The efficiency and performance of any vehicle heavily depend on the intricacies of its shifting system. A well-functioning mechanism ensures smooth transitions between gears, enhancing overall driving experience. However, when complications arise, it’s crucial to address them promptly to avoid further issues.

In this section, we will explore various aspects of restoring and maintaining the shifting system. From identifying common challenges to implementing effective solutions, our focus will be on the techniques and best practices that lead to optimal functionality. Knowledge about this essential component not only contributes to vehicle longevity but also ensures safety on the road.

As we delve into the details, we will highlight critical factors that influence the operation of this complex assembly. Understanding these elements can empower vehicle owners and enthusiasts alike, making informed decisions regarding upkeep and troubleshooting. With the right information, anyone can enhance their driving experience and maintain the integrity of their automobile.

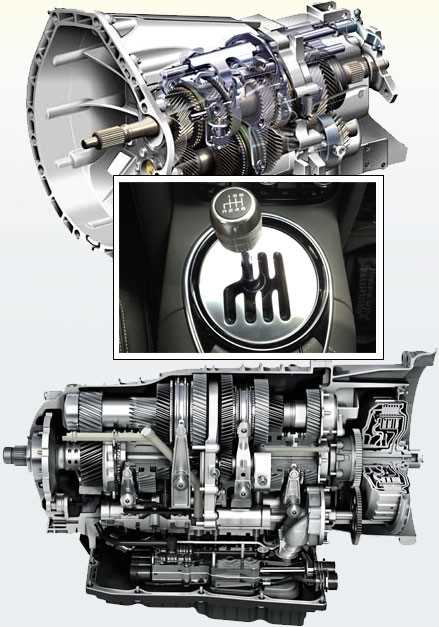

Understanding Manual Transmission Basics

This section aims to provide a foundational overview of how specific gear systems function in vehicles. Knowing these essentials helps in troubleshooting and enhances driving experience.

Key Components

- Gear Sets: Various arrangements allow for different speeds and torque outputs.

- Clutch Mechanism: Engages and disengages the engine from the system, facilitating gear changes.

- Linkage: Connects the gear stick to the internal components, enabling driver control.

Operation Principles

- Engagement: The driver presses the pedal to disconnect the engine, allowing for gear selection.

- Shifting: The driver moves the gear lever to select the desired gear based on speed requirements.

- Re-engagement: Releasing the pedal connects the engine back, allowing for acceleration.

Common Symptoms of Transmission Issues

Experiencing problems with your vehicle’s shifting mechanism can lead to a range of noticeable symptoms. Understanding these signs is crucial for identifying potential complications early and ensuring a smooth driving experience.

- Slipping Gears: The vehicle unexpectedly changes gears or loses power during acceleration.

- Delayed Engagement: There is a noticeable lag when shifting into gear, causing hesitation before the vehicle moves.

- Unusual Noises: Sounds such as grinding, clunking, or whining when changing gears may indicate underlying issues.

- Fluid Leaks: Puddles or spots of fluid under the vehicle can signal leakage, which may lead to operational failures.

- Warning Lights: Illuminated dashboard indicators often suggest that a system check is necessary.

- Burning Smell: A burnt odor could indicate overheating, which can damage internal components.

- Inconsistent Shifting: Irregular or harsh shifts can suggest malfunctions within the system.

Addressing these symptoms promptly can help prevent more significant issues and prolong the life of your vehicle’s components.

Essential Tools for Transmission Repair

When it comes to the restoration and maintenance of automotive gear systems, having the right set of instruments is crucial for ensuring efficiency and accuracy. A well-equipped workspace enables technicians to address a variety of tasks effectively, minimizing the risk of errors and enhancing overall performance.

Basic Hand Tools

Among the most vital implements are standard hand tools, which include wrenches, screwdrivers, and pliers. These items form the foundation for any mechanical endeavor. A reliable set of sockets, particularly those with metric and standard sizes, is essential for accessing tight spaces and securely fastening components.

Specialized Equipment

In addition to basic hand tools, specialized equipment plays a key role in the process. For instance, a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, while a gear puller allows for the safe removal of gears without causing damage. Furthermore, a bench vice can provide stability, making it easier to work on intricate parts.

Overall, a well-rounded toolkit not only enhances the quality of work but also contributes to a smoother workflow during any automotive servicing.

Step-by-Step Repair Process Explained

This section provides a detailed overview of the comprehensive approach to addressing issues related to gear shifting systems. Understanding each stage of the process is essential for effective restoration and optimal functionality.

- Initial Inspection:

Begin with a thorough examination of the entire system. Look for signs of wear, fluid leaks, and any unusual noises. This helps identify the root cause of the problem.

- Fluid Assessment:

Check the quality and level of the fluid. Contaminated or low fluid can lead to malfunctions, so ensure it meets the necessary standards.

- Component Disassembly:

Carefully remove the necessary parts to gain access to the internal components. Take note of the order of disassembly for easier reassembly.

- Part Examination:

Inspect each component for damage or excessive wear. Replace any parts that do not meet specifications to ensure proper function.

- Cleaning Process:

Thoroughly clean all components to remove debris and contaminants. This step is crucial for maintaining efficiency and longevity.

- Reassembly:

Reassemble the components in the reverse order of disassembly. Follow manufacturer guidelines to ensure proper alignment and fit.

- Final Testing:

After reassembly, conduct a series of tests to confirm that the system operates smoothly. Monitor for any irregularities that may indicate lingering issues.

Following these structured steps will help ensure a successful resolution to any issues, enhancing the performance of the shifting mechanism.

Diagnosing Gear Shifting Problems

Identifying issues related to gear engagement can be crucial for maintaining vehicle performance. Various factors may contribute to difficulties in changing gears, and understanding these can lead to effective solutions. By systematically examining the components involved, one can pinpoint the underlying causes of shifting anomalies.

Common symptoms may include grinding noises, resistance when moving the gear lever, or unexpected disconnections. These signs often indicate wear or malfunction in related parts. A thorough inspection of the linkage, fluid levels, and internal mechanisms is essential to diagnose the problem accurately.

It’s also advisable to consider environmental influences, such as temperature fluctuations or moisture, which can affect functionality. Regular maintenance checks can help prevent such issues from arising, ensuring smooth and reliable gear changes.

How to Replace Clutch Components

Replacing the key components of a vehicle’s engagement system can significantly enhance performance and prolong its lifespan. This process involves several steps to ensure that everything is installed correctly and functions optimally.

Follow these steps for a successful replacement:

- Gather Necessary Tools and Parts

- Clutch kit

- Socket set

- Torque wrench

- Jack and jack stands

cssCopy code

- Park on a level surface.

- Disconnect the battery.

- Lift the vehicle securely using the jack.

- Detach the drive shafts.

- Take off the old engagement unit.

- Inspect for any additional damage.

- Position the new engagement unit carefully.

- Secure it with the specified torque settings.

- Reattach the drive shafts.

- Reconnect the battery.

- Lower the vehicle.

- Test the new components for functionality.

By following these guidelines, you can effectively replace the essential components of the vehicle’s engagement system, ensuring smoother operation and reliability.

Fluid Types for Manual Transmissions

Choosing the right liquids for gear systems is crucial for optimal performance and longevity. Various formulations are available, each serving specific functions to ensure smooth operation and protect internal components.

- Synthetic Oils: These are engineered fluids that offer enhanced stability and performance under extreme conditions. They often provide better lubrication and reduce wear compared to conventional options.

- Conventional Oils: Derived from natural sources, these fluids are commonly used in many systems. While they may be adequate for regular driving conditions, they might not perform as well in high-stress situations.

- Additive-Enhanced Oils: Some fluids come with specialized additives designed to improve specific properties, such as viscosity, anti-wear characteristics, and resistance to oxidation.

When selecting the appropriate liquid, it’s essential to consider the manufacturer’s recommendations, the operating environment, and the specific requirements of the system. Using the correct fluid not only enhances performance but also helps in maintaining the overall health of the components involved.

Preventative Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s components requires consistent attention and care. By implementing a series of proactive measures, you can significantly extend the lifespan of essential systems, reduce the risk of breakdowns, and enhance overall performance.

Regular inspections and timely interventions can make a substantial difference. Below are key strategies to maintain the functionality of your vehicle’s systems:

| Maintenance Tip | Description |

|---|---|

| Fluid Checks | Regularly inspect and top off essential fluids, including oil and coolant, to ensure optimal operation. |

| Periodic Servicing | Schedule routine servicing to check for wear and tear on critical components, addressing issues before they escalate. |

| Driving Habits | Avoid aggressive driving and sudden stops, which can place undue stress on vehicle systems. |

| Heat Management | Monitor temperature levels and ensure proper cooling system functionality to prevent overheating. |

| Environmental Factors | Be mindful of driving conditions, such as heavy traffic or rough terrains, that can impact system performance. |

Incorporating these practices into your vehicle maintenance routine will help safeguard against premature wear, ensuring reliable performance for years to come.

Common Misconceptions About Repairs

Understanding the nuances of vehicle servicing can often lead to confusion and misconceptions. Many car owners hold beliefs that can cloud their judgment when it comes to addressing issues with their vehicles. This section aims to clarify some of the prevalent misunderstandings regarding vehicle maintenance and the associated processes.

One widespread myth is that all issues require extensive intervention, leading to unnecessary anxiety about costs and time. In reality, many problems can be resolved through simple adjustments or routine maintenance.

Another common belief is that only dealerships provide quality service. However, independent mechanics can offer equally proficient solutions at competitive prices, often with a more personalized approach.

Additionally, there’s a notion that regular maintenance is optional. Neglecting routine checks can lead to significant complications down the line, resulting in higher expenses and more extensive work than if the initial maintenance had been performed.

| Myth | Reality |

|---|---|

| All issues require major work | Many problems can be fixed easily |

| Dealerships are the only reliable option | Independent mechanics can provide quality service |

| Routine checks are optional | Neglecting maintenance can lead to bigger issues |

Cost Factors in Transmission Services

The expenses associated with gearbox maintenance can vary widely based on several influencing elements. Understanding these factors is crucial for vehicle owners to anticipate potential costs and make informed decisions regarding their machinery’s upkeep.

Labor Costs

One of the primary contributors to overall expenses is the labor involved in servicing. The complexity of the task and the skill level required can significantly affect the hourly rates charged by professionals. Highly experienced technicians may command higher fees, but their expertise often results in more efficient and effective solutions.

Parts and Materials

The cost of components plays a vital role in determining the total price of servicing. Original equipment manufacturer (OEM) parts typically come at a premium compared to aftermarket alternatives. Additionally, the availability of specific parts can impact pricing, as rare components may necessitate longer wait times and increased shipping costs.

Choosing a Reliable Repair Shop

Finding a trustworthy service provider for your vehicle is crucial for ensuring its optimal performance and longevity. A dependable shop not only offers quality work but also fosters a relationship built on transparency and customer satisfaction. It is important to consider several factors when selecting a location that will cater to your needs effectively.

Here are some key aspects to evaluate when making your choice:

| Criteria | Description |

|---|---|

| Experience | Look for a shop with a proven track record in handling similar issues. |

| Certifications | Verify that technicians hold relevant qualifications and training. |

| Customer Reviews | Check online reviews to gauge previous customer satisfaction and reliability. |

| Warranty | Ensure the shop provides a warranty on their services, reflecting their confidence in quality. |

| Estimates | Request written estimates to compare prices and avoid hidden fees. |

By carefully assessing these factors, you can select a service center that meets your expectations and provides the care your vehicle deserves.

Real-Life Repair Case Studies

This section explores practical examples of vehicle restoration challenges, highlighting the techniques and solutions employed in various situations. Through real-life scenarios, we can understand the complexities involved and the innovative approaches taken by skilled professionals in the field.

Case Study 1: A client brought in a vehicle experiencing persistent shifting issues. After a thorough assessment, it was determined that a combination of worn components and improper adjustments was to blame. The technician meticulously disassembled the assembly, replaced faulty parts, and fine-tuned the system, ultimately restoring smooth functionality.

Case Study 2: Another instance involved a vehicle with unusual noises during gear engagement. The expert diagnosed the problem as insufficient lubrication and incorrect alignment. By reconfiguring the setup and applying high-quality lubricant, the technician successfully eliminated the noise and improved overall performance.

Case Study 3: A vintage model was experiencing difficulties during acceleration. The investigation revealed that age-related wear had compromised critical elements. The technician crafted bespoke solutions, utilizing both modern materials and classic techniques to preserve the vehicle’s integrity while enhancing its driving experience.

These case studies exemplify the expertise required to tackle various challenges in the automotive realm, demonstrating the importance of detailed analysis and hands-on skills in achieving successful outcomes.