In the realm of culinary appliances, understanding the intricacies of functionality is essential for any home chef. Whether it’s about enhancing performance or addressing minor issues, having a comprehensive understanding of your cooking device can significantly improve your culinary experience.

This guide serves as a resource for navigating common challenges encountered in high-end cooking systems. By equipping yourself with knowledge, you can ensure optimal operation and longevity of your appliance, making every meal preparation a seamless journey.

From troubleshooting specific functionalities to routine maintenance practices, this information aims to empower users. Emphasizing proactive care not only enhances the efficiency of your device but also contributes to delightful cooking adventures.

This section highlights prevalent challenges faced by users of high-end cooking appliances. Understanding these common difficulties can facilitate effective troubleshooting and enhance the overall cooking experience.

- Temperature Inconsistencies

- Uneven Cooking Results

- Malfunctioning Control Panels

- Heating Element Failures

- Self-Cleaning Cycle Problems

- Door Seal Issues

- Noise During Operation

- Lighting Failures

- Gas Supply Complications

- Power Supply Interruptions

- Timer Malfunctions

- Interior Surface Damage

Each of these points provides a foundation for understanding specific issues and potential solutions. Addressing these aspects can significantly improve the functionality and longevity of the cooking equipment.

Identifying Faulty Heating Elements

In electric cooking devices, consistent heat production is crucial for achieving desired temperatures and ensuring proper cooking performance. When heating components begin to show signs of inefficiency, recognizing and diagnosing these issues promptly can prevent further complications and maintain steady operation.

To identify a malfunctioning heating component, start by observing temperature inconsistencies, such as an unexpected drop in heat or uneven distribution during use. Uneven browning or cold spots on surfaces can be clear indicators that something isn’t functioning as intended. These signs often point to the need for a closer examination of the

Troubleshooting Temperature Problems

When dealing with inconsistencies in temperature, identifying the root cause can help restore optimal function. Below are some common issues and steps to resolve them effectively.

- Check Temperature Sensor: Ensure the sensor is clean and positioned correctly, as improper placement or dirt can impact accuracy. Adjust or clean if necessary.

- Inspect Heating Elements: Examine the heating components for any visible damage or wear. Replacing or repairing faulty elements can restore proper heat levels.

- Test Thermostat Settings: Verify that the thermostat is accurately set to the desired temperature. A misaligned thermostat may cause irregular temperature readings.

- Control Panel Settings: Review settings on the control panel, ensuring there are no conflicting options enabled that could lead to te

Cleaning and Maintenance Tips

Regular care extends the life of any appliance, ensuring it stays in top condition for optimal performance. Consistent upkeep not only keeps equipment looking fresh but also helps prevent issues that can arise from accumulated grime and wear. Here, you’ll find simple routines and effective practices for maintaining peak functionality over time.

Daily and Weekly Cleaning

- Wipe down surfaces with a damp cloth to remove spills and splatters immediately after use. This prevents buildup and makes deeper cleaning easier.

- Once a week, use a gentle, non-abrasive cleaner to thoroughly clean areas that tend to collect grease or residue.

- Ensure vents and other key components are free from dust and debris, which can affect performance and efficiency.

Monthly Deep Clean

- Disconnect from any power source to safely access all areas.

- Remove and soak removable components in warm, soapy water, scrubbing gently to

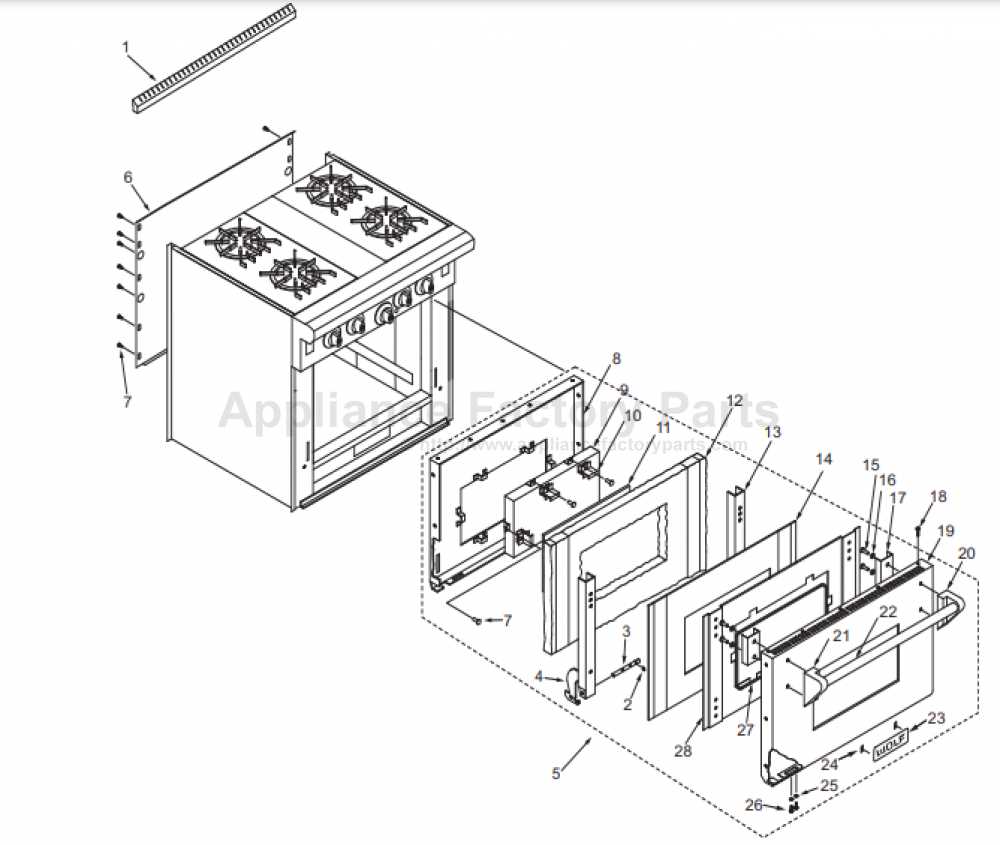

Replacing Oven Door Seals

Maintaining the effectiveness of your appliance often involves changing its door seals, a task that preserves energy and ensures uniform heating. Over time, seals can wear out, leading to heat loss and uneven cooking. Regular checks and replacements as needed can keep your appliance functioning optimally.

Recognizing Worn Seals

Signs of degraded seals typically include visible cracks, a hardened texture, or even noticeable heat escaping. Damaged seals may cause your appliance to take longer to reach the desired temperature or lead to inconsistent results. Carefully inspecting these areas allows you to catch issues early, ensuring optimal performance.

Steps for Replacing Seals

Before starting, unplug the appliance and allow it to cool completely. Remove the old seal gently by pulling it

Understanding Error Codes and Signals

In modern cooking appliances, error codes and signals provide crucial insights into how the system is functioning. These alerts are designed to notify users of specific issues, allowing for quick identification of the source of any disruption in normal operation. Recognizing and interpreting these indicators can help pinpoint technical glitches, sensor anomalies, or performance irregularities that may need attention.

Types of Signals may range from visual indicators to audio alerts, each signaling different levels of urgency. Some messages are informative, guiding users through maintenance steps, while others highlight potential system errors or critical faults.

Common Error Categories typically relate to temperature inconsistencies, sensor malfunctions, or power fluctuations. By learning

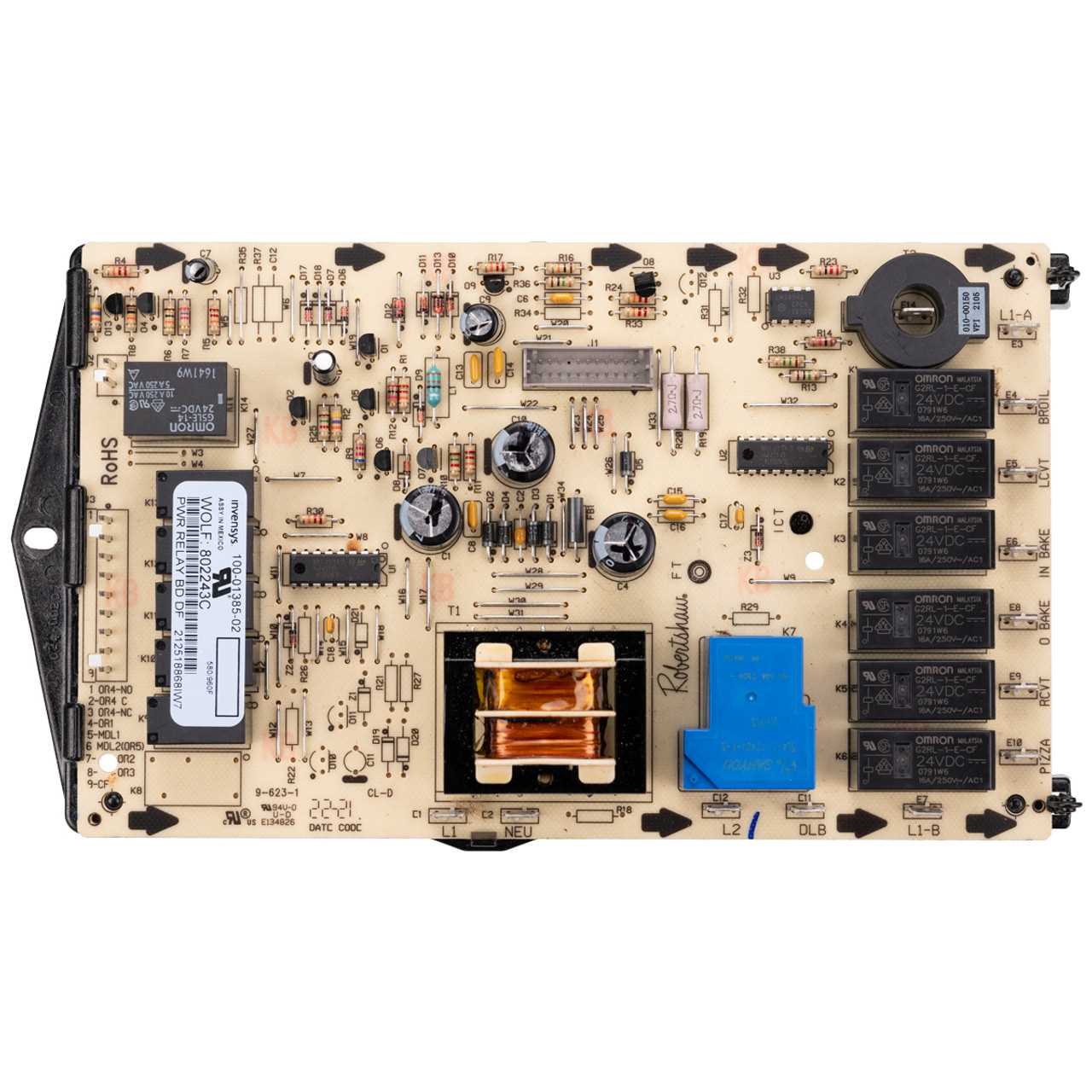

Fixing Electrical Connection Issues

When dealing with connectivity problems, addressing power-related concerns can be essential to restoring full functionality. Recognizing and resolving these electrical challenges can enhance safety and performance by ensuring stable power flow through the appliance’s circuits.

Identifying Common Connection Problems

Electrical issues may manifest in several ways, including intermittent operation or complete power failure. These disruptions often result from loose or damaged connections, affecting the

Repairing the Control Panel Functions

The control panel plays a crucial role in ensuring seamless access to various features and settings. This section covers ways to address common issues that may arise with control functions, providing guidance for restoring full functionality.

Identifying Common Issues

Start by examining the primary signs of malfunctions in the control area. Often, issues can stem from minor faults, such as unresponsive buttons, dim or blank displays, or intermittent power signals. Understanding these signs helps in pinpointing the potential causes.

- Button Non-Responsiveness: If certain buttons do not respond, the underlying issue might relate to the wiring or connectors.

- Display Dimness or Absence: Dim or non

Checking Gas Supply for Ovens

Ensuring a steady and safe gas supply is essential for the smooth operation of any cooking appliance. A reliable connection and consistent flow are necessary to maintain consistent performance and avoid potential issues. Regular checks can help identify any interruptions or adjustments needed in the system, contributing to safety and efficiency.

Begin by confirming the main valve is fully open and that there are no blockages in the line. If there is an external shut-off valve, make sure it is also in the correct position. For safety, inspect the line visually for any signs of wear or leaks.

Next, examine the connections to ensure they are tightly secured and free of corrosion. If any signs of damage or looseness are detected, it may be necessary to seek further inspection or replace parts to maintain a secure setup.

Assessing Fan and Ventilation Problems

Ensuring effective airflow and cooling mechanisms is essential for maintaining consistent performance and preventing overheating. Fan and ventilation components play a crucial role in managing heat and air circulation, helping to extend the equipment’s lifespan and optimize function.

Common Fan Issues

Several signs can indicate fan-related problems, often affecting temperature consistency and efficiency. Below are typical symptoms:

- Unusual noises, such as grinding or rattling, often suggest wear or obstruction.

- Erratic air movement or reduced cooling can indicate accumulated debris or motor issues.

- Increased operational heat may result from insufficient airflow or blockages.

Ventilation Blockages

Professional Help or DIY Repair?

Deciding between calling in a specialist or tackling the issue on your own can often be challenging. Each option comes with distinct advantages and considerations, from cost to convenience and expertise. This section outlines factors to help you choose the most effective solution for your situation.

Benefits of Expert Assistance

Hiring a professional brings peace of mind, especially for complex technical problems. Specialists bring knowledge, tools, and experience that can often lead to quicker solutions and long-term reliability. While this option might be pricier, it reduces the risk of further complications that might arise from inexperience or improper handling.

Advantages of a DIY Approach

Choosing to address minor malfunctions yourself can be both rewarding and cost-effective. With basic

Essential Tools for Wolf Oven Repair

Having the right instruments at your disposal is crucial when addressing issues with high-end cooking appliances. This section outlines the necessary equipment that will facilitate effective troubleshooting and restoration, ensuring optimal performance of the unit.

Basic Hand Tools

- Screwdriver Set: A variety of Phillips and flathead screwdrivers will help you tackle different fasteners.

- Socket Wrench: Useful for loosening or tightening bolts, ensuring secure connections.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating small components.

- Utility Knife: Ideal for cutting through packaging or electrical insulation.

Specialized Equipment

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Heat Gun: Useful for loosening adhesive or plastic components without damaging surrounding areas.

- Digital Thermometer: Helps verify temperature accuracy and ensure proper functionality.

- Wire Stripper: Necessary for safely handling and connecting electrical wires.