In the world of automotive excellence, ensuring the smooth operation of a vehicle’s power delivery system is paramount. An intricate assembly of components works together to provide a seamless driving experience. When these elements encounter issues, prompt attention is essential to restore functionality and maintain performance.

Understanding the complexities of this system allows for informed decisions when issues arise. From diagnosing symptoms to implementing effective solutions, knowledge is key. Whether it’s enhancing performance or addressing wear and tear, specialized services are available to keep your vehicle in optimal condition.

Professional assistance is crucial in navigating the intricacies of these mechanical systems. Skilled technicians employ their expertise to identify problems accurately and apply the necessary techniques for rejuvenation. Investing in quality care not only prolongs the life of your vehicle but also enhances its overall reliability.

Understanding Manual Transmission Basics

This section delves into the fundamental principles governing the operation of vehicles equipped with a traditional gear-shifting system. Grasping these essentials is vital for those looking to maintain or enhance their knowledge in automotive mechanics.

At its core, this system facilitates the selection of various gear ratios, allowing drivers to optimize engine performance for different driving conditions. Here are some key components involved:

- Clutch: Engages and disengages the engine from the drivetrain, enabling gear changes.

- Gear Selector: A lever used by the driver to choose the desired gear.

- Gear Set: A collection of gears that provide different speed ratios.

- Flywheel: A rotating disk that stabilizes the engine and aids in smooth engagement of the clutch.

The interaction between these components ensures seamless operation and performance. Understanding how each part functions enhances the ability to troubleshoot and resolve potential issues.

Key advantages of this system include:

- Greater control over vehicle speed and engine power.

- Improved fuel efficiency when managed correctly.

- Enhanced driving experience for enthusiasts who prefer a hands-on approach.

In summary, familiarity with the basic elements and operations allows for better decision-making regarding maintenance and performance optimization.

Common Issues in Manual Transmissions

Vehicles with standard gear systems may encounter various challenges that affect performance and drivability. Understanding these common problems can help owners maintain their vehicles and address issues promptly, ensuring a smoother driving experience.

| Issue | Description |

|---|---|

| Difficulty Shifting Gears | This may indicate problems with the clutch or linkage, making it hard to engage or disengage gears smoothly. |

| Slipping Gears | This occurs when the system unexpectedly shifts out of gear while driving, often due to worn components. |

| Noisy Operation | Unusual sounds, such as grinding or whining, may signal issues with internal components or insufficient lubrication. |

| Fluid Leaks | Fluid escaping from seals or gaskets can lead to inadequate lubrication, resulting in overheating and damage. |

| Burnt Clutch | Signs of a burnt clutch, including a burning smell and difficulty engaging gears, may indicate overuse or wear. |

Signs Your Transmission Needs Repair

Recognizing when your vehicle requires attention is essential for maintaining its performance and safety. Various symptoms can indicate underlying issues, and addressing them promptly can prevent further complications.

1. Unusual Noises: If you hear grinding, whining, or clunking sounds while shifting gears, it may signal internal problems. Such noises often suggest that components are worn or misaligned.

2. Slipping Gears: Experiencing a sensation where the gears unexpectedly shift or disengage can be alarming. This issue might indicate that parts are not functioning correctly or need lubrication.

3. Fluid Leaks: Any spots of liquid under your vehicle can be a warning sign. If you notice a reddish or brown fluid, it could point to issues that require immediate attention.

4. Warning Lights: Dashboard indicators are designed to alert you to potential issues. If a warning light related to performance illuminates, it is advisable to have your vehicle checked by a professional.

5. Difficulty Shifting: If you find it increasingly hard to change gears, this could indicate that the system is facing mechanical challenges. Smooth transitions are crucial for optimal operation.

6. Burning Smell: A burning odor may suggest overheating or friction within the system. This symptom should not be ignored, as it can lead to serious damage if not addressed.

Paying attention to these signs can help you maintain your vehicle’s efficiency and longevity. Regular inspections and prompt action when issues arise are key to ensuring smooth operation.

Essential Tools for Transmission Work

When engaging in the intricate task of servicing gear systems, having the right instruments is crucial for achieving optimal results. A well-equipped workspace can significantly enhance efficiency and precision, ensuring that every component functions as intended.

Basic Instruments

- Wrenches: Various sizes for loosening and tightening bolts.

- Sockets: Essential for reaching tight spots and securing fasteners.

- Torque wrench: Guarantees the correct tightness of bolts to prevent damage.

Specialized Equipment

- Gear pullers: Useful for removing components without causing damage.

- Fluid pumps: Essential for adding and removing lubricants efficiently.

- Alignment tools: Ensures that parts are positioned accurately during assembly.

Step-by-Step Repair Process Overview

This section provides a comprehensive outline of the procedures involved in fixing a vehicle’s shifting mechanism. Understanding the workflow is crucial for ensuring that each phase is executed efficiently and effectively, leading to optimal performance.

1. Initial Assessment: Begin by evaluating the overall condition of the system. Look for any signs of wear, unusual noises, or performance issues that may indicate underlying problems.

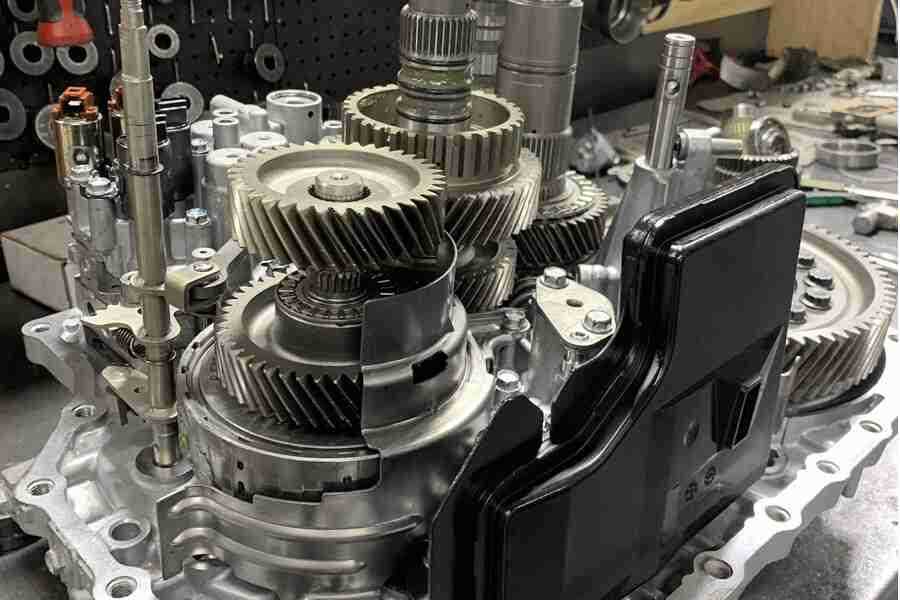

2. Component Disassembly: Carefully take apart the necessary components, ensuring that all parts are cataloged. This step is vital for maintaining organization and facilitating reassembly.

3. Cleaning and Inspection: Clean each component thoroughly and inspect for damage. Look for cracks, excessive wear, or any debris that may hinder functionality.

4. Replacement of Worn Parts: Identify parts that need replacement based on the inspection. Using high-quality replacements is essential for restoring proper function.

5. Reassembly: Carefully reassemble all components in the reverse order of disassembly. Ensure that all fasteners are secured properly to avoid future issues.

6. Testing: Once everything is reassembled, conduct a series of tests to ensure everything operates smoothly. Pay attention to any abnormalities during this phase.

7. Final Adjustments: Make necessary adjustments based on test results. Fine-tuning can greatly enhance overall performance and reliability.

Diagnosing Gear Shifting Problems

When experiencing difficulties with gear changes, it’s crucial to identify the underlying issues to ensure smooth operation. Various factors can contribute to shifting complications, and understanding these can help in diagnosing the problem effectively.

Signs of Trouble: Common indicators include grinding noises, difficulty in engaging or disengaging gears, or a feeling of resistance when attempting to shift. Recognizing these symptoms early can prevent further complications.

Fluid Levels: One of the first aspects to check is the fluid levels. Insufficient lubricant can lead to friction and overheating, resulting in poor shifting performance. Ensure that the fluid is at the correct level and in good condition.

Linkage and Cables: Inspecting the linkage and cables is essential. If they are worn or misaligned, they may not facilitate smooth transitions between gears. Adjustments or replacements may be necessary to restore proper function.

Internal Components: Internal wear and tear can also be a factor. Gears, synchros, or other internal parts may become damaged over time, impacting overall performance. A thorough inspection may be required to assess their condition.

Diagnostic Tools: Utilizing diagnostic equipment can provide insights into electronic or sensor-related issues that may affect shifting. Accessing the vehicle’s onboard computer can help identify error codes related to the shifting system.

By systematically examining these areas, one can accurately diagnose and address shifting problems, ensuring optimal performance and longevity of the system.

How to Inspect Transmission Fluid

Evaluating the condition of the fluid within your vehicle’s system is essential for maintaining optimal performance and longevity. Regular checks can help identify issues early, preventing more significant problems down the line.

Follow these steps to ensure a thorough inspection:

| Step | Description |

|---|---|

| 1 | Park your vehicle on a level surface and turn off the engine. Allow it to cool for a few minutes. |

| 2 | Locate the dipstick, usually found near the back of the engine bay. Remove it and wipe it clean with a lint-free cloth. |

| 3 | Reinsert the dipstick fully and then remove it again to check the fluid level. The fluid should be within the designated range marked on the dipstick. |

| 4 | Examine the fluid’s color and consistency. Healthy fluid is typically a bright red or pink hue, while dark or brown fluid may indicate degradation. |

| 5 | Smell the fluid. A burnt odor suggests overheating, which could lead to significant system issues. |

| 6 | If you notice any abnormalities, consider seeking professional assistance for further evaluation. |

Regular inspections are key to ensuring that your vehicle operates smoothly and efficiently. Addressing any issues promptly can save you time and money in the long run.

Replacing Worn Clutch Components

Over time, certain elements of the engagement system can become fatigued, leading to performance issues and difficulties in gear shifting. Addressing these worn components is crucial for maintaining optimal functionality and ensuring a smooth driving experience.

Identifying Worn Components

Recognizing signs of wear is the first step in the replacement process. Common indicators include slipping, difficulty in engaging gears, and unusual noises during operation. Regular inspections can help catch these issues early.

Replacement Process

Once worn parts are identified, replacing them typically involves several key steps. Below is a summary of the components commonly replaced during this maintenance procedure:

| Component | Description |

|---|---|

| Clutch Plate | The main friction component that engages with the flywheel to transfer power. |

| Pressure Plate | Exerts force on the clutch plate to ensure proper engagement and disengagement. |

| Release Bearing | Facilitates smooth operation by allowing the pressure plate to disengage when needed. |

| Flywheel | Rotating component that serves as a surface for the clutch plate to engage with. |

Adjusting Linkage and Cables

Ensuring proper function of the shifting mechanism is crucial for optimal vehicle operation. Proper alignment and tension of the connecting components enhance responsiveness and reliability.

Steps for Adjustment

- Start by inspecting the linkage for any visible wear or damage.

- Locate the adjustment points on the cables or rods.

- Loosen the necessary fasteners to allow for movement.

- Make adjustments to achieve the correct tension and alignment.

- Tighten the fasteners securely after adjustments are made.

Common Issues to Watch For

- Difficulty in engaging gears.

- Excessive play in the shifter.

- Unusual noises during shifting.

- Inconsistent gear engagement.

Common Myths About Manual Transmissions

There are numerous misconceptions surrounding vehicles with a certain type of shifting mechanism. These beliefs can lead to misunderstandings regarding their operation, maintenance, and overall reliability. Here, we explore some prevalent myths that may misinform drivers and enthusiasts alike.

Myth 1: They Are Difficult to Drive

Many people believe that operating vehicles with a shifting mechanism is overly complicated. In reality, while there is a learning curve, many find the experience rewarding and engaging once they become accustomed to the controls.

Myth 2: They Are Always More Reliable

Another common belief is that vehicles with this type of system are inherently more dependable than their counterparts. However, reliability depends on various factors, including maintenance and driving habits, rather than the design itself.

| Myth | Truth |

|---|---|

| Difficult to drive | Requires practice but can be enjoyable |

| Always more reliable | Depends on maintenance and usage |

| Better fuel efficiency | Varies with model and driving style |

Choosing Quality Replacement Parts

When it comes to ensuring the longevity and efficiency of your vehicle, selecting top-notch components is crucial. Quality parts not only enhance performance but also reduce the likelihood of future issues, leading to a smoother driving experience.

Benefits of High-Quality Components

- Durability: Premium parts are designed to withstand wear and tear, providing greater reliability over time.

- Performance: Quality replacements can improve your vehicle’s responsiveness and efficiency.

- Safety: Using trusted components reduces the risk of malfunction, enhancing overall safety on the road.

Factors to Consider

- Manufacturer Reputation: Research brands known for their reliability and quality standards.

- Material Quality: Choose parts made from durable materials that resist corrosion and wear.

- Warranty: Look for components that come with a warranty, indicating the manufacturer’s confidence in their product.

By prioritizing high-quality replacements, you ensure your vehicle operates at its best while extending its lifespan. Make informed choices and invest in parts that offer long-term benefits.

Importance of Professional Assistance

Seeking expert help when facing issues with vehicle gear systems is crucial for ensuring optimal performance and longevity. Skilled technicians possess the knowledge and experience to accurately diagnose problems, making them invaluable in restoring functionality. Relying on professionals not only enhances safety but also saves time and money in the long run.

Benefits of Expert Help

Utilizing professional services provides numerous advantages that contribute to the overall health of the vehicle:

| Benefit | Description |

|---|---|

| Expert Diagnosis | Professionals use advanced tools to identify issues that may be overlooked by untrained individuals. |

| Quality Repairs | Experienced technicians ensure repairs are conducted to high standards, reducing the likelihood of future problems. |

| Time Efficiency | Professionals can complete the work more quickly due to their expertise, minimizing vehicle downtime. |

| Warranty Protection | Using certified services can help maintain warranties, protecting the owner’s investment. |

Conclusion

In summary, enlisting the aid of skilled professionals is essential for maintaining the functionality and safety of vehicle systems. Their expertise ensures that issues are resolved efficiently and effectively, providing peace of mind to vehicle owners.

Preventative Maintenance Tips for Longevity

Ensuring the longevity of your vehicle’s key components requires proactive care and attention. Regular maintenance not only enhances performance but also helps prevent costly issues down the line. By adopting a few simple habits, you can significantly extend the lifespan of these essential systems.

Regular Fluid Checks

Maintaining the appropriate levels of various fluids is crucial. Regularly inspect and top off oils, coolants, and other vital fluids. Changing these fluids at manufacturer-recommended intervals can greatly enhance efficiency and reduce wear and tear.

Routine Inspections

Conducting routine inspections is vital to identify potential problems before they escalate. Look for signs of wear, leaks, or unusual noises. Addressing these issues promptly can prevent more severe damage and keep your vehicle operating smoothly.