Maintaining outdoor machinery is crucial for ensuring optimal performance and longevity. This section focuses on common issues that users may encounter with their gardening tools, providing insightful solutions to enhance their efficiency.

Understanding the mechanics behind these devices can significantly improve user experience. By following systematic approaches to identify and resolve problems, individuals can prevent costly repairs and extend the life of their equipment.

From basic maintenance tips to more complex adjustments, this guide offers practical advice tailored to various scenarios. Equipped with this knowledge, users will be empowered to tackle challenges confidently, ensuring their tools remain in peak condition.

This section will provide insights into the essential components and functionalities of your gardening tool. Understanding its design and operation is crucial for effective maintenance and troubleshooting. Below are key topics that will guide you through the various aspects of the equipment.

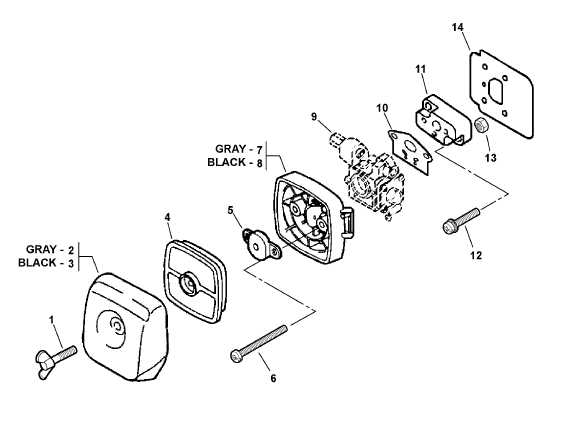

Overview of Equipment Components

Familiarize yourself with the main parts that make up the tool.

- Engine Specifications

- Fuel System Elements

- Cutting Mechanism Details

Common Issues and Symptoms

Recognizing signs of malfunction can aid in timely intervention.

- Difficulty Starting the Engine

- Inconsistent Power Output

- Excessive Vibration During Operation

Basic Maintenance Practices

Regular upkeep is essential for optimal performance.

- Cleaning the Air Filter

- Inspecting the Spark Plug

- Sharpening Cutting Blades

Fuel Type and Mixture

Understanding fuel requirements can prevent damage.

- Recommended Fuel Types

- Proper Oil-Fuel Ratio

Safety Precautions During Use

Prioritizing safety ensures a secure working environment.

- Wearing Protective Gear

- Checking Surroundings Before Use

Troubleshooting Starting Problems

Resolve starting difficulties with systematic checks.

- Battery Condition Check

- Inspecting Fuel Lines

Adjusting Idle Speed

Proper adjustments enhance performance and fuel efficiency.

- Locating Idle Speed Screw

- Making Necessary Adjustments

Cleaning and Storing Procedures

Proper storage prolongs the lifespan of your equipment.

- Cleaning After Each Use

- Storing in a Dry Place

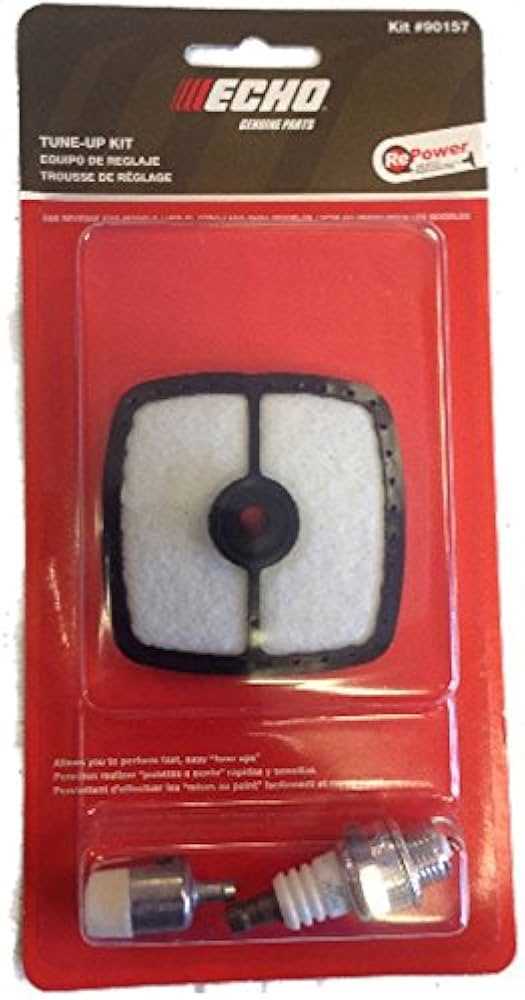

Replacing Worn-Out Parts

Identifying when components need replacement is vital.

- Signs of Wear and Tear

- Choosing Quality Replacement Parts

Using the Right Accessories

Utilizing appropriate accessories enhances functionality.

- Types of Compatible Blades

- Optional Attachments for Versatility

Expert Tips for Longevity

Insider knowledge can lead to better performance.

- Regular Professional Servicing

- Staying Informed About Updates

Resources for Further Assistance

Accessing additional resources can provide more insights.

- Online Forums and Communities

- Manufacturer’s Support Websites

Common Issues and Troubleshooting Steps

This section aims to address frequent challenges faced by users of outdoor power equipment and provides helpful solutions to enhance performance and functionality. Understanding these common problems can significantly improve the user experience and prolong the life of the device.

Frequent Problems

Users may encounter a variety of issues, including difficulty starting, inconsistent performance, or unusual noises during operation. Identifying the root cause of these problems is essential for effective resolution.

Troubleshooting Guide

Below is a table summarizing common issues and their corresponding troubleshooting steps:

| Issue | Troubleshooting Steps |

|---|---|

| Difficulty starting |

|

| Inconsistent power |

|

| Unusual noises |

|

Essential Tools for Repairing Equipment

When it comes to maintaining and fixing outdoor machinery, having the right instruments is crucial for effective work. Proper tools not only enhance efficiency but also ensure safety during the maintenance process. This section outlines the must-have items for anyone looking to perform upkeep on their equipment.

- Screwdrivers: A set of various sizes, both flathead and Phillips, is essential for loosening and tightening screws on different components.

- Wrenches: Both adjustable and fixed wrenches are important for tackling nuts and bolts. A good socket set can also be beneficial.

- Pliers: Needle-nose and regular pliers are useful for gripping, bending, and cutting wires or small parts.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage to components.

- Multimeter: Ideal for diagnosing electrical issues, a multimeter can help measure voltage, current, and resistance.

In addition to the basic tools, a few specialized items may be necessary depending on the type of machinery being serviced.

- Fuel System Cleaner: This product helps maintain the fuel system and can prevent issues related to fuel contamination.

- Lubricants: Various types of lubricants are essential for ensuring smooth operation and reducing wear on moving parts.

- Cleaning Supplies: Brushes, rags, and degreasers are important for keeping components clean and free from debris.

Equipping yourself with these fundamental tools will prepare you for successful maintenance tasks and extend the lifespan of your machinery.

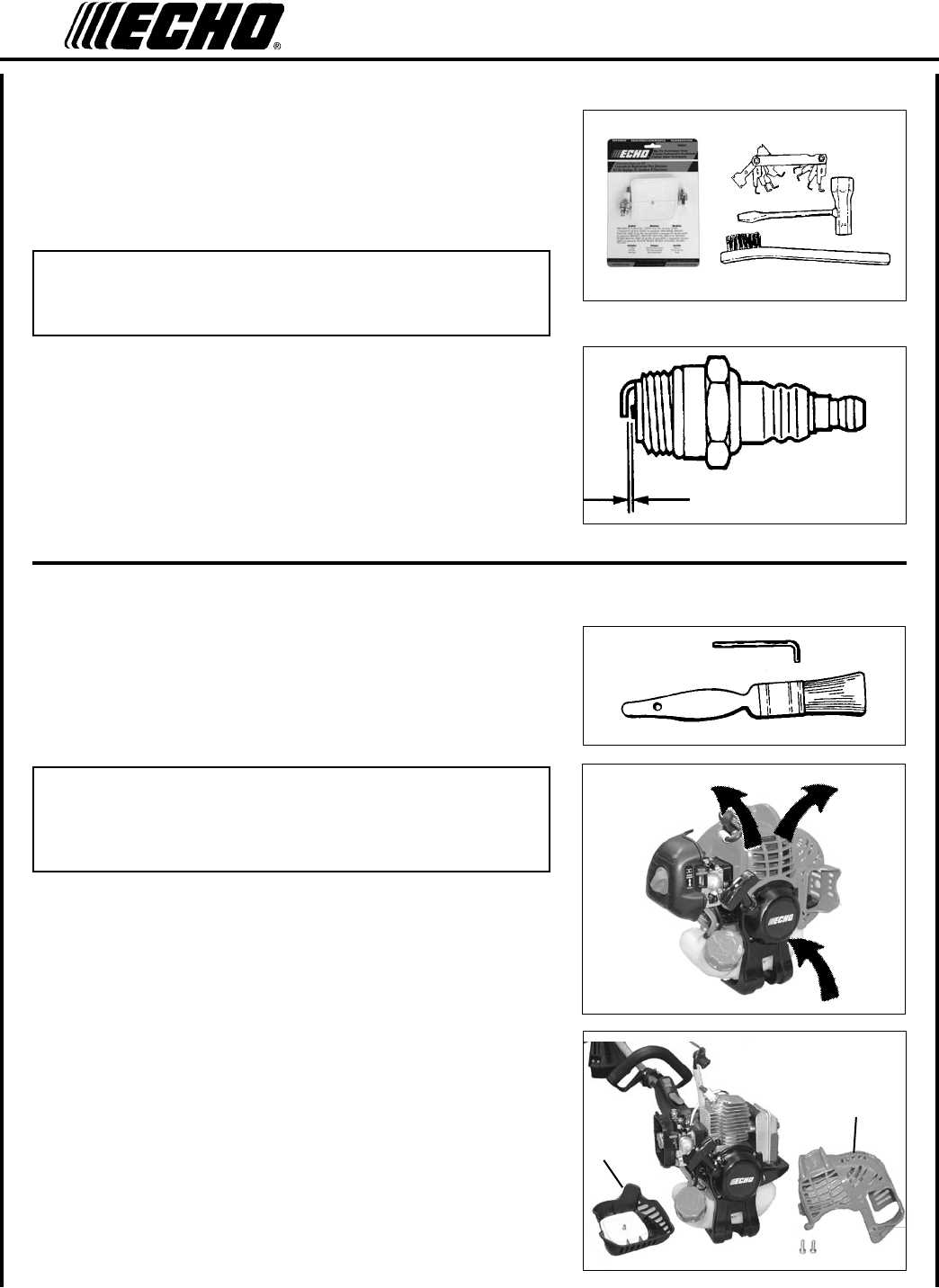

Step-by-Step Maintenance Guidelines

Regular upkeep of your gardening tool is essential to ensure optimal performance and longevity. By following a systematic approach to maintenance, users can prevent issues before they arise, thus enhancing the overall efficiency of the equipment.

Routine Inspection

Begin with a thorough examination of the device before each use. Check for signs of wear, damage, or loose components. Pay special attention to the cutting mechanism and handle. Identifying issues early can save time and reduce the need for extensive repairs later.

Cleaning and Lubrication

After each session, clean the tool to remove dirt, debris, and grass clippings. Use a soft brush and cloth for this purpose. Additionally, applying a suitable lubricant to moving parts will help prevent rust and ensure smooth operation. Regular cleaning not only maintains performance but also extends the life of the equipment.

Replacing the Fuel Filter

Maintaining optimal performance of your outdoor power equipment is crucial for its longevity. One essential maintenance task is the replacement of the fuel filter, which ensures that the engine receives clean fuel for efficient operation. A clogged filter can lead to poor performance and potential damage to the engine.

To begin the replacement process, gather the necessary tools: a new fuel filter, pliers, and a container to catch any spills. Start by locating the fuel line and carefully disconnect it from the filter. Use the pliers to pinch the clamps and slide them away from the filter. Once the line is detached, remove the old filter from the system.

Install the new filter by connecting it to the fuel line, ensuring the direction of flow is correct, typically indicated by an arrow on the filter. Slide the clamps back into place, securing the connection. Reattach the fuel line to the appropriate component, making sure it is secure. After replacing the filter, check for any leaks and test the equipment to confirm it operates smoothly.

Remember, regular inspection and replacement of the fuel filter can significantly enhance the performance and reliability of your equipment, minimizing the risk of breakdowns during use.

How to Clean the Spark Plug

Maintaining the performance of your outdoor equipment is crucial, and one essential task is the cleaning of the ignition component. This part plays a significant role in ensuring efficient combustion and smooth operation of the engine. Regularly cleaning it can enhance performance and prolong the life of your device.

Gather Necessary Tools

Before you start, make sure you have the right tools at hand. You will need a socket wrench, a wire brush, and a cleaning solution specifically designed for spark plugs. Having these items ready will streamline the process and make it more efficient.

Cleaning Procedure

Begin by disconnecting the spark plug from the ignition system. Use the socket wrench to remove it gently, being careful not to damage any surrounding components. Once removed, inspect it for any signs of wear or buildup. Use the wire brush to remove carbon deposits and debris from the surface. If necessary, soak it in a cleaning solution for a few minutes to break down stubborn grime. Rinse thoroughly and allow it to dry completely before reinstalling.

Regular maintenance of this component can significantly improve engine efficiency and reduce issues related to starting or performance. Make it a part of your routine care to ensure optimal functioning of your machinery.

Fixing the Trimmer Head

The trimmer head is a crucial component of any lawn maintenance tool, affecting its overall performance and efficiency. Addressing issues related to the trimmer head can enhance the functionality of the device, ensuring clean cuts and optimal operation. This section will guide you through common problems and their solutions to help maintain your equipment in top condition.

Common Issues and Solutions

Understanding the typical malfunctions associated with the trimmer head can aid in quick diagnosis and resolution. Below are some frequent problems along with their corresponding fixes:

| Issue | Possible Cause | Solution |

|---|---|---|

| Line not feeding | Worn line or incorrect installation | Replace the line and ensure it is properly threaded. |

| Line tangling | Incorrect line length or spool issue | Trim the line to the recommended length and check the spool for damage. |

| Excessive vibration | Loose or damaged components | Tighten all screws and inspect for any damaged parts that need replacement. |

Maintenance Tips

Regular maintenance can prevent many issues from occurring. Here are some useful tips to keep your trimmer head functioning effectively:

- Clean the trimmer head after each use to remove debris.

- Inspect the line for wear and replace it regularly.

- Lubricate moving parts to ensure smooth operation.

Adjusting the Carburetor Settings

Properly tuning the fuel delivery system is essential for optimal performance and efficiency. Fine-tuning the settings can significantly enhance the operation of your device, ensuring smooth functionality and reducing emissions. This process involves adjusting the air-fuel mixture to achieve the best balance for various conditions.

To begin the adjustment, locate the mixture screws, typically marked as low and high speed. These screws control the amount of fuel that mixes with air during operation. Start with the low-speed screw; turning it clockwise usually reduces the fuel flow, while counterclockwise increases it. Aim for a steady idle by making small adjustments and observing the engine’s response.

Next, focus on the high-speed screw. This setting impacts performance at full throttle. Similar to the low-speed adjustment, turn the screw slightly in either direction and listen for changes in engine sound. The ideal setting will result in a clean, powerful response without excessive revving or stalling.

After making adjustments, allow the engine to run for a few minutes to stabilize. It’s crucial to perform a final check by observing how the machine operates under load. Adjustments may need to be refined based on actual usage conditions to ensure optimal performance.

Regular maintenance of the carburetor can prevent common issues such as flooding and poor acceleration. Ensure that all components are clean and free from debris to maintain the integrity of the air-fuel mixture.

In summary, taking the time to accurately adjust the fuel system settings can lead to improved performance and longevity of your equipment. Regular checks and fine-tuning as necessary will contribute to a more efficient and effective operation.

Replacing the Cutting Line

Maintaining an efficient trimming tool is essential for achieving a well-groomed landscape. One critical aspect of upkeep involves replacing the line that performs the cutting action. This task ensures optimal performance and longevity of the device.

Gathering Necessary Tools

Before starting the process, collect the required tools and materials. You will need a replacement cutting line, scissors or a cutting tool, and possibly a pair of gloves for safety. Ensure the new line is compatible with your model for seamless installation.

Step-by-Step Process

Begin by disconnecting the power source to avoid any accidental activation. Next, locate the spool, which houses the cutting line. Remove the spool from the device and carefully unwind any remaining line. Cut a length of the new line according to the specifications provided with the replacement product. Insert one end of the line into the spool, winding it in the direction indicated, and leave enough length to extend beyond the spool edges. Finally, reattach the spool to the tool, ensuring it is secured properly. Your device is now ready for use, equipped with fresh cutting line for efficient operation.

Identifying Electrical Problems

Electrical issues in outdoor power tools can significantly affect their performance. Recognizing the signs of these problems is crucial for proper troubleshooting and maintenance. In this section, we will discuss common symptoms and diagnostic methods that can help in pinpointing electrical faults.

Common Symptoms of Electrical Issues

Various indications may suggest underlying electrical complications. The most prevalent symptoms include:

| Symptom | Description |

|---|---|

| No Power | The device does not respond when switched on, indicating a possible power supply issue. |

| Intermittent Operation | The tool starts and stops unexpectedly, suggesting loose connections or damaged components. |

| Unusual Noises | Strange sounds during operation may signal motor or electrical malfunctions. |

| Burning Smell | An acrid odor can indicate overheating parts or electrical shorts. |

Diagnostic Techniques

Utilizing systematic diagnostic methods can aid in uncovering electrical faults. Here are some effective approaches:

- Check power source: Ensure that the outlet or battery is functional.

- Inspect wiring: Look for frayed or broken wires that may disrupt power flow.

- Test connections: Use a multimeter to verify continuity in switches and connectors.

- Examine the motor: Assess for signs of wear or damage that could impair operation.

Safety Precautions During Repairs

When performing maintenance or troubleshooting on outdoor power tools, ensuring a safe working environment is essential. Adhering to safety measures not only protects the individual but also preserves the integrity of the equipment. Proper precautions minimize risks and enhance efficiency during the servicing process.

Personal Protective Equipment

Wearing appropriate gear is crucial when handling machinery. Use gloves to protect your hands from sharp components, and goggles to shield your eyes from debris. Hearing protection is advisable, especially when operating power tools that generate significant noise levels. A sturdy pair of boots will provide traction and prevent slips.

Work Environment Considerations

Maintain a clean and organized workspace to avoid accidents. Ensure that the area is well-lit and free of clutter, which can lead to tripping hazards. Always work on a flat, stable surface to prevent equipment from rolling or falling. Proper ventilation is also vital when using any chemicals or fuels.

When to Seek Professional Help

Identifying when to consult a specialist is crucial for maintaining your outdoor equipment. While many issues can be addressed through basic troubleshooting, certain problems may require expert intervention to ensure safety and efficiency.

Signs That Indicate Professional Assistance is Needed

- Persistent performance issues despite following troubleshooting guidelines.

- Unusual sounds or vibrations during operation.

- Fuel leaks or other signs of damage to the fuel system.

- Difficulty starting the machine after multiple attempts.

- Electrical problems, such as faulty wiring or malfunctioning ignition systems.

Benefits of Professional Maintenance

- Access to specialized tools and diagnostic equipment.

- Expert knowledge and experience with various equipment models.

- Time savings, allowing you to focus on other important tasks.

- Assurance of proper repairs, reducing the risk of future issues.