When it comes to maintaining high-performance machinery, understanding the intricacies of their components is essential. This guide delves into the fundamental aspects of service techniques aimed at enhancing the longevity and efficiency of crucial parts. Mastering these procedures ensures that operators can keep their equipment running smoothly and reliably.

In the following sections, readers will encounter a structured approach to troubleshooting and maintenance, emphasizing practical solutions and effective methods. Each topic is crafted to provide clarity, offering step-by-step instructions that cater to both novices and seasoned professionals alike. This resource serves as a valuable reference for anyone looking to deepen their knowledge of mechanical systems.

Furthermore, special attention is given to common issues encountered during upkeep, along with insightful tips to avoid potential pitfalls. By following the guidance provided, individuals can cultivate a thorough understanding of their machinery, ultimately leading to improved performance and reduced downtime. Whether you’re an enthusiast or a professional, this compilation will be an indispensable asset in your toolkit.

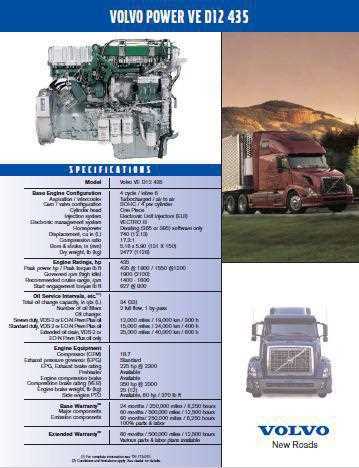

Understanding the Volvo D12 Engine

This section delves into the intricacies of a powerful automotive powerhouse known for its reliability and performance. Designed for heavy-duty applications, this unit is a remarkable feat of engineering that combines efficiency with durability. A solid grasp of its components and functioning can significantly enhance the maintenance and longevity of the vehicle.

Key Features and Specifications

At the heart of this remarkable machine lies a robust design that ensures optimal performance under various conditions. Key characteristics include a multi-cylinder layout, advanced fuel injection technology, and sophisticated cooling systems. These features work in harmony to deliver exceptional torque and horsepower, making it suitable for demanding tasks.

Maintenance Insights

Regular upkeep is essential to preserve the longevity and efficiency of this mechanical marvel. Understanding the common issues that may arise, such as wear and tear of components, helps in preemptive actions. Routine checks on filters, fluids, and electrical systems can mitigate potential problems, ensuring smooth operation over time.

Common Issues with Volvo D12

In the realm of heavy-duty machinery, certain challenges often arise that can affect performance and reliability. Understanding these prevalent concerns can assist operators in maintaining optimal functionality and extending the lifespan of their vehicles. This section explores some of the most frequent problems encountered in this category of machinery.

Typical Challenges

Several issues may arise, impacting overall efficiency. Here are some common challenges faced:

| Issue | Description | Symptoms |

|---|---|---|

| Oil Leaks | Leaks can occur due to worn seals or gaskets. | Visible oil spots under the vehicle. |

| Overheating | Cooling system failures can lead to excessive temperatures. | Temperature gauge reads high; warning lights may activate. |

| Fuel Inefficiency | Issues with injectors or filters can decrease fuel economy. | Increased fuel consumption; frequent refueling required. |

| Power Loss | Mechanical problems or air intake issues can result in reduced power. | Sluggish acceleration; difficulty maintaining speed. |

Preventive Measures

Regular maintenance and timely inspections can help mitigate these issues. Keeping an eye on fluid levels, monitoring performance, and addressing small problems before they escalate are crucial steps in ensuring longevity and reliability in heavy-duty operations.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments can significantly influence the efficiency and quality of the work. The following tools are crucial for ensuring that every job is executed with precision and care.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket wrenches, to accommodate different fasteners.

- Screwdrivers: Both flathead and Phillips options are essential for various applications.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting.

- Hammer: A rubber or dead-blow hammer can prevent damage while providing adequate force.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Diagnostic Tools: Essential for troubleshooting and assessing the condition of components.

- Compression Gauge: Useful for checking the health of internal mechanisms.

- Fluid Transfer Pump: Facilitates the easy movement of liquids during service procedures.

Equipping yourself with these essential tools not only makes the process smoother but also enhances the longevity and performance of the systems you are working on.

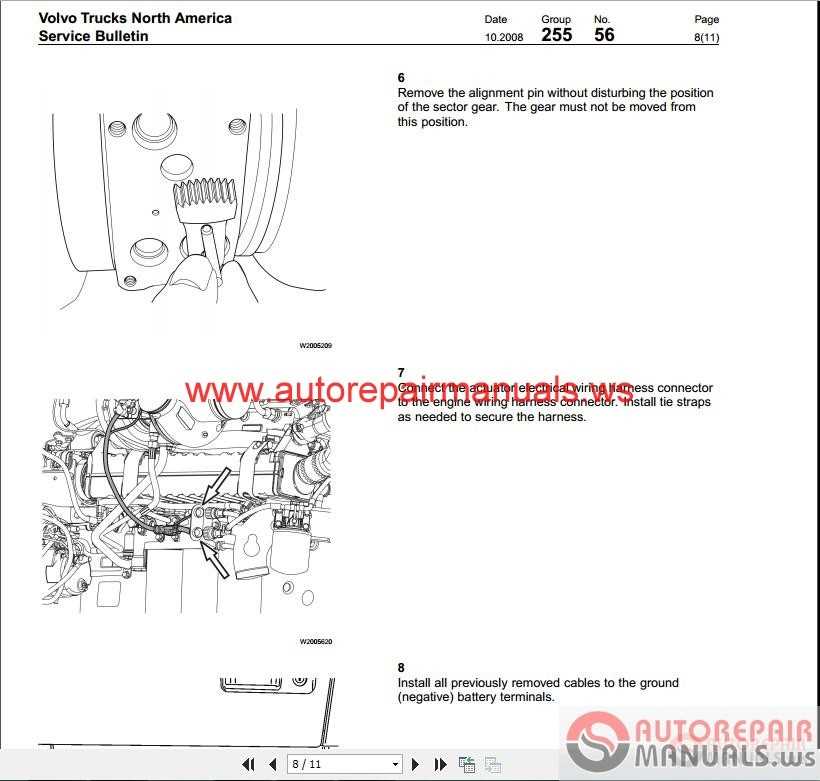

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues associated with complex machinery. Following these organized steps can significantly enhance the effectiveness and efficiency of maintenance tasks, ensuring optimal performance and longevity.

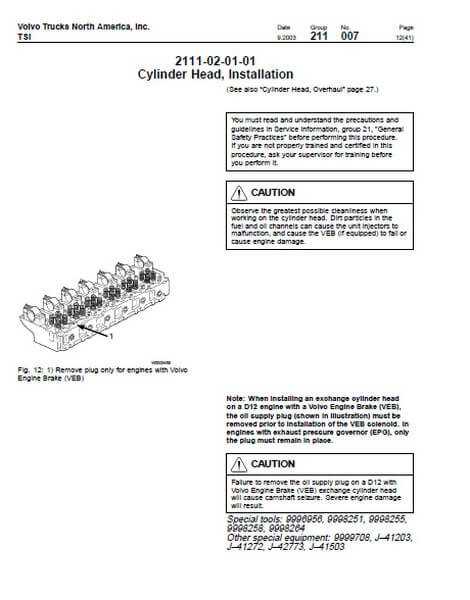

1. Preparation and Safety: Before beginning any task, ensure that all necessary tools and equipment are readily available. Additionally, put on appropriate personal protective gear to minimize risks associated with mechanical work.

2. Assessment: Conduct a thorough examination to identify the specific problems. Look for signs of wear, leaks, or irregular sounds that could indicate underlying issues. Document your findings for reference.

3. Disassembly: Carefully remove any components that obstruct access to the area of concern. Keep track of all parts, and label them as necessary to facilitate reassembly. Use proper techniques to avoid damaging sensitive parts.

4. Cleaning: Clean all components meticulously to remove any dirt, oil, or debris. This step is crucial for accurate diagnosis and ensures that any repairs can be made effectively.

5. Inspection: Examine each component for damage or signs of fatigue. Use precision measuring tools where applicable to determine if parts are within specifications. Replace any items that do not meet required standards.

6. Reassembly: Carefully reassemble all parts in the reverse order of disassembly. Ensure that all fasteners are torqued to the manufacturer’s specifications to avoid issues during operation.

7. Testing: Once everything is reassembled, conduct tests to verify that the machine operates correctly. Monitor performance closely and address any anomalies that arise.

8. Documentation: Finally, document the entire process, including any findings and actions taken. This record will be valuable for future maintenance and can assist others in troubleshooting similar problems.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your machinery requires a proactive approach to upkeep and care. By following a series of essential practices, you can significantly extend the lifespan and efficiency of your equipment.

- Regularly check fluid levels and replace them as necessary to prevent wear and tear.

- Inspect filters and replace them according to the manufacturer’s recommendations to maintain optimal operation.

- Schedule routine inspections to identify and address potential issues before they escalate.

- Keep the exterior clean to prevent dirt accumulation, which can lead to overheating and damage.

- Monitor temperature and pressure levels consistently to ensure everything is functioning within normal ranges.

In addition to these basic practices, consider implementing the following advanced techniques:

- Utilize high-quality lubricants to reduce friction and enhance performance.

- Adhere to recommended service intervals to keep components in peak condition.

- Train operators on best practices to promote efficient and safe usage.

- Invest in diagnostic tools to facilitate timely maintenance and troubleshooting.

- Store the machinery in a protected environment to minimize exposure to harsh elements.

By integrating these strategies into your routine, you can help ensure that your equipment remains reliable and performs optimally for years to come.

Diagnostic Techniques for Engine Problems

Identifying issues within a power unit requires a systematic approach to uncover underlying faults. Employing various methodologies can streamline the troubleshooting process and lead to effective solutions. The integration of technology and traditional practices enhances accuracy in diagnostics, ensuring that even subtle anomalies are detected.

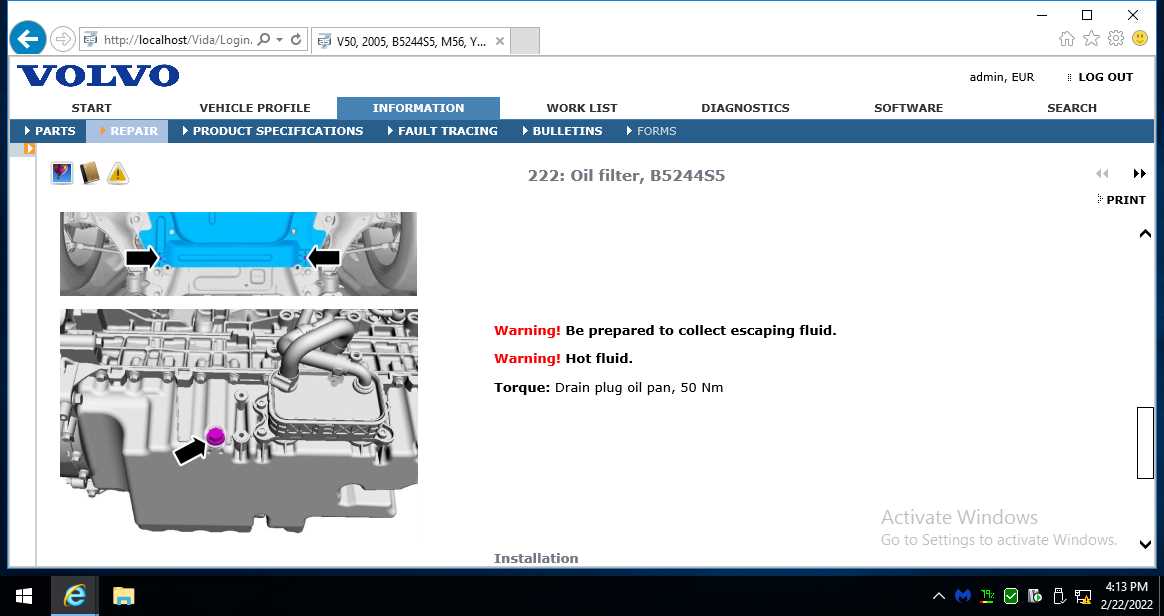

One fundamental technique is the use of onboard diagnostic systems, which provide valuable data on performance metrics and error codes. Analyzing these readings helps pinpoint specific areas of concern. Additionally, visual inspections play a crucial role; checking for leaks, wear, and corrosion can reveal physical damage that may not be recorded electronically.

Another important method is conducting compression tests. These evaluations assess the integrity of internal components and can highlight issues such as worn piston rings or valve malfunctions. Furthermore, sound analysis can be beneficial; unusual noises often indicate misalignments or failing parts that require immediate attention.

Regular maintenance checks also contribute to preventive diagnostics. Keeping detailed service records allows technicians to track patterns and foresee potential failures before they escalate. By combining these strategies, operators can effectively manage and mitigate performance-related challenges, ensuring optimal functioning of the machinery.

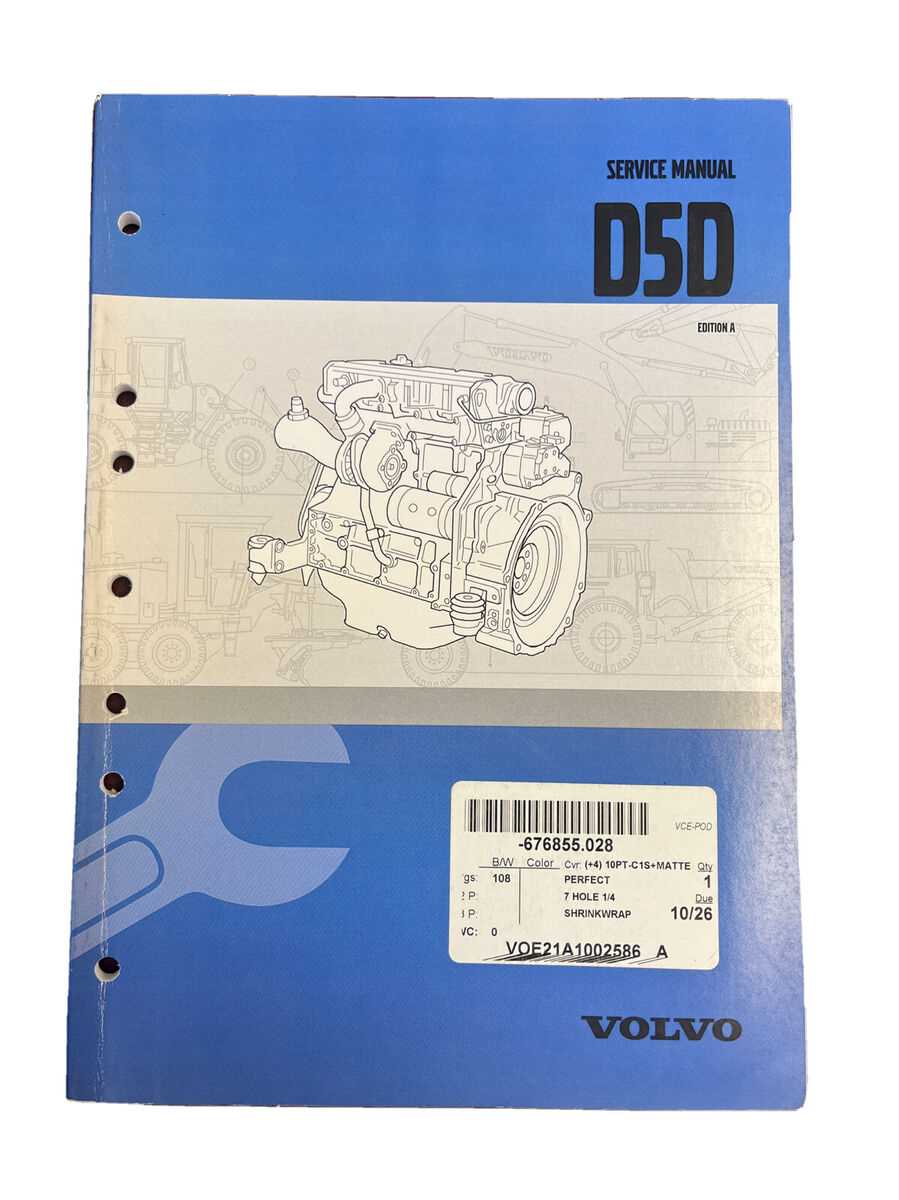

Parts Replacement Guide

This section provides a comprehensive overview of how to effectively replace components in heavy machinery. Proper knowledge of part identification, selection, and installation is crucial for maintaining optimal performance and longevity.

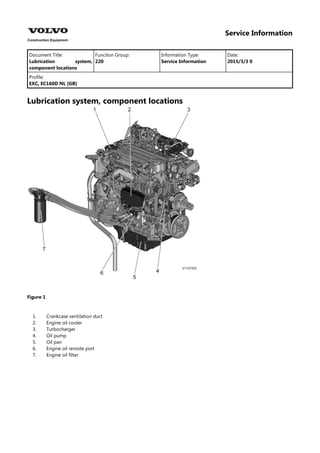

Identifying Components

Before proceeding with any substitutions, it’s essential to accurately identify the worn or damaged parts. Utilize the manufacturer’s specifications to ensure compatibility. Consult diagrams and documentation to familiarize yourself with the layout and function of each element. This foundational step is vital for a successful overhaul.

Replacement Process

Once the necessary components are identified, follow a systematic approach to removal and installation. Begin by preparing the workspace, ensuring all tools and new parts are readily available. Carefully detach the old components, taking note of their arrangement for reference. When installing the new items, adhere to the torque specifications and alignment guidelines to prevent future issues. Regular maintenance checks post-replacement will help ensure everything is functioning as intended.

Understanding Engine Specifications

Grasping the technical details of a power unit is crucial for anyone looking to enhance performance or address maintenance concerns. These specifications serve as a foundation for assessing the capabilities and limitations of the machinery. From power output to fuel efficiency, every parameter plays a significant role in the overall functionality.

Key metrics typically include displacement, compression ratio, and torque figures, each contributing to the operational characteristics. Displacement reflects the volume of the cylinders, influencing the engine’s ability to produce power. The compression ratio indicates how effectively the air-fuel mixture is utilized, affecting both performance and efficiency. Torque, on the other hand, is a measure of rotational force, critical for determining acceleration and load-bearing capacity.

Furthermore, understanding these specifications allows for informed decision-making regarding modifications or replacements. It aids in troubleshooting issues, ensuring that any adjustments align with the intended use of the vehicle. Familiarity with these details can lead to more effective maintenance practices and enhanced longevity of the machinery.

Best Practices for Engine Testing

Conducting thorough assessments of machinery is crucial for ensuring optimal performance and longevity. A systematic approach not only identifies potential issues but also enhances the overall reliability of the unit. Implementing best practices during these evaluations can lead to significant improvements in functionality.

Here are some essential guidelines to follow during assessments:

- Preparation: Ensure all tools and equipment are in good working condition before starting the evaluation.

- Documentation: Keep detailed records of all tests performed, including results and any anomalies observed.

- Safety First: Always prioritize safety by wearing appropriate protective gear and following standard operating procedures.

- Warm-Up: Allow the unit to reach operating temperature before conducting performance tests to ensure accurate readings.

- Consistent Conditions: Perform assessments under similar conditions to obtain reliable and comparable data.

Incorporating these practices can significantly enhance the effectiveness of your evaluations, leading to better decision-making and improved maintenance strategies.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to ensure a secure working environment. Awareness of potential hazards and taking proactive measures can significantly reduce the risk of accidents and injuries. Implementing proper safety protocols is essential for both novice and experienced technicians alike.

Personal Protective Equipment (PPE) should always be worn. This includes gloves, safety glasses, and steel-toed boots, which provide necessary protection against spills, sharp objects, and heavy components. Additionally, appropriate clothing should be worn to minimize exposure to harmful substances.

It is important to maintain a clean and organized workspace. Clutter can lead to tripping hazards and make it difficult to locate tools and parts when needed. Regularly cleaning up any spills and ensuring that tools are stored properly can enhance safety during the process.

Proper Ventilation is another critical aspect. Working in an enclosed space can lead to the accumulation of harmful fumes and dust. Ensure that the area is well-ventilated, or use appropriate extraction systems to minimize inhalation risks.

Finally, familiarizing yourself with the tools and components is vital. Understanding how each tool functions and the correct procedures to follow can help prevent accidents and ensure effective handling. Always consult relevant resources to enhance your knowledge and skills.

How to Find Genuine Parts

Locating authentic components for your vehicle is crucial for ensuring optimal performance and longevity. Counterfeit or substandard parts can lead to significant issues, affecting both safety and functionality. This guide outlines effective strategies for sourcing high-quality materials that meet industry standards.

Research Authorized Dealers: Start by identifying certified distributors or official retailers. These sources are more likely to stock genuine components and often provide warranties, giving you peace of mind regarding your purchase.

Verify Part Numbers: Always cross-reference the part numbers before making a purchase. Genuine components typically have distinct identifiers that can be verified through various online databases or the manufacturer’s website.

Seek Recommendations: Engage with online communities or forums dedicated to your vehicle type. Enthusiasts and professionals often share insights about reputable suppliers and their experiences, guiding you toward reliable options.

Inspect Packaging: When you receive your order, carefully examine the packaging for authenticity markers. Genuine parts often come with specific labels or seals that can help you confirm their legitimacy.

Utilize Online Platforms: Various e-commerce sites specialize in automotive components. Look for those that emphasize the authenticity of their inventory and provide detailed descriptions, including manufacturer details.

By following these steps, you can ensure that the parts you procure are not only genuine but also enhance the overall reliability and performance of your vehicle.

Resources for Further Learning

Expanding your knowledge in the field of automotive mechanics can greatly enhance your understanding and skills. Whether you’re a professional or a passionate hobbyist, having access to a variety of educational materials is essential. This section highlights valuable resources that can provide deeper insights into maintenance, troubleshooting, and overall vehicle performance.

Online Courses and Webinars

Many platforms offer comprehensive courses tailored for those interested in automotive systems. Look for online classes that cover advanced diagnostics and maintenance practices. Additionally, webinars hosted by industry experts can provide real-time insights and the latest trends in vehicle technology.

Books and Technical Guides

Investing in well-reviewed literature and technical guides can serve as an invaluable resource. Many publications focus on specific systems and components, providing detailed explanations and illustrations that enhance understanding. Consider joining local libraries or online forums where you can share recommendations and access rare texts.