Maintaining outdoor machinery is essential for ensuring their longevity and optimal performance. This section focuses on providing valuable insights and practical knowledge for owners of various types of lawn care devices. By understanding the intricacies of these tools, users can enhance their efficiency and minimize downtime.

From routine checks to troubleshooting common issues, this resource aims to empower individuals with the skills needed to address potential challenges. Knowledge of components and functions can significantly improve the overall experience, allowing for seamless operation and effective maintenance. Whether you are a novice or have some experience, this guide serves as a comprehensive tool for enhancing your understanding.

Equipping yourself with the right information not only saves time and resources but also fosters confidence in managing your equipment. Embracing a proactive approach to maintenance can lead to better performance and reduced repair costs in the long run. With this in mind, let’s explore the essential techniques and insights that will aid in the upkeep of your machinery.

Common Issues with Riding Mowers

Operating a garden vehicle can sometimes lead to unexpected challenges that may hinder performance and efficiency. Recognizing these common problems is essential for maintaining optimal function and ensuring a seamless experience. Below are several prevalent complications faced by users, along with their potential causes and remedies.

- Starting Difficulties:

This is often the most frustrating issue. Problems may arise from:

- Weak battery

- Faulty ignition switch

- Clogged fuel line

- Uneven Cutting:

Uneven grass trimming can indicate a need for adjustments. Causes may include:

- Dull blades

- Incorrect tire pressure

- Uneven deck height

- Stalling:

A vehicle may stall during operation due to:

- Fuel shortage

- Overheating engine

- Clogged air filter

- Transmission Issues:

Problems with the drive mechanism can lead to poor mobility, often resulting from:

- Low fluid levels

- Worn belts

- Obstructed pulleys

- Vibrations and Noises:

Excessive shaking or unusual sounds can indicate mechanical failure, potentially due to:

- Loose components

- Worn-out bearings

- Unbalanced blades

lessCopy code

Addressing these common issues promptly can enhance the longevity and effectiveness of your garden vehicle, ensuring a more pleasant experience during use.

Essential Tools for Maintenance

Maintaining outdoor equipment requires a set of fundamental instruments that ensure optimal performance and longevity. Having the right tools on hand not only simplifies the upkeep process but also enhances the efficiency of each task. This section highlights crucial implements that every enthusiast should consider for their maintenance activities.

Basic Hand Tools

Among the most important instruments are basic hand tools such as wrenches, screwdrivers, and pliers. These versatile implements are essential for various tasks, including tightening loose components and making minor adjustments. Quality hand tools can significantly reduce the time spent on maintenance while ensuring that every part is securely fastened.

Power Equipment

In addition to hand tools, certain power equipment is invaluable for more extensive maintenance tasks. Electric or gas-powered tools can expedite processes like cleaning and sharpening blades, enabling more effective performance. Investing in reliable power equipment allows for a smoother maintenance routine and can lead to better overall functionality.

Step-by-Step Repair Procedures

This section provides a comprehensive approach to troubleshooting and fixing common issues encountered during maintenance tasks. Following a systematic process not only ensures effective solutions but also helps in identifying potential problems early on.

- Diagnosis:

Begin by observing the symptoms. Take note of any unusual sounds, vibrations, or performance issues. This initial assessment is crucial for determining the root cause.

- Gather Tools and Materials:

Collect all necessary tools and replacement parts required for the task. Having everything on hand minimizes interruptions during the process.

- Safety Precautions:

Before commencing any work, ensure safety measures are in place. Disconnect the power source and wear appropriate protective gear.

- Follow the Procedures:

Adhere to the specific steps outlined for the particular issue being addressed. Common areas to focus on include:

- Engine maintenance

- Transmission checks

- Blade adjustments

- Fuel system inspection

- Testing:

After completing the repairs, conduct a thorough test. Monitor the performance and listen for any irregularities. This final step confirms that the work was successful.

- Documentation:

Keep a record of the repairs made, including any parts replaced and observations during the process. This documentation can be invaluable for future maintenance.

Diagnosing Engine Problems

Identifying issues with the power unit is crucial for maintaining optimal performance. This process involves a systematic approach to pinpoint the source of malfunctions, which can range from minor inefficiencies to significant failures. Understanding common symptoms and the underlying causes can greatly enhance the troubleshooting process.

Begin by observing the unit during operation. Look for irregular sounds, vibrations, or any abnormal behavior. Strange noises may indicate mechanical wear, while excessive vibrations could suggest misalignment or loose components. If the unit fails to start, check for issues such as a dead battery or faulty ignition system.

Next, examine the fuel system. Ensure that there is an adequate supply of clean fuel and that the filters are not clogged. Fuel starvation can lead to poor performance or failure to run. Additionally, inspect the air intake for blockages that could hinder airflow, affecting combustion efficiency.

Lastly, pay attention to the cooling system. Overheating can cause significant damage, so it’s essential to check the coolant levels and ensure that the radiator is free from debris. Routine maintenance of these components can prevent major issues and extend the lifespan of the equipment.

Electrical System Troubleshooting

Troubleshooting electrical systems requires a systematic approach to identify and resolve issues effectively. Understanding the components and their functions is crucial for diagnosing problems. This section will guide you through common electrical faults and provide steps to rectify them.

Identifying Common Issues

Electrical failures often manifest in various ways, such as non-starting engines, dim lights, or malfunctioning accessories. Begin by checking the battery connections for corrosion and ensuring a secure fit. A multimeter can be invaluable for measuring voltage levels and continuity throughout the system.

Testing Components

After identifying symptoms, focus on testing individual components. Start with the ignition system, ensuring the spark plug is clean and in good condition. Examine the fuses for any signs of damage, as a blown fuse can interrupt power flow. If necessary, consult the specifications to verify component functionality.

Regular maintenance and proactive checks can prevent many electrical issues from arising, ensuring smooth operation and longevity of the equipment.

Blade Sharpening Techniques

Maintaining the cutting edge of your lawn tool is essential for optimal performance. Proper sharpening techniques ensure that blades cut efficiently, leading to healthier grass and a more attractive lawn. This section outlines various methods and tips for achieving a sharp edge.

Here are some effective techniques for sharpening blades:

- Whetstone Method: Using a whetstone is a traditional approach. It involves rubbing the blade against the stone at a consistent angle to achieve a sharp edge.

- File Method: A flat file can be used to sharpen blades. This method allows for precision, especially in reaching tight spots.

- Power Sharpener: For those seeking efficiency, power sharpeners can quickly restore the blade’s edge. This tool is particularly useful for heavy-duty blades.

- Angle Grinder: An angle grinder provides rapid sharpening but requires careful handling to avoid overheating the blade, which can damage the temper.

Regardless of the method chosen, adhering to the following guidelines can enhance the sharpening process:

- Maintain the Correct Angle: Consistency in angle during sharpening is crucial for achieving an effective edge.

- Clean the Blade: Before starting, ensure the blade is free of debris and rust, as this can hinder the sharpening process.

- Test Sharpness: After sharpening, a simple test on a piece of paper or soft wood can indicate the effectiveness of the process.

- Safety First: Always wear appropriate safety gear, such as gloves and eye protection, to prevent injuries while sharpening.

Regular maintenance and sharpening of blades will significantly improve the performance and longevity of your cutting tool, ensuring a well-kept outdoor space.

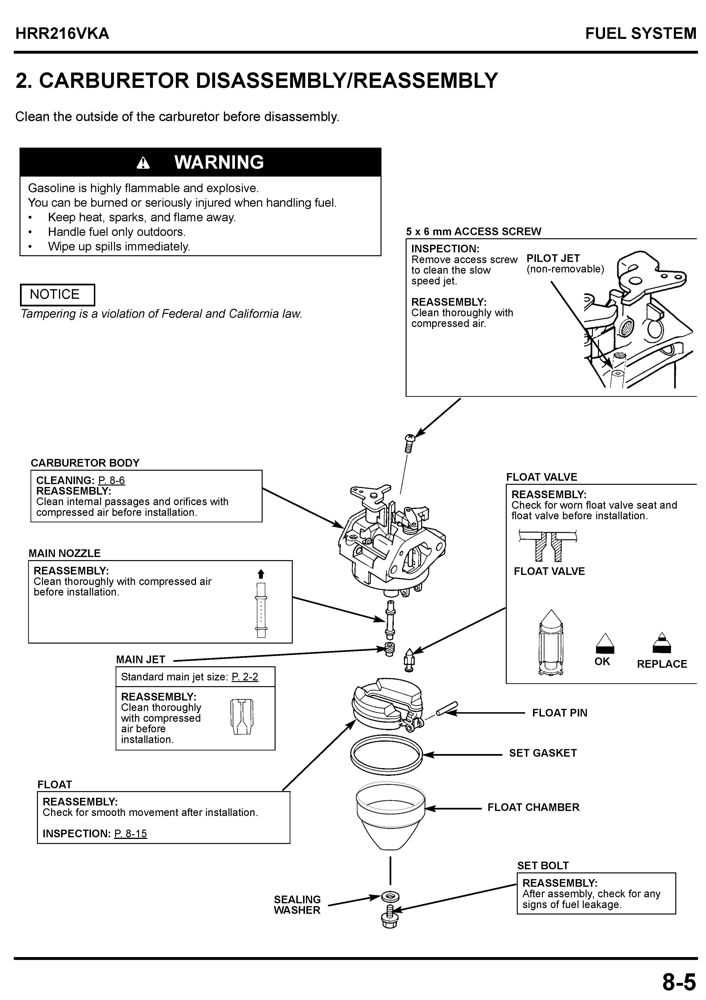

Maintaining Fuel System Efficiency

Ensuring optimal performance of the fuel delivery system is crucial for the longevity and functionality of small engines. Regular maintenance practices can significantly enhance fuel efficiency, reduce emissions, and improve overall engine responsiveness. Proper attention to this system not only prevents costly repairs but also promotes a smoother operation.

Regular Inspection: Periodic checks of the entire fuel system, including filters and lines, are essential. Clogged filters can restrict fuel flow, leading to performance issues. Replacing or cleaning these components at recommended intervals helps maintain a steady fuel supply.

Quality Fuel: Using high-quality fuel can make a substantial difference in engine efficiency. Fuel that contains additives can help keep the system clean and minimize deposits that may lead to blockages. Always opt for fuel that meets the manufacturer’s specifications.

Fuel Stabilizers: When storing equipment for an extended period, incorporating fuel stabilizers can prevent degradation. Stabilizers help maintain fuel quality, reducing the likelihood of engine start-up problems and ensuring smooth operation when the machine is brought back into service.

Drain Old Fuel: If equipment is not going to be used for a while, draining the fuel tank is advisable. Stale fuel can lead to various complications, including difficulty starting and poor engine performance. Replacing it with fresh fuel will enhance efficiency and reliability.

By implementing these practices, users can significantly improve the efficiency of the fuel system, ensuring reliable performance and extending the lifespan of their machinery.

Understanding Tire Care and Replacement

Tires play a crucial role in the performance and safety of outdoor equipment, influencing not only maneuverability but also overall efficiency. Proper maintenance ensures longevity and optimal functionality, while timely replacement is essential for preventing accidents and equipment damage. This section delves into best practices for tire upkeep and guidelines for when to consider a change.

Maintenance Tips for Longevity

Regular attention to tire condition can significantly extend their lifespan. Here are essential maintenance practices:

| Maintenance Practice | Description |

|---|---|

| Pressure Check | Regularly verify that the air pressure aligns with the manufacturer’s recommendations, as improper inflation can lead to uneven wear and poor handling. |

| Visual Inspection | Frequent examinations for cracks, bulges, or foreign objects will help identify issues early, allowing for timely intervention. |

| Cleaning | Keep tires clean from mud and debris to prevent deterioration of the rubber and maintain traction. |

When to Replace Tires

Recognizing the signs that indicate a need for new tires is vital for safety and efficiency. Key indicators include:

| Indicator | Action |

|---|---|

| Worn Tread | If tread depth is below 2/32 inches, replacement is necessary to ensure traction and control. |

| Cracking | Visible cracks or signs of dry rot suggest that the rubber has degraded, warranting a replacement. |

| Vibration | Excessive vibration during operation can indicate structural damage, necessitating immediate inspection and possible replacement. |

Cleaning and Caring for Filters

Maintaining optimal performance of your outdoor equipment heavily relies on the cleanliness of its filtration components. Regular attention to these elements ensures efficient operation and prolongs the lifespan of the machinery. Proper maintenance techniques can prevent potential issues and enhance overall functionality.

Inspection is the first step in caring for filters. Regularly check for any visible dirt or debris accumulation. If filters appear clogged or discolored, it may be time for a thorough cleaning or replacement. Always refer to the manufacturer’s guidelines for specific recommendations.

For cleaning purposes, start by removing the filters carefully, ensuring that no dirt enters the engine compartment. Use a soft brush or compressed air to eliminate loose particles. For more stubborn grime, a gentle wash with soapy water can be effective. Rinse thoroughly and allow them to dry completely before reinstalling.

In addition to cleaning, preventative care is essential. Establishing a regular maintenance schedule can help maintain filter cleanliness. Consider factors such as the environment in which the equipment operates, as dustier areas may necessitate more frequent cleaning. Always store filters in a clean, dry place when not in use to prevent contamination.

By prioritizing the maintenance of these crucial components, you can ensure that your machinery operates smoothly and efficiently, allowing for a more enjoyable and productive experience.

Best Practices for Seasonal Storage

Ensuring proper maintenance during seasonal storage is crucial for extending the lifespan of your equipment. This involves a series of steps that help protect against wear and damage when the machine is not in use. By following these best practices, you can ensure that your unit remains in optimal condition, ready for operation when needed.

Preparation Steps

Before placing your equipment in storage, it is essential to perform a thorough cleaning. Remove any debris, dirt, or grass clippings that may have accumulated. This prevents corrosion and blockages. Additionally, check for any loose or damaged components and address them promptly. If necessary, change the oil and replace filters to ensure the system runs smoothly when it is time to use it again.

Storage Environment

Choosing the right storage environment is vital for protecting your equipment. Ideally, store it in a dry, temperature-controlled area to prevent rust and other moisture-related issues. Covering the unit with a breathable tarp can also shield it from dust and contaminants while allowing moisture to escape. Regularly check on the stored equipment throughout the off-season to ensure it remains in good condition.

Safety Tips During Repairs

When undertaking maintenance tasks on outdoor equipment, ensuring personal safety should always be the top priority. Proper precautions can prevent accidents and injuries, allowing for a smoother and more efficient process. Following a few fundamental guidelines will create a safer environment, whether you are a seasoned technician or a novice enthusiast.

Essential Safety Precautions

Before starting any work, it is crucial to assess the work area and gather the necessary protective gear. Here are some basic precautions to keep in mind:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Wear safety glasses, gloves, and sturdy footwear to protect against potential hazards. |

| Work Environment | Ensure the workspace is clean and well-lit to reduce the risk of tripping or mishandling tools. |

| Disconnect Power | Always unplug equipment or remove the battery before starting maintenance to avoid accidental starts. |

| Tool Inspection | Check tools for damage or wear before use to prevent malfunctions during operation. |

Handling Hazardous Materials

Be mindful of any chemicals or fluids that may be involved in the maintenance process. Proper handling and disposal are essential to prevent environmental contamination and personal harm.