Ensuring the longevity and optimal performance of industrial machinery is essential for any workshop. Proper upkeep not only enhances productivity but also minimizes downtime caused by unexpected malfunctions. This guide delves into the essential procedures and techniques necessary for maintaining a specific model of a precision surface tool.

Understanding the intricate workings of such equipment can significantly aid operators in diagnosing issues and implementing effective solutions. The following sections will provide detailed insights into the components, common challenges, and the systematic approach required to restore functionality. By familiarizing oneself with these practices, users can confidently navigate maintenance tasks and enhance the overall efficiency of their operations.

In addition to technical advice, this resource emphasizes the importance of regular inspections and proactive measures. Developing a routine for checking critical elements not only prevents wear but also fosters a deeper appreciation of the machinery’s capabilities. Embracing these practices will ultimately contribute to a more productive and safer working environment.

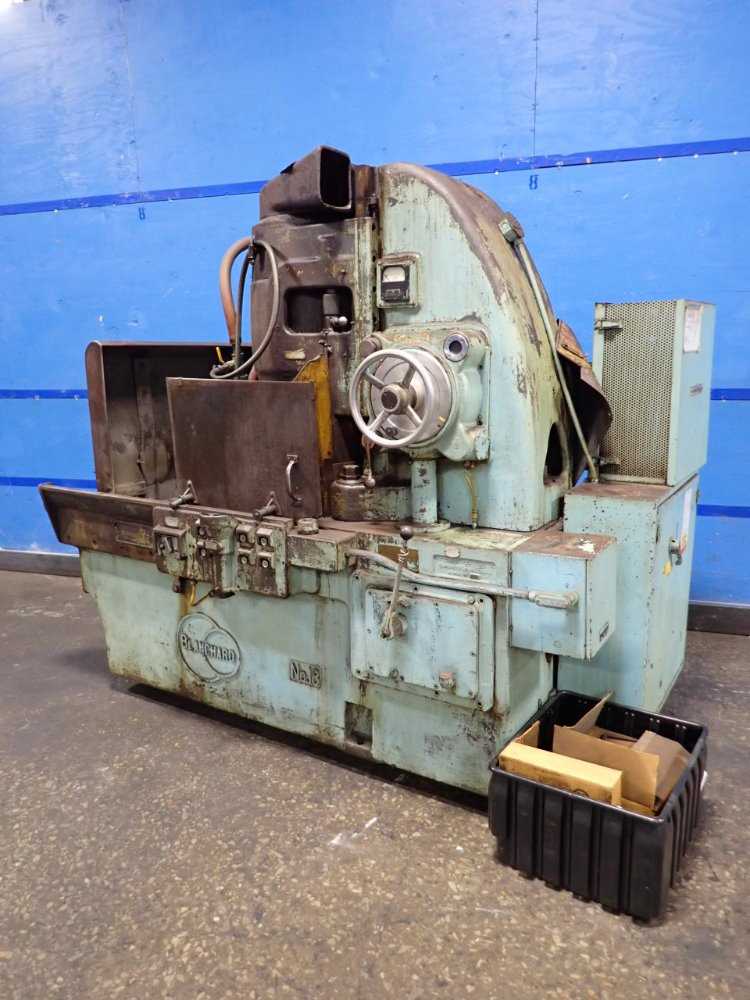

Overview of Blanchard Grinder No 18

This section provides a comprehensive look at a specific model known for its robust performance and versatility in precision machining. It is widely recognized for its ability to handle large workpieces efficiently, making it an essential tool in various industrial applications.

Key Features

- Sturdy construction for durability and long-lasting operation.

- High-capacity table to accommodate substantial materials.

- Advanced control systems for enhanced accuracy and repeatability.

- Versatile configuration options to suit different machining needs.

Applications

- Precision surface finishing in manufacturing.

- Large component processing for aerospace and automotive industries.

- Heavy-duty machining tasks in metal fabrication.

- Restoration and maintenance of various mechanical parts.

Understanding these attributes allows users to maximize the efficiency and effectiveness of this exceptional machine in their operations.

Common Issues with Blanchard Grinders

Understanding the typical challenges faced by users of surface processing machines is crucial for maintaining optimal performance and longevity. Various factors can contribute to operational inefficiencies, leading to decreased productivity and increased downtime.

One prevalent concern is uneven wear on the cutting surface, which can result in inconsistent finishes. This often stems from improper alignment or inadequate maintenance practices. Additionally, excessive vibration during operation can indicate underlying mechanical issues, affecting both precision and quality.

Another common problem involves hydraulic system failures, which may manifest as erratic movements or power loss. Ensuring the fluid levels are adequate and free of contaminants is essential for smooth operation. Moreover, electrical malfunctions can disrupt control systems, leading to unexpected halts and requiring immediate attention.

Lastly, the accumulation of debris and dust can impair the functionality of various components. Regular cleaning and inspection are necessary to prevent such build-up and maintain the machine’s efficiency over time.

Essential Tools for Grinder Repair

Maintaining and restoring machinery requires a well-equipped toolkit to ensure efficiency and precision. Having the right instruments not only simplifies the process but also enhances the quality of the work performed. Below is a compilation of vital items that are indispensable for effectively working on these complex machines.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners with ease. |

| Wrenches | Essential for adjusting various components and securing bolts. |

| Torque Wrench | Ensures fasteners are tightened to the specified torque settings. |

| Screwdriver Set | Used for removing and securing screws on covers and panels. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small parts. |

| Caliper | For precise measurement of parts to ensure proper fit and alignment. |

| Multimeter | Used to check electrical connections and troubleshoot issues. |

| Cleaning Supplies | Essential for removing debris and maintaining cleanliness of components. |

Equipping oneself with these tools will not only streamline the process but also help achieve a successful outcome in any maintenance task.

Step-by-Step Repair Process

This section outlines a detailed approach to restoring your equipment, ensuring it functions optimally. Following these steps will help you systematically address any issues, enhancing longevity and performance.

- Assessment: Begin by evaluating the machine for visible damage or wear.

- Gather Tools: Collect all necessary tools and replacement parts for the job.

- Disassembly: Carefully take apart the unit, noting the order of components.

- Cleaning: Remove any debris or buildup from internal parts.

- Inspection: Check each component for signs of damage or excessive wear.

- Replacement: Substitute any faulty parts with new or refurbished ones.

- Reassembly: Rebuild the machine in reverse order of disassembly.

- Testing: Conduct thorough tests to ensure everything operates correctly.

- Final Adjustments: Make any necessary tweaks for optimal performance.

Following these steps will guide you through the restoration process, ultimately enhancing the functionality of your equipment.

Maintaining Your Blanchard Grinder

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular attention to key components not only enhances efficiency but also prevents unexpected failures, ensuring that your equipment operates smoothly. Establishing a consistent maintenance routine can save time and resources in the long run.

Essential Maintenance Practices

To maintain the highest standards of operation, consider the following practices:

| Practice | Description | Frequency |

|---|---|---|

| Cleaning | Remove debris and dust from surfaces and components to prevent contamination. | Daily |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. | Weekly |

| Inspection | Examine critical parts for signs of wear or damage to identify issues early. | Monthly |

| Calibration | Check and adjust settings to ensure precision and accuracy in operation. | Quarterly |

| Professional Servicing | Engage a technician for thorough evaluation and maintenance of complex systems. | Annually |

Benefits of Regular Upkeep

Consistent maintenance minimizes the risk of breakdowns, enhances productivity, and extends the life of your machinery. By proactively addressing potential issues, operators can ensure reliable performance, leading to higher quality outputs and reduced operational costs.

Replacement Parts for Blanchard No 18

Maintaining optimal performance in industrial machinery often requires sourcing specific components. For the model in question, various parts are essential to ensure longevity and efficiency. Understanding the key components that may need replacement helps operators keep their machines running smoothly.

Essential Components

Several vital parts are frequently replaced due to wear and tear. These include items responsible for precision and stability, as well as those that ensure safety during operation. Operators should be aware of common replacements to minimize downtime.

Common Replacement Parts Table

| Part Name | Description | Typical Issues |

|---|---|---|

| Drive Belt | Transfers power from the motor to the spindle. | Wear and slippage over time. |

| Bearings | Support the rotating components, reducing friction. | Noise and overheating due to degradation. |

| Motor Brushes | Conduct electricity to the motor’s rotor. | Loss of power and sparking when worn. |

| Spindle Assembly | Houses the main rotating shaft. | Vibration and instability if damaged. |

| Control Panel | Interface for machine settings and monitoring. | Malfunctions leading to operational errors. |

Troubleshooting Grinding Problems

When working with surface finishing equipment, various issues may arise that affect the quality of the workpiece. Identifying and addressing these problems promptly is crucial to maintaining efficiency and ensuring desired results. This section provides guidance on common challenges faced during operation and suggests potential solutions.

Common Issues and Their Causes

| Issue | Possible Causes | Solutions |

|---|---|---|

| Uneven Surface Finish | Improper wheel alignment, worn abrasive | Check and adjust wheel alignment; replace wheel if necessary |

| Overheating | Insufficient coolant, excessive pressure | Increase coolant flow; reduce pressure applied |

| Chattering | Loose machine components, incorrect speed | Tighten all components; adjust speed settings |

| Excessive Wear | Improper material selection, incorrect feed rate | Select appropriate material; adjust feed rate accordingly |

Preventive Measures

To minimize the occurrence of these issues, regular maintenance and proper operational practices are essential. Keeping equipment clean, ensuring components are secure, and using the right materials can significantly enhance performance and extend the lifespan of the machinery.

Safety Precautions During Repair

Ensuring a secure environment while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to proper guidelines can significantly reduce risks associated with the work process. This section outlines essential safety measures to keep in mind when undertaking any mechanical maintenance.

Personal Protective Equipment (PPE)

Wearing the appropriate gear is fundamental in safeguarding against potential hazards. The following items should always be utilized:

- Safety goggles: Protects eyes from debris and harmful substances.

- Gloves: Provides hand protection from sharp edges and chemicals.

- Hearing protection: Necessary when working in loud environments.

- Steel-toed boots: Protects feet from heavy falling objects.

Work Environment

Maintaining a safe workspace is equally important. Consider these recommendations:

- Ensure proper ventilation to avoid inhalation of harmful fumes.

- Keep the work area organized and free of clutter to prevent tripping hazards.

- Use appropriate tools for each task, and inspect them regularly for damage.

- Implement lockout/tagout procedures to ensure machinery is properly shut down during maintenance.

By following these guidelines, the likelihood of accidents can be significantly minimized, promoting a safer and more efficient working environment.

Upgrades for Enhanced Performance

Improving the efficiency and precision of machinery is crucial for maintaining productivity and achieving high-quality results. Various enhancements can be implemented to optimize performance, extending the lifespan of the equipment while minimizing downtime. This section explores several key modifications that can lead to significant improvements.

1. Motor Upgrades: Replacing the existing motor with a more powerful and energy-efficient model can lead to faster operation and reduced energy consumption. Consider options that offer variable speed settings for added versatility in handling different tasks.

2. Enhanced Control Systems: Integrating advanced control systems can provide greater accuracy and consistency. Features such as programmable settings and digital displays allow for better monitoring and adjustments during operation.

3. Precision Components: Upgrading to higher-quality components, such as bearings and belts, can drastically improve the overall stability and performance of the machinery. Using precision-engineered parts reduces friction and enhances operational smoothness.

4. Improved Cooling Systems: Installing more efficient cooling systems can prevent overheating and prolong the lifespan of critical components. Options include advanced coolant circulation systems or heat exchangers designed for optimal thermal management.

5. Automation Features: Incorporating automation can streamline processes, reduce manual intervention, and enhance safety. Features such as automatic shutdown mechanisms and integrated sensors can help ensure smooth operation and protect against potential failures.

Implementing these upgrades can lead to remarkable enhancements in both performance and efficiency. As technology advances, staying informed about the latest innovations can ensure optimal operation and competitive advantage.

Where to Find Repair Manuals

Locating technical documentation for machinery is essential for effective maintenance and troubleshooting. Whether you’re looking for comprehensive guides or specific troubleshooting advice, there are various resources available to assist you.

- Manufacturer’s Website: Check the official website of the equipment producer for downloadable resources. Many companies provide digital access to technical guides.

- Online Marketplaces: Websites like eBay or Amazon often list both new and used technical documentation, which can be valuable for older models.

- Industry Forums: Engaging in online communities dedicated to machinery can yield recommendations and links to essential documents from experienced users.

- Libraries and Archives: Local libraries or specialized archives might have physical copies of the guides you need, especially for historical equipment.

- Trade Shows and Expos: Attending industry events can provide opportunities to acquire literature directly from manufacturers or distributors.

Utilizing these avenues will increase your chances of finding the necessary documentation to support your machinery effectively.