Owning a vehicle comes with its own set of responsibilities, particularly when it comes to upkeep and servicing. Proper maintenance not only enhances the longevity of the automobile but also ensures optimal performance on the road. This section aims to provide valuable insights into effectively managing your vehicle’s needs, offering guidance on various aspects of care and restoration.

Understanding the nuances of vehicle maintenance is essential for every owner. From routine checks to identifying potential issues, being proactive can prevent more significant problems down the line. Whether you’re addressing minor adjustments or tackling more complex challenges, knowledge is key to successful management.

In this guide, you will find essential information that covers the essential components of vehicle care, along with step-by-step procedures. This resource serves as a foundation for both novice and experienced individuals seeking to enhance their understanding of automotive mechanics and maintenance practices.

In any automotive undertaking, having the right instruments is crucial to achieving success. This section outlines the fundamental implements necessary for effective maintenance and restoration of your vehicle. A well-equipped workspace not only enhances efficiency but also ensures that tasks are completed safely and accurately.

| Tool | Purpose |

|---|---|

| Socket Set | Essential for loosening and tightening bolts and nuts of various sizes. |

| Wrench Set | Used for gripping and turning fasteners, providing leverage for a secure fit. |

| Screwdriver Set | Necessary for fastening or loosening screws in various components. |

| Pliers | Versatile tools for gripping, twisting, and cutting wires or components. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specified tension. |

| Jack and Stands | Used for lifting the vehicle for maintenance tasks that require access underneath. |

| Oil Filter Wrench | Facilitates the removal and installation of oil filters. |

| Multimeter | Helpful for diagnosing electrical issues by measuring voltage and resistance. |

| Diagnostic Scanner | Used to read error codes from the vehicle’s onboard computer system. |

| Work Light | Provides illumination in tight or dark spaces, improving visibility during tasks. |

Understanding Common Mechanical Issues

Vehicles often encounter a variety of mechanical challenges that can impact their performance and longevity. Understanding these issues is crucial for maintaining optimal functionality and ensuring safety on the road. This section delves into frequent problems, their symptoms, and potential solutions.

Engine Performance Problems

Engine-related issues can manifest in numerous ways, including rough idling, stalling, or reduced power during acceleration. These symptoms may indicate complications such as a clogged air filter, failing spark plugs, or fuel delivery problems. Regular maintenance and timely diagnostics are essential for preventing these issues from escalating.

Transmission Difficulties

Transmission malfunctions can lead to erratic shifting, slipping gears, or unusual noises while driving. Common causes of these problems include low fluid levels, worn-out components, or faulty sensors. Addressing transmission issues promptly can help avoid costly repairs and prolong the vehicle’s lifespan.

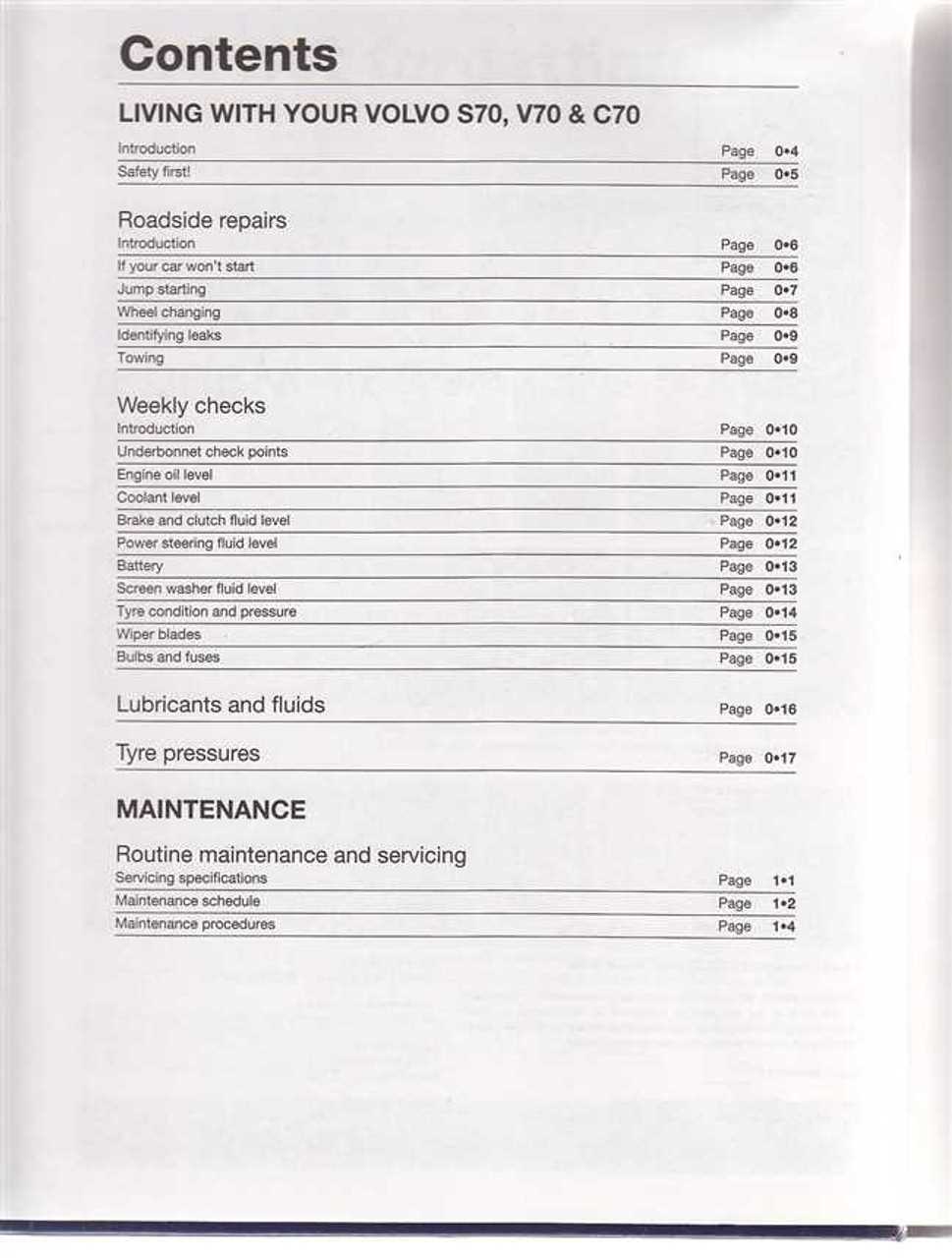

Step-by-Step Maintenance Procedures

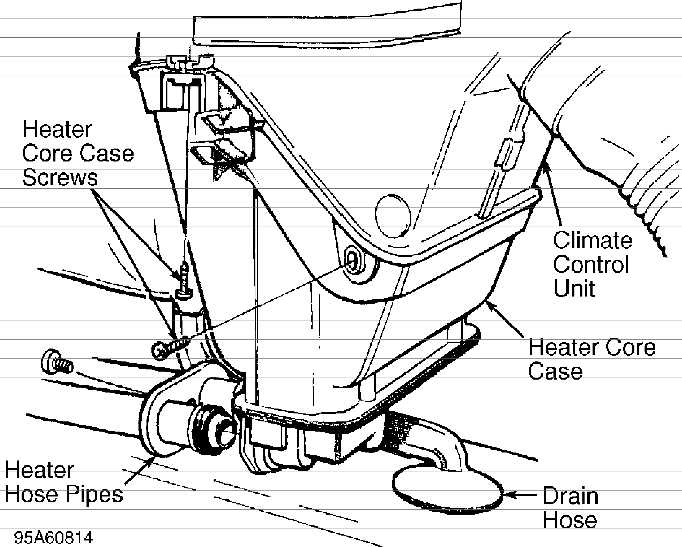

Regular upkeep is crucial for ensuring optimal performance and longevity of your vehicle. Following a systematic approach to maintenance helps identify potential issues early and keeps essential components functioning smoothly. This section provides clear instructions for various maintenance tasks that every owner should consider.

Fluid Checks and Changes

Maintaining proper fluid levels is essential for vehicle efficiency. Here are the key fluids to monitor:

- Engine oil: Change according to the manufacturer’s schedule.

- Transmission fluid: Check level and condition regularly.

- Coolant: Inspect for leaks and maintain proper levels.

- Brake fluid: Ensure it is at the correct level for safe operation.

Filter Replacements

Replacing filters is vital for protecting engine and cabin air quality. Follow these steps:

- Engine air filter: Replace every 15,000 to 30,000 miles, or as needed.

- Cabin air filter: Check and replace at least once a year.

- Fuel filter: Replace according to the maintenance schedule, typically every 30,000 miles.

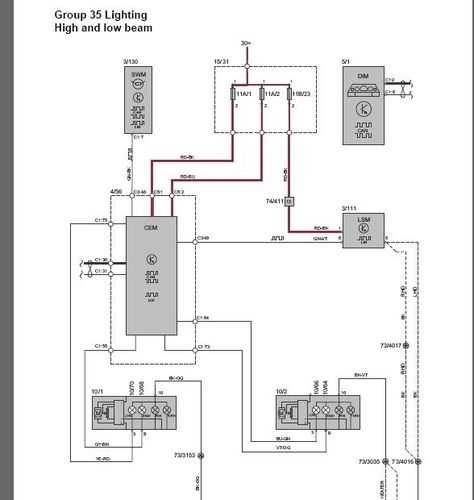

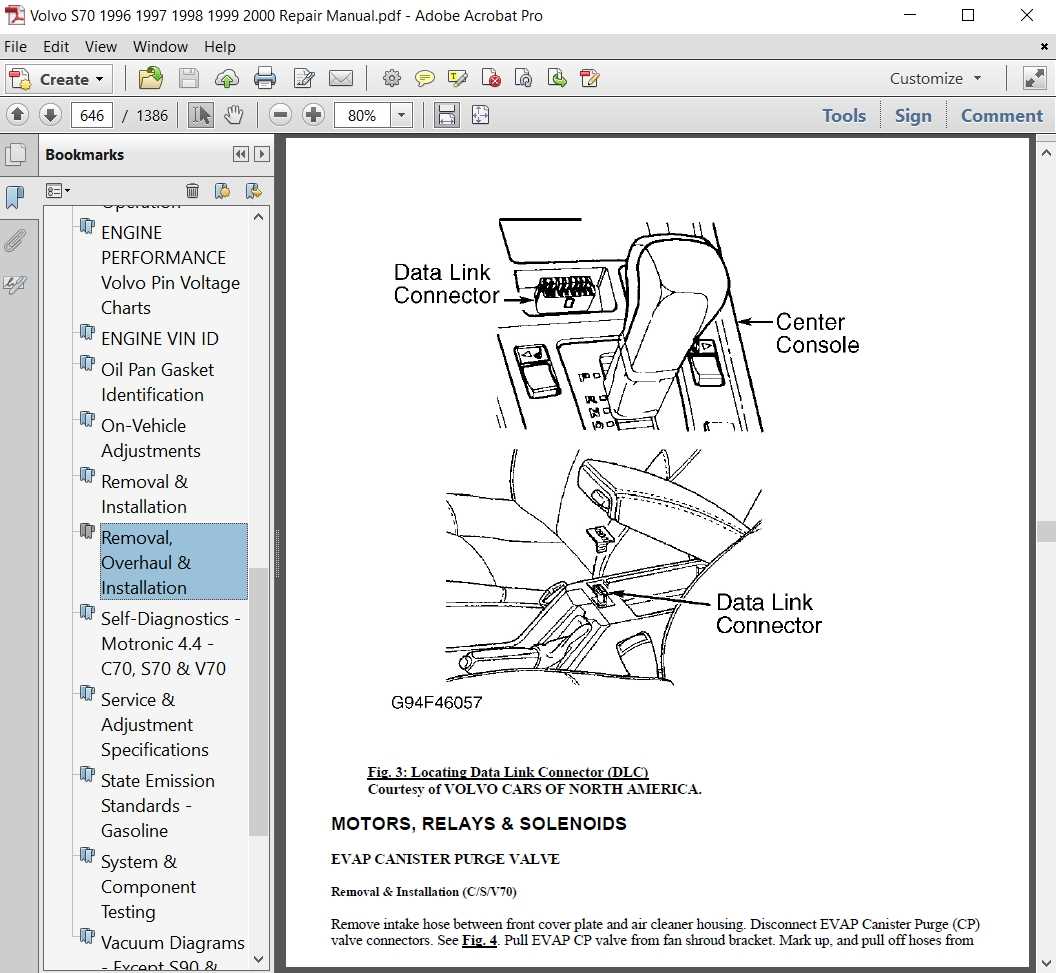

Electrical System Troubleshooting Guide

This section aims to assist users in diagnosing and resolving issues related to the electrical components of their vehicle. A well-functioning electrical system is crucial for optimal performance and reliability. The following guide outlines common problems, potential causes, and suggested solutions to facilitate effective troubleshooting.

When faced with electrical difficulties, it is essential to systematically assess each component. Start by checking the battery’s condition and connections, as they are often the primary source of issues. Next, examine the fuses, wiring, and other critical elements within the electrical network.

| Issue | Potential Causes | Suggested Solutions |

|---|---|---|

| Lights not functioning | Blown fuse, faulty bulb, wiring issues | Inspect and replace fuses; check bulbs and wiring integrity |

| Dashboard indicators not working | Defective gauge, wiring fault, blown fuse | Test gauge functionality; check connections and replace fuses |

| Starter not engaging | Weak battery, faulty starter, bad wiring | Charge or replace battery; test starter; inspect wiring |

| Power windows malfunction | Blown fuse, faulty switch, motor issues | Check fuses; test switch and motor functionality |

By following this guide, individuals can methodically troubleshoot electrical problems, ensuring their vehicle remains reliable and safe on the road.

Engine Components and Their Functions

The engine comprises various interconnected parts that work together to convert fuel into motion. Each component plays a crucial role in ensuring efficient power generation, smooth operation, and reliability. This section provides an overview of these elements and their individual responsibilities within the system.

Primary Engine Parts

Understanding the primary elements of the engine is essential for maintaining optimal performance. Each part is meticulously designed to fulfill a unique purpose, contributing to the engine’s ability to operate under varying conditions.

| Component | Function | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Block | The main structure housing the cylinders, where combustion occurs to generate power. | ||||||||||||||||

| Pistons | Move within the cylinders to compress air and fuel, initiating the combustion process that propels the vehicle. | ||||||||||||||||

| Crankshaft | Converts the linear motion of the pistons into rotational energy, driving the wheels. | ||||||||||||||||

| Camshaft | Controls the opening and closing of intake and exhaust valves, ensuring precise fuel-air intake and exhaust expulsion. | ||||||||||||||||

| Spark Plugs | Generate the spark necessary to ignite the

Transmission Care and AdjustmentsMaintaining the transmission is essential to ensure smooth and reliable vehicle performance. Regular attention to this system helps to prevent issues related to gear shifting and overall driveability. Adjustments and care can prolong the lifespan of the components and enhance driving efficiency. Below is a table outlining some common adjustments and checks to keep the transmission in optimal condition:

|