Maintaining small engines is crucial for ensuring their longevity and optimal performance. This section provides a thorough overview of the essential procedures and techniques necessary to keep these power units in top condition. Understanding the intricacies of engine care not only enhances functionality but also extends the lifespan of the equipment.

In this guide, you will discover various aspects of upkeep, from basic troubleshooting to more advanced restoration techniques. Each topic is designed to equip you with the knowledge needed to tackle common issues effectively. Whether you are a novice or an experienced user, this resource aims to enhance your proficiency in engine management.

By following the guidelines outlined here, you can achieve remarkable results in maintaining your engine. Emphasis is placed on best practices and key strategies that contribute to optimal operation. With the right approach, even complex challenges can be addressed with confidence.

Understanding Small Engine Mechanics

This section delves into the fundamentals of small engine mechanics, focusing on their design and operational principles. A thorough understanding of these components is crucial for effective maintenance and troubleshooting.

Key Components of Small Engines

- Fuel System: Responsible for delivering the right mixture of air and fuel.

- Ignition System: Initiates combustion to power the engine.

- Lubrication System: Ensures all moving parts operate smoothly.

- Cooling System: Maintains optimal operating temperature.

Common Issues and Troubleshooting

Identifying and resolving frequent problems is essential for ensuring the longevity and performance of small engines. Here are some typical issues:

- Starting Difficulties: Often caused by fuel delivery problems or ignition failures.

- Overheating: May result from inadequate cooling or low oil levels.

- Poor Performance: Can stem from clogged filters or improper fuel mixtures.

Common Issues with Model 31P677

Understanding typical challenges that users face with this particular engine can help in maintaining optimal performance. Identifying these problems early can prevent further complications and ensure longevity.

Starting Difficulties

Many users report issues with ignition, which can stem from various factors. A clogged fuel line or a faulty spark plug may prevent the engine from starting efficiently. Regular checks and maintenance of these components are essential to avoid such setbacks.

Overheating Concerns

Another common problem is overheating, which can lead to serious damage if not addressed. This may be caused by insufficient coolant or a malfunctioning cooling system. Ensuring proper fluid levels and maintaining the cooling system can mitigate this risk significantly.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing engines effectively. This section outlines the fundamental instruments necessary for successful troubleshooting and restoration tasks, ensuring efficiency and precision throughout the process.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To manipulate various screws in components. |

| Socket Set | For accessing hard-to-reach fasteners. |

| Plier | For gripping and bending materials. |

| Multimeter | To measure electrical properties for diagnostics. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your engine. Following a structured approach to maintenance can help prevent issues and enhance efficiency. Below are detailed steps to guide you through essential maintenance tasks.

1. Initial Inspection: Begin by examining the unit for any visible wear or damage. Check for loose connections, leaks, and the condition of the components. This initial assessment helps identify areas needing attention.

2. Oil Change: It is crucial to replace the oil periodically. Drain the old lubricant and refill with fresh oil according to the manufacturer’s specifications. Ensure the engine is cool before starting this process.

3. Air Filter Cleaning: A clean air filter is vital for optimal air intake. Remove the filter and clean it with compressed air or replace it if it is excessively dirty or damaged. This step helps maintain airflow and engine efficiency.

4. Spark Plug Inspection: Check the spark plug for signs of wear or deposits. Clean or replace it as necessary to ensure reliable ignition. Proper spark plug function is critical for smooth operation.

5. Fuel System Care: Inspect the fuel lines and connections for leaks or deterioration. Replace any worn parts and consider adding a fuel stabilizer to keep the fuel fresh during storage.

6. Final Checks: Once maintenance tasks are completed, reassemble all components and conduct a final inspection. Test the engine to ensure it operates smoothly, listening for any unusual noises that may indicate further issues.

Troubleshooting Engine Performance Problems

Addressing issues related to engine performance is essential for ensuring optimal operation and longevity. Various factors can contribute to decreased efficiency, ranging from fuel quality to mechanical malfunctions. Identifying these problems early can prevent further damage and enhance the overall functionality of the equipment.

Common Symptoms and Their Causes

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Dead battery, faulty ignition, or fuel blockage |

| Stalling | Clogged air filter or fuel filter |

| Poor acceleration | Worn spark plugs or improper fuel mixture |

| Excessive smoke | Oil contamination or incorrect oil type |

Steps to Diagnose Issues

Begin the troubleshooting process by examining the fuel system for blockages and ensuring that the correct fuel is used. Next, inspect the air intake and filters for obstructions. Spark plugs should be checked for wear, and connections should be verified to rule out electrical issues. Each step helps pinpoint the source of the problem and facilitates effective resolution.

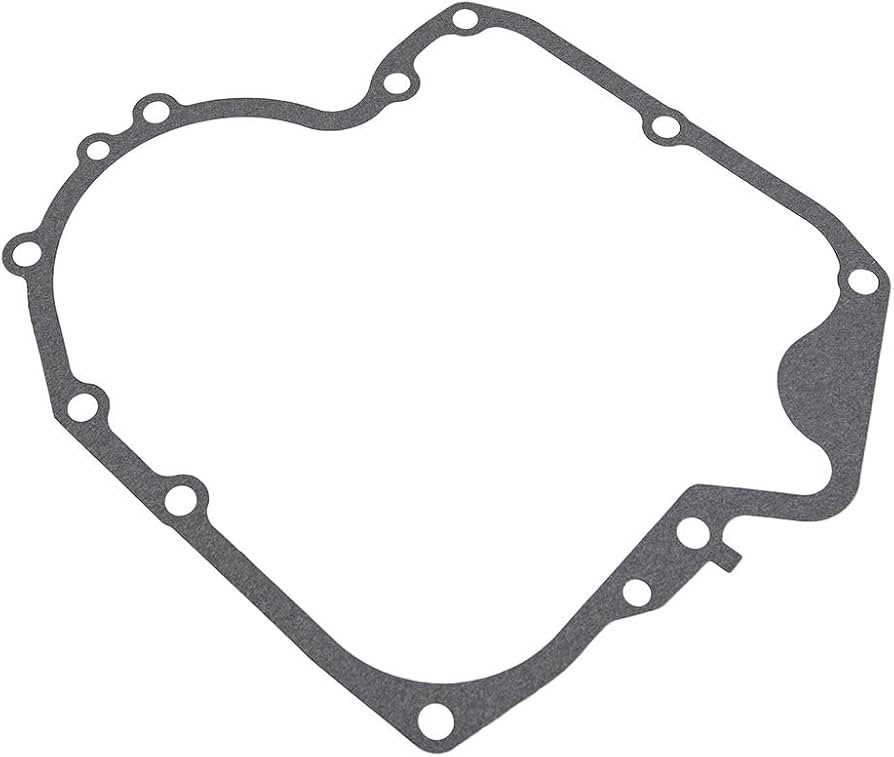

Replacing Key Components Safely

Ensuring the correct replacement of vital parts is essential for maintaining optimal performance and longevity of your equipment. Proper procedures not only enhance functionality but also ensure user safety during the process.

Before beginning the replacement, it is crucial to gather all necessary tools and materials. Always disconnect the power source to prevent any accidental start-ups. Wearing protective gear, such as gloves and safety goggles, is highly recommended to shield yourself from potential hazards.

When handling components, take care to follow the manufacturer’s guidelines. Labeling wires and connections can significantly simplify the reassembly process. Additionally, ensure that all parts are compatible and in good condition to avoid future issues.

After replacing the components, perform a thorough check to confirm that everything is secure and properly aligned. Reconnect the power source and conduct a test run to verify functionality. Adhering to these safety measures will help ensure a smooth and successful replacement experience.

Fuel System Maintenance Guidelines

Proper upkeep of the fuel system is essential for the optimal performance of your engine. Regular attention to this component not only enhances efficiency but also prolongs the lifespan of the machinery. By following these maintenance practices, you can ensure a reliable operation and minimize potential issues.

Regular Inspection

Conduct frequent examinations of the fuel lines and connectors for any signs of wear or leaks. Inspecting these elements helps in early detection of problems that could lead to serious malfunctions. Replace any damaged components immediately to maintain the integrity of the fuel delivery system.

Cleaning the Fuel Filter

The fuel filter plays a crucial role in keeping contaminants out of the engine. It is recommended to clean or replace the filter periodically, depending on usage. Regular maintenance of this part helps in preventing clogging, which can disrupt the flow of fuel and adversely affect performance.

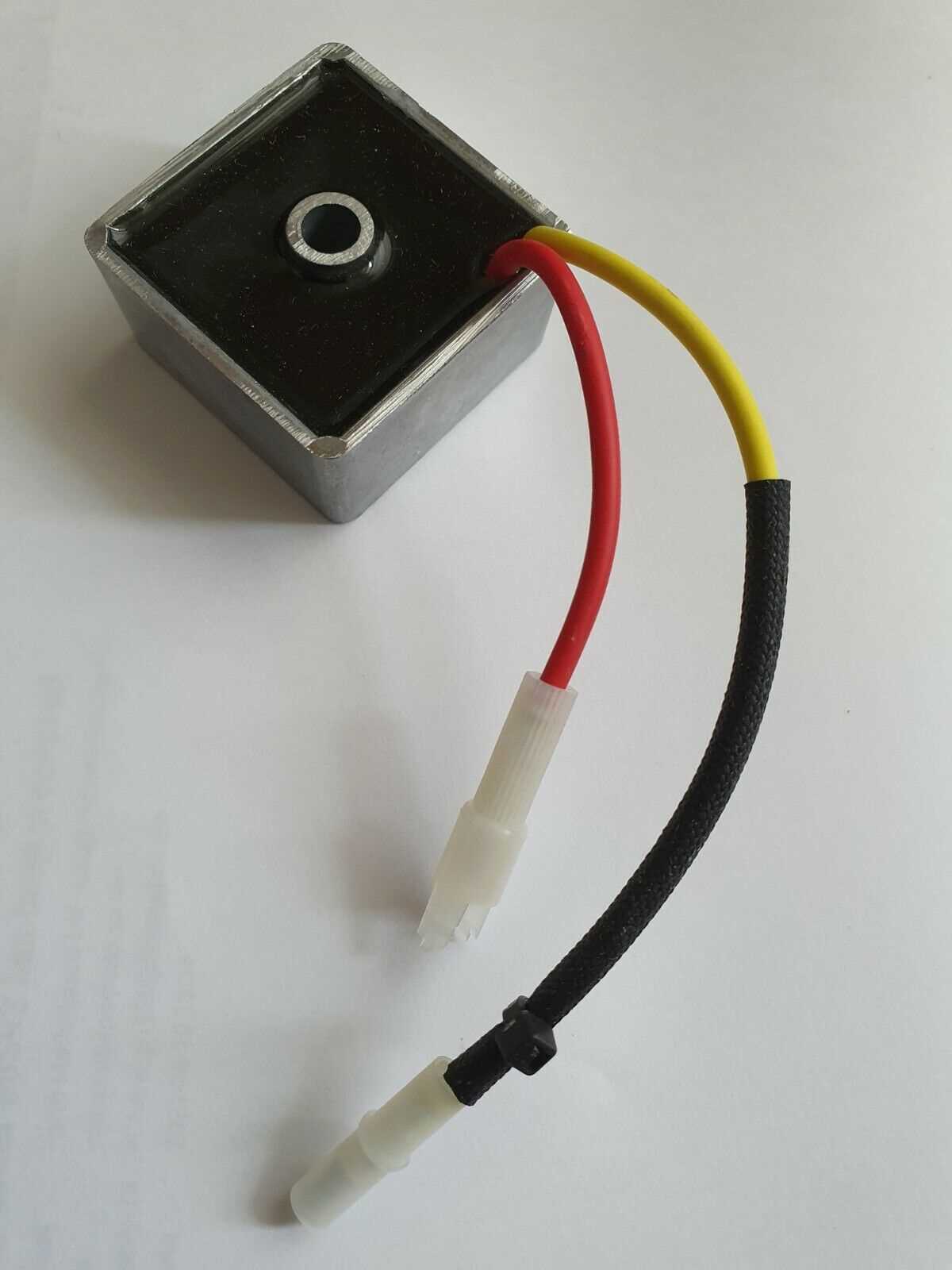

Electrical System Diagnostics

Diagnosing the electrical system of small engines is crucial for maintaining optimal performance. Understanding the components involved, such as the ignition system and battery, can help in identifying issues effectively. A systematic approach can lead to quicker resolutions and prevent further complications.

Visual Inspection: Start with a thorough examination of the wiring and connections. Look for signs of wear, corrosion, or loose fittings that may hinder electrical flow. Ensuring that all components are securely connected is essential for reliable operation.

Testing Voltage: Utilize a multimeter to check voltage levels at various points in the system. This step will help ascertain whether the electrical supply is adequate. Pay attention to both the battery voltage and output from the ignition coil.

Continuity Checks: Conduct continuity tests to verify that circuits are complete. This process involves checking for breaks in the wiring that could interrupt the electrical pathway. A lack of continuity often indicates the need for repairs or replacements.

Component Functionality: Assess individual components like the starter motor and alternator for proper functionality. Testing these parts can reveal underlying issues that affect overall performance. If any component fails to operate as expected, consider servicing or replacing it.

By following these diagnostic steps, you can effectively troubleshoot electrical problems, ensuring the engine runs smoothly and efficiently.

Engine Lubrication Best Practices

Proper lubrication is essential for the longevity and efficiency of any engine. Ensuring that the internal components are adequately coated with the right type of fluid helps reduce friction and wear, promoting optimal performance. Adopting effective lubrication strategies can significantly enhance the durability of the machinery.

Regular Oil Changes: It is vital to replace the lubricant at regular intervals to prevent the buildup of contaminants. Fresh fluid maintains its protective properties, ensuring that the engine operates smoothly.

Use the Correct Type of Lubricant: Different engines require specific types of oils. Always refer to the manufacturer’s guidelines to select a suitable product that meets the required viscosity and performance standards.

Monitor Fluid Levels: Keeping an eye on the oil level is crucial. Low levels can lead to inadequate lubrication, resulting in potential damage. Regularly checking and topping up the fluid helps maintain proper function.

Inspect for Leaks: Regularly examining the engine for signs of leakage can prevent further issues. Addressing any leaks promptly ensures that the lubrication system remains effective.

Maintain Clean Components: A clean engine operates more efficiently. Regularly removing dirt and debris from the lubrication system can help maintain fluid integrity and enhance overall performance.

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance and efficiency of any power unit. These parameters provide insight into the capabilities and limitations of the machinery, influencing everything from fuel consumption to operational reliability. Familiarity with these details is essential for anyone looking to maintain or enhance the functionality of their engine.

Key Performance Metrics

Among the various specifications, power output and torque are vital indicators of an engine’s performance. Power output, typically measured in horsepower, reflects the engine’s ability to perform work efficiently. Torque, on the other hand, signifies the rotational force available, essential for tasks requiring substantial power at lower speeds. Understanding these metrics helps in selecting the right engine for specific applications.

Maintenance Considerations

Proper maintenance is influenced by the engine’s specifications. Knowledge of the recommended oil type, filter requirements, and cooling system design can significantly impact longevity and reliability. Regular checks and adherence to the manufacturer’s guidelines ensure optimal functioning, reducing the risk of unexpected failures and enhancing overall performance.

Importance of Regular Inspections

Conducting frequent evaluations of equipment is crucial for maintaining optimal performance and longevity. Regular assessments help identify potential issues before they escalate, ensuring that machinery operates efficiently and safely.

Early Problem Detection

By performing routine checks, users can spot irregularities or wear and tear early on. This proactive approach not only minimizes the risk of breakdowns but also reduces repair costs, as minor issues can be addressed promptly.

Enhanced Safety

Frequent inspections contribute to a safer operating environment. Equipment that is regularly examined is less likely to malfunction unexpectedly, protecting users from potential accidents. Safety should always be a priority, making routine evaluations an essential practice.

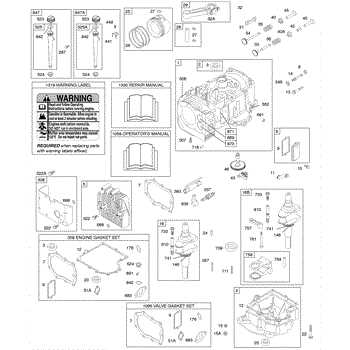

Finding Replacement Parts Easily

Locating the right components for your machinery can be a straightforward process with the right approach. By utilizing various resources, you can efficiently identify and acquire the necessary items to ensure optimal performance.

Start by exploring online platforms that specialize in spare parts for various equipment. Many of these websites provide detailed catalogs and user-friendly search functions that allow you to filter results based on specific needs. Additionally, customer reviews can offer insights into the quality and compatibility of the parts you are considering.

Another effective strategy is to consult with local dealers or authorized service centers. These professionals possess valuable knowledge and can guide you to the correct components for your machinery. They often have access to a broader range of parts and can assist in placing special orders if needed.

Lastly, joining online forums or communities dedicated to equipment maintenance can be beneficial. Engaging with other users can lead to recommendations for reliable sources and tips on how to ensure that the parts you select meet your requirements.

Tips for Efficient Repairs

Ensuring optimal functioning of your equipment requires strategic approaches during maintenance tasks. Adopting effective techniques not only enhances performance but also prolongs lifespan.

Here are some helpful suggestions:

| Tip | Description |

|---|---|

| Understand Components | Familiarize yourself with the parts and their functions to identify issues quickly. |

| Use Quality Tools | Invest in reliable tools to ensure precision and avoid damage during servicing. |

| Follow Procedures | Adhere to established guidelines to ensure safety and effectiveness throughout the process. |

| Keep Workspace Organized | Maintain a tidy area to easily locate tools and parts, reducing time spent searching. |

| Regular Maintenance | Implement routine checks to prevent minor issues from escalating into major problems. |