Owning a vintage sewing device can be a rewarding experience, offering both nostalgia and functionality. This section aims to provide essential insights into the upkeep of a specific model known for its durability and reliability. Understanding how to care for and troubleshoot this type of equipment is crucial for ensuring its longevity and optimal performance.

From routine checks to more intricate adjustments, mastering the maintenance process can enhance your skills and keep the machine in top condition. This guide will cover fundamental aspects of care, addressing common issues that may arise during operation. By following these steps, enthusiasts can preserve their equipment’s value and efficiency.

Whether you are a novice or an experienced user, familiarizing yourself with the nuances of this classic model will empower you to tackle any challenges confidently. Explore the various techniques and tips outlined here to ensure your sewing companion continues to serve you well for years to come.

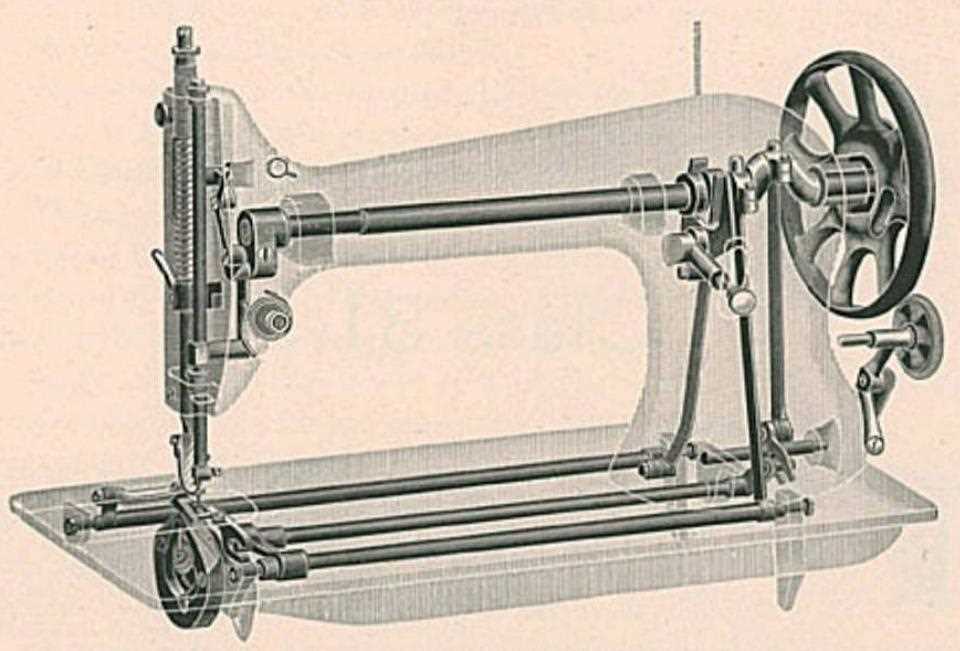

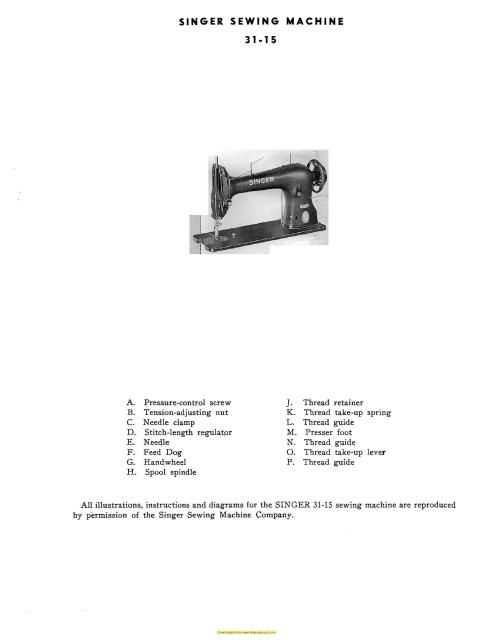

Overview of Singer 31-15 Features

This section delves into the distinctive characteristics of a specific sewing machine model that has garnered appreciation for its versatility and efficiency. The design elements and functionalities make it an ideal choice for various sewing applications, ensuring smooth operation and reliable results.

Key Functionalities

The machine is equipped with a robust motor that enhances its performance, allowing for quick stitching and the ability to handle multiple fabric types. The adjustable settings enable users to customize their sewing experience, ensuring precision in every project.

User-Friendly Design

Designed with the user in mind, this model features an intuitive layout that simplifies the sewing process. The accessible controls and clear instruction guide make it suitable for both beginners and experienced sewists, promoting a seamless and enjoyable crafting experience.

Common Issues and Solutions

In the realm of sewing machines, users often encounter a variety of challenges that can hinder their creative process. Understanding these common difficulties and their corresponding remedies can greatly enhance the experience and longevity of the equipment.

Thread Bunching: One frequent issue is the occurrence of thread bunching beneath the fabric. This can usually be resolved by checking the thread tension and ensuring the machine is properly threaded. Regular cleaning of the bobbin area can also prevent this problem.

Needle Breakage: If the needle frequently breaks, it may be due to using the wrong type or size for the fabric. Switching to the appropriate needle can significantly reduce this issue. Additionally, ensuring the needle is inserted correctly is essential.

Skipping Stitches: Another common frustration is skipped stitches. This can result from a dull needle or improper threading. Replacing the needle and re-threading the machine often rectifies this problem.

Uneven Stitching: For uneven stitching, it’s important to inspect the feed dogs and presser foot pressure. Adjusting these settings can lead to more consistent results. Regular maintenance, such as oiling, can also contribute to smoother operation.

Essential Tools for Repairs

To ensure efficient maintenance and troubleshooting of sewing equipment, having the right instruments is crucial. A well-equipped workspace not only enhances productivity but also simplifies the process of addressing various mechanical issues.

Basic Instruments

- Screwdrivers: Essential for loosening and tightening screws of various sizes.

- Wrenches: Useful for adjusting nuts and bolts securely.

- Pliers: Ideal for gripping, twisting, and cutting wires.

- Scissors: Needed for trimming threads and fabric accurately.

Specialized Equipment

- Oiling tools: Important for maintaining smooth operation and preventing rust.

- Cleaning brushes: Help remove dust and debris from hard-to-reach areas.

- Measuring tools: Ensure precision when aligning components.

- Replacement parts: Having a stock of commonly needed components can speed up the process of fixing issues.

Step-by-Step Maintenance Guide

Proper upkeep of your sewing apparatus is essential for optimal performance and longevity. This section provides a detailed outline to ensure your equipment remains in top condition, helping you avoid common issues and extend its lifespan.

1. Cleaning: Begin by unplugging the device and removing any accumulated dust and lint. Use a soft brush and a lint roller to clean the area around the needle and feed dogs. Pay attention to the bobbin case, ensuring it is free from debris.

2. Lubrication: After cleaning, apply a few drops of suitable oil to the moving parts as indicated in the specifications. This step is crucial to reduce friction and enhance efficiency during operation.

3. Tension Adjustment: Check the thread tension regularly. Adjust the upper and lower tension settings according to the fabric type being used to achieve the desired stitch quality. Test on scrap fabric to confirm the settings are correct.

4. Needle Replacement: Inspect the needle for any signs of wear or damage. A dull or bent needle can lead to poor stitching. Replace it with a new one appropriate for the fabric you are working with.

5. Regular Inspections: Periodically examine all components for signs of wear or damage. Ensure that all screws and parts are tightened and secure. Address any issues promptly to prevent further complications.

6. Professional Servicing: Consider scheduling a thorough check-up with a qualified technician annually. This ensures that any hidden problems are addressed and that your machine continues to operate smoothly.

By following these steps diligently, you can maintain your sewing device effectively, ensuring it serves you well for many projects to come.

Adjusting Tension and Stitch Quality

Achieving optimal stitch formation requires careful attention to the balance between thread tension and fabric characteristics. Properly adjusted tension ensures that stitches lie flat and maintain their integrity, preventing issues such as puckering or skipped stitches.

To begin, examine the thread paths and ensure that they are correctly threaded through the machine. Adjust the tension dials, gradually modifying the settings until the desired balance is reached. It is crucial to test on a fabric scrap similar to your project, as different materials may require distinct adjustments.

Pay attention to the stitch appearance: a well-balanced stitch will show equal amounts of thread on both the top and bottom sides of the fabric. If the top thread appears tight or the bobbin thread is visible on the top, further adjustments may be necessary. Regularly checking and fine-tuning these settings will greatly enhance the quality of your sewing projects.

Replacing Needles and Threads

Properly changing the needle and thread is essential for maintaining optimal performance in sewing machines. Regularly updating these components can significantly enhance the quality of your stitching and prevent potential issues during operation.

To begin, ensure that the machine is powered off to avoid any accidents. Carefully remove the old needle by loosening the screw that holds it in place. When selecting a new needle, consider the type of fabric you will be working with, as different materials require specific needle types and sizes for best results.

Next, insert the new needle with the flat side facing the correct direction, securing it tightly in place. Once the needle is replaced, it’s time to thread the machine. Choose a suitable thread that matches your fabric, ensuring it is properly wound and free of tangles. Follow the threading path indicated on the machine to avoid any threading errors, which can lead to uneven stitches or jams.

After threading, perform a few test stitches on a scrap piece of fabric to confirm that everything is functioning correctly. Regular maintenance, including needle and thread replacement, will ensure smooth operation and high-quality results in your sewing projects.

Cleaning and Lubricating Mechanisms

Maintaining the functionality of sewing equipment involves regular cleaning and proper lubrication of its internal components. This process ensures smooth operation and prolongs the lifespan of the machine.

To effectively clean and lubricate, follow these essential steps:

- Gather Necessary Supplies:

- Soft cloths

- Brushes for dust removal

- Machine oil or lubricant

- Cleaning solution (if required)

- Turn Off and Unplug: Always ensure the device is turned off and unplugged before starting any maintenance work.

- Remove Dust and Debris:

Using a brush, gently remove dust and lint from the exterior and interior parts, especially around the feed dogs and the bobbin area.

- Clean Surfaces:

Wipe down all accessible surfaces with a soft cloth slightly dampened with cleaning solution, if necessary.

- Lubricate Moving Parts:

Apply a small amount of lubricant to the key moving components as recommended by the manufacturer. Avoid over-lubricating, as excess oil can attract dust.

- Check for Obstructions:

Inspect the needle and thread paths to ensure there are no blockages that could impede operation.

- Reassemble and Test:

After cleaning and lubricating, reassemble any removed parts, plug the device back in, and perform a test run to ensure everything functions smoothly.

By adhering to these guidelines, you can maintain the efficiency and performance of your sewing equipment, ensuring it operates optimally for years to come.

Understanding the Electrical Components

This section aims to provide a comprehensive overview of the electrical elements found in sewing machines. Grasping the function and significance of these components is crucial for effective troubleshooting and maintenance.

Main Electrical Parts

- Power Supply: Converts the main voltage to a usable level for the machine.

- Motor: Responsible for driving the needle and various mechanisms.

- Switches: Control the operation, allowing the user to start or stop the machine.

- Wiring Harness: Connects different electrical components, ensuring efficient communication.

Functionality and Maintenance

Each component plays a vital role in the overall operation of the machine. Regular inspection of these parts can help prevent malfunctions.

- Check connections for signs of wear or damage.

- Ensure the power supply is functioning correctly.

- Inspect the motor for unusual noises or overheating.

By understanding these elements, users can better maintain their machines and enhance their longevity.

Troubleshooting Operational Problems

This section focuses on identifying and resolving common issues that may arise during the operation of your sewing machine. By systematically assessing various components and their functions, you can effectively diagnose problems and restore optimal performance.

Common Issues and Solutions

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Machine not starting | Power supply issue, faulty switch | Check power cord and outlet, test the switch |

| Thread bunching | Incorrect threading, dull needle | Re-thread machine, replace needle |

| Skipped stitches | Improper needle size, incorrect tension | Use appropriate needle size, adjust tension settings |

| Unusual noise | Lack of lubrication, foreign objects | Lubricate moving parts, check for obstructions |

Preventive Measures

To minimize operational problems, regular maintenance is essential. Keep your sewing machine clean, ensure proper lubrication, and use the correct materials for your projects. Regularly checking settings and components can prevent many issues before they occur.

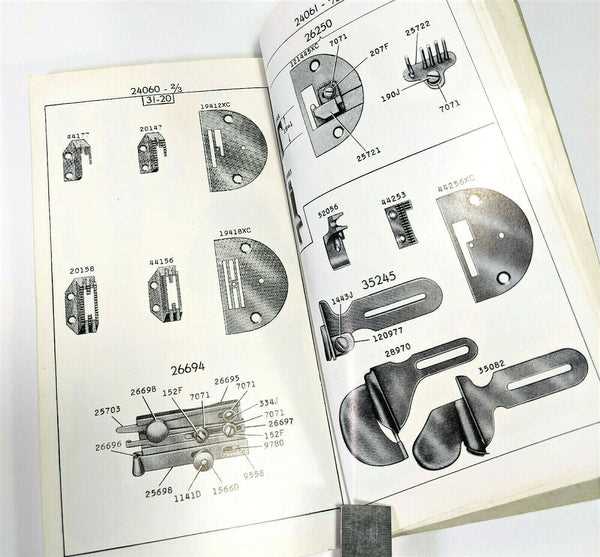

Upgrading Parts for Better Performance

Enhancing the functionality of your machine can significantly improve its efficiency and longevity. By replacing certain components with upgraded versions, you can experience smoother operation and increased reliability. This section will explore various enhancements that can lead to better performance, making your device more effective in meeting your needs.

Key Components for Upgrade

Consider focusing on the following essential parts when looking to boost performance:

| Component | Benefits of Upgrade |

|---|---|

| Needles | Improved precision and reduced wear. |

| Belts | Enhanced durability and smoother operation. |

| Presser Foot | Increased versatility for various fabrics. |

| Bobbin Case | Better tension control for consistent stitching. |

Considerations for Upgrading

Before proceeding with any upgrades, assess compatibility and functionality. Ensure that the new components are suitable for your specific model. Proper installation and adjustment are also crucial to maximize the benefits of the upgrades, ultimately leading to an enhanced experience and better outcomes in your projects.

Safety Precautions During Repairs

When working on mechanical devices, ensuring safety is paramount. Proper precautions not only protect the individual performing the task but also safeguard the equipment from potential damage. Adhering to specific guidelines can mitigate risks and enhance the overall experience.

- Always disconnect the power source before starting any maintenance work to prevent accidental activation.

- Utilize appropriate personal protective equipment, such as gloves and safety goggles, to shield against injury.

- Keep the workspace organized and free from clutter to minimize the chance of accidents.

- Be mindful of sharp edges and moving parts; handle components with care.

- Ensure adequate lighting in the workspace to facilitate visibility and reduce strain.

- Follow manufacturer guidelines and specifications to avoid improper handling of the machine.

By implementing these measures, individuals can foster a safer environment, leading to more efficient and effective maintenance tasks.

Resources for Additional Support

When seeking further assistance with your sewing machine, numerous resources are available to provide guidance and enhance your understanding. Whether you’re facing technical challenges or simply looking to expand your knowledge, leveraging these tools can significantly improve your experience.

Online Communities and Forums

Participating in online forums and communities dedicated to sewing enthusiasts can be incredibly beneficial. These platforms allow users to share their experiences, ask questions, and receive advice from fellow sewers. Engaging in discussions can also lead to valuable tips and techniques that enhance your skills.

Video Tutorials and Webinars

Exploring video tutorials and webinars can offer visual guidance on various aspects of machine operation and maintenance. Many experienced users and experts create content that addresses common issues and provides step-by-step instructions. This type of resource can be especially helpful for visual learners seeking practical demonstrations.