In the world of farming, efficient and reliable equipment is paramount for success. Understanding the intricacies of your machinery not only ensures optimal performance but also prolongs its lifespan. This section aims to provide valuable insights into the maintenance and troubleshooting of essential agricultural equipment, helping you navigate common issues and enhancing your operational efficiency.

Proper upkeep is vital for any piece of machinery. By delving into the various aspects of servicing and care, you can identify potential problems before they escalate, ensuring that your equipment remains a dependable partner in your daily tasks. This guide emphasizes the significance of routine checks, parts replacement, and general best practices, enabling you to keep your machinery in peak condition.

Whether you are a seasoned professional or a newcomer to the field, having a comprehensive understanding of your equipment’s functionality will empower you to make informed decisions. With the right approach, you can tackle challenges head-on, ensuring that your agricultural operations run smoothly and efficiently. Embrace the knowledge presented here, and equip yourself with the skills needed for successful machinery management.

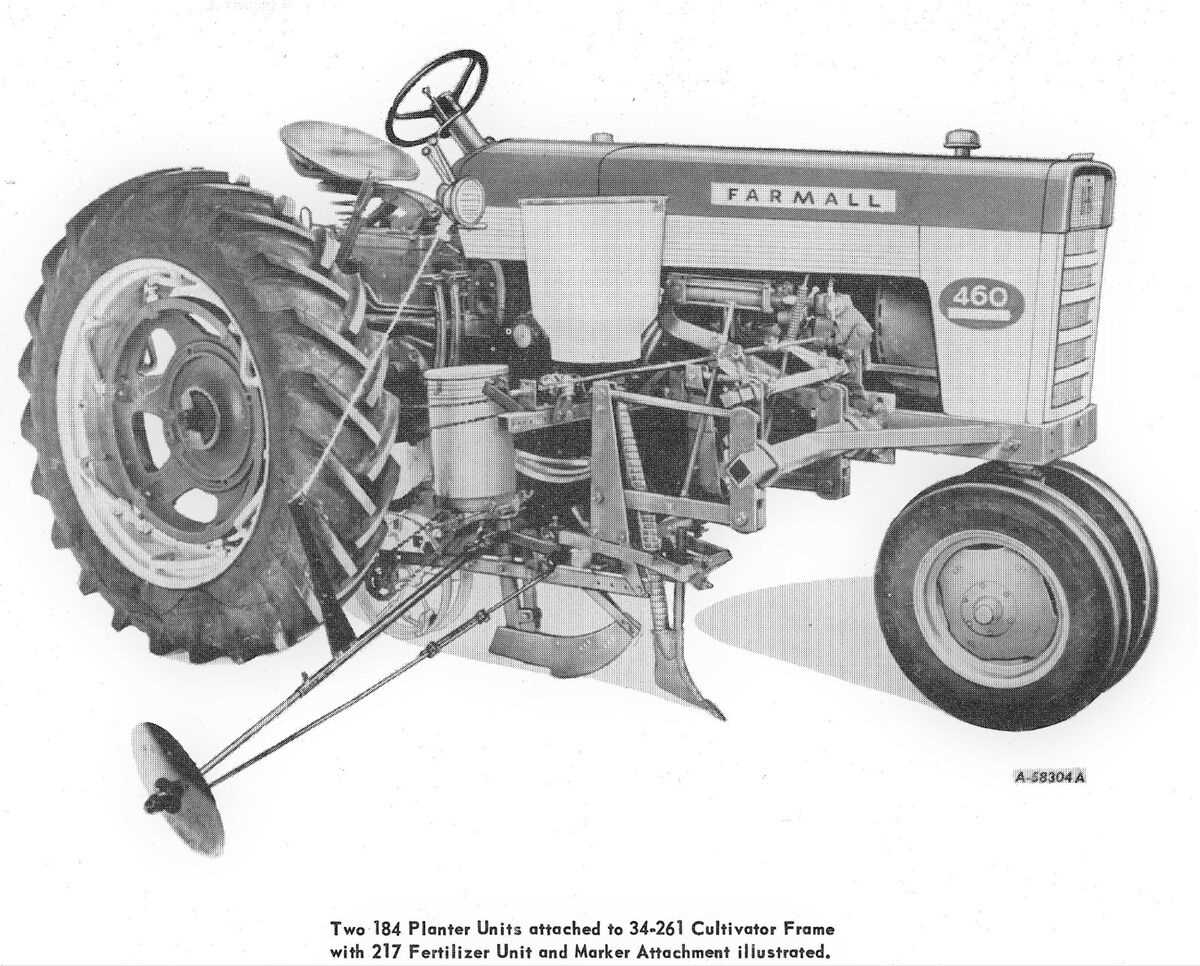

Overview of Farmall 140 Features

This section provides a comprehensive look at the key characteristics of a well-known agricultural machine, highlighting its innovative design and functional capabilities. With a focus on efficiency and usability, this vehicle has become a valuable asset for farmers and landowners alike.

Key Specifications

- Engine Type: Four-cylinder, air-cooled

- Horsepower: Approximately 30 HP

- Transmission: Manual with multiple gears

- Weight: Around 3,500 lbs

Notable Features

- Versatility: Designed to handle a variety of tasks, from plowing to hauling.

- User-Friendly Controls: Intuitive layout for easy operation.

- Durability: Built with robust materials to withstand tough working conditions.

- Compact Size: Ideal for navigating tight spaces and small farms.

Common Issues with Farmall 140

When operating vintage agricultural machinery, users may encounter a range of typical problems. Understanding these common issues can help in maintaining optimal performance and extending the lifespan of the equipment.

- Engine Starting Problems:

- Weak battery or faulty starter.

- Fuel supply issues, such as clogged filters.

- Improper spark plug function.

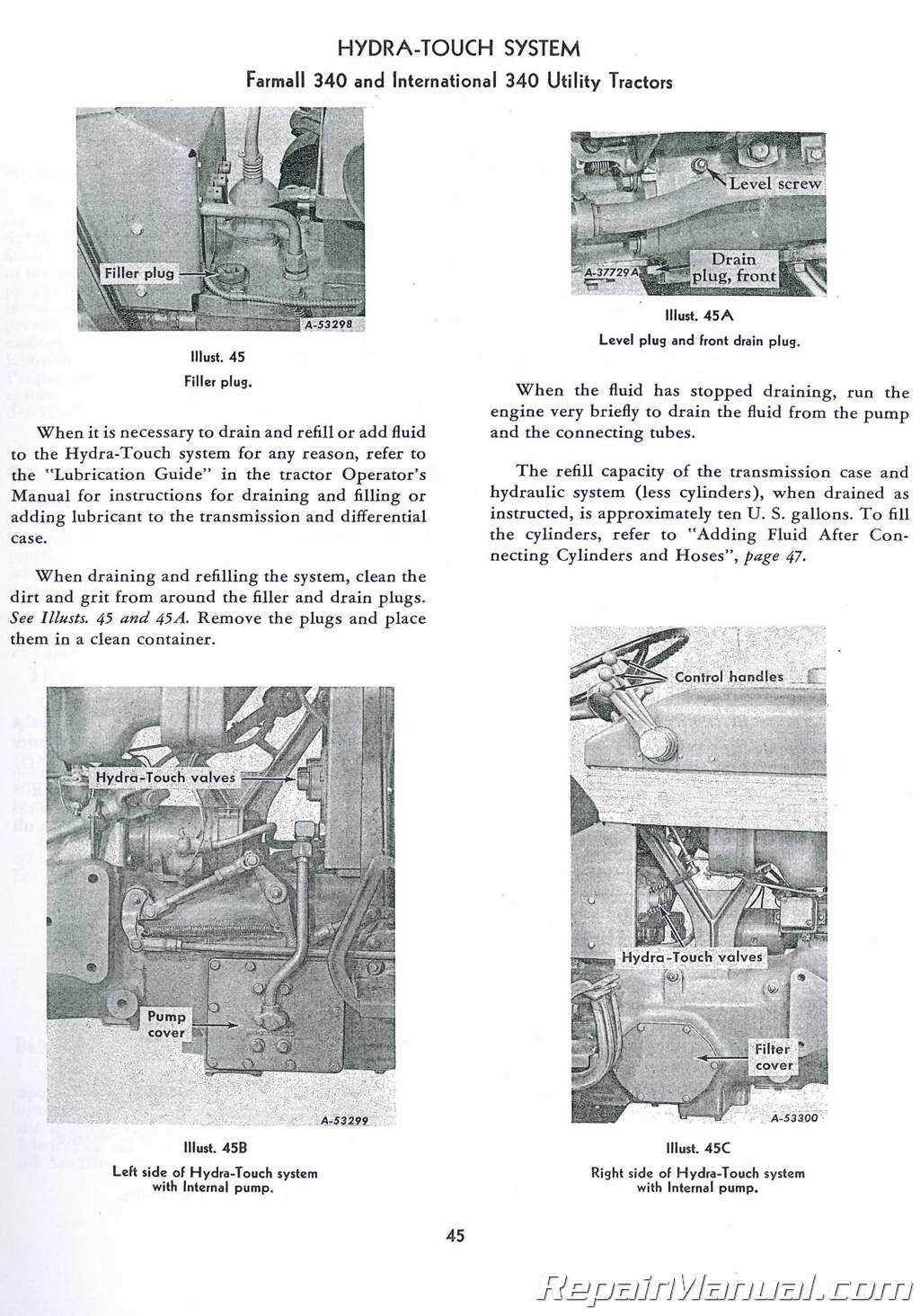

- Hydraulic System Failures:

- Fluid leaks from hoses or connections.

- Low fluid levels affecting operation.

- Malfunctioning hydraulic pumps.

- Transmission Difficulties:

- Shifting problems due to worn gears.

- Fluid contamination leading to performance issues.

- Noise indicating potential internal damage.

- Electrical System Malfunctions:

- Corroded wiring causing shorts or failures.

- Faulty lights or indicators.

- Defective ignition system components.

- Cooling System Overheating:

- Blocked radiator causing poor airflow.

- Low coolant levels or leaks.

- Failed water pump reducing circulation.

Addressing these frequent concerns with timely maintenance and thorough inspections can greatly enhance the reliability of the machinery. Awareness of these issues allows operators to act promptly, ensuring efficient and effective agricultural operations.

Essential Tools for Repairs

Having the right set of instruments is crucial for effectively maintaining and restoring machinery. A well-equipped workspace not only enhances productivity but also ensures that tasks are completed safely and efficiently. This section outlines the fundamental tools necessary for tackling common issues encountered in agricultural equipment.

Wrenches are indispensable for loosening and tightening various nuts and bolts. A good set typically includes both open-end and socket types, allowing for versatility in different situations.

Socket sets are essential for working with fasteners that require a higher level of torque. They come in various sizes and drive types, enabling users to address a wide range of components with ease.

Pliers are another vital addition to any toolkit. They provide grip and leverage for holding objects firmly, making them useful for tasks such as bending or cutting wires and other materials.

Hammers can be invaluable for tasks requiring forceful impact, whether for driving nails, aligning components, or breaking loose rusted parts. A rubber mallet is often preferred to minimize damage to sensitive areas.

Screwdrivers in multiple sizes and types–both flat and Phillips–are necessary for securing and adjusting smaller components. They offer precision in handling delicate parts and fasteners.

Measuring tools, such as tape measures and calipers, are critical for ensuring that parts fit correctly and align as intended. Accurate measurements prevent costly mistakes during assembly or adjustments.

Lastly, having a reliable toolbox to keep all these items organized is essential. A well-organized workspace minimizes downtime and allows for quicker access to tools, making any maintenance task more manageable.

Engine Maintenance and Troubleshooting

Proper upkeep of the power unit is essential for optimal performance and longevity. Regular attention to various components can prevent common issues and ensure smooth operation. This section provides guidelines for routine care and strategies for diagnosing problems effectively.

Routine Maintenance Tasks

- Oil Changes: Regularly replacing the oil is crucial. Check the manufacturer’s recommendations for intervals.

- Air Filter Inspection: A clean air filter ensures efficient combustion. Inspect and replace as necessary.

- Coolant Levels: Maintain proper coolant levels to prevent overheating. Regularly check for leaks.

- Fuel System Care: Keep the fuel system clean and free from contaminants. Use quality fuel and consider periodic cleaning of injectors.

- Belts and Hoses: Inspect belts for wear and replace frayed or cracked ones. Check hoses for leaks or brittleness.

Troubleshooting Common Issues

- Engine Won’t Start:

- Check battery voltage and connections.

- Inspect the starter motor and solenoid.

- Examine the fuel supply and ensure proper flow.

- Overheating:

- Verify coolant levels and check for leaks.

- Inspect the thermostat and water pump functionality.

- Ensure the radiator is free from obstructions.

- Excessive Smoke:

- Identify the color of the smoke: blue may indicate oil burning, while black suggests too much fuel.

- Check for oil leaks or worn piston rings.

- Examine the fuel injectors and air intake system.

By adhering to these maintenance tips and troubleshooting methods, you can enhance the reliability and efficiency of the engine, ensuring it performs at its best for years to come.

Transmission System Insights

The transmission system is a crucial component that facilitates power transfer from the engine to the wheels, ensuring optimal performance and efficiency. Understanding its intricacies can significantly enhance maintenance practices and overall functionality. This section delves into the essential aspects of this system, emphasizing its operation, common issues, and solutions.

Key Components and Functionality

At the heart of the transmission are several vital elements, including gears, clutches, and shafts. Each plays a unique role in adjusting speed and torque. The seamless engagement of these parts enables smooth acceleration and deceleration, allowing the vehicle to respond effectively to varying load conditions. Regular inspection of these components is essential to prevent wear and ensure reliable operation.

Common Issues and Solutions

Frequent problems encountered in transmission systems include fluid leaks, slipping gears, and unusual noises. Fluid leaks can lead to inadequate lubrication, risking significant damage. Addressing this involves checking seals and gaskets. Slipping gears often signal worn clutches or linkage issues, which require timely adjustments or replacements. Additionally, any unusual noises may indicate misalignment or damage, necessitating thorough diagnostics to pinpoint and resolve the underlying cause.

Hydraulic System Repair Techniques

The hydraulic system plays a crucial role in the efficient functioning of machinery, relying on fluid power to transmit force and motion. Addressing issues within this system is essential for maintaining optimal performance and prolonging the lifespan of the equipment. Understanding various techniques for troubleshooting and restoring the hydraulic components can greatly enhance operational efficiency.

Identifying Common Issues

Before diving into the restoration process, it is vital to recognize common symptoms of malfunction. Issues such as leaks, erratic performance, or unusual noises can indicate underlying problems. Conducting a thorough inspection of hoses, connectors, and cylinders can help pinpoint the source of the trouble. Regular maintenance and observation can prevent minor issues from escalating into major repairs.

Effective Restoration Techniques

Once the problem has been identified, various approaches can be employed to rectify it. Replacing damaged seals and gaskets is a common solution for leaks. Additionally, ensuring proper fluid levels and quality can prevent cavitation and overheating. For more complex issues, disassembling the hydraulic components may be necessary. Cleaning, realigning, and recalibrating these parts can restore their functionality. After completing repairs, always conduct a thorough test to confirm that the system operates smoothly and efficiently.

Electrical System Diagnostics

The electrical system of any machinery is crucial for its overall functionality and performance. Diagnosing issues within this system requires a systematic approach to identify faults and ensure optimal operation. Understanding the components involved and their interactions can greatly enhance troubleshooting efforts.

Common symptoms of electrical problems include malfunctioning lights, starting issues, and erratic behavior of electrical components. Proper diagnostic techniques can help isolate the root causes and guide necessary interventions.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Dead battery or faulty connections | Check battery voltage and clean terminals |

| Flickering lights | Loose wiring or failing alternator | Inspect wiring for damage and test alternator output |

| Inconsistent gauge readings | Bad ground connections or defective gauges | Verify ground points and test gauges individually |

Utilizing a multimeter and other diagnostic tools can aid in measuring voltage, current, and resistance throughout the electrical network. A step-by-step approach ensures that each component is evaluated, leading to accurate and efficient troubleshooting.

Routine Maintenance Procedures Explained

Regular upkeep of agricultural machinery is essential to ensure optimal performance and longevity. Implementing a structured approach to maintenance helps identify potential issues before they escalate, ultimately enhancing productivity and reducing downtime. This section outlines key procedures to maintain equipment effectively.

Key Maintenance Tasks

- Fluid Checks: Regularly inspect and top off engine oil, coolant, and hydraulic fluid levels.

- Filter Replacements: Change air, fuel, and oil filters as recommended to ensure efficient operation.

- Tire Maintenance: Monitor tire pressure and tread wear; rotate and replace tires when necessary.

- Belt and Chain Inspection: Check for wear and proper tension; replace if frayed or damaged.

Scheduling and Documentation

- Establish a maintenance schedule based on usage and manufacturer recommendations.

- Document all maintenance activities to track history and plan for future tasks.

- Involve trained personnel to perform complex checks and repairs, ensuring safety and compliance.

By adhering to these procedures, operators can maintain their machinery in peak condition, minimizing the risk of unexpected breakdowns and maximizing efficiency in their operations.

Parts Replacement Guide

This section aims to provide a comprehensive approach to the process of substituting components in agricultural machinery. Understanding the nuances of each part is essential for maintaining optimal performance and longevity of the equipment.

When considering part replacement, it’s vital to follow a systematic method to ensure proper functionality. Below are key steps to guide you through the process:

- Identification:

Start by accurately identifying the component that needs replacement. Refer to the specifications or diagrams available for your equipment.

- Compatibility:

Ensure the new part is compatible with the existing machinery. Check manufacturer recommendations for specifications.

- Procurement:

Purchase the part from a reputable supplier. Look for quality guarantees and warranty information to ensure reliability.

- Preparation:

Before installation, gather necessary tools and prepare the workspace. Safety precautions are essential during this stage.

- Installation:

Carefully follow the installation instructions. Ensure that all connections are secure and components are aligned correctly.

- Testing:

After installation, perform tests to verify that the new part is functioning properly. Monitor performance closely in the initial usage period.

Regular maintenance and timely replacement of worn-out components can significantly enhance the efficiency of your machinery. Adhering to this guide will facilitate smoother operations and minimize downtime.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety is paramount. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Understanding the potential hazards associated with machinery work is essential for anyone involved in such activities.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Keep tools organized and in good condition to prevent mishaps during use.

- Disconnect power sources before beginning any disassembly to prevent accidental activation.

- Be aware of your surroundings and remove any unnecessary objects from the work area.

Emergency Preparedness

- Familiarize yourself with the location of first aid kits and fire extinguishers.

- Have a clear plan for emergencies, including contact information for medical services.

- Communicate with others about your tasks and any potential risks involved.

By prioritizing safety and following these guidelines, you can create a secure environment for effective maintenance work. Always stay vigilant and prepared to handle any unforeseen situations that may arise.

Upgrading Farmall 140 Components

Enhancing the performance of vintage agricultural machinery can significantly improve efficiency and productivity. This section explores various strategies to modernize key elements, ensuring longevity and better functionality. Upgrading components not only revitalizes the equipment but also optimizes its capabilities for contemporary agricultural practices.

Engine Enhancements: Upgrading the engine can lead to improved power output and fuel efficiency. Consider installing a high-performance carburetor or a more efficient exhaust system to achieve these goals.

Transmission Upgrades: Modernizing the transmission can facilitate smoother gear shifts and enhance overall drivability. Options include installing a synchronized transmission or improving the existing components for better performance.

Hydraulic System Improvements: Enhancing the hydraulic system can significantly boost lifting capacity and responsiveness. Upgrading hoses, valves, and pumps ensures more reliable operation during heavy tasks.

Electrical System Modifications: Updating the electrical components can enhance reliability and reduce maintenance needs. Consider replacing old wiring with modern, durable materials and installing upgraded lighting for improved visibility.

By focusing on these key areas, operators can breathe new life into their machinery, making it more capable of meeting today’s agricultural demands.