Ensuring the longevity and efficiency of heavy machinery requires a thorough understanding of its intricacies. Proper upkeep not only enhances performance but also significantly extends the lifespan of the equipment. This section aims to provide essential insights into the various aspects of engine servicing, focusing on key components and processes.

From routine checks to intricate troubleshooting techniques, mastering the fundamentals is vital for operators and technicians alike. A systematic approach to maintenance can prevent common issues and ensure that machinery operates smoothly under demanding conditions. By exploring best practices and expert recommendations, readers can equip themselves with the knowledge needed for effective oversight.

Whether you are a seasoned professional or a newcomer to the field, this guide offers valuable information that caters to a diverse audience. Emphasis will be placed on practical steps and actionable advice to empower users in their efforts to maintain peak operational standards.

Kubota V3600 Repair Manual Overview

This section provides a comprehensive overview of the essential documentation necessary for understanding and maintaining a specific engine model. It serves as a crucial resource for technicians and operators alike, offering detailed insights into troubleshooting, maintenance procedures, and technical specifications. Such resources empower users to effectively manage and optimize the performance of their machinery.

Key Features

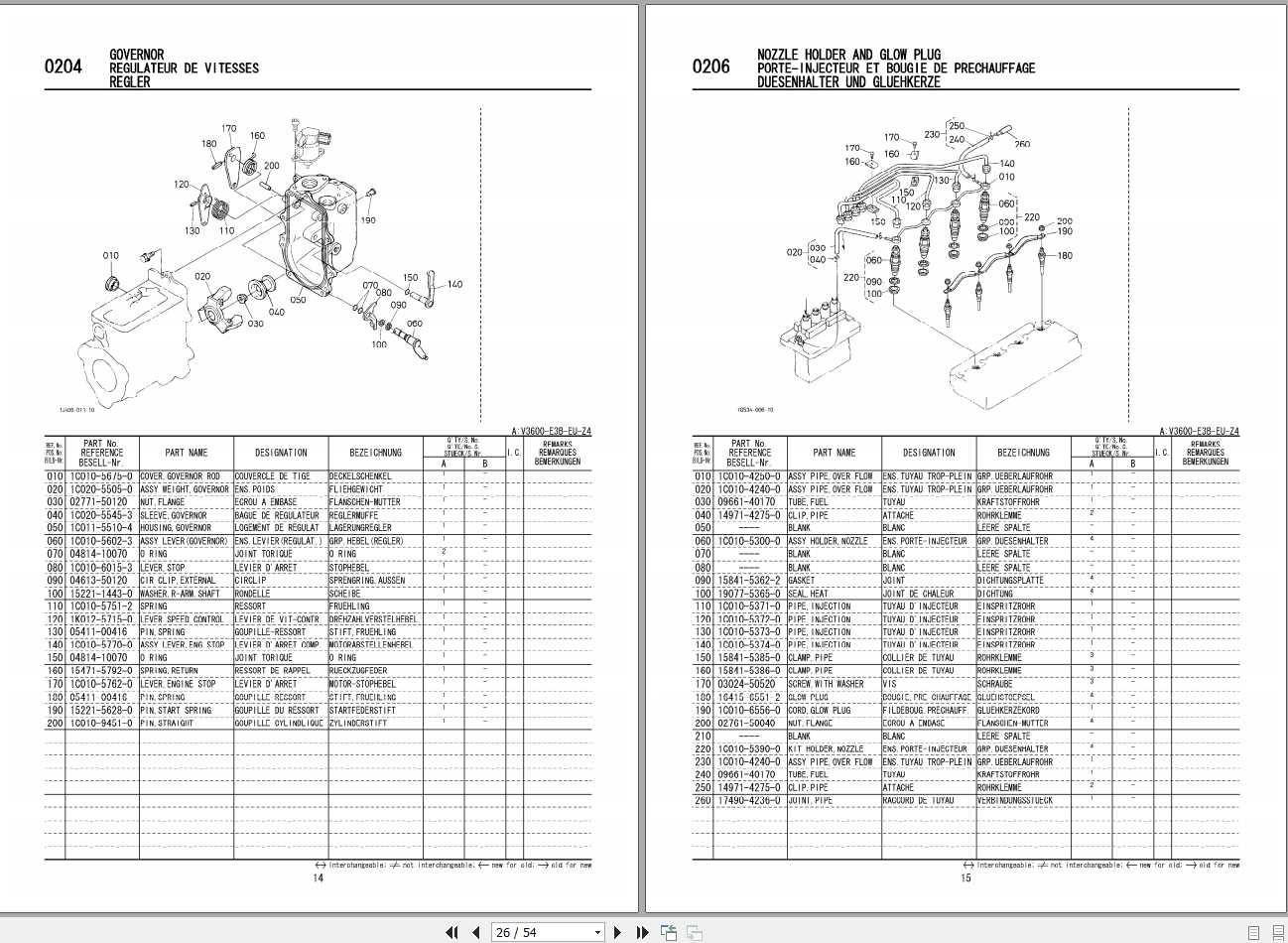

Among the standout elements of this documentation are the step-by-step instructions for various tasks. These guidelines ensure that users can perform maintenance with precision, reducing the likelihood of errors. Additionally, diagrams and schematics are included to enhance clarity and facilitate the repair process.

Benefits of Utilizing the Documentation

Engaging with this resource not only streamlines the maintenance process but also extends the lifespan of the equipment. By following the recommended practices, users can achieve better efficiency and reliability, ultimately leading to reduced downtime and lower operational costs. Furthermore, having access to troubleshooting advice can help quickly resolve any issues that arise, ensuring that the equipment remains in peak condition.

Understanding the Engine Specifications

Comprehending the intricacies of engine specifications is vital for optimal performance and maintenance. Knowledge of these details not only aids in identifying suitable applications but also enhances the overall functionality of the machinery. By familiarizing oneself with various characteristics, operators can ensure longevity and efficiency in operation.

Key Specifications Overview

The following table outlines essential specifications that are commonly associated with high-performance engines. These details provide insights into the engine’s capabilities and help in making informed decisions regarding usage and maintenance.

| Specification | Details |

|---|---|

| Cylinder Configuration | Inline 4-cylinder |

| Displacement | 3.6 liters |

| Power Output | 75 HP |

| Torque | 200 Nm |

| Fuel Type | Diesel |

Importance of Understanding Specifications

Grasping these specifications not only facilitates troubleshooting but also aids in optimizing performance under varying conditions. Operators can tailor their maintenance routines based on the specific needs outlined in these characteristics, thus enhancing reliability and efficiency in the field.

Common Issues with Kubota V3600

Every engine can encounter problems over time, and this specific model is no exception. Understanding the frequent complications can help in maintaining optimal performance and longevity. Below are some of the prevalent challenges faced by users.

Engine Performance Problems

- Overheating due to coolant leaks or blockages.

- Loss of power often linked to fuel delivery issues.

- Difficulty in starting, potentially caused by battery failure or glow plug malfunctions.

Mechanical Failures

- Wear and tear on belts and hoses, leading to premature failure.

- Oil leaks stemming from worn gaskets or seals.

- Noise from the engine, which may indicate problems with bearings or timing components.

Essential Tools for Maintenance

Proper upkeep of machinery requires a variety of tools to ensure optimal performance and longevity. Having the right equipment on hand can significantly simplify maintenance tasks and enhance efficiency. Understanding which tools are essential will empower operators to perform routine checks and necessary repairs effectively.

Basic Hand Tools

Every maintenance kit should include a selection of basic hand tools. These typically consist of wrenches, screwdrivers, and pliers. Wrenches in various sizes are crucial for tightening and loosening bolts, while screwdrivers assist in adjusting components. Pliers provide the grip needed for handling smaller parts, making them indispensable for detailed work.

Diagnostic Equipment

In addition to hand tools, diagnostic equipment plays a vital role in identifying issues. Tools like multimeters and pressure gauges allow technicians to assess electrical systems and fluid pressures accurately. Having access to these devices helps in detecting problems early, preventing more significant damage and costly repairs.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing and resolving issues with your engine. By following the steps outlined below, you can efficiently identify the root cause of problems and apply appropriate solutions.

Begin by gathering essential tools and equipment. A methodical examination of the components will help ensure that no detail is overlooked.

| Step | Description |

|---|---|

| 1 | Visual Inspection: Check for any obvious signs of wear, leaks, or damage in the engine and surrounding areas. |

| 2 | Check Fluids: Ensure all fluids, including oil and coolant, are at the appropriate levels and are in good condition. |

| 3 | Examine Filters: Inspect air and fuel filters for clogs or dirt buildup that may hinder performance. |

| 4 | Test Electrical Systems: Verify the functionality of the battery, alternator, and wiring connections to rule out electrical issues. |

| 5 | Run Diagnostic Checks: Utilize available diagnostic tools to pinpoint specific error codes or irregularities. |

| 6 | Review Maintenance History: Assess past service records for any recurring issues that may need further attention. |

| 7 | Perform Component Testing: Isolate and test individual parts like injectors and pumps to confirm their operation. |

| 8 | Seek Professional Assistance: If the issue persists, consider consulting with a qualified technician for expert evaluation. |

By adhering to these steps, you can systematically troubleshoot problems, leading to more effective repairs and enhanced engine longevity.

Replacing Engine Components Effectively

Ensuring the longevity and efficiency of an engine often involves the careful substitution of worn or damaged parts. This process not only restores functionality but can also enhance overall performance. Understanding the necessary steps and best practices is crucial for successful execution.

Preparation Steps

Prior to initiating any component replacement, it is essential to gather the appropriate tools and parts. Create a workspace that is clean and organized, allowing easy access to all necessary items. Referencing a detailed guide can streamline the process, providing clarity on specific tasks and safety measures.

Replacement Process

When executing the replacement, follow these key steps to ensure effectiveness:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidental start-up. |

| 2 | Carefully remove the old component, noting any specific connections. |

| 3 | Install the new part, ensuring proper alignment and fit. |

| 4 | Reconnect all necessary connections and secure components. |

| 5 | Test the system to confirm proper operation. |

Regular Maintenance Procedures Explained

Consistent upkeep is essential for ensuring the longevity and optimal performance of any machinery. By following a structured maintenance routine, users can minimize unexpected failures and enhance operational efficiency. This section outlines fundamental procedures that are crucial for the proper functioning of engines and related systems.

Routine maintenance encompasses various tasks that can be categorized as follows:

- Fluid Checks:

- Engine oil levels

- Coolant levels

- Fuel quality and levels

- Filter Replacements:

- Oil filter

- Air filter

- Fuel filter

- Visual Inspections:

- Belts and hoses for wear

- Electrical connections

- Leakages or corrosion

Following a systematic approach to these tasks can lead to improved reliability and performance. It is recommended to establish a regular schedule, noting the specific intervals for each procedure based on operational hours or time periods.

- Weekly Tasks:

- Check fluid levels and top up as needed.

- Inspect air filter condition.

- Monthly Tasks:

- Change oil and replace the oil filter.

- Examine belts and hoses for signs of wear.

- Annual Tasks:

- Complete a thorough inspection of the entire system.

- Replace the coolant if necessary.

By adhering to these regular maintenance procedures, operators can significantly extend the service life of their equipment, ensuring it remains in peak operating condition throughout its lifespan.

Safety Precautions During Repairs

When engaging in maintenance tasks on machinery, adhering to safety guidelines is paramount. Proper precautions not only protect the individual performing the work but also extend the life of the equipment and ensure optimal performance.

Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and steel-toed boots. These items act as a barrier against potential hazards such as sharp edges, flying debris, or chemicals.

Ensure a clean and organized workspace. Clutter can lead to accidents, so keeping tools and materials neatly arranged minimizes the risk of trips and falls.

Familiarize yourself with the equipment before starting any task. Understanding the specific components and functions helps in identifying risks and handling them appropriately.

Disconnect power sources prior to beginning any maintenance work. This simple step can prevent accidental start-ups, which pose significant dangers.

Follow manufacturer guidelines for maintenance procedures. These instructions provide critical information for safe handling and effective servicing, reducing the likelihood of errors.

Use tools properly. Each tool is designed for a specific purpose; improper use can lead to accidents or damage. Always ensure that tools are in good condition and suitable for the task at hand.

Keep emergency contacts readily available. In the event of an accident, knowing how to quickly reach assistance can make a significant difference in outcomes.

By observing these safety measures, individuals can significantly reduce the risk of injury and ensure a more efficient maintenance process.

Performance Tuning Tips and Tricks

Enhancing the efficiency and responsiveness of your machinery can lead to significant improvements in overall performance. By making a few strategic adjustments, you can optimize power output, fuel efficiency, and operational smoothness. This section presents valuable insights into tuning techniques that can help you achieve optimal performance.

Regular Maintenance Checks

Routine inspections and maintenance are crucial for ensuring that all components are functioning correctly. Clean air filters, check fuel injectors, and monitor fluid levels regularly. Keeping the engine and its parts in good condition not only enhances performance but also extends the lifespan of your equipment.

Adjusting Fuel and Air Mixtures

Fine-tuning the fuel-to-air ratio can lead to improved combustion efficiency. Ensure that the air intake is unobstructed and that the fuel delivery system is calibrated properly. By optimizing this balance, you can achieve better throttle response and reduce emissions, making your equipment more efficient and environmentally friendly.

Diagnostic Techniques for Engine Problems

Identifying issues within an engine requires a systematic approach to uncover the root cause of malfunctions. Utilizing various diagnostic methods enables technicians to efficiently pinpoint problems, ensuring that corrective measures are both effective and timely. Understanding the underlying symptoms and employing the right techniques are essential for optimal engine performance.

Visual Inspection

One of the first steps in diagnosing engine issues is conducting a thorough visual examination. Inspecting components for signs of wear, leaks, or damage can reveal critical information. Pay attention to hoses, connections, and belts, as well as checking for any abnormal vibrations or noises that may indicate mechanical failures.

Utilizing Diagnostic Tools

Incorporating advanced diagnostic tools significantly enhances the troubleshooting process. Analyzing data from sensors and onboard diagnostic systems provides insights into the engine’s operational parameters. Additionally, employing tools such as multimeters and compression testers helps assess electrical and mechanical health, guiding technicians toward precise solutions.

Parts Replacement: What to Know

When it comes to maintaining machinery, understanding how to properly swap out components is crucial for optimal performance. Regularly updating worn or damaged parts ensures longevity and efficiency, minimizing downtime and costly repairs. This section outlines essential considerations for successfully navigating the replacement process.

Identifying Components

Before initiating a replacement, it’s vital to accurately identify the specific parts that require attention. Referencing diagrams or guides can facilitate this process, helping to locate the components within the assembly. Ensuring that the right parts are sourced is essential for maintaining compatibility and functionality.

Tools and Techniques

Having the appropriate tools on hand is necessary for a smooth replacement process. Commonly required tools include wrenches, sockets, and screwdrivers. Additionally, understanding the proper techniques for removing and installing components can prevent damage and ensure a secure fit. Always follow best practices to maintain safety and efficiency throughout the procedure.

Using the Repair Manual Effectively

Utilizing a comprehensive guide for maintenance and troubleshooting can significantly enhance your understanding and efficiency when working on machinery. Such a resource provides structured information, allowing users to locate specific procedures, diagrams, and safety protocols quickly. Mastering the use of this tool not only streamlines the repair process but also helps in preventing errors that could lead to costly mistakes.

Familiarizing with the Structure

Before diving into any specific tasks, take the time to understand the layout of the document. Familiarize yourself with the table of contents, as it provides a roadmap to navigate various sections seamlessly. Each chapter typically covers different aspects of the equipment, from basic operation to advanced troubleshooting techniques. Knowing where to find relevant information can save you valuable time during repairs.

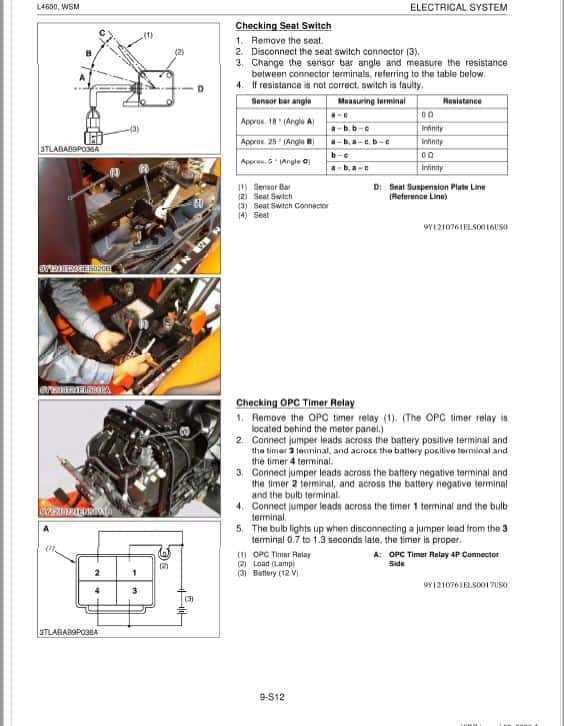

Utilizing Visual Aids

Diagrams, illustrations, and charts play a crucial role in clarifying complex procedures. These visual aids can help you comprehend assembly instructions or identify parts more easily. When facing a challenging issue, refer back to these images to ensure accuracy in your work. Engaging with visual resources alongside textual instructions enhances retention and improves overall comprehension.

Maintaining Fuel Efficiency in V3600

Achieving optimal fuel efficiency is crucial for any engine operation. Proper maintenance practices not only enhance performance but also reduce operational costs. By implementing a few key strategies, you can ensure that your engine runs smoothly while maximizing fuel usage.

- Regular Inspections: Conduct frequent checks on fuel lines and filters to prevent blockages that can hinder performance.

- Quality Fuel: Always use high-quality fuel to minimize impurities that can affect combustion efficiency.

- Air Filter Maintenance: Keep the air filter clean and replace it as necessary to ensure optimal airflow.

In addition to these practices, consider the following actions:

- Monitor engine performance metrics regularly to identify any anomalies.

- Ensure proper lubrication of moving parts to reduce friction and energy loss.

- Follow recommended operational procedures, including warm-up routines, to optimize efficiency from the start.

By adhering to these guidelines, you can significantly improve the fuel efficiency of your engine, leading to better performance and reduced environmental impact.