Maintaining an all-terrain vehicle requires a thorough understanding of its components and systems. This section aims to provide essential insights into the upkeep and troubleshooting of these versatile machines, ensuring they perform optimally in various conditions. Whether you are a seasoned enthusiast or a newcomer, this guide will equip you with the knowledge necessary to keep your vehicle in top shape.

Every rider knows that proper maintenance can significantly extend the lifespan of their vehicle. This resource offers detailed information on diagnostics, servicing procedures, and parts replacement. By following the outlined steps, you can confidently address common issues and ensure your vehicle remains reliable on any adventure.

Emphasizing the importance of regular check-ups and preventive measures, this guide serves as a valuable companion for anyone seeking to enhance their understanding of ATV care. With practical advice and clear instructions, you will be empowered to tackle maintenance tasks effectively, fostering a deeper connection with your vehicle.

Overview of Polaris Sportsman 500

This section provides a comprehensive look at a popular all-terrain vehicle, known for its reliability and performance. Designed to tackle various terrains, it is favored by outdoor enthusiasts for its versatility and robust engineering. Users appreciate its power and ease of handling, making it suitable for both recreational and practical applications.

The vehicle is equipped with advanced features that enhance user experience and safety. Its design focuses on durability, ensuring it can withstand tough conditions while providing a smooth ride. Additionally, the incorporation of modern technology allows for better navigation and control.

| Feature | Description |

|---|---|

| Engine Type | Single-cylinder, four-stroke engine |

| Transmission | Automatic with low and high ranges |

| Drive System | All-wheel drive (AWD) capability |

| Suspension | Independent front and rear suspension for stability |

| Storage Capacity | Ample storage compartments for gear and supplies |

Overall, this vehicle stands out in its category for delivering exceptional performance and reliability, appealing to both new and experienced riders alike.

Common Issues with Sportsman 500

This section highlights frequent problems encountered by enthusiasts of all-terrain vehicles. Understanding these challenges can enhance the ownership experience and ensure smoother operation in various conditions.

One prevalent concern involves starting difficulties, often attributed to battery issues or faulty ignition components. Regular maintenance and timely battery replacements can mitigate these problems.

Another common issue is overheating, which may arise from inadequate coolant levels or a malfunctioning radiator. Ensuring the cooling system is in good condition can help maintain optimal operating temperatures.

Transmission glitches are also reported, with users experiencing unexpected shifting or unusual noises. Routine inspection of fluid levels and component wear can prevent these issues from escalating.

Finally, tire wear is a significant consideration. Proper inflation and alignment are essential for maximizing tire life and ensuring safe handling on rugged terrains.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your all-terrain vehicle. Adopting a systematic approach to maintenance not only enhances performance but also helps prevent potential issues that may arise from neglect. Here are some crucial tips to keep your vehicle running smoothly.

Regular Inspections

- Check fluid levels, including engine oil, coolant, and brake fluid.

- Inspect the tires for wear and proper inflation.

- Examine the brakes for any signs of wear or damage.

- Look for any loose bolts or connections throughout the vehicle.

Routine Cleaning

- Wash the exterior to remove dirt and debris that can cause corrosion.

- Clean the air filter regularly to ensure optimal airflow.

- Clear any mud or grime from the undercarriage and suspension components.

By incorporating these practices into your routine, you can maintain your vehicle’s performance and enjoy a safer, more reliable riding experience.

Essential Tools for Repairs

When it comes to maintaining and enhancing the functionality of your all-terrain vehicle, having the right equipment at your disposal is crucial. Proper tools not only facilitate the repair process but also ensure that tasks are completed efficiently and safely. This section highlights the must-have implements for effective vehicle maintenance.

Basic Hand Tools

- Wrenches: A set of adjustable and fixed wrenches is essential for loosening and tightening various fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers in multiple sizes allow for versatile adjustments.

- Pliers: Needle-nose and standard pliers are helpful for gripping and bending wires or components.

Specialized Equipment

- Torque Wrench: Ensures that nuts and bolts are tightened to the manufacturer’s specifications.

- Jack and Stands: Vital for safely lifting the vehicle for undercarriage work.

- Diagnostic Tools: Electronic testers and multimeters can assist in troubleshooting electrical issues.

Equipping yourself with these tools will streamline the maintenance process and contribute to the longevity of your vehicle.

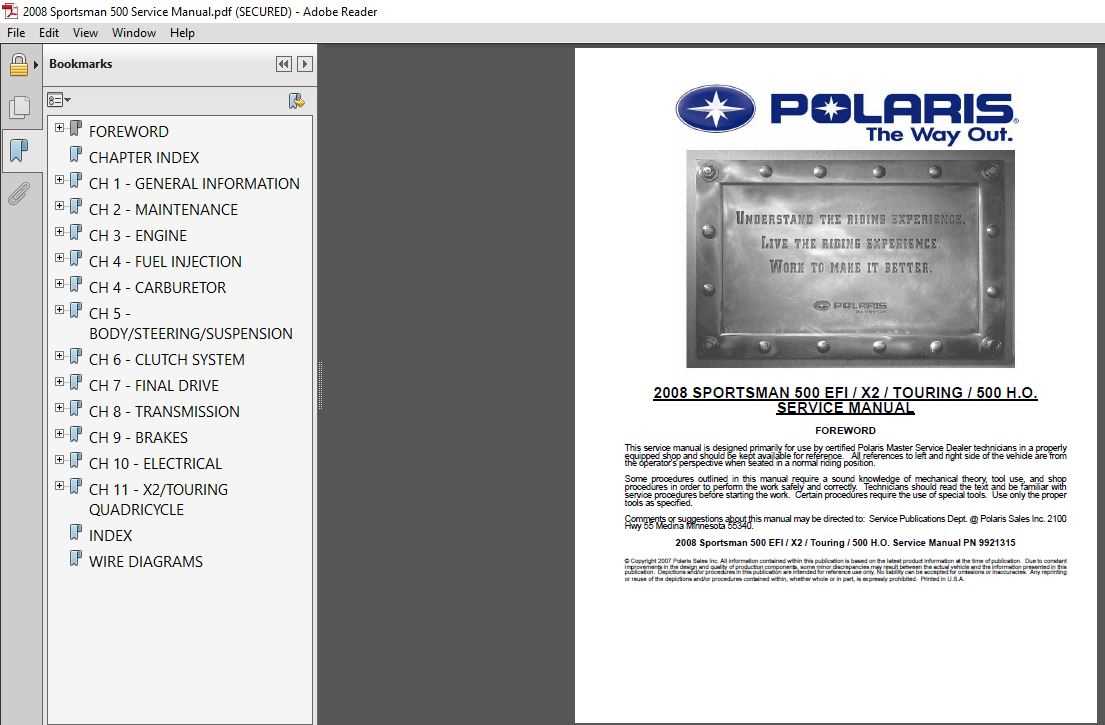

Step-by-Step Repair Procedures

This section outlines detailed instructions for addressing various issues with your all-terrain vehicle. Following a systematic approach ensures that tasks are completed efficiently and effectively, ultimately prolonging the lifespan of the machinery.

Begin by gathering all necessary tools and components. Ensure that your workspace is organized to facilitate a smooth workflow. Before proceeding, refer to specific diagnostic guidelines to accurately identify the problem.

Once the issue is identified, disassemble the relevant parts carefully. Take note of each component’s placement to ensure proper reassembly later. Clean all surfaces and check for wear or damage that may require attention.

Replace any faulty components with high-quality substitutes. Follow the manufacturer’s specifications for torque settings and assembly sequences. After reassembly, perform a thorough inspection to confirm that everything is securely fastened and aligned.

Finally, conduct a test run to verify that the vehicle operates as intended. Monitor for any unusual noises or performance issues that may indicate further adjustments are necessary. Regular maintenance following these procedures will help prevent future complications.

Understanding the Electrical System

The electrical system of an all-terrain vehicle plays a crucial role in its overall functionality and performance. This complex network is responsible for powering various components, ensuring that the machine operates smoothly and efficiently. A comprehensive understanding of this system is essential for effective troubleshooting and maintenance.

Key Components

The primary elements of the electrical setup include the battery, wiring harness, ignition system, and lighting. Each part works in tandem to provide power and control. The battery serves as the energy source, while the wiring harness connects all electrical components, facilitating the flow of electricity. The ignition system is vital for starting the engine, and the lighting enhances visibility and safety during operation.

Troubleshooting Tips

When issues arise within the electrical system, identifying the root cause is crucial. Begin by inspecting the battery for signs of corrosion or low voltage. Next, check the connections within the wiring harness for any frayed or damaged wires. Regularly testing the ignition system can also prevent potential failures. A systematic approach to diagnosing these components will help maintain optimal performance.

Engine Troubleshooting Techniques

When faced with engine issues, it is essential to employ effective strategies to diagnose the problem accurately. Understanding the symptoms and utilizing systematic approaches can significantly enhance the repair process. By identifying the root cause of malfunctions, one can apply the appropriate solutions to restore optimal performance.

Step 1: Observation

Begin by closely observing the engine’s behavior. Pay attention to unusual sounds, vibrations, or performance issues. Documenting these observations can help pinpoint specific problems.

Step 2: Visual Inspection

A thorough visual examination is crucial. Check for leaks, loose connections, or damaged components. Inspecting belts, hoses, and electrical connections can reveal hidden issues that may affect engine functionality.

Step 3: Diagnostic Tools

Utilizing diagnostic tools, such as multimeters and compression testers, can provide valuable insights into engine performance. These instruments help assess electrical systems, fuel delivery, and overall engine health.

Step 4: Systematic Testing

Performing systematic tests allows for a methodical approach to troubleshooting. Start with the fuel system, then check the ignition and exhaust systems. This step-by-step process can help isolate the malfunctioning area.

Step 5: Consult Resources

Refer to relevant resources, including technical guides and forums, for additional insights and solutions. Engaging with a community of experienced individuals can provide alternative perspectives and proven techniques for resolution.

By following these troubleshooting techniques, one can effectively address engine problems and ensure reliable performance in the long run.

Suspension Adjustments and Repairs

Proper tuning and maintenance of the suspension system are crucial for optimal performance and rider comfort. This section delves into the necessary adjustments and fixes to ensure that the suspension operates effectively, enhancing stability and handling in various terrains.

Begin by assessing the current state of the suspension components. Regular inspections help identify wear and potential issues that may affect ride quality. The following table outlines common adjustments and repairs that can be performed to maintain a well-functioning suspension system.

| Adjustment/Repair | Description | Frequency |

|---|---|---|

| Shock Absorber Replacement | Replace worn or damaged shock absorbers to improve responsiveness. | Every 2-3 years or as needed |

| Spring Tension Adjustment | Modify the tension of the springs to accommodate different weights and riding styles. | Before long trips or changes in load |

| Linkage Lubrication | Apply lubricant to the linkage components to reduce friction and enhance performance. | Every season or after heavy use |

| Alignment Check | Ensure proper alignment of suspension components to prevent uneven wear. | Monthly or after significant impacts |

By regularly performing these adjustments and repairs, you can ensure that the suspension system remains in top condition, providing a smoother and safer riding experience.

Transmission System Insights

The transmission system plays a crucial role in the overall performance and efficiency of any all-terrain vehicle. Understanding its components and functions can greatly enhance the experience of both novice and experienced riders. This section delves into the intricacies of the transmission mechanism, shedding light on its significance and operation.

Key Components

- Gearbox: Responsible for altering the torque and speed.

- Drive Belt: Transfers power from the engine to the wheels.

- Clutch: Engages and disengages the power transmission smoothly.

- Torque Converter: Ensures a seamless transition between different speeds.

Functionality Overview

Each element within the transmission system contributes to the overall efficiency and responsiveness of the vehicle. The gearbox adjusts the torque, allowing the rider to navigate various terrains effectively. The drive belt is essential for maintaining the connection between the engine and wheels, while the clutch ensures that power is delivered smoothly without stalling.

Regular maintenance of the transmission system is vital to prevent wear and tear. Ensuring proper lubrication and timely inspections can help avoid costly repairs and extend the life of the vehicle.

Finding Replacement Parts Effectively

Locating suitable components for your vehicle can be a straightforward process with the right approach. Understanding where to search and how to evaluate options will save time and ensure you get the best quality parts for your needs.

Here are some effective strategies for finding replacement components:

- Utilize Online Resources: Numerous websites specialize in aftermarket and OEM parts. Be sure to compare prices and check reviews to find reputable sellers.

- Visit Local Dealerships: Authorized dealerships often carry original components. While prices may be higher, the assurance of quality can be worth it.

- Explore Salvage Yards: Salvage or junk yards can be treasure troves for finding used parts at a fraction of the cost. Inspect items carefully before purchasing.

- Join Online Forums: Community forums can be valuable for advice and recommendations on sourcing parts. Enthusiasts often share their experiences and sources.

- Check Classified Ads: Websites and local listings can sometimes yield great deals on components being sold by other owners.

When searching for parts, always ensure that you have the correct specifications to avoid compatibility issues. Keeping a detailed record of your vehicle’s requirements will streamline the process significantly.

Safety Precautions During Repairs

When performing maintenance or service tasks on any vehicle, ensuring a safe working environment is paramount. Adopting proper safety measures can significantly reduce the risk of accidents and injuries. Being aware of potential hazards and following guidelines helps create a secure atmosphere for effective work.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes and gases.

- Ensure that the vehicle is securely positioned, using wheel chocks and jack stands when necessary.

- Keep a fire extinguisher nearby, especially when working with flammable materials.

- Disconnect the battery before starting any electrical work to prevent shocks or shorts.

Maintaining a Clean Workspace

Clutter can lead to accidents, so it’s crucial to keep the work area organized. Regularly remove unnecessary tools and materials from the vicinity to minimize tripping hazards.

- Store tools in designated places after use.

- Clean spills immediately to prevent slips.

- Use proper containers for hazardous materials to avoid contamination.

By following these precautions, you can ensure a safer and more efficient working experience while tackling maintenance tasks.