In the world of automated beverage preparation, understanding the intricacies of these devices is essential for maintaining their functionality and performance. This section delves into the common issues faced by users, offering insights into diagnostics and solutions that can enhance the brewing experience.

Whether dealing with unexpected malfunctions or routine maintenance, having a structured approach can make a significant difference. By exploring various components and their functions, users can gain valuable knowledge that empowers them to address challenges effectively.

This resource aims to provide detailed steps and considerations, ensuring that enthusiasts and casual users alike can enjoy their daily brews without interruption. Emphasizing clarity and practicality, the content guides readers through the process of restoring optimal operation to their coffee machines.

This section aims to provide an overview of a popular beverage brewing device designed for convenience and efficiency. Understanding the fundamental components and functionalities of this machine is essential for effective troubleshooting and maintenance. It is crucial to familiarize yourself with the various parts that contribute to its operation and the common issues users might encounter.

| Component | Description |

|---|---|

| Water Reservoir | A detachable container that holds the liquid used for brewing. |

| Drip Tray | A removable tray that catches excess liquid during brewing, helping to keep the area clean. |

| Control Panel | The interface used to operate the machine, allowing users to select brewing options. |

| Heating Element | The component that heats the water to the desired temperature for brewing. |

| Brewing Chamber | The area where the coffee pod is placed, and water is infused to create the beverage. |

Common Issues and Troubleshooting Tips

This section addresses frequent problems that users may encounter with their coffee brewing machines, along with effective solutions to enhance performance and reliability. Understanding these common concerns can significantly improve the brewing experience and extend the lifespan of the device.

One typical issue is insufficient water flow, which may lead to weak coffee or the machine not functioning properly. To resolve this, check for any blockages in the water reservoir or the internal pathways. Regular cleaning and descaling can help maintain optimal performance.

Another common concern involves the device failing to heat water adequately. This may indicate a malfunctioning heating element. Users should ensure the machine is plugged in properly and check the temperature settings. If problems persist, a thorough inspection may be necessary.

Additionally, the appearance of error messages can cause frustration. These messages often signal specific problems. Consulting the user guide can provide insights into the meanings behind these alerts and suggest appropriate actions.

Finally, if the brewing cycle is interrupted or the machine shuts off unexpectedly, it may be due to a power issue or internal fault. Ensure that the power source is stable and consider resetting the device. If the problem continues, professional assistance may be required.

Essential Tools for Repairs

To effectively address issues with your beverage maker, having the right instruments is crucial. These essential implements ensure that tasks can be performed smoothly and efficiently, allowing you to resolve problems without unnecessary complications. Below is a list of commonly needed tools that will assist you in the maintenance and troubleshooting of your device.

Basic Hand Tools

- Screwdrivers: A set of various sizes, including flathead and Phillips, for removing screws.

- Pliers: Useful for gripping and manipulating components.

- Wrenches: Adjustable wrenches can help loosen or tighten nuts and bolts.

Cleaning and Maintenance Supplies

- Cleaning Solution: A mild detergent or specific cleaner for removing residue.

- Microfiber Cloths: Ideal for wiping surfaces without scratching.

- Brushes: Small brushes help reach tight spots and clear out buildup.

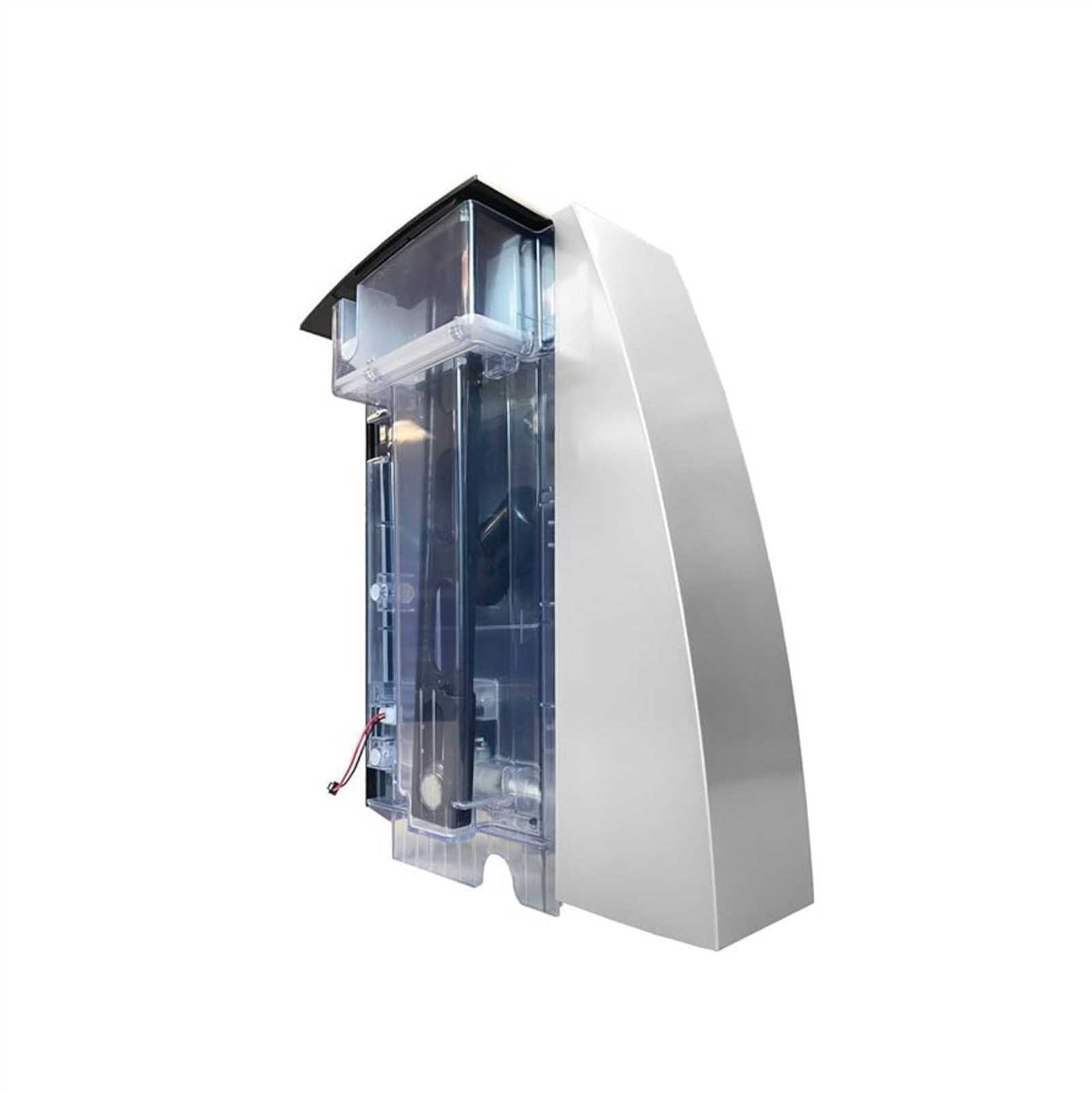

Disassembling Your Keurig K150P

When it comes to taking apart your coffee brewing machine, a systematic approach is essential. This section will guide you through the process, ensuring that you can effectively access the internal components without causing any damage.

Begin by unplugging the appliance and clearing away any remaining water. Carefully remove the top panel by unscrewing the fasteners, which may be hidden beneath rubber feet or stickers. Patience is key as you maneuver the components apart to avoid breaking any clips or connectors.

Next, focus on the side panels. Gently pry them away from the main body, using a flat tool if necessary to assist in separating the parts. Ensure you keep track of all screws and small pieces, placing them in a container to prevent loss. Once the sides are off, you will have clearer access to the internal mechanisms, allowing for further inspection or cleaning.

Finally, take your time with the assembly of the internal parts. Carefully detach any connections that may need attention, such as tubing or electrical connectors. By following these steps with care, you can successfully disassemble your machine for maintenance or troubleshooting purposes.

Cleaning and Maintenance Procedures

Proper upkeep of your beverage maker is essential to ensure optimal performance and longevity. Regular cleaning and maintenance help to prevent buildup and keep all components functioning smoothly, which in turn enhances the quality of each cup.

Start by regularly descaling the unit to remove mineral deposits. This process typically involves using a suitable descaling solution mixed with water, followed by running multiple cycles to ensure thorough cleaning. Additionally, the water reservoir and drip tray should be emptied and washed frequently to avoid any unwanted residue or odors.

Inspect the brewing parts periodically for any signs of wear or obstruction. Regularly replacing filters and checking the brewing mechanism will contribute to a consistent and enjoyable brewing experience. By adhering to these practices, you can maintain the efficiency and taste of your beverages for years to come.

Replacing the Water Filter

Maintaining a clean water source is essential for optimal performance of your beverage maker. Regularly changing the filtration element ensures that your drinks taste fresh and free from impurities. This section outlines the steps necessary to replace the filtration component effectively.

Steps to Follow

Begin by gathering the necessary tools and materials. Ensure you have a replacement filtration element and any required utensils for the process. Follow these steps for a successful replacement:

- Turn off the appliance and unplug it from the power source.

- Remove the water reservoir carefully.

- Locate the filtration compartment, usually situated at the bottom of the reservoir.

- Take out the old filtration element and dispose of it properly.

- Unpack the new filtration element and insert it into the compartment, ensuring a snug fit.

- Reattach the water reservoir and fill it with fresh water.

- Plug the appliance back in and allow it to prime if necessary.

Filtration Element Specifications

| Type | Capacity | Frequency of Replacement |

|---|---|---|

| Activated Carbon Filter | 60 gallons | Every 2 months |

| Micro Filtration | 90 gallons | Every 3 months |

By adhering to these guidelines, you can ensure that your beverage maker continues to produce high-quality drinks. Regular maintenance not only enhances flavor but also prolongs the lifespan of your appliance.

Fixing Clogging Problems

Clogging can be a common issue when using brewing devices, often leading to unsatisfactory performance. Identifying the source of the blockage is essential to restoring smooth operation. Regular maintenance and cleaning are crucial steps to prevent buildup and ensure optimal functionality.

Start by examining the water pathway and components for any obstructions. Descaling solutions can effectively remove mineral deposits that accumulate over time. Follow the manufacturer’s guidelines for the best practices in maintenance and troubleshooting. Consistent care will enhance longevity and reliability.

Electrical Issues and Solutions

In the realm of coffee brewing systems, electrical problems can often hinder optimal performance. Understanding these common challenges and their solutions is crucial for ensuring a seamless experience.

Common Electrical Problems

Users may encounter various electrical issues such as faulty power connections, inconsistent heating, or malfunctioning control panels. These complications can lead to unexpected interruptions during the brewing process. Recognizing the signs of these issues is the first step toward resolution.

Troubleshooting Steps

To address electrical concerns, it is essential to check all connections for stability and cleanliness. A loose or dirty connection can prevent proper functionality. Additionally, inspecting the power source and ensuring it meets the device’s requirements is vital. If issues persist, resetting the system may restore normal operation. For more complex problems, consulting a qualified technician is recommended.

Updating Software and Firmware

Keeping your beverage system’s software and firmware up to date is essential for optimal performance and enhanced features. Regular updates can fix bugs, improve functionality, and ensure compatibility with the latest technology. This section outlines the steps to successfully update the system.

Steps to Update

- Connect the device to a stable Wi-Fi network.

- Access the settings menu using the control panel.

- Select the option for software updates.

- Follow the on-screen instructions to download and install updates.

Benefits of Updating

- Improved functionality and performance.

- Access to new features and enhancements.

- Fixes for known issues and bugs.

- Increased device longevity and reliability.

Reassembling the Coffee Maker

Reassembling the coffee brewing device is a crucial step in ensuring its functionality and longevity. This process involves carefully putting together various components that were previously disassembled, ensuring that each part is in its rightful place.

Start by gathering all the pieces you removed earlier. Organize them to make the assembly process smoother. Inspect each component for any wear or damage before proceeding. Pay close attention to seals and gaskets, as they play a significant role in maintaining the machine’s integrity.

Next, follow the reverse order of disassembly. Begin with the base and work your way up, ensuring that all screws and clips are securely fastened. Take your time to align parts correctly; misalignment can lead to operational issues later. Once everything is in place, perform a final check to ensure all components are securely attached.

Finally, plug in the device and conduct a test run to verify that it operates smoothly. This step is essential to confirm that your reassembly was successful and the appliance is ready for daily use.

Testing After Repairs

Once maintenance work is completed, it is essential to conduct evaluations to ensure everything is functioning correctly. This phase is critical for verifying that all issues have been resolved and the unit operates as intended. Proper testing helps in identifying any remaining problems that may need further attention.

Conducting Functional Assessments

Start by performing various functional assessments. Check all features and settings to confirm that they are responsive and working as expected. This includes running test cycles to simulate normal usage conditions. Observing the unit during these tests allows for early detection of any anomalies.

Evaluating Performance Metrics

After functional assessments, measure performance metrics to gauge efficiency. Look for indicators such as speed, output quality, and overall reliability. Ensure that the appliance meets its operational standards, which is crucial for long-term satisfaction.

Safety Precautions to Follow

Ensuring a safe working environment is crucial when handling any appliance. Understanding and implementing basic safety measures can prevent accidents and promote effective usage. This section outlines important guidelines to consider before starting any maintenance tasks.

General Guidelines

Before proceeding with any service, make sure the device is unplugged. Avoid using wet hands or working in damp conditions to prevent electrical hazards. Familiarize yourself with the components involved, and use appropriate tools to avoid damaging parts or causing injuries.

Personal Protection

Wearing protective gear, such as gloves and safety glasses, is essential to shield against potential spills or sharp edges. Additionally, ensure your workspace is free from clutter to minimize the risk of accidents while working.

When to Seek Professional Help

Understanding when to enlist the assistance of experts is crucial for ensuring efficient and effective resolution of issues. While many problems can be addressed independently, certain situations may require specialized knowledge or tools that only professionals possess.

Signs Indicating the Need for Assistance

- Persistent issues despite troubleshooting efforts

- Unusual sounds or leaks that could signal underlying damage

- Malfunctioning parts that are difficult to replace

- Warning indicators that remain illuminated

- Unclear instructions or lack of confidence in performing repairs

Benefits of Professional Intervention

- Access to specialized tools and equipment

- Expertise in diagnosing complex problems

- Guaranteed quality of service and repairs

- Time-saving by avoiding trial-and-error methods

- Potential for extended warranties on services performed