Maintaining a well-functioning machine requires understanding its specific upkeep needs. For those relying on dependable performance, regular check-ups and precise adjustments are essential to ensure optimal operation. This section provides insights into effective care practices that help prolong the life of your equipment and maintain its reliability.

In-depth maintenance instructions, covering all key components, offer clear steps for servicing to keep the machinery in top shape. From inspecting critical parts to troubleshooting potential issues, each aspect is designed to aid operators in handling their equipment with confidence. Proper attention to details like oil levels, filters, and other essential parts can make a significant difference in longevity and efficiency.

Furthermore, the guidelines emphasize preventive measures to minimize wear and avoid unexpected downtime. Following these recommendations, you can maximize performance, ensuring your machine continues to meet demanding tasks effectively. This guide covers all vital areas, from basic adjustments to more comprehensive servicing, providing valuable support for any equipment owner.

Equipment Maintenance Instructions Guide

Ensuring consistent performance and longevity of your machinery requires following precise upkeep guidelines. This guide provides a structured approach to managing necessary checks and fixes, helping operators maintain efficiency and prevent common malfunctions.

Regular maintenance includes inspecting key components, cleaning vital systems, and replacing parts as needed. By following these steps, you’ll optimize machine reliability, addressing issues before they escalate. Each section covers essential tasks, from fluid level monitoring to parts lubrication, all aimed at keeping your equipment in top working order.

With a focus on straightforward instructions, this guide is ideal for anyone responsible for routine upkeep or handling unexpected issues. Performing these steps consistently can extend machinery lifespan and enhance overall productivity, ensuring you’re prepared for any operational challenges.

Engine Troubleshooting and Solutions

Understanding and addressing common engine issues can significantly improve the performance and longevity of your machinery. By identifying early signs of malfunctions, you can prevent major breakdowns and ensure efficient operation.

One of the primary areas to examine is the fuel system. Problems in fuel flow or contamination can lead to rough idling, stalling, or poor starting performance. Regular inspection of fuel filters and lines is essential to avoid these issues. Checking for any clogs or leaks and ensuring that clean fuel is consistently used can help keep the system in optimal condition.

Another critical focus should be on the air intake system. Blockages in air filters or intake passages can restrict airflow, causing reduced power output and overheating. Cleaning or replacing air filters regularly, especially in dusty environments, helps maintain proper air supply to the engine.

The cooling system also plays a vital role in engine performance. Overheating can result from low coolant levels, leaks, or a malfunctioning radiator. Periodic coolant level checks and inspections for possible leaks are recommended to keep the system functioning correctly. Ensuring that the radiator and hoses are free

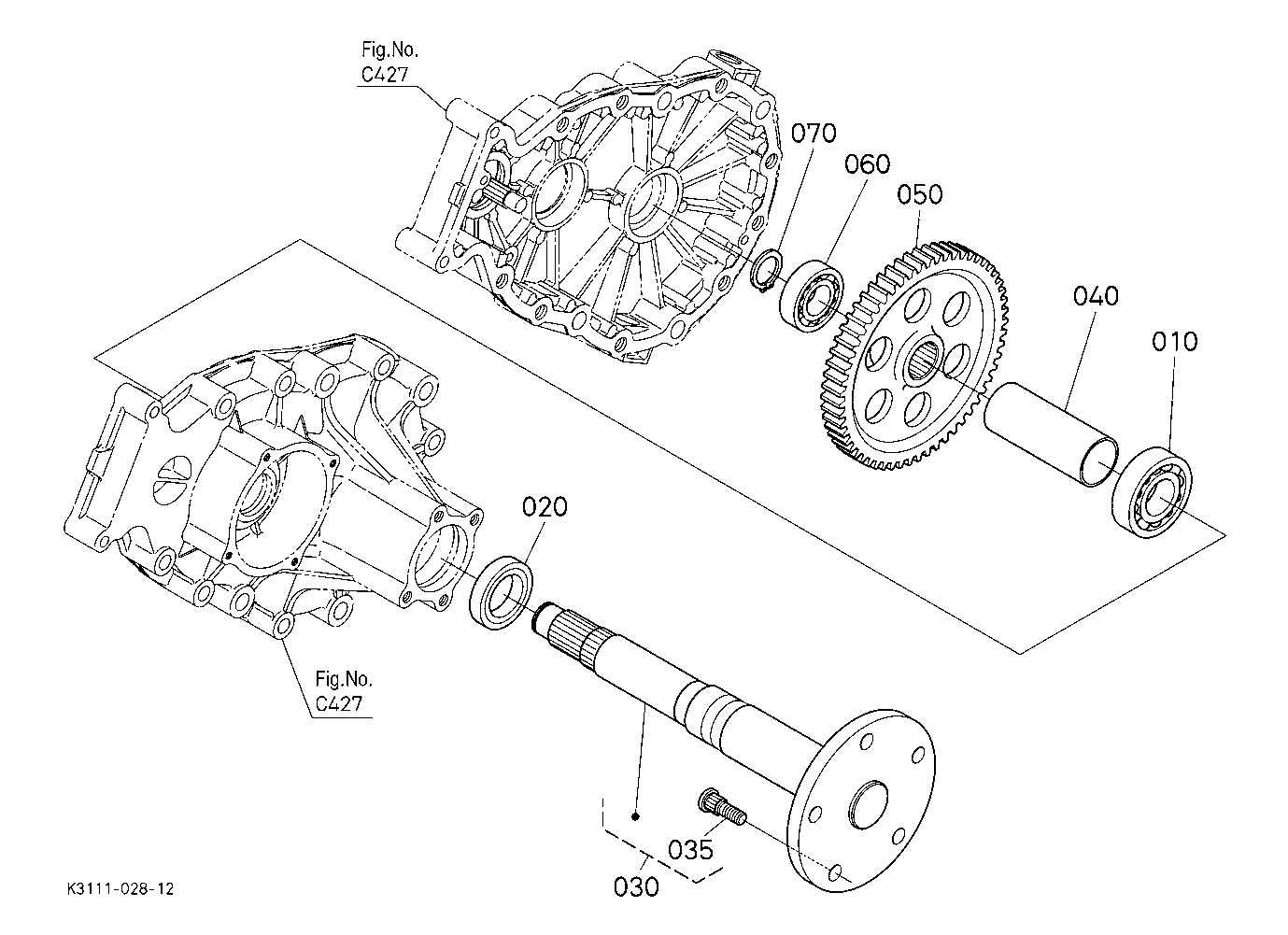

Transmission System Maintenance Tips

Effective transmission maintenance ensures long-lasting performance and reduces the likelihood of system malfunctions. Regular attention to the transmission components aids in preserving optimal power flow and extending the equipment’s operational life.

Check Fluid Levels Regularly

One of the most crucial aspects of transmission upkeep is monitoring fluid levels consistently. Insufficient lubrication can lead to overheating and increased wear on internal components, potentially resulting in severe damage. Inspect the fluid levels frequently and refill or replace them according to the manufacturer’s recommendations to maintain smooth operation.

Inspect and Replace Filters

Filters play an essential role in keeping contaminants out of the transmission system. Over time, these filters may become clogged, reducing efficiency and causing undue stress on the transmission parts. Periodically checking and replacing filters as needed helps to prevent buildup and maintain fluid cleanliness, enhancing the system’s reliability and longevity.

By adhering to these maintenance practices, you can ensure the transmission remains in peak condition, minimizing downtime and costly repairs. A proactive approach to system care

Hydraulic System Diagnostic Procedures

Efficiently diagnosing issues within the hydraulic system requires a systematic approach to identify and resolve potential faults. This section will outline key steps to evaluate hydraulic functions, focusing on recognizing symptoms, testing pressure, and inspecting the overall system for irregularities.

Visual Inspection and Leak Detection

Start by conducting a thorough visual examination of the hydraulic system. Look for signs of leakage around hoses, fittings, and seals, as these are common areas where wear occurs. Observe fluid levels and ensure they align with optimal operating ranges. Low fluid levels or visible leaks can indicate a need for immediate attention and maintenance.

Pressure Testing and Flow Evaluation

After the initial inspection, perform a pressure test to confirm the system is operating within the recommended parameters. Attach a pressure gauge to the main hydraulic line and gradually increase pressure while monitoring for inconsistencies. Low or fluctuating pressure levels could suggest blockages or pump inefficiencies. Additionally, assess flow rates in critical points to ensure adequate fluid movement through the system, as restricted flow can lead to po

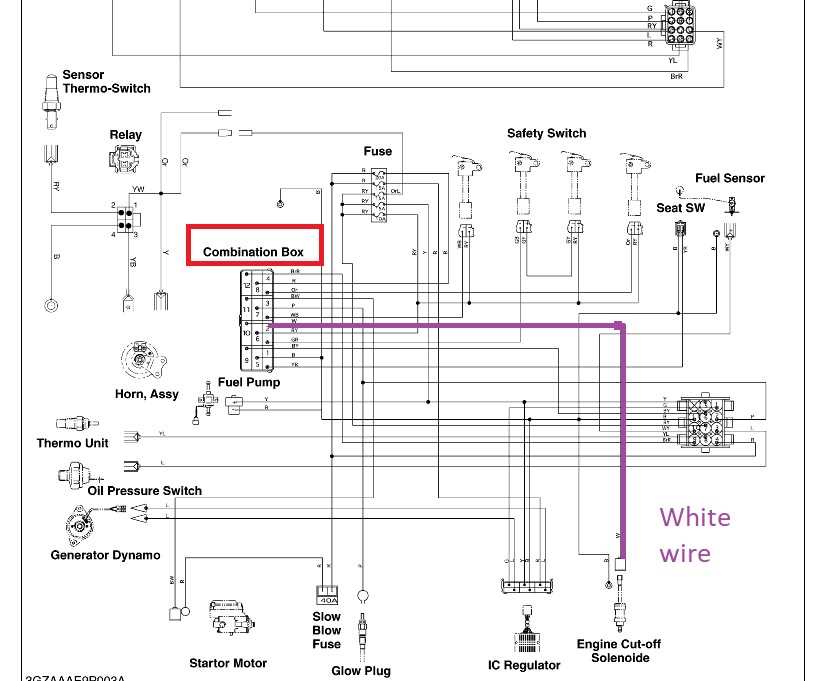

Electrical System Repair Instructions

This section provides essential guidance on maintaining and troubleshooting the electrical framework, ensuring smooth operation and safety during usage. By following the outlined steps, you can effectively address typical issues and enhance the system’s reliability.

Key Components and Connections

Understanding the layout of the electrical system is vital for identifying potential problems. The primary parts include:

- Battery: Provides power to the system. Regularly check for corrosion or loose terminals.

- Wiring Harness: Ensures electrical signals reach the correct destinations. Inspect for any visible damage or disconnections.

- Starter: Activates the engine. Look for signs of wear or loose connections.

Basic Troubleshooting Steps

If you encounter issues with the system, follow these troubleshooting methods to pinpoint the source:

- Begin with the battery. Confirm it’s charged and properly connected. If necessary, clean terminals to enhance contact.

-

Cooling System Issues and Fixes

The efficiency of any machinery heavily relies on its cooling system, which prevents overheating and ensures optimal performance. Problems within this system can lead to serious malfunctions, decreased efficiency, and potentially costly repairs. Understanding common cooling system complications and their solutions can help maintain the longevity of your equipment.

Common Problems in the Cooling System

One prevalent issue is clogged coolant passages, which can hinder fluid flow and result in overheating. Additionally, leaks in hoses or connections can cause a drop in coolant levels, leading to insufficient cooling. Lastly, faulty thermostats may fail to regulate temperature properly, resulting in erratic engine behavior.

Solutions and Preventive Measures

To address these issues, regularly inspect coolant levels and hoses for any signs of wear or damage. Flushing the cooling system periodically can help eliminate debris and prevent blockages. Furthermore, replacing faulty thermostats promptly ensures that the engine maintains the correct operating temperature. Implementing these practices will enhance the reliability of the cooling system and extend the life of your machinery.

Fuel System Cleaning and Care

Maintaining the cleanliness and functionality of the fuel system is essential for optimal performance and longevity of the equipment. Regular upkeep prevents the accumulation of debris and contaminants, ensuring that the fuel supply remains unimpeded and the engine operates efficiently. Proper care not only enhances the performance but also minimizes the risk of mechanical failures.

Regular Inspection and Cleaning

Conducting frequent inspections of the fuel components is crucial. Pay close attention to filters and lines, as these parts are prone to clogging. Cleaning or replacing filters as needed will help maintain a clear flow of fuel. Additionally, using a specialized cleaning solution can assist in removing any built-up residues, ensuring that all elements are functioning correctly.

Best Practices for Fuel Quality

Utilizing high-quality fuel significantly contributes to the overall health of the system. It is advisable to avoid fuels with high levels of impurities and water, as these can lead to corrosion and other issues. Incorporating additives designed for fuel stabilization can also enhance performance and prevent deterioration over time.

Blade and Deck Adjustment Techniques

Proper maintenance of cutting implements and support structures is essential for optimal performance and longevity of lawn care equipment. Adjusting these components ensures a clean cut and enhances the overall efficiency of the machinery.

To achieve the best results, consider the following adjustment techniques:

- Leveling the Deck: Ensuring the cutting deck is level can prevent uneven cutting. Check the height on both sides and make necessary adjustments to achieve uniformity.

- Blade Height Adjustment: Set the cutting height according to the type of grass and desired lawn length. This can be done by modifying the deck height or adjusting the blade settings.

- Sharpening Blades: Regularly sharpening blades maintains cutting efficiency. Dull blades can tear grass rather than cutting it, leading to unhealthy turf.

- Inspecting Blade Alignment: Ensure blades are correctly aligned and securely fastened. Misalignment can cause uneven cutting and unnecessary wear on the equipment.

Implementing these techniques will enhance performance, ensuring a well-maintained lawn and efficient operation of the equipment.

Steering System Inspection and Repair

The steering mechanism is a crucial component of any vehicle, ensuring precise control and responsiveness. Regular assessment and maintenance of this system are vital for optimal performance and safety. In this section, we will explore the essential steps for inspecting and fixing steering elements effectively.

Inspection Steps

- Begin by examining the steering wheel for excessive play or unusual resistance.

- Inspect the steering column for any signs of wear or damage, paying close attention to the joints and connections.

- Check the condition of the steering gear, ensuring it is free from leaks and operating smoothly.

- Evaluate the power steering fluid level and quality, replacing it if necessary.

- Look for any loose or damaged components, including tie rods and control arms.

Repair Procedures

- If any play is detected in the steering wheel, adjust the steering gear as per the specifications.

- Replace any worn or damaged parts, ensuring all components meet manufacturer standards.

- Flush and refill the power steering system with the recommended fluid.

- Tighten any loose bolts or connections to ensure stability and prevent further issues.

- After repairs, conduct a test drive to verify that the steering operates smoothly and without noise.

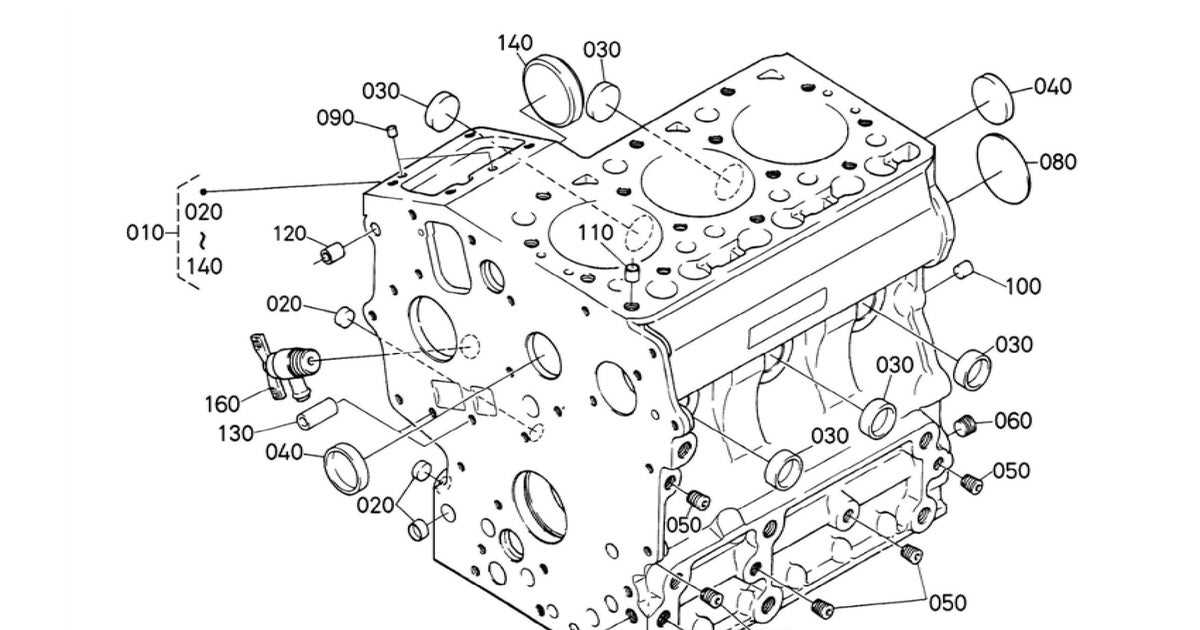

Replacing Worn Parts Efficiently

Maintaining optimal functionality of machinery involves the timely replacement of worn components. This process ensures that equipment operates smoothly, reducing the likelihood of breakdowns and extending its lifespan. Understanding how to efficiently replace these parts is crucial for effective maintenance and performance.

Identifying Signs of Wear

Regular inspection is essential for identifying components that require replacement. Look for signs of deterioration such as unusual noises, decreased performance, or visible damage. Early detection allows for proactive action, minimizing potential operational disruptions.

Steps for Effective Replacement

Once worn parts are identified, follow a systematic approach for replacement. First, gather all necessary tools and new components. Then, carefully remove the old part, ensuring no further damage occurs. Install the new component according to the manufacturer’s specifications to guarantee proper functionality. Finally, conduct a thorough test to confirm that the replacement has restored performance.

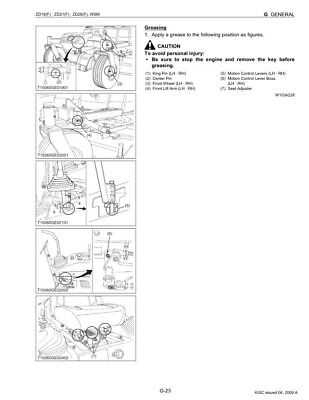

Regular Maintenance for Optimal Performance

To ensure the longevity and efficiency of your equipment, it is crucial to adhere to a routine upkeep schedule. Regular attention not only enhances performance but also prevents unexpected breakdowns, thereby saving time and costs associated with repairs.

Key Aspects of Routine Upkeep

- Fluid Checks: Regularly inspect and replace engine oil, coolant, and hydraulic fluid to maintain optimal functioning.

- Filter Replacements: Change air, oil, and fuel filters to ensure clean intake and prevent contaminants from affecting performance.

- Inspection of Belts and Hoses: Routinely check for wear and tear, replacing any damaged components to avoid potential failures.

- Tire Maintenance: Monitor tire pressure and tread depth to ensure safe and efficient operation.

Importance of Seasonal Maintenance

Seasonal checks are vital in adapting the machinery to varying environmental conditions. Preparing equipment for harsh winters or hot summers can significantly enhance performance and reduce wear.

- Winter Preparation: Ensure that the antifreeze levels are adequate and that batteries are fully charged.

- Summer Maintenance: Check cooling systems and clean radiators to prevent overheating.

Safety Guidelines During Repairs

Ensuring a safe working environment is paramount when conducting maintenance on machinery. Adhering to specific safety protocols minimizes the risk of accidents and injuries, providing a secure atmosphere for technicians and operators alike. Awareness of potential hazards and proper usage of protective equipment are essential components in achieving these goals.

Essential Safety Equipment

Utilizing appropriate personal protective gear is critical for safeguarding oneself against various risks. Essential equipment includes helmets, gloves, goggles, and steel-toed boots. Each item serves a unique purpose in protecting against specific dangers encountered during maintenance tasks.

Protective Gear Purpose Helmet Protects the head from falling objects Gloves Prevents cuts and abrasions Goggles Protects eyes from debris and chemicals Steel-Toed Boots Offers foot protection against heavy items Proper Handling Techniques

Implementing correct procedures for managing tools and equipment reduces the likelihood of mishaps. Techniques such as securing loose components and utilizing proper lifting methods are vital for maintaining safety. Additionally, being aware of the surroundings and ensuring a clutter-free workspace contribute to a safer environment.

Common Problems and Preventative Measures

Every machinery enthusiast knows that regular maintenance is key to prolonging the lifespan and efficiency of their equipment. This section will explore frequent issues encountered with garden tractors and outline effective strategies to mitigate them. By understanding these common challenges and implementing preventative steps, operators can ensure optimal performance and reduce the risk of unexpected failures.

Issue Description Preventative Measure Engine Overheating Excessive heat can lead to severe engine damage. Regularly check coolant levels and ensure proper airflow. Battery Drain A drained battery can leave the unit inoperable. Inspect battery terminals for corrosion and ensure connections are secure. Blade Dullness Blades that are not sharp can cause uneven cuts. Sharpen blades regularly and inspect for damage. Fuel System Clogs Blocked fuel lines can impede engine performance. Use clean fuel and replace filters at recommended intervals. Transmission Issues Poor shifting or slipping can indicate transmission problems. Check fluid levels and look for leaks or unusual noises.