Ensuring the optimal performance of heavy machinery involves a deep understanding of various systems that enable smooth operation. This section delves into the essential knowledge required to address issues related to power transfer mechanisms in industrial equipment.

With a focus on practical techniques and essential tips, the following information aims to equip users with the necessary skills to troubleshoot and resolve common challenges. By familiarizing yourself with these processes, you can enhance the longevity and efficiency of your equipment.

Whether you are a seasoned technician or a newcomer to machinery upkeep, the insights provided here will serve as a valuable resource. The objective is to empower you with the confidence to handle maintenance tasks effectively, ensuring your machinery remains reliable and efficient in its operations.

Understanding Clark Transmission Basics

This section provides an overview of fundamental principles related to the mechanism that facilitates power transfer in various machinery. A thorough grasp of these concepts is essential for effective maintenance and troubleshooting.

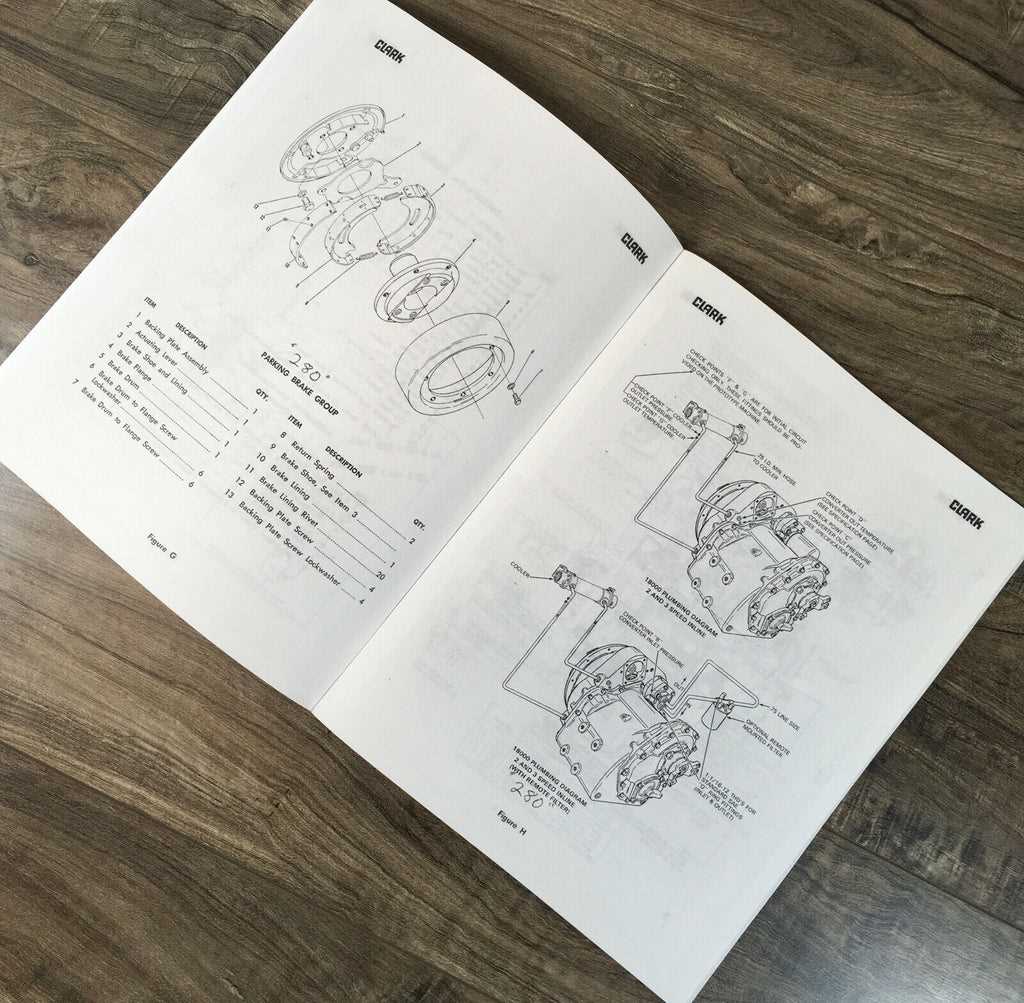

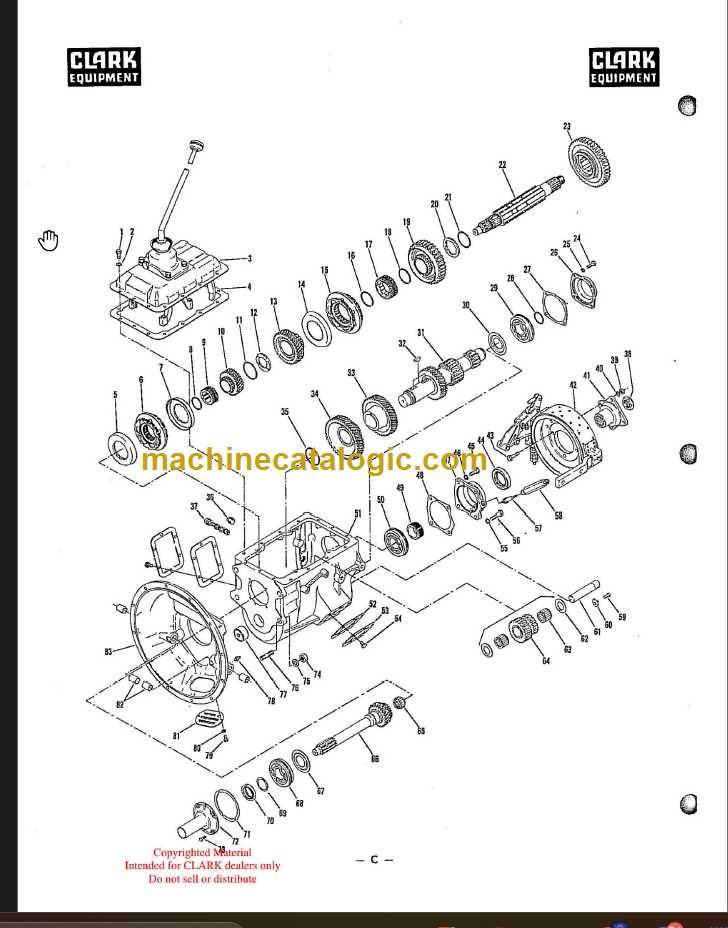

Key Components

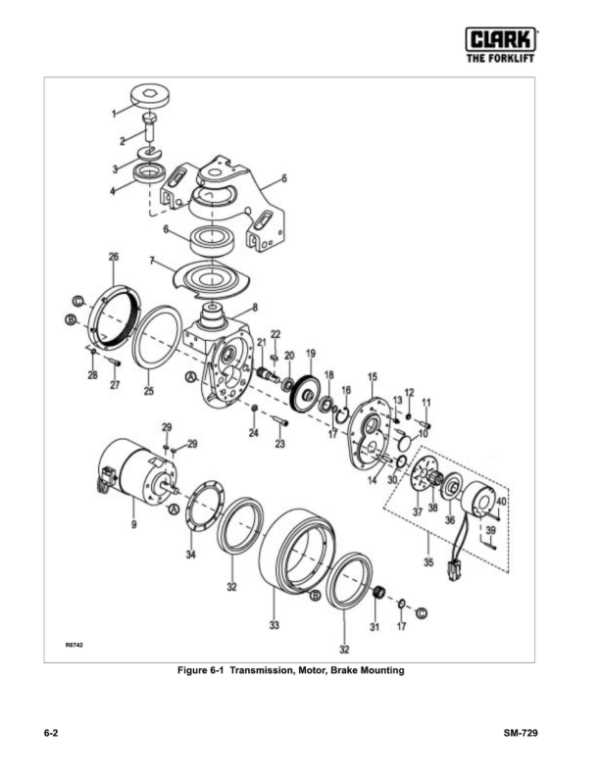

Several vital parts contribute to the overall functionality of the system. Each element plays a crucial role in ensuring smooth operation and longevity.

| Component | Function |

|---|---|

| Gear Set | Transmits torque and alters speed ratios. |

| Clutch Mechanism | Engages and disengages power flow. |

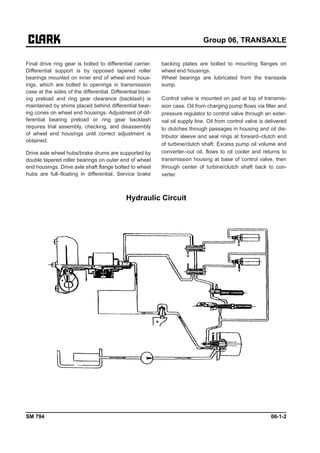

| Hydraulic System | Controls movement and pressure within the assembly. |

Operating Principles

Understanding how these elements interact is crucial. Efficient power transfer relies on precise alignment and coordination among all components, allowing for optimal performance.

Common Transmission Issues Explained

Understanding frequent problems that can arise in vehicle gear systems is essential for maintaining optimal performance. This section highlights typical complications encountered, shedding light on their symptoms and potential causes, allowing for informed decisions regarding maintenance and troubleshooting.

Slipping Gears

One prevalent issue is when the gears unexpectedly disengage or fail to remain engaged. This can result from worn components, low fluid levels, or air contamination. Drivers may notice a sudden loss of power, making it difficult to accelerate or maintain speed.

Unusual Noises

Another common concern involves strange sounds emanating from the system, such as grinding or whining. These noises often indicate internal wear or damage, requiring immediate attention. Regular inspections can help identify these sounds early, preventing more significant issues down the line.

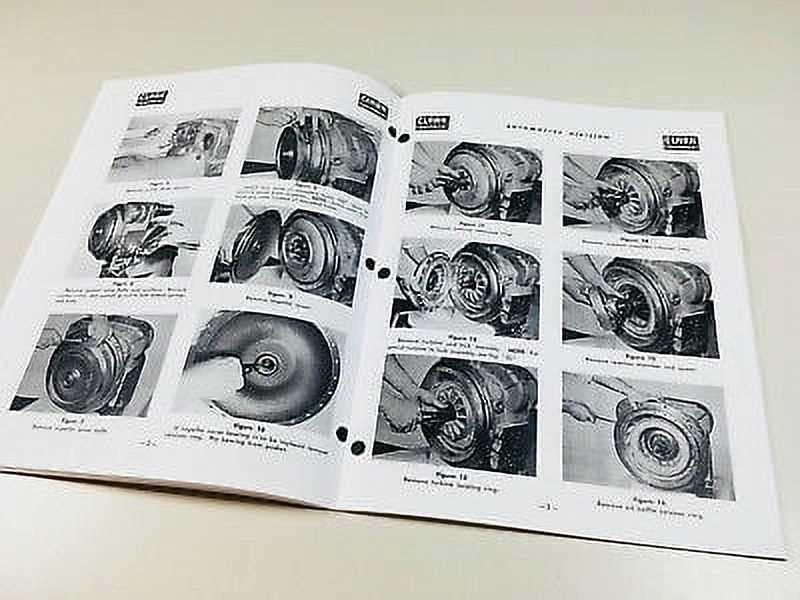

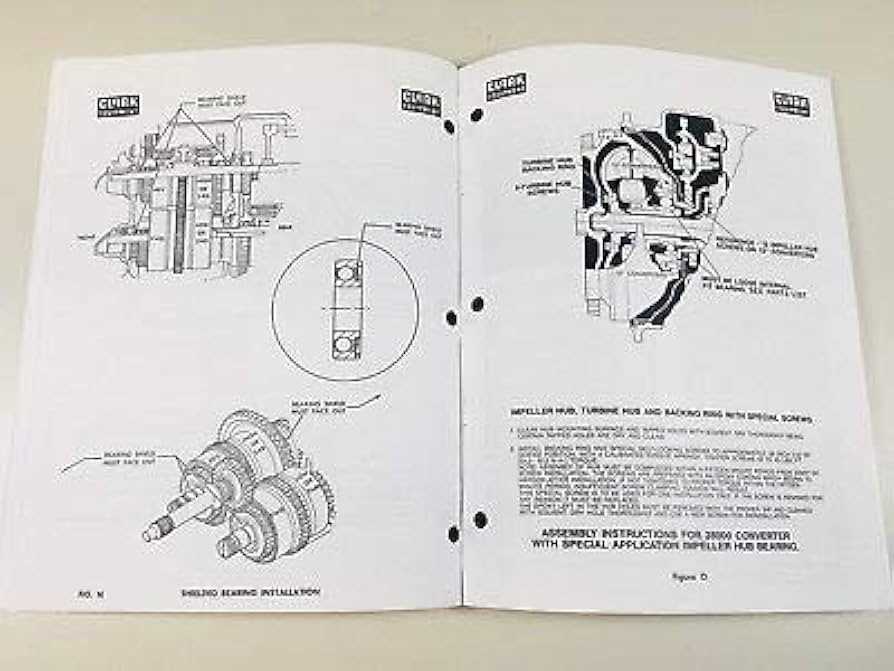

Step-by-Step Repair Procedures

This section outlines the detailed processes necessary for addressing issues commonly encountered in hydraulic systems. By following these structured steps, you can ensure effective troubleshooting and resolution of malfunctions, leading to enhanced performance and reliability.

Begin by gathering the essential tools and components required for the task. A thorough understanding of each step is crucial to avoid complications during the procedure.

| Step | Description |

|---|---|

| 1 | Disconnect the power source to ensure safety before starting any work. |

| 2 | Remove the outer casing carefully to access internal mechanisms. |

| 3 | Inspect components for signs of wear or damage, noting any irregularities. |

| 4 | Replace any defective parts with high-quality replacements to maintain efficiency. |

| 5 | Reassemble the unit, ensuring all connections are secure and properly aligned. |

| 6 | Reconnect the power source and conduct a functionality test to confirm successful restoration. |

Adhering to these guidelines will facilitate a smoother process and minimize the likelihood of recurring issues.

Essential Tools for Transmission Work

Engaging in complex mechanical tasks requires a specific set of instruments to ensure precision and efficiency. Utilizing the right equipment not only facilitates the process but also enhances safety and effectiveness in the workflow. Below are key implements that are crucial for undertaking intricate assembly and disassembly tasks in the field of automotive mechanics.

Basic Hand Tools

Starting with the essentials, a solid collection of hand tools is paramount. Wrenches, screwdrivers, and pliers form the backbone of any toolkit, allowing for the manipulation of various components. It is advisable to have a range of sizes and types to accommodate different fittings and fasteners encountered during the procedure.

Specialized Equipment

Beyond the basics, specialized tools are necessary for more detailed work. A torque wrench is critical for applying the correct force to bolts, ensuring they are secured without being overtightened. Additionally, fluid extraction pumps and gauges are vital for maintaining proper levels and diagnosing issues. Investing in high-quality equipment tailored for specific tasks can significantly improve the overall outcome of the project.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is essential to prevent accidents and injuries. Proper awareness and adherence to safety protocols can significantly reduce risks associated with mechanical interventions. This section highlights key considerations to follow during service procedures.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. Safety goggles, gloves, and steel-toed boots are recommended to shield against potential hazards. Additionally, utilizing ear protection can safeguard against loud noises generated during the servicing process.

Workspace Organization

A well-organized workspace contributes to a safer environment. Keeping tools and equipment neatly arranged minimizes the chance of accidents. Ensure that the area is well-lit and free from clutter, allowing for easy movement and reducing the risk of trips and falls.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By following a few key practices, you can enhance performance and extend the lifespan of your machinery. Consistent upkeep not only prevents unexpected failures but also contributes to overall efficiency.

Here are some essential maintenance strategies:

| Tip | Description |

|---|---|

| Regular Inspections | Conduct periodic evaluations to identify any wear or damage early on. |

| Fluid Checks | Monitor and replace fluids as needed to ensure optimal operation. |

| Clean Components | Keep all parts clean to prevent dirt accumulation, which can cause inefficiency. |

| Follow Manufacturer Guidelines | Adhere to recommended schedules for maintenance tasks provided by the manufacturer. |

| Use Quality Parts | When replacements are necessary, choose high-quality components to maintain performance. |

Implementing these practices will contribute to the reliability and longevity of your equipment, ensuring that it operates smoothly over time.

Diagnosing Electrical Problems

Identifying issues related to electrical systems requires a systematic approach. Understanding how different components interact and the symptoms of failures is essential for accurate troubleshooting. This section outlines the key steps to diagnose electrical malfunctions effectively.

Common Symptoms of Electrical Failures

- Inconsistent performance of machinery

- Unusual noises from electrical components

- Frequent blown fuses or tripped breakers

- Burning smells or visible damage to wiring

Steps to Diagnose Issues

- Check for visible damage: Inspect all wiring and connections for signs of wear or burn marks.

- Test with a multimeter: Measure voltage, current, and resistance to ensure components are functioning within specifications.

- Examine ground connections: Ensure that all grounding points are secure and free of corrosion.

- Isolate components: Disconnect components systematically to identify faulty parts without affecting the entire system.

By following these steps, you can systematically approach and resolve electrical issues, ensuring optimal functionality of the equipment.

Fluid Types and Their Importance

Choosing the right liquids for machinery is crucial for ensuring optimal performance and longevity. Different types of fluids serve specific functions and can greatly influence the overall efficiency of the system.

Here are some key reasons why selecting the appropriate fluid is essential:

- Lubrication: Proper lubrication reduces friction between moving parts, minimizing wear and tear.

- Cooling: Fluids help dissipate heat generated during operation, preventing overheating and potential damage.

- Contamination Prevention: The right fluids can help protect internal components from contaminants, thus enhancing reliability.

- Performance Optimization: Each fluid type is formulated to meet specific operational requirements, ensuring peak performance.

It’s vital to understand the characteristics of various liquid types, including viscosity, thermal stability, and chemical compatibility. Regularly checking and replacing fluids according to manufacturer guidelines can significantly extend the life of machinery and improve functionality.

Rebuilding Your Transmission: A Guide

Revitalizing your gear mechanism can be a rewarding endeavor, restoring performance and extending its lifespan. This guide outlines essential steps and considerations to help you through the process.

Essential Tools and Materials

- Wrenches and sockets

- Gaskets and seals

- Lubricants and fluids

- Torque wrench

- Cleaning supplies

Steps to Rebuild

- Remove the unit from the vehicle carefully.

- Disassemble the components, noting their arrangement.

- Inspect each part for wear and damage.

- Replace any defective components with high-quality alternatives.

- Reassemble the system, ensuring all connections are secure.

- Refill with appropriate fluids and check for leaks.

Common Misconceptions About Repairs

When it comes to maintaining complex machinery, several misunderstandings often arise, leading to confusion and poor decision-making. Recognizing these inaccuracies is crucial for ensuring efficient maintenance and longevity of equipment.

- All Issues Require Professional Help: Many believe that every problem needs to be handled by a specialist. However, some minor issues can be effectively managed by individuals with basic knowledge and skills.

- High Cost Equals Quality: There’s a common belief that higher expenses always correlate with better service. This isn’t necessarily true, as some budget-friendly options can deliver excellent results.

- Immediate Fixes are Permanent Solutions: Some assume that a quick fix resolves the problem for good. In reality, temporary solutions may mask underlying issues that require more comprehensive attention.

- New Parts are Always Better: There’s a notion that brand-new components are always superior. However, refurbished or quality used parts can perform just as well, if not better, in certain situations.

- Maintenance is Unnecessary: Many overlook the importance of regular upkeep, believing that as long as equipment is functioning, there’s no need for preventive measures. This can lead to significant problems down the line.

By debunking these myths, individuals can make informed choices, enhancing the performance and durability of their machinery.

Signs You Need Professional Help

Recognizing when to seek expert assistance can save time and resources. Various indicators can signal that your equipment requires attention from a trained technician. Ignoring these signs may lead to further complications and increased repair costs.

- Unusual Noises: If you hear grinding, whining, or clunking sounds, it’s a clear indication that something is wrong.

- Fluid Leaks: Any signs of fluid pooling under the machinery should be investigated promptly.

- Shifting Issues: Difficulty in engaging gears or unexpected changes in speed can point to serious problems.

- Warning Lights: Dashboard alerts or indicators are designed to notify you of potential issues and should not be ignored.

- Unresponsive Controls: If the controls feel sluggish or unresponsive, it’s time to consult a professional.

Addressing these symptoms early can prevent costly repairs down the line and ensure your equipment operates smoothly.

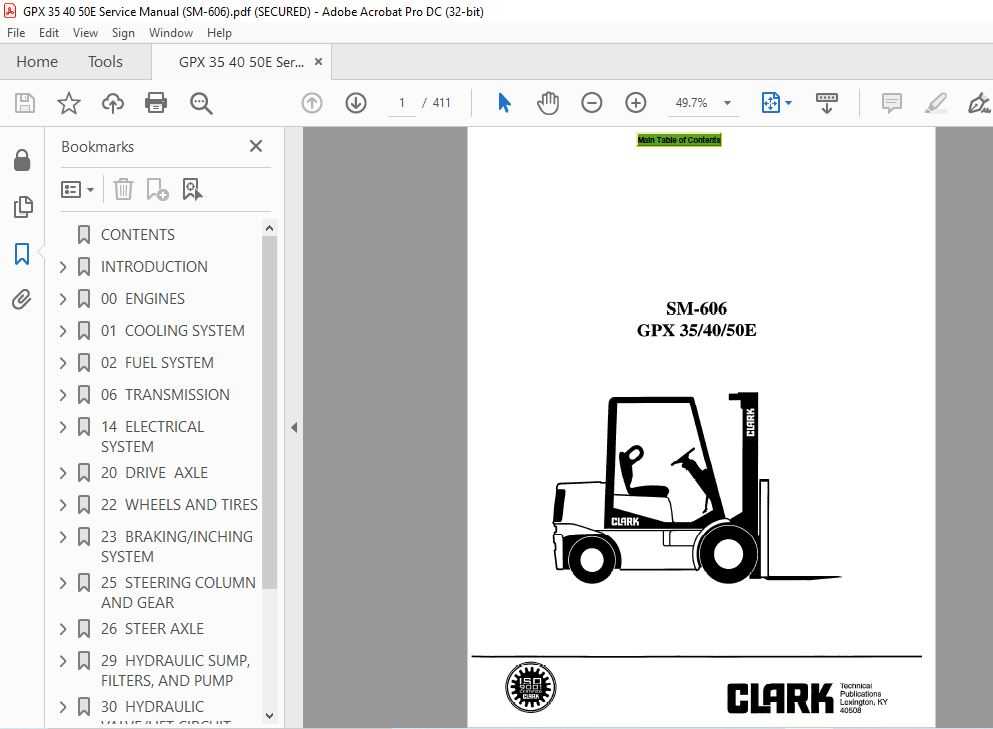

Resources for Further Learning

Exploring additional resources can significantly enhance your understanding of mechanical systems and their intricacies. Whether you are seeking foundational knowledge or advanced techniques, various platforms and materials are available to support your learning journey.

Online Courses and Tutorials

Numerous websites offer structured courses designed for both beginners and experienced individuals. These platforms often include video tutorials, interactive quizzes, and community forums where you can ask questions and share insights. Look for courses that focus on mechanical engineering principles and system maintenance.

Books and Reference Guides

Investing in comprehensive literature is a valuable way to deepen your knowledge. Look for texts that cover the fundamentals as well as specialized topics within the field. Reference guides can serve as excellent tools for quick consultations and detailed explanations.

Utilizing these resources will empower you to develop your skills and stay updated with the latest advancements in technology.