Proper upkeep of gardening tools is essential for optimal performance and longevity. Understanding the fundamentals of equipment functionality can significantly enhance your experience and efficiency while working in your garden or yard. This section delves into various techniques and tips that ensure your devices operate smoothly.

Maintaining your tools not only prevents unexpected breakdowns but also maximizes their potential. Regular inspections and timely interventions are crucial in preserving the functionality of your equipment. Familiarity with the components and their respective roles will empower you to address minor issues effectively.

In this guide, we will explore essential practices that contribute to the effective management of your gardening tools. By following these recommendations, you can ensure that your devices remain in excellent condition, ready to assist you in achieving a beautifully maintained landscape.

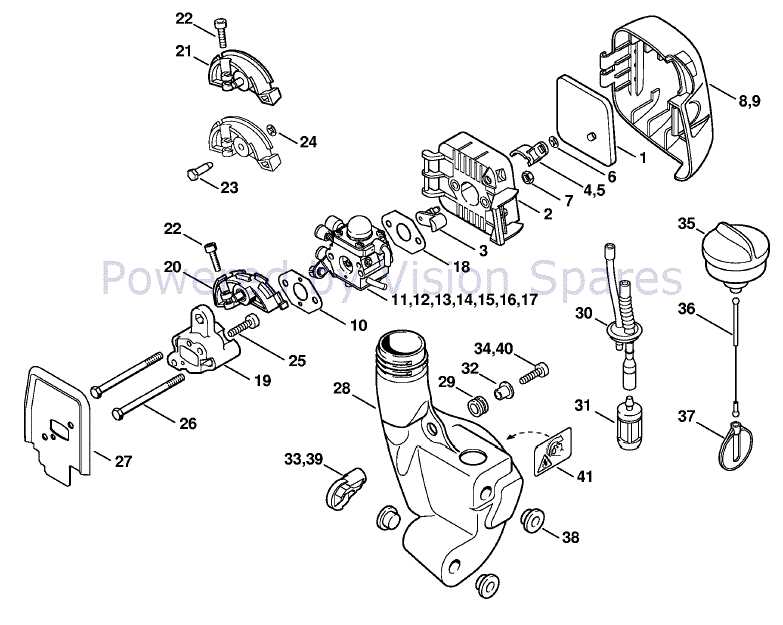

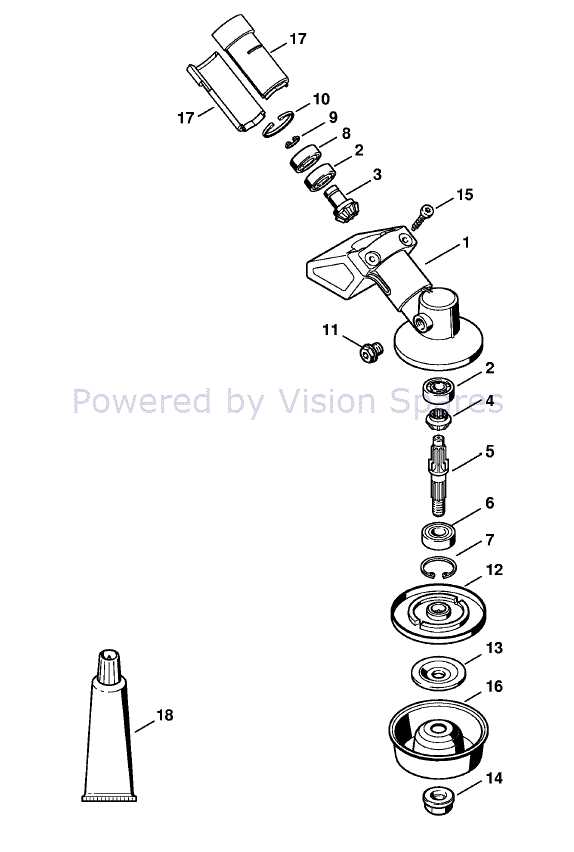

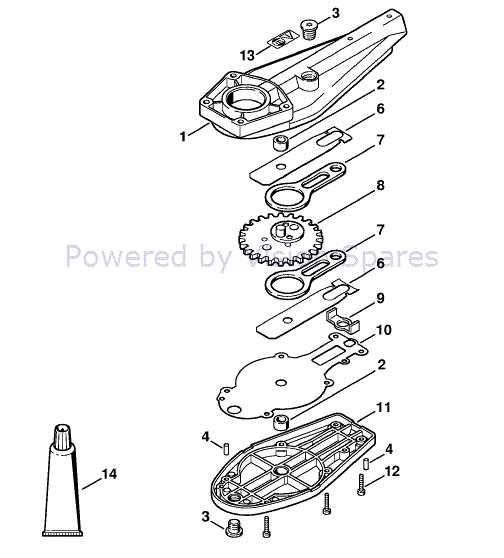

This section aims to provide a comprehensive overview of the essential parts involved in the operation of a particular gardening tool. Understanding these components is crucial for effective usage and maintenance.

- Engine: The power source that drives the entire system.

- Cutter Head: The section responsible for cutting grass or weeds.

- Line Spool: Housed within the cutter head, it holds the cutting line.

- Throttle Control: Allows the user to adjust the speed and power.

- Shaft: Connects the engine to the cutter head, ensuring smooth operation.

Familiarity with these elements not only enhances performance but also aids in troubleshooting and maintenance tasks.

Common Issues and Their Solutions

Many users encounter various challenges when using garden maintenance equipment. Understanding these common problems and their solutions can enhance efficiency and prolong the lifespan of the device.

Engine Won’t Start

If the power unit fails to ignite, it may be due to several factors. Checking the fuel, spark plug, and air filter can often resolve the issue.

Uneven Cutting Performance

Inconsistent cutting can arise from dull blades or incorrect line length. Regular maintenance and proper adjustments can ensure optimal performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Empty fuel, faulty spark plug, clogged air filter | Refill fuel, replace spark plug, clean or replace air filter |

| Uneven Cutting | Dull blades, incorrect line length | Sharpen blades, adjust line length |

| Excessive Vibration | Loose components, imbalanced cutting head | Tighten loose parts, balance the cutting head |

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your outdoor equipment requires consistent upkeep and attention. By implementing simple maintenance practices, you can enhance the performance and lifespan of your tools, reducing the need for extensive repairs.

Regular Cleaning

After each use, it is essential to remove debris and dirt from the device. A clean exterior not only improves efficiency but also prevents buildup that can lead to mechanical issues over time. Use a soft brush or cloth to gently wipe down surfaces and check for any signs of wear.

Check and Replace Components

Frequent inspections of critical parts are crucial. Look for any signs of damage or wear, particularly on cutting elements and power sources. Replacing worn components promptly will help maintain optimal performance. Always refer to manufacturer guidelines for recommended parts and replacement intervals.

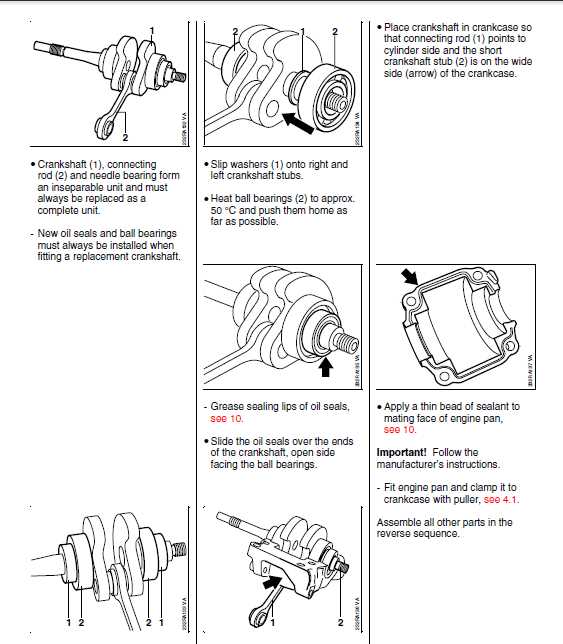

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues with a garden tool commonly used for maintaining yards. Following a structured method can help ensure efficient troubleshooting and restoration of functionality.

Initial Assessment

Begin by examining the device to identify any visible signs of damage or wear. This preliminary evaluation is crucial for determining the next steps in the correction process.

- Inspect the cutting mechanism for any obstructions.

- Check the power source for proper connection and charge.

- Look for signs of corrosion or debris in essential components.

Disassembly and Cleaning

Once the initial assessment is complete, disassemble the unit carefully. Ensure that all parts are organized for easy reassembly.

- Remove the outer casing using appropriate tools.

- Take out the internal components, paying attention to their arrangement.

- Clean each part with a suitable solvent to remove dirt and grime.

Tools Needed for Repairs

When addressing maintenance tasks for your gardening equipment, having the right instruments is essential for effective and efficient work. The following items will assist you in conducting various tasks, ensuring your device operates smoothly.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will help you loosen or tighten screws.

- Wrenches: Adjustable wrenches or a socket set are necessary for working with nuts and bolts.

- Pliers: Needle-nose pliers and regular pliers can be used for gripping and pulling components.

- Replacement Parts: Keeping a stock of essential components, such as lines and filters, is crucial for swift repairs.

- Lubricants: Proper lubrication will enhance the longevity and performance of moving parts.

- Protective Gear: Safety goggles and gloves should always be worn to protect yourself during maintenance tasks.

Gathering these tools will prepare you for a range of maintenance activities, helping you keep your equipment in optimal condition.

Identifying Trimmer Models

Understanding different models is crucial for effective usage and maintenance. Each version may feature distinct characteristics, making it essential to recognize them accurately.

Common Identification Methods

- Model Number: Often found on the body, this number helps pinpoint specifications and compatibility.

- Color Scheme: Certain variants have unique color combinations that aid in identification.

- Design Features: Look for specific design elements that may vary between models, such as handle types and cutting mechanisms.

Utilizing Resources

- Consult the manufacturer’s website for detailed information on each model.

- Refer to user forums or community groups for insights from other users.

- Access instructional videos that demonstrate identifying features.

Replacing Worn Parts Effectively

Maintaining optimal performance of outdoor power equipment often requires the timely replacement of components that have experienced wear and tear. Addressing these issues not only prolongs the lifespan of the device but also ensures it operates efficiently and safely.

Identifying Worn Components

Regular inspections are crucial for recognizing parts that may need replacement. Look for signs such as unusual noises, decreased performance, or physical damage. Components like cutting elements and drive systems are particularly susceptible to wear, so pay close attention to their condition.

Steps for Replacement

Once worn parts are identified, the next step involves careful removal and replacement. Start by consulting a parts guide to obtain the correct specifications. When removing old components, use appropriate tools to avoid causing further damage. After installing the new parts, ensure they are securely fitted and test the equipment to confirm proper operation.

Safety Precautions During Repairs

When undertaking maintenance on equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure that the machinery remains in optimal condition throughout the process.

Essential Safety Measures

Before beginning any service task, it is important to take the following steps to minimize risks:

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the work area is clean and well-lit to avoid hazards.

- Disconnect the power source to prevent accidental activation of the equipment.

Handling Tools Safely

Utilizing tools safely is vital for a successful maintenance process. Consider the following guidelines:

| Tool | Safety Tip |

|---|---|

| Screwdrivers | Always use the correct type and size to avoid slipping. |

| Wrenches | Ensure a secure grip and never use a wrench that is too large. |

| Cutting Tools | Handle with care and keep blades sharp to reduce the risk of injury. |

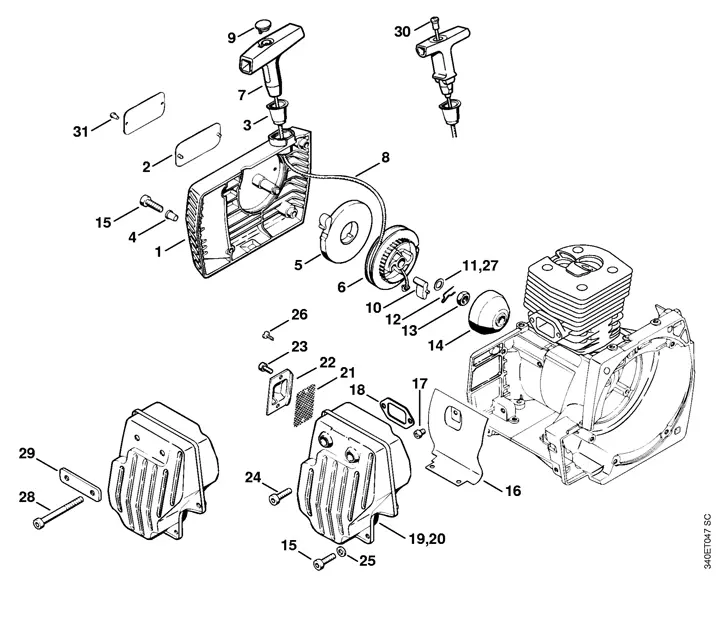

Diagnosing Engine Performance Problems

Identifying issues with engine performance is crucial for maintaining optimal functionality. Various symptoms may indicate underlying problems that need addressing to ensure smooth operation.

Common signs of engine performance issues include:

- Reduced power output

- Unusual noises during operation

- Difficulty starting

- Inconsistent idling

- Excessive vibration

To effectively diagnose these concerns, follow a systematic approach:

- Visual Inspection: Check for any visible damage or loose components that may affect performance.

- Fuel Quality: Ensure that the fuel used is fresh and free from contaminants.

- Air Filter: Examine the air intake filter for dirt and blockages that could hinder airflow.

- Spark Plug: Inspect the spark plug for wear or fouling, as this can impact ignition efficiency.

- Compression Test: Conduct a compression test to evaluate the engine’s internal pressure.

By methodically addressing these areas, you can pinpoint the root causes of performance issues and take appropriate action to restore functionality.

When to Seek Professional Help

Understanding when to consult an expert can be crucial for maintaining optimal performance of your equipment. While many minor issues can be addressed independently, certain complications may require specialized knowledge and tools. Identifying these scenarios early can prevent further damage and ensure a swift resolution.

Signs That Indicate Expert Assistance is Needed

Several indicators can signal the need for professional intervention:

| Indicator | Description |

|---|---|

| Persistent Malfunctions | If problems persist despite attempts at troubleshooting, it may be time to seek help. |

| Unusual Noises | Strange sounds during operation can be a sign of internal issues that require expert evaluation. |

| Performance Decrease | A significant drop in efficiency or functionality often indicates deeper underlying problems. |

| Unfamiliar Symptoms | New or unexplained behaviors that are outside the norm should prompt a professional consultation. |

Benefits of Consulting a Specialist

Engaging a qualified technician not only helps in resolving current issues but also provides peace of mind. Professionals bring experience, advanced tools, and comprehensive knowledge that can prevent future complications and enhance the longevity of your equipment.