Understanding the intricacies of diesel-powered vehicles can be both rewarding and essential for their long-term performance. From navigating unique engine components to handling specific maintenance routines, a systematic approach can make all the difference in ensuring smooth and efficient operation.

Whether you’re a seasoned mechanic or a vehicle enthusiast, diving into the details of a diesel setup reveals the importance of knowing the key functional elements. These elements, along with strategic upkeep practices, provide a reliable foundation to address a wide range of common issues, helping you extend the lifespan of your vehicle.

This guide will take you through step-by-step instructions tailored to enhance your understanding of crucial aspects, from diagnosing underlying issues to executing precise adjustments. Armed with this knowledge, you can tackle both routine care and complex challenges with confidence.

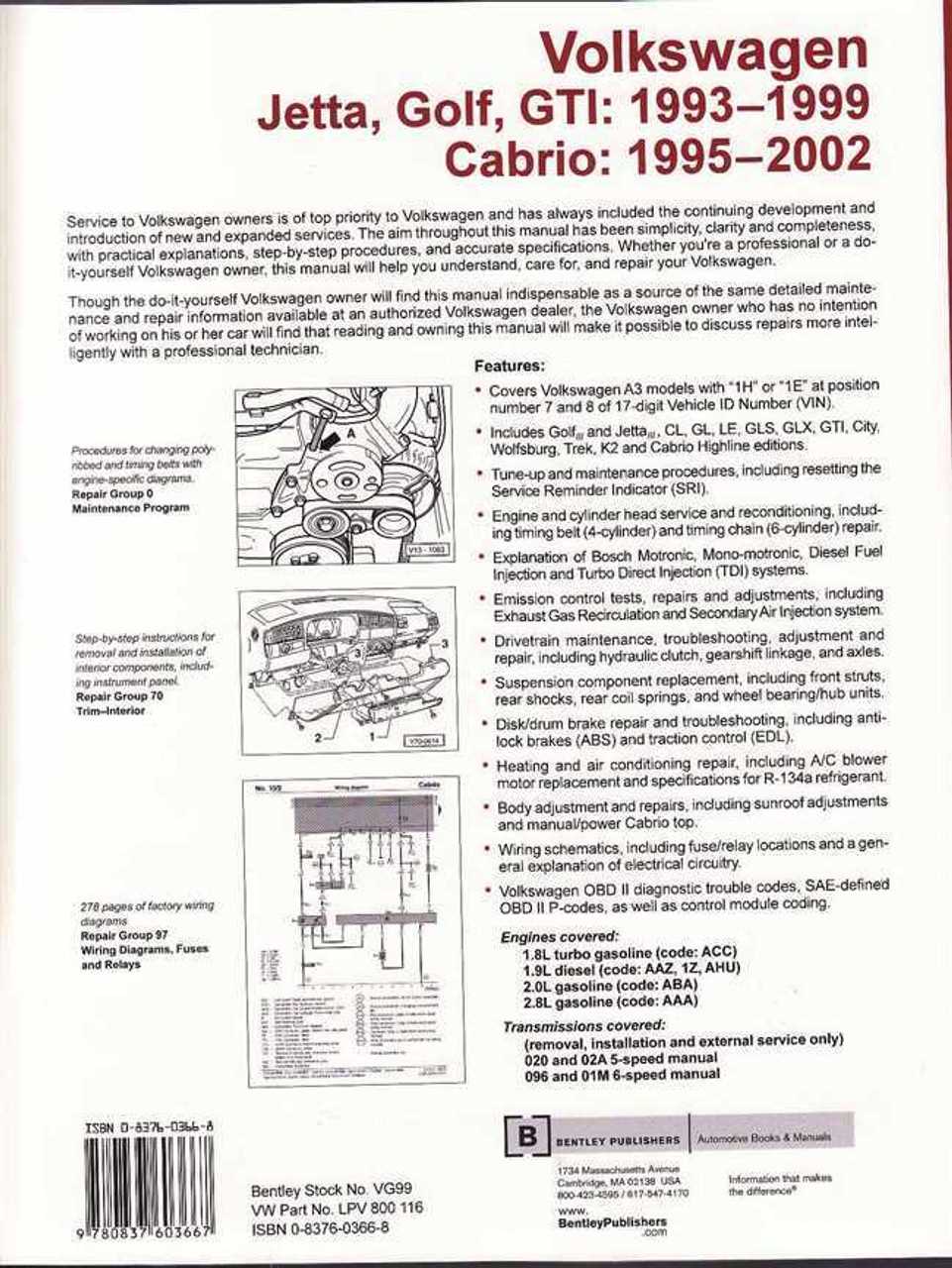

Jetta TDI Repair Guide

This guide provides essential insights for those looking to restore or enhance the performance and longevity of their diesel-powered vehicle. It covers core areas of maintenance, from troubleshooting common issues to understanding key components and best practices for upkeep.

Efficient upkeep requires familiarity with the engine’s unique design and fuel system, which differ notably from gasoline counterparts. Regular attention to these systems helps maintain efficiency, minimize wear, and prolong the life of each part. This section offers practical steps and checks to ensure smooth operation and effective problem prevention.

Each area outlined here highlights critical steps and tips that drivers and enthusiasts can rely on for regular maintenance and addressing potential malfunctions. Whether tackling issues related to airflow, fuel distribution, or the electrical system, this guide equips you with the essentials for optimal upkeep and consistent performance.

Understanding Common Engine Issues

Engine challenges can arise from multiple components within the power system, each requiring attention for efficient vehicle performance. Regular awareness of these common issues can help in diagnosing early signs of wear or malfunction, which in turn minimizes the likelihood of more significant, costly repairs.

Signs of Reduced Fuel Efficiency

One of the most frequent concerns relates to a decline in fuel economy. If the engine appears to consume more fuel than usual, it might be due to issues like fuel injector clogging, inefficient oxygen sensors, or wear in key components such as spark plugs. Addressing these areas promptly can help restore optimal fuel usage and improve overall vehicle f

Fuel System Troubleshooting Tips

Ensuring the reliable performance of a vehicle often requires close attention to its fuel delivery setup. When issues arise, pinpointing the source quickly can prevent extensive wear or further complications. A well-functioning fuel mechanism is essential for smooth and efficient driving.

Check Fuel Pressure: Consistent pressure is vital for fuel distribution. If the engine shows signs of stalling or hesitating, it may indicate irregularities in pressure levels. Use a gauge to monitor this and identify any irregular flow.

Inspect Fuel Lines: Cracks or blockages within fuel lines can lead to reduced performance. Routinely inspect these connections for any visible wear, leaks, or debris that may obstruct fuel passage.

Examine the Fuel Pump: A malfunctioning pump can disrupt the entire fuel system. Listen for unusual sounds from the pump, and consider replacing it if these issues persist. Regular inspection can prevent unexpected breakdowns.

Evaluate

Battery and Electrical Maintenance

Proper upkeep of the battery and electrical components is essential for ensuring consistent performance and reliability. Regular checks and preventive measures can help avoid unexpected breakdowns and extend the longevity of various electrical parts within the vehicle.

Battery Health and Charging

Monitoring the health of the battery is crucial for maintaining power flow throughout the vehicle. Frequent inspections of the battery terminals for corrosion, tightness, and cleanliness help improve conductivity. Additionally, charging the battery when necessary and avoiding deep discharges can significantly enhance its lifespan. Battery maintenance goes beyond simple replacement; it involves proactive care and adjustments as conditions change.

Inspecting Electrical Connections

Electrical connections throughout the vehicle are prone to wear and environmental effects, impacting overall performance. Ensuring that cables and connectors are in optimal condition and free of rust or damage is essential. Loose or damaged connections can lead to power issues, so periodic tightening and inspection are recommended. By keeping all electrical pathways secure, the system’s effici

Cooling System Inspection Guide

Ensuring a well-functioning cooling system is essential for maintaining the engine’s optimal temperature and preventing overheating issues. A regular examination of each part can reveal early signs of wear, allowing for timely adjustments and reducing the risk of costly damage.

Essential Components to Check

- Radiator: Inspect for any visible damage, leaks, or blockages. Clean the fins and check for any buildup that may obstruct airflow.

- Coolant Levels: Verify the fluid level is within the recommended range and that it is free from contaminants.

Exhaust System Diagnostics

Effective assessment of the exhaust system is crucial for maintaining optimal vehicle performance. This section delves into essential methods and techniques used to evaluate exhaust functionality, identifying potential issues that may impact efficiency and emissions. Through systematic inspection and testing, technicians can ensure that the exhaust system operates within specifications.

The diagnosis process typically involves several steps, each focusing on different components of the exhaust system. Common symptoms, such as unusual noises or decreased engine performance, can serve as indicators of underlying problems. Below is a table summarizing key diagnostic methods and their corresponding purposes.

Diagnostic Method Purpose Visual Inspection To identify physical damage, rust, or loose connections in the exhaust components. Smoke Test To detect leaks in the exhaust system that may affect performance. Back Pressure Test To measure exhaust back pressure and assess the condition of catalytic converters. Oxygen Sensor Testing To evaluate the efficiency of the fuel-to-air ratio and overall emissions. By implementing these diagnostic methods, professionals can accurately pinpoint issues within the exhaust system, allowing for timely interventions and enhanced vehicle performance.

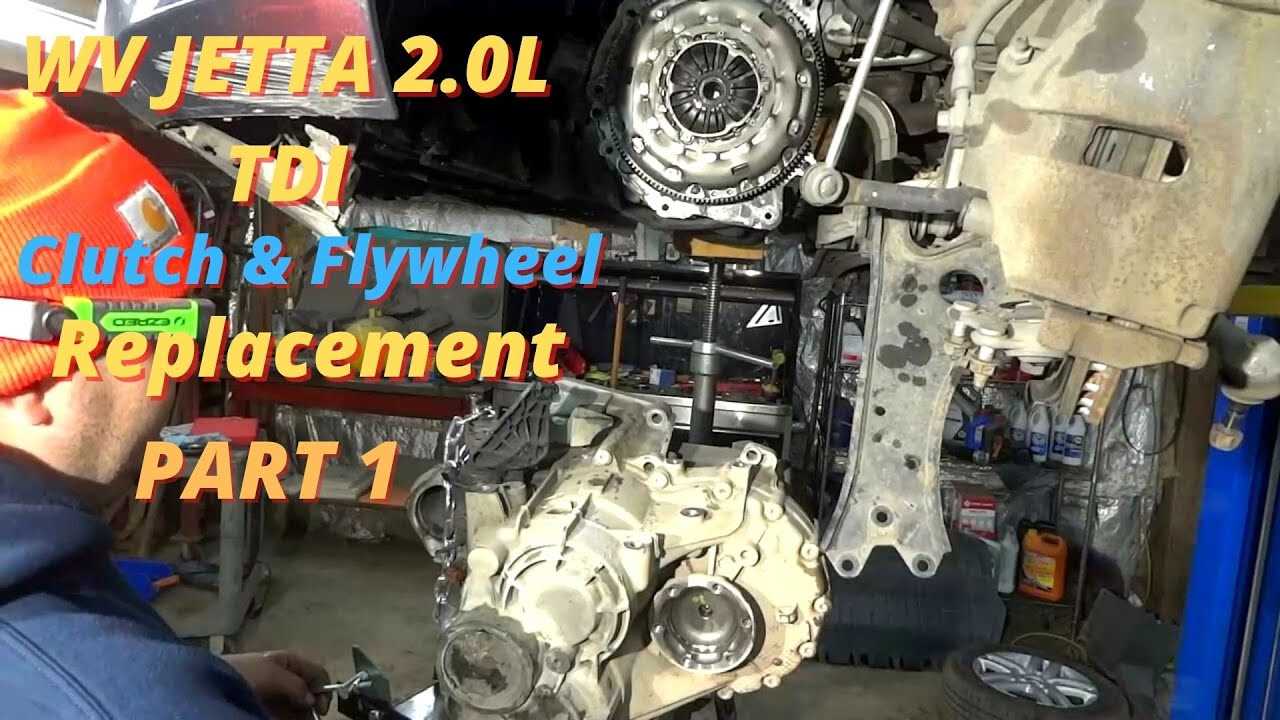

Transmission Repair Essentials

Addressing issues within the gear-shifting system is crucial for ensuring optimal performance and longevity of a vehicle. Understanding the fundamental components and common complications associated with this intricate system can facilitate effective solutions. Whether dealing with slipping gears or unusual noises, a comprehensive approach to diagnosis and rectification can significantly enhance driving experience.

Key Components of the Gearbox

The gearbox comprises various integral parts, each playing a vital role in overall functionality. Key components include gears, synchronizers, and shift forks. Gears are responsible for translating engine power into appropriate rotational force, while synchronizers aid in smooth engagement during shifts. Shift forks direct the movement of gears, ensuring precise operation. Familiarity with these elements is essential for effective troubleshooting and maintenance.

Common Issues and Solutions

Several typical problems can arise within the transmission system. One common issue is fluid leakage, which may lead to insufficient lubrication and overheating. Regular inspection of seals and gaskets can help prevent this problem. Additionally, unusual sounds during gear changes often indicate internal wear or damage. Timely diagnostics and appropriate interventions can prevent minor issues from escalating into significant repairs, thus saving time and resources.

Brakes and Suspension Checks

Ensuring optimal performance of a vehicle’s stopping and handling systems is essential for safety and drivability. Regular inspections and maintenance of these components help identify potential issues before they escalate, providing a smoother and safer driving experience.

When assessing the braking and suspension systems, consider the following key aspects:

- Brake Pads: Check for wear and tear. Look for any signs of uneven wear or excessive thickness.

- Brake Rotors: Inspect for scoring, warping, or corrosion. Ensure they meet manufacturer specifications.

- Brake Fluid: Verify the fluid level and quality. Replace if it appears discolored or contaminated.

- Suspension Components: Examine bushings, struts, and shocks for any signs of damage or excessive play.

- Tire Condition: Assess tread depth and uneven wear, which can indicate alignment or suspension issues.

- Alignment: Ensure that the wheels are properly aligned to enhance handling and reduce tire wear.

Regularly performing these checks can prolong the lifespan of critical vehicle systems and enhance overall safety. Always consult a professional if you notice any abnormalities during your inspection.

Turbocharger Performance and Care

The efficiency and longevity of a turbocharger significantly influence the overall performance of a vehicle’s engine. Proper maintenance and understanding of how a turbocharger functions are crucial for ensuring optimal output and preventing premature wear. By adhering to specific care practices, vehicle owners can enhance power delivery and fuel efficiency, leading to a more satisfying driving experience.

Understanding Turbocharger Functionality

A turbocharger operates by utilizing exhaust gases to spin a turbine, which compresses incoming air. This process increases the volume of air entering the engine, allowing for more fuel combustion and greater power output. Maintaining clean air filters and ensuring proper oil circulation are essential to support the effective functioning of this component, as they help reduce stress and potential damage during operation.

Essential Maintenance Practices

Regular inspections and timely replacement of worn parts are vital for preserving the integrity of the turbocharger. Using high-quality oil and adhering to recommended change intervals will promote optimal lubrication, minimizing the risk of overheating. Additionally, monitoring for any unusual noises or performance drops can aid in early detection of issues, ensuring swift resolutions and continued performance.

Engine Oil and Filter Replacement

Maintaining optimal performance in your vehicle involves regular changes of lubricating fluid and the accompanying filtration system. This essential task ensures the engine operates smoothly and prolongs its lifespan. It is vital to follow the correct procedure to prevent damage and maintain efficiency.

Before starting the replacement process, gather the necessary tools and materials, including high-quality lubricant, a new filtration unit, a wrench set, and an oil catch pan. Having these items ready will streamline the procedure and reduce the risk of overlooking any critical steps.

Step Description 1 Warm up the engine for a few minutes to help the old lubricant drain out more easily. 2 Secure the vehicle on a level surface and use jack stands if necessary for safety. 3 Remove the drain plug and allow the old oil to flow into the catch pan completely. 4 Replace the oil filter, ensuring the rubber gasket is properly seated. 5 Reinstall the drain plug and tighten it to the specified torque. 6 Pour the new lubricant into the engine, checking the level with the dipstick as you go. 7 Start the engine and let it run for a few minutes, checking for leaks around the filter and drain plug. 8 Dispose of the old oil and filter properly, following local regulations. Following these steps diligently will help ensure that your engine remains in top condition, reducing the likelihood of issues arising from poor lubrication or filtration. Regular maintenance not only enhances performance but also contributes to the longevity of your vehicle.

Interior and Exterior Detailing

Maintaining the pristine condition of your vehicle involves meticulous attention to both the interior and exterior surfaces. This process not only enhances the aesthetic appeal but also protects the components from wear and environmental factors. A thorough detailing regimen ensures that every nook and cranny receives the care it deserves, resulting in a vehicle that looks and feels brand new.

Exterior detailing focuses on cleaning, restoring, and protecting the outer surfaces. Techniques such as washing, polishing, and waxing are essential to remove dirt, scratches, and contaminants. Utilizing high-quality products can significantly improve the shine and longevity of the paintwork. Regular attention to the exterior also helps in preserving the vehicle’s resale value.

Interior detailing encompasses the deep cleaning of all internal surfaces, including upholstery, carpets, and hard surfaces. Vacuuming, steam cleaning, and conditioning materials contribute to a clean and fresh environment. This not only enhances comfort for occupants but also eliminates allergens and unpleasant odors, promoting a healthier atmosphere within the vehicle.

By investing time in both interior and exterior detailing, owners can ensure their vehicles maintain a high standard of appearance and performance. Establishing a regular detailing schedule is an effective way to keep the vehicle in optimal condition for years to come.

Tools and Equipment Recommendations

When undertaking vehicle maintenance and troubleshooting, having the right tools and equipment is essential for ensuring efficiency and effectiveness. Proper instruments can significantly enhance the quality of work, making tasks simpler and safer. Below is a list of recommended items to facilitate various procedures.

Essential tools for comprehensive vehicle servicing include:

- Socket Set: A versatile collection of sockets is crucial for loosening and tightening various bolts and nuts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for diagnosing electrical issues, this device measures voltage, current, and resistance.

- OBD-II Scanner: An invaluable tool for reading diagnostic trouble codes and troubleshooting engine performance issues.

In addition to hand tools, certain equipment can enhance the overall repair experience:

- Mechanics Creeper: This allows for easy movement under the vehicle, reducing strain and increasing comfort during repairs.

- Floor Jack and Jack Stands: Essential for safely lifting and securing the vehicle while working underneath.

- Work Light: Adequate lighting is vital for visibility in dark areas, helping to identify problems easily.

- Magnetic Tray: This keeps small fasteners and components organized and prevents them from being lost during work.

Investing in high-quality tools and equipment not only streamlines the repair process but also contributes to achieving better results. Always ensure that your toolkit is well-organized and complete before starting any maintenance task.