In the world of two-wheeled transportation, ensuring optimal performance and longevity of your vehicle is paramount. This section is dedicated to providing essential insights and procedures for effectively managing common issues and routine upkeep. Whether you’re a seasoned mechanic or a novice enthusiast, having a reliable resource at hand can significantly enhance your experience.

Understanding the intricacies of your machine can empower you to tackle various challenges confidently. From basic adjustments to more complex repairs, this guide will navigate through key aspects, helping you cultivate a deeper connection with your ride. Each step is designed to demystify the process, allowing you to maintain your vehicle with ease.

Equipped with the right knowledge, you’ll be better prepared to address potential setbacks and ensure smooth operation. Our goal is to equip you with valuable techniques and information that will not only resolve issues but also prevent future complications. Let’s embark on this journey to mastery together.

Overview of Yamaha Breeze 125

This section provides a comprehensive understanding of a popular two-wheeled vehicle known for its reliability and efficiency. Designed for both urban commuting and leisurely rides, it has become a favorite among enthusiasts and everyday riders alike.

With its lightweight frame and user-friendly design, this model offers excellent maneuverability, making it ideal for navigating through busy streets. Its robust engine ensures a smooth performance, while the comfortable seating allows for extended journeys without fatigue.

Maintenance is straightforward, thanks to well-organized components that facilitate quick inspections and servicing. Whether you’re a novice or an experienced mechanic, you’ll find that addressing any issues is manageable.

| Feature | Description |

|---|---|

| Engine Type | Air-cooled, four-stroke engine providing efficient power delivery. |

| Transmission | Automatic transmission for effortless riding. |

| Fuel Capacity | Generous tank capacity for longer trips between refuels. |

| Brakes | Reliable braking system ensuring safety and control. |

| Weight | Lightweight construction enhances agility and handling. |

Key Features and Specifications

This section provides an overview of the essential characteristics and technical details of the vehicle, highlighting what sets it apart from others in its class. Understanding these aspects is crucial for both enthusiasts and those seeking practical knowledge for maintenance and usage.

Core Attributes

Designed with functionality in mind, this model features a reliable engine, efficient fuel system, and a comfortable riding experience. Each component contributes to its overall performance, ensuring both durability and user satisfaction.

Technical Data

| Specification | Details |

|---|---|

| Engine Type | Single-cylinder, four-stroke |

| Displacement | 124 cc |

| Fuel System | Carbureted |

| Transmission | Automatic |

| Brakes | Disc front, drum rear |

| Seat Height | 780 mm |

Maintenance Essentials for Longevity

Ensuring the durability and optimal performance of your vehicle requires a commitment to regular upkeep. By following a structured approach to care, you can significantly extend its lifespan and maintain peak functionality. This section highlights essential practices that contribute to the long-term reliability of your machine.

Routine Inspections

Conducting frequent examinations is vital for identifying potential issues before they escalate. Focus on checking fluid levels, brakes, and tire conditions. Additionally, inspect the battery and electrical components to ensure they are functioning correctly. Early detection can save time and resources down the line.

Regular Cleaning and Lubrication

Keeping your vehicle clean not only enhances its appearance but also prevents corrosion and wear. Regularly wash the exterior and remove any debris that may accumulate in hard-to-reach areas. Lubricate moving parts as per the manufacturer’s recommendations to ensure smooth operation and reduce friction, thereby promoting longevity.

Common Issues and Solutions

This section addresses frequent complications encountered with certain two-wheeled vehicles, offering practical remedies to enhance performance and longevity. Understanding these typical concerns allows for proactive maintenance and troubleshooting.

Below are some prevalent problems along with their corresponding solutions:

| Issue | Solution |

|---|---|

| Engine Not Starting | Check the battery charge and connections; replace the spark plug if necessary. |

| Unusual Noises from Engine | Inspect for loose components and ensure proper lubrication of moving parts. |

| Poor Fuel Efficiency | Clean the fuel system and replace the air filter for optimal airflow. |

| Electrical Issues | Examine wiring for damage and ensure all connections are secure. |

| Overheating | Check coolant levels and ensure the radiator is free from blockages. |

Step-by-Step Repair Instructions

This section provides detailed guidance for effectively addressing common issues with your vehicle. Following a structured approach can simplify the process, ensuring that each task is completed thoroughly and safely.

Preparation and Safety

Before starting any work, ensure you have the necessary tools and protective equipment. Clear the workspace to minimize hazards and enhance efficiency. Familiarize yourself with the components you will be working on to avoid confusion.

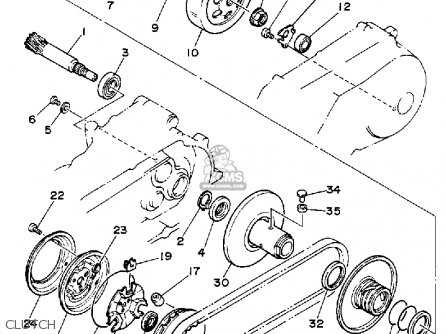

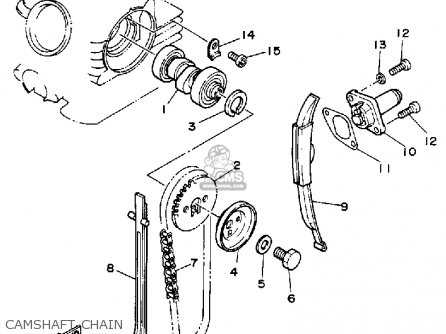

Disassembly and Inspection

Begin by carefully removing the outer casing or covers, taking note of the screws and clips. As you proceed, inspect each part for wear or damage. Document any irregularities you encounter, as this information will guide your subsequent actions.

Utilizing these instructions will facilitate a smoother process, helping you to achieve successful outcomes with your vehicle’s maintenance and enhancement.

Tools Required for Repairs

When maintaining and servicing a two-wheeled vehicle, having the right instruments is essential for efficient and effective work. This section outlines the essential implements that will assist in addressing various issues and performing routine maintenance tasks.

Essential Hand Tools

Basic hand tools form the foundation of any maintenance kit. A set of wrenches, screwdrivers, and pliers is necessary for loosening and tightening components. A torque wrench is particularly important for ensuring that fasteners are secured to the correct specifications. Additionally, a set of Allen keys can be invaluable for working with certain fittings.

Specialized Equipment

Beyond standard hand tools, some specialized equipment can enhance the repair process. A multimeter is useful for diagnosing electrical issues, while a compression tester helps assess engine performance. For tasks involving fluids, having a funnel, oil catch pan, and various fluid containers can streamline maintenance tasks and minimize spills.

Engine Troubleshooting Techniques

Effective diagnostics of internal combustion mechanisms is crucial for maintaining optimal performance. Identifying issues early can prevent further complications, ensuring longevity and reliability. This section outlines essential methodologies for assessing and rectifying common concerns encountered in the engine system.

Initial Assessment Steps

Begin with a thorough inspection of the engine components, checking for visible signs of wear or damage. Listening for unusual sounds during operation can provide clues about potential failures. Additionally, monitoring performance metrics such as vibrations and exhaust emissions helps pinpoint areas needing attention.

Systematic Testing Methods

Utilizing diagnostic tools enhances accuracy in identifying problems. Compression tests evaluate the integrity of the cylinders, while electrical diagnostics assess the functionality of ignition systems. Implementing these methods ensures a comprehensive understanding of the engine’s health and facilitates effective solutions.

Electrical System Diagnostics

This section focuses on the procedures and techniques essential for assessing the functionality of the electrical components within a two-wheeled vehicle. Effective diagnostics can prevent malfunctions and ensure optimal performance.

To accurately evaluate the electrical system, follow these steps:

- Visual Inspection:

- Check for any signs of wear or damage on wires and connectors.

- Look for corrosion at terminal points.

lessCopy code

- Measure the voltage output using a multimeter.

- Inspect the battery for leaks or swelling.

- Start the engine and measure the voltage across the battery terminals.

- Ensure the output is within the manufacturer’s specified range.

- Test all lights and indicators for proper operation.

- Verify that the ignition system is functioning correctly.

By systematically following these diagnostic steps, you can identify and rectify issues within the electrical system, enhancing reliability and performance.

Replacing Key Components

Maintaining the optimal performance of a two-wheeled vehicle often requires attention to essential parts that may wear out over time. This section focuses on the procedures and considerations involved in substituting these critical elements, ensuring the vehicle remains reliable and efficient. Proper replacement techniques can enhance longevity and improve functionality.

When approaching the task of component substitution, it is vital to first identify which parts require replacement. Regular inspections can reveal signs of wear or malfunction, enabling timely intervention. Gather the necessary tools and components before beginning the process to ensure a smooth workflow.

For each specific part being replaced, refer to detailed guidelines to understand the proper installation techniques. Pay close attention to alignment and securing mechanisms to avoid future issues. After replacement, conducting a thorough check can confirm that everything is functioning as intended, allowing for a safe riding experience.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is crucial for both personal safety and the longevity of the equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Understanding potential hazards and taking proactive measures will create a safer workspace.

Personal Protective Equipment (PPE)

Utilizing appropriate personal protective gear is essential when performing any maintenance. This includes wearing gloves, goggles, and sturdy footwear to shield against possible injuries.

Work Area Management

A well-organized workspace contributes to safety and efficiency. Keeping tools and materials neatly arranged can prevent slips and falls, allowing for a smoother process.

| Precaution | Description |

|---|---|

| Wear Safety Goggles | Protects eyes from debris and chemicals. |

| Use Gloves | Prevents skin injuries from sharp objects and harmful substances. |

| Secure Work Area | Eliminates clutter to avoid accidents. |

| Ensure Proper Ventilation | Minimizes inhalation of harmful fumes. |

Tips for Efficient Servicing

Maintaining your vehicle effectively requires a blend of knowledge, preparation, and the right tools. By following certain strategies, you can ensure that your maintenance tasks are completed smoothly and efficiently, ultimately extending the lifespan of your machine.

Here are some key recommendations to enhance your servicing experience:

| Tip | Description |

|---|---|

| Organize Tools | Keep all necessary tools in a designated area to minimize time spent searching for them during servicing. |

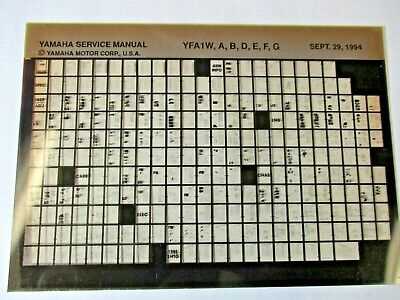

| Consult Documentation | Review technical documents for specifications and guidelines before starting any maintenance tasks. |

| Use Quality Parts | Always opt for high-quality replacement parts to ensure optimal performance and durability. |

| Follow a Checklist | Create a checklist of maintenance tasks to ensure nothing is overlooked during the servicing process. |

| Keep a Clean Workspace | Maintain a tidy work area to enhance safety and efficiency, reducing the risk of accidents or misplaced tools. |

Where to Find Spare Parts

Locating components for your vehicle can be a straightforward process if you know where to look. Various sources offer both genuine and aftermarket parts, catering to different preferences and budgets.

- Authorized Dealerships: Visiting a certified dealer guarantees access to original components. They often have the latest parts available and can assist with specific requests.

- Online Marketplaces: Websites such as eBay, Amazon, and specialized automotive platforms frequently list a wide range of components. User reviews can guide your choices.

- Local Auto Parts Stores: These establishments may stock common items and can order specific components if not readily available.

- Forums and Community Groups: Joining online communities dedicated to your model can lead to recommendations for reliable sources and potential sales from other enthusiasts.

- Salvage Yards: Visiting a salvage yard can provide opportunities to find used parts at reduced prices, which can be beneficial for budget-conscious repairs.

By exploring these avenues, you can efficiently source the components needed to keep your vehicle in optimal condition.