Owning a compact vehicle often comes with the necessity for regular upkeep and understanding of its intricate systems. This guide aims to empower owners with the knowledge needed to troubleshoot and maintain their automobiles effectively. By familiarizing oneself with the components and functions, drivers can enhance performance and longevity.

Understanding the Basics of vehicle operation is essential. Familiarity with various elements, from the engine to the electrical systems, can make a significant difference in everyday driving experiences. Recognizing common issues and their solutions is a valuable skill for any car enthusiast or everyday user.

Moreover, having access to a structured reference can greatly facilitate the learning process. This resource will provide step-by-step instructions and tips to ensure that you can address minor challenges independently, ultimately saving time and money while boosting your confidence in handling automotive tasks.

Overview of Citroen C2 Repair Manual

This section provides a comprehensive understanding of the documentation designed to assist vehicle owners and technicians in maintaining and troubleshooting a specific model. The resources aim to facilitate efficient handling of various issues, ensuring optimal performance and longevity of the automobile.

Key Features of the Documentation

The materials typically include detailed illustrations, step-by-step procedures, and specifications for various components. Such content is essential for both novice and experienced individuals looking to address mechanical problems or perform routine maintenance tasks. Furthermore, the guidelines emphasize safety protocols, ensuring that all actions taken are both effective and secure.

Importance of Comprehensive Guidance

Having access to thorough instructions and troubleshooting techniques is crucial for minimizing downtime and reducing repair costs. By following the outlined procedures, users can confidently tackle issues ranging from simple adjustments to more complex mechanical failures. The emphasis on clarity and precision within the documents helps streamline the maintenance process, fostering a deeper understanding of the vehicle’s systems.

Common Issues with Citroen C2

The vehicle in question is known for its compact design and efficiency, yet it can experience a variety of challenges over time. Understanding these common problems can help owners anticipate and address potential issues, ensuring better performance and longevity.

Frequent Mechanical Problems

- Suspension Wear: Many owners report premature wear in suspension components, leading to a rougher ride.

- Electrical Faults: Issues with the electrical system, such as malfunctioning lights or dashboard warnings, are not uncommon.

- Engine Performance: Some vehicles experience a decrease in engine performance, often linked to fuel delivery or ignition system problems.

Interior and Comfort Concerns

- Seat Wear: The upholstery may show signs of wear more quickly than expected, affecting comfort and aesthetics.

- Climate Control Issues: Problems with the air conditioning and heating systems can lead to uncomfortable driving conditions.

- Noise Levels: Increased cabin noise can be a sign of aging seals or insulation breakdown.

Addressing these concerns proactively can enhance the driving experience and extend the vehicle’s life on the road.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for efficiency and effectiveness. The appropriate instruments not only facilitate the process but also enhance safety and ensure optimal results. Below are some fundamental items that are indispensable for any mechanical endeavor.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are necessary for loosening and tightening bolts.

- Screwdrivers: A selection of flathead and Phillips head screwdrivers will cover most fastening needs.

- Pliers: Needle-nose and standard pliers are essential for gripping, twisting, and cutting wires.

- Hammers: A rubber mallet and a claw hammer can be used for driving and removing parts without causing damage.

Specialized Equipment

- Jack and Stands: Essential for lifting the vehicle safely to access undercarriage components.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications, preventing over-tightening.

- Diagnostic Tools: An OBD-II scanner helps identify issues by reading trouble codes from the vehicle’s computer.

- Fluid Containers: Useful for collecting and disposing of old fluids responsibly.

Equipping yourself with these essential tools can significantly enhance the maintenance experience, ensuring that tasks are completed efficiently and correctly.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. This section outlines detailed procedures that will help you systematically care for your car, enhancing its reliability and safety. By following these guidelines, you can address common issues and perform essential tasks efficiently.

1. Engine Oil Change

Begin by warming up the engine slightly to thin the oil, making it easier to drain. Then, secure the vehicle on a level surface and lift it using appropriate tools. Remove the drain plug and allow the old oil to flow into a container. Replace the oil filter and reinstall the drain plug before adding fresh oil through the designated filler cap.

2. Tire Inspection and Rotation

Check tire pressure using a gauge and adjust as necessary. Inspect the tread depth and look for any signs of wear or damage. To promote even wear, rotate the tires according to the manufacturer’s recommendations, typically every 5,000 to 7,500 miles.

3. Brake System Examination

Visually inspect the brake pads and rotors for wear. If the pads are less than 3mm thick, consider replacing them. Check the brake fluid level and top it up if necessary. Listen for any unusual noises when braking, as this may indicate the need for further inspection.

4. Battery Maintenance

Ensure that the battery terminals are clean and free of corrosion. Check the battery’s charge level and test its performance if it is more than three years old. If you notice any signs of leakage or swelling, replace the battery immediately.

5. Fluid Levels Check

Regularly inspect all essential fluid levels, including coolant, transmission fluid, and power steering fluid. Refill any fluids that are low and monitor for leaks, which may indicate a more serious issue.

6. Air Filter Replacement

Remove the air filter from its housing and inspect it for dirt and debris. A clogged filter can reduce engine efficiency, so replace it if it appears dirty or as part of a routine schedule, usually every 12,000 to 15,000 miles.

By adhering to these step-by-step procedures, you can ensure that your vehicle remains in top condition, ultimately leading to a smoother driving experience and reducing the likelihood of costly repairs in the future.

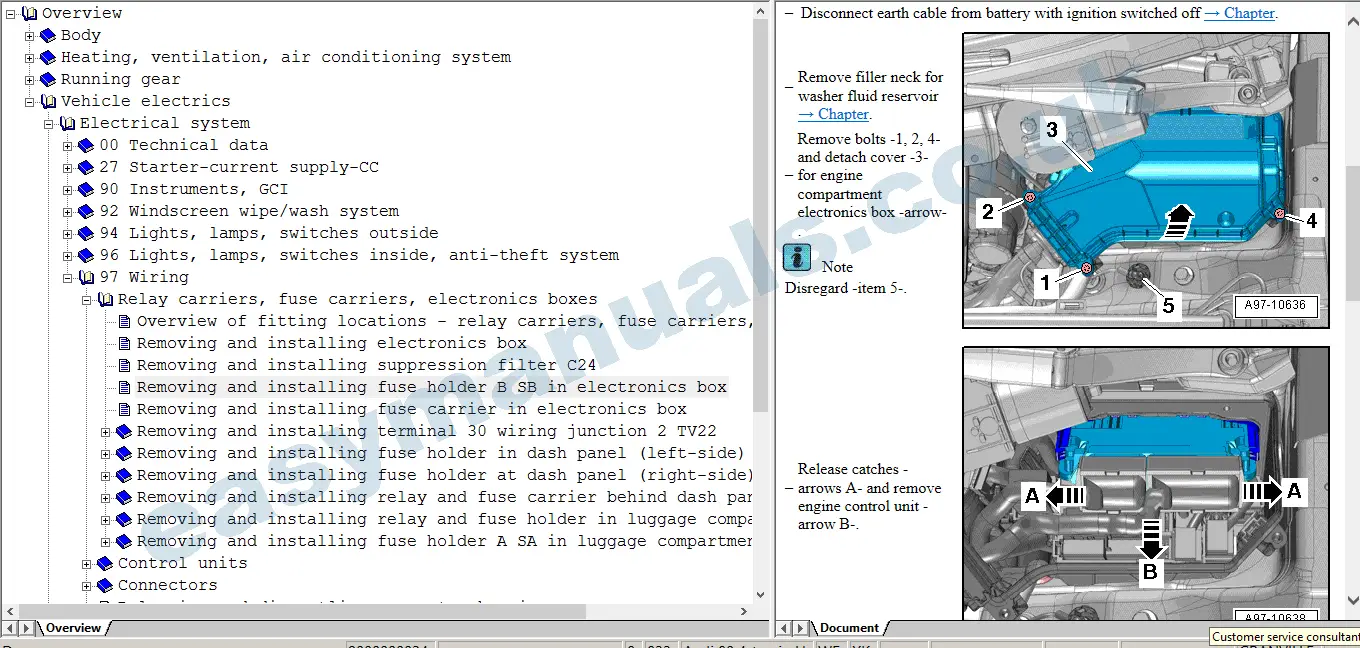

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues within the electrical framework of your vehicle. Understanding how to identify and rectify common problems can enhance performance and reliability. By following systematic methods, you can efficiently isolate faults and implement effective solutions.

Start by checking the battery condition, ensuring it is adequately charged and free from corrosion. A weak or damaged battery can lead to various electrical failures. Next, inspect the fuses for any signs of damage or breakage, as blown fuses can interrupt power to critical systems.

Examine the wiring harness for signs of wear, fraying, or loose connections. Pay particular attention to grounding points, as poor grounding can result in erratic behavior of electrical components. Utilize a multimeter to test voltage levels at various points, ensuring that the electrical supply meets specifications.

If issues persist, delve into individual components such as lights, sensors, and the ignition system. Testing these parts independently can reveal whether they are functioning correctly or require replacement. Always refer to technical specifications for guidance on acceptable parameters.

Document all findings and actions taken during troubleshooting. This record can be invaluable for future reference and helps track recurring problems, enabling more effective long-term solutions.

Engine Components and Repairs

The functionality of any vehicle heavily relies on its power unit, which comprises various parts working in unison. Understanding these components is essential for maintaining performance and ensuring longevity. This section delves into the critical elements of the engine and the procedures involved in addressing common issues that may arise.

Key Components

The heart of the engine includes essential parts such as the cylinders, pistons, crankshaft, and camshaft. Each component plays a specific role in the combustion process and overall operation. For instance, cylinders house the pistons that move up and down, converting fuel into mechanical energy.

Common Issues

Over time, various factors such as wear and tear, overheating, or lack of lubrication can lead to significant problems. Identifying symptoms like unusual noises, decreased power, or warning lights can help pinpoint issues early. Regular inspections are crucial to catch these concerns before they escalate.

Addressing Problems

When dealing with faults, it’s vital to follow a systematic approach. Begin by diagnosing the issue, which often requires specialized tools and knowledge. After determining the root cause, you can proceed with corrective actions, whether it involves replacing parts, adjusting settings, or performing cleaning procedures.

Preventive Measures

To minimize the risk of complications, routine maintenance should not be overlooked. Regular oil changes, timely replacement of filters, and monitoring of coolant levels are practices that can enhance engine performance and durability. Keeping detailed records of maintenance can also aid in future troubleshooting.

Transmission Maintenance and Repair Tips

Ensuring the longevity and optimal performance of your vehicle’s gearbox is essential for a smooth driving experience. Regular upkeep not only prevents unexpected breakdowns but also enhances the overall efficiency of your car. Below are some essential suggestions for maintaining and fixing transmission issues effectively.

Routine Fluid Checks

Monitoring the condition of the transmission fluid is critical. Inspect the fluid level regularly and look for any discoloration or burnt smell, which may indicate contamination. Top off or replace the fluid as needed, following the manufacturer’s specifications to ensure proper lubrication and functionality.

Component Inspection

Periodically examining key components can help identify potential problems before they escalate. Pay close attention to seals and gaskets for any signs of leakage. Additionally, listen for unusual noises while driving, which can signal mechanical issues. Addressing these concerns early can save time and costs associated with more extensive interventions.

Suspension System Diagnostics

The suspension system plays a crucial role in maintaining vehicle stability, comfort, and overall handling. Diagnosing issues within this system is essential for ensuring optimal performance and safety on the road. This section outlines key methods and techniques to identify potential problems effectively.

Common Symptoms of Suspension Issues

Drivers may notice several indicators that suggest a malfunction in the suspension system. These can include excessive bouncing after hitting bumps, uneven tire wear, or a noticeable drop in ride height. Additionally, unusual noises such as clunking or rattling while driving over rough surfaces can signify underlying concerns that require attention.

Diagnostic Techniques

To accurately assess the condition of the suspension system, various diagnostic techniques can be employed. Visual inspections are crucial; mechanics should examine components such as struts, springs, and bushings for signs of wear or damage. Furthermore, a test drive can provide insights into how the vehicle handles and responds to different road conditions, allowing for a more comprehensive evaluation of the suspension’s performance.

Brake System Inspection and Fixes

Ensuring optimal performance of the stopping mechanism is crucial for vehicle safety. Regular checks and timely interventions can prevent serious issues and enhance driving confidence. This section provides essential steps for evaluating the braking components and executing necessary corrections.

Inspection Steps

Begin by performing a thorough examination of the braking system. Focus on the following components:

- Brake Pads: Look for wear indicators and uneven surfaces.

- Brake Discs: Check for grooves, warping, and thickness.

- Brake Fluid: Assess the fluid level and condition; replace if contaminated.

- Hoses and Lines: Inspect for cracks, leaks, or bulges.

- Calipers: Ensure proper operation and check for leaks.

Common Fixes

If any component shows signs of wear or damage, consider the following solutions:

- Replacing Brake Pads: If pads are worn, replace them with new ones to restore efficiency.

- Machining or Replacing Discs: If discs are warped, they can either be machined or replaced to ensure smooth operation.

- Flushing Brake Fluid: Contaminated fluid should be flushed and replaced with fresh fluid.

- Repairing Hoses: Any damaged hoses must be replaced to maintain system integrity.

- Servicing Calipers: Calipers can be serviced by cleaning or replacing seals as needed.

By following these inspection and correction steps, you can maintain a safe and reliable braking system, ultimately enhancing the overall driving experience.

Fuel System Care and Troubleshooting

The proper maintenance of the fuel delivery system is crucial for optimal vehicle performance. A well-functioning fuel system ensures that the engine receives the correct mixture of fuel and air, leading to efficient combustion and power output. Neglecting this system can result in decreased performance, increased emissions, and even engine damage. This section outlines essential care tips and troubleshooting steps to help identify and resolve common fuel-related issues.

Regular Maintenance Practices

To keep the fuel system in top shape, consider the following practices:

- Regularly check and replace the fuel filter as recommended to prevent debris from clogging the system.

- Inspect fuel lines for leaks or cracks that could lead to fuel loss or contamination.

- Use high-quality fuel to avoid impurities that can cause performance issues.

- Clean the fuel injectors periodically to ensure a consistent spray pattern and optimal fuel atomization.

Troubleshooting Common Issues

If you encounter problems with the fuel system, the following steps may help identify the root cause:

- Check for warning lights on the dashboard that may indicate a fuel system fault.

- Listen for unusual noises from the fuel pump, which could signal a malfunction.

- Monitor fuel consumption; an increase may indicate a leak or injector issue.

- Examine the spark plugs; excessive fouling may point to fuel system inefficiencies.

Addressing fuel system care and troubleshooting can significantly enhance the longevity and performance of your vehicle. Regular inspections and prompt attention to issues are key to avoiding costly repairs down the line.

Cooling System Repair Techniques

Maintaining optimal engine temperature is crucial for vehicle performance. Addressing issues within the cooling system can prevent overheating and prolong engine life. This section outlines effective approaches to troubleshoot and resolve common challenges encountered in these systems.

Key techniques include:

- Leak Detection: Regularly inspect hoses and connections for any signs of coolant leaks. Use dye testing for hard-to-find leaks.

- Thermostat Testing: Ensure the thermostat is functioning correctly to regulate coolant flow. Replace it if it fails to open or close as needed.

- Radiator Maintenance: Clean the radiator fins to enhance airflow. Flush the system periodically to remove any debris or buildup.

- Water Pump Inspection: Check the water pump for any signs of wear or damage. Listen for unusual noises indicating a malfunction.

Implementing these techniques can significantly improve the efficiency and reliability of the cooling system. Regular maintenance practices help identify potential problems before they escalate, ensuring a smoother driving experience.

For a thorough evaluation, follow these steps:

- Start with a visual inspection of all components.

- Check fluid levels and top off as necessary.

- Test the system under pressure to identify hidden leaks.

- Perform temperature checks to ensure proper operation during engine run.

By adopting these strategies, vehicle owners can effectively manage the health of their cooling system, leading to enhanced engine performance and longevity.

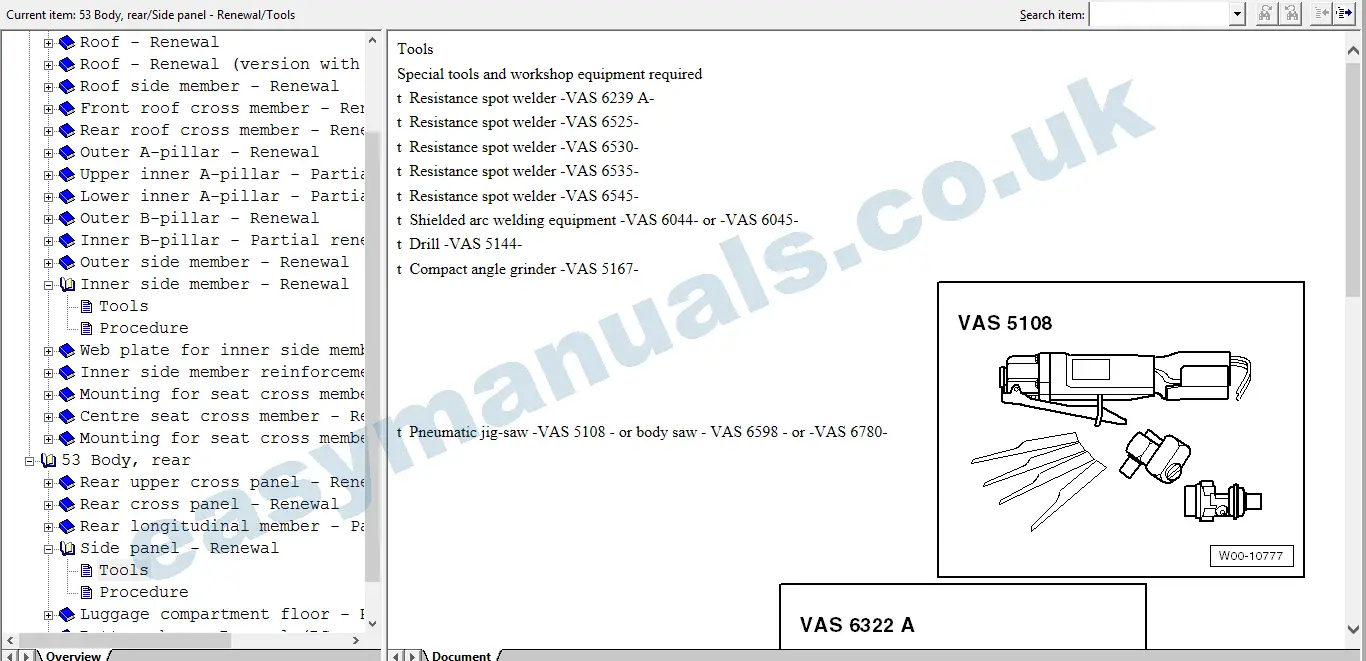

Bodywork Repairs and Paint Matching

Maintaining the exterior aesthetics of a vehicle is crucial for both appearance and longevity. This section focuses on methods for addressing surface imperfections and achieving a seamless finish that aligns with the original hue of the automobile.

When dealing with exterior damage, consider the following steps:

- Assess the Damage: Identify the extent of dents, scratches, or rust.

- Gather Materials: Ensure you have the necessary tools such as sandpaper, filler, and paint.

- Prepare the Surface: Clean and sand the affected area to promote adhesion.

- Apply Filler: Use appropriate filler for dents and scratches, then sand it smooth.

For effective color matching, follow these guidelines:

- Identify the Color Code: Locate the vehicle’s color code usually found in the door jamb or owner’s manual.

- Test Paint Samples: Obtain small samples of paint to test on a discreet area.

- Consider Lighting Conditions: Inspect the color match under different lighting to ensure accuracy.

- Layering Technique: Apply multiple thin layers of paint, allowing adequate drying time between coats for a uniform finish.

By following these practices, you can ensure that your vehicle’s exterior remains in top condition, enhancing its overall appeal and value.

Frequently Asked Questions About Repairs

This section aims to address common inquiries related to maintenance and troubleshooting for a specific vehicle model. By providing clear answers, we hope to assist enthusiasts and owners in understanding their needs better.

Common Issues and Solutions

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Engine Won’t Start | Faulty battery or starter | Check battery connections and consider replacing the battery or starter. |

| Strange Noises While Driving | Worn suspension components | Inspect suspension and replace any damaged parts. |

| Overheating | Coolant leak | Check for leaks and ensure proper coolant levels. |

Maintenance Tips

Regular inspections and timely interventions can prevent major issues. Always refer to manufacturer guidelines for recommended intervals and procedures. Keeping a record of services performed will also help track the vehicle’s condition over time.