrench and protective gloves, to facilitate a smooth procedure.

Next, lift the deck to access the blades easily. Carefully remove the retaining nuts or bolts securing the blades in place. It is advisable to inspect the mounting hardware for signs of damage and replace it if necessary. When installing new blades, ensure they are oriented correctly and securely fastened to avoid operational issues.

After the installation, double-check that all components are tightly secured and perform a brief inspection of the deck for any debris or damage. Regular maintenance and prompt blade replacement not only extend the lifespan of the equipment but also enhance its cutting efficiency.

Troubleshooting Engine Problems

When dealing with issues related to engine performance, it is essential to systematically identify and resolve the underlying causes. Common symptoms can range from starting difficulties to unusual noises during operation. This section provides guidance on diagnosing and rectifying various engine-related challenges.

| Symptoms | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Dead battery, faulty starter, or bad ignition switch | Check battery voltage, inspect starter connections, and test ignition switch. |

| Engine sputters | Clogged fuel filter or dirty carburetor | Replace fuel filter and clean carburetor components. |

| Excessive smoke | Overfilled oil or worn piston rings | Check oil levels and replace piston rings if necessary. |

| Unusual noises | Loose parts or damaged bearings | Tighten loose components and inspect bearings for wear. |

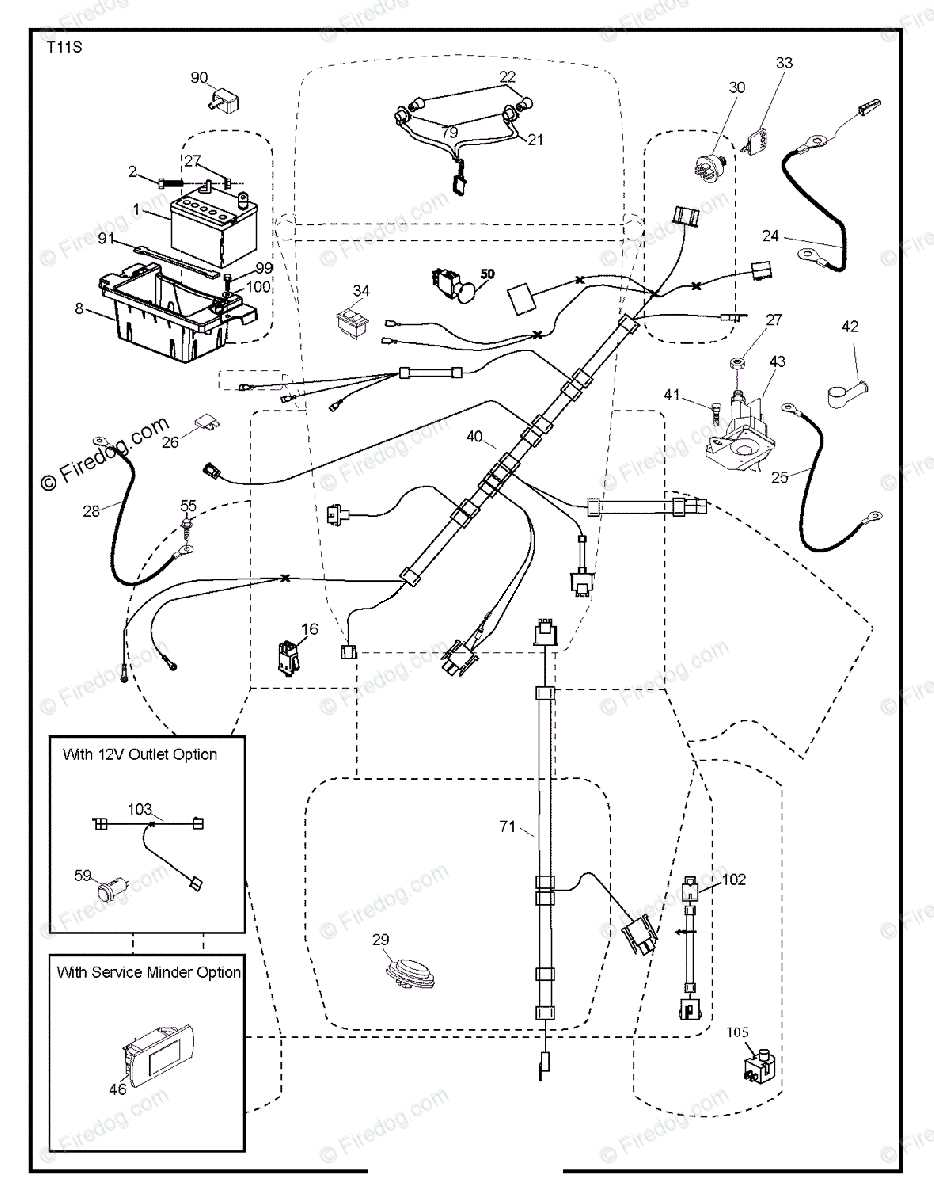

Electrical System Checkup Tips

Regular maintenance of the electrical components in your equipment is essential for optimal performance and longevity. Ensuring that all connections are secure and that the system is free from corrosion can prevent potential issues. This section provides valuable insights into effectively checking and maintaining the electrical system.

Inspecting Connections

Start by examining all wiring and connections for signs of wear or damage. Look for frayed wires, loose terminals, and any corrosion on connectors. Tightening any loose connections and replacing damaged wires will help maintain a reliable electrical system.

Testing the Battery

Regularly check the battery’s charge level and clean the terminals to ensure good conductivity. Using a multimeter can help determine the battery’s voltage, and if readings are low, consider charging or replacing the battery to avoid starting issues.

Transmission and Gearbox Insights

The transmission system plays a crucial role in ensuring efficient power transfer from the engine to the wheels. Understanding the components and functionality of this system is essential for maintaining optimal performance and longevity. This section delves into the intricacies of transmission mechanisms and gear configurations, shedding light on their significance in various applications.

Key Components of Transmission Systems

Transmission systems consist of various parts that work in unison to manage power delivery. These include gears, shafts, and clutches, each serving a specific purpose. The interaction between these components determines the overall efficiency and effectiveness of the machinery.

Common Issues and Maintenance Tips

Regular maintenance is vital to prevent common problems such as slipping gears or noisy operation. Routine inspections and timely adjustments can significantly enhance the lifespan of the transmission system. It is advisable to consult a professional for thorough diagnostics and repair when issues arise.

| Component | Function |

|---|---|

| Gears | Regulate speed and torque |

| Shafts | Transmit power between components |

| Clutches | Engage and disengage power flow |

Winterizing Your Lawn Tractor

Preparing your garden vehicle for the cold months is essential to ensure its longevity and optimal performance. Properly storing your machine can prevent damage caused by freezing temperatures and prolonged inactivity.

Step 1: Begin by cleaning the exterior and undercarriage thoroughly. Remove any debris, grass clippings, and dirt that may accumulate, as these can trap moisture and lead to rust.

Step 2: Drain the fuel system or add a fuel stabilizer to prevent gumming and corrosion. If you choose to drain, ensure that you run the engine until it consumes the remaining fuel.

Step 3: Check and change the oil if necessary. Fresh oil protects the engine from internal corrosion during storage.

Step 4: Remove the battery and store it in a cool, dry place. Consider using a battery maintainer to keep it charged throughout the winter.

Step 5: Finally, cover your lawn tractor with a breathable tarp or cover to shield it from dust and moisture while allowing air circulation.

Parts Replacement and Upgrades

Maintaining and enhancing the performance of your lawn tractor involves strategic component upgrades and timely replacements. Ensuring that each part is functioning optimally contributes not only to the longevity of the machine but also to its efficiency and effectiveness during operation.

Common Parts for Replacement

Routine maintenance often requires the replacement of key components such as the air filter, spark plug, and blades. These elements play a crucial role in the overall performance and should be inspected regularly to prevent any potential issues that could arise from wear and tear.

Upgrading Components for Better Performance

Upgrading specific parts can significantly enhance the capabilities of your equipment. Consider options like improved blades for a cleaner cut, or a more efficient engine air filter to boost performance. Such upgrades can lead to better fuel efficiency and improved handling, making your machine more reliable for any task.

When to Seek Professional Help

Knowing when to consult a specialist is crucial for maintaining the longevity and performance of your equipment. While many issues can be resolved independently, there are specific situations where expert intervention is advisable to prevent further damage and ensure optimal functionality.

Signs of Complex Issues

If you encounter persistent problems that do not improve with basic troubleshooting, it is a clear indication that professional assistance is needed. Unusual noises, erratic behavior, or failure to start can suggest underlying complications that require expert diagnosis.

Safety Concerns

When safety is at risk, seeking help from a qualified technician is essential. If you notice leaks, excessive vibrations, or electrical issues, it is imperative to address these matters promptly to avoid accidents or injuries. A professional can provide the necessary expertise to handle potentially hazardous situations.