Understanding the intricacies of engine upkeep is essential for anyone seeking optimal performance and longevity from their machinery. This section delves into the fundamental aspects of maintaining a specific type of engine known for its robust design and versatility. With a focus on effective techniques and best practices, this guide aims to empower users with the knowledge necessary to enhance their engines’ functionality.

The need for comprehensive support documents becomes evident when faced with common issues and challenges. By exploring detailed instructions and insights, individuals can gain confidence in diagnosing problems and implementing solutions. This approach not only facilitates smoother operation but also fosters a deeper appreciation for the mechanics at work.

Through this exploration, enthusiasts will discover valuable tips, tricks, and procedures that can significantly impact the efficiency of their equipment. Whether it’s regular maintenance or troubleshooting specific malfunctions, having access to a well-structured resource can make all the difference in achieving peak performance.

Engines, especially those with dual-cylinder configurations, often face a range of challenges that can impact their performance and reliability. Understanding these common problems and their remedies can help maintain optimal functioning and longevity.

Frequent Problems

- Starting Difficulties: Many users encounter issues when attempting to start the engine.

- Overheating: Excessive heat can lead to significant wear and potential damage.

- Inefficient Fuel Consumption: Some engines may exhibit poor fuel efficiency, indicating underlying issues.

- Vibration or Noise: Unusual sounds or vibrations can signify mechanical concerns.

Effective Solutions

- Starting Troubles: Check the battery, fuel supply, and ignition system for any faults.

- Managing Heat: Ensure proper cooling system function and check for obstructions in airflow.

- Improving Efficiency: Regularly inspect and clean fuel filters and injectors.

- Addressing Noise: Examine mounts and components for wear, replacing any that are damaged.

Maintenance Tips for Longevity

To ensure the enduring performance of your engine, regular upkeep is essential. By following a structured maintenance routine, you can significantly enhance the lifespan of your equipment. This involves checking key components, performing timely replacements, and adhering to manufacturer recommendations.

Routine Checks

Regular inspections are vital for identifying potential issues before they escalate. Focus on fluid levels, filter conditions, and overall cleanliness. Keeping these elements in optimal condition helps prevent costly repairs and extends operational efficiency.

Proper Storage and Care

When not in use, ensure your engine is stored in a clean, dry environment. Protect it from extreme temperatures and moisture to avoid rust and corrosion. Additionally, consider using protective covers to shield against dust and debris, which can affect performance over time.

Tools Needed for Repairs

Proper equipment is essential for conducting maintenance tasks effectively. Whether you’re addressing minor adjustments or more significant issues, having the right tools on hand can make all the difference in achieving optimal results.

Essential Equipment

- Wrenches: A variety of sizes will allow for versatile use.

- Screwdrivers: Both flathead and Phillips types are necessary.

- Socket Set: A comprehensive socket collection can facilitate easier access to hard-to-reach areas.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Oil Filter Wrench: Specially designed to remove and install oil filters efficiently.

Additional Tools

- Diagnostic Scanner: Helps identify issues through error codes.

- Pliers: Useful for gripping and twisting tasks.

- Flashlight: Provides visibility in dimly lit spaces.

- Jack and Stands: Essential for elevating the unit safely for underneath access.

- Cleaning Supplies: Keeps components free of dirt and debris for optimal performance.

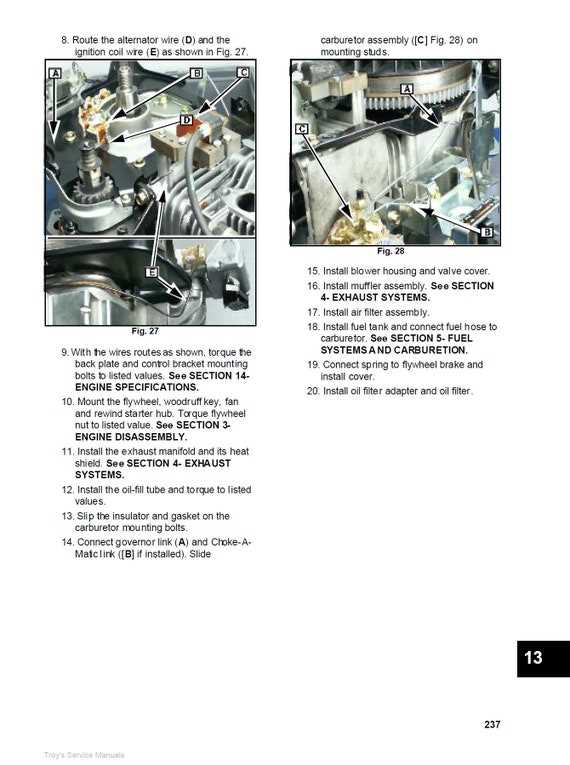

Step-by-Step Repair Procedures

This section provides a comprehensive approach to addressing common issues that may arise during maintenance. Following systematic steps can enhance efficiency and ensure thorough understanding of the components involved.

Before beginning any task, ensure you have the necessary tools and safety equipment at hand. Familiarizing yourself with the specific procedures is crucial for achieving optimal results.

| Step | Description |

|---|---|

| 1 | Gather all required tools and protective gear. |

| 2 | Identify the component that needs attention. |

| 3 | Carefully disassemble surrounding parts to access the area of focus. |

| 4 | Inspect the component for wear or damage. |

| 5 | Replace or repair as necessary, ensuring all specifications are met. |

| 6 | Reassemble all components, ensuring proper alignment. |

| 7 | Conduct a thorough test to confirm functionality. |

By adhering to these organized steps, the process becomes manageable, allowing for a better understanding of each part’s role and function.

Understanding Engine Specifications

Grasping the fundamental attributes of an engine is crucial for effective maintenance and performance optimization. These specifications not only define the power unit’s capabilities but also guide users in making informed decisions regarding modifications and troubleshooting.

Key aspects to consider include:

- Displacement: The total volume of the engine’s cylinders, affecting power output and efficiency.

- Compression Ratio: The ratio of the maximum to minimum cylinder volume, influencing performance and fuel consumption.

- Power Rating: The engine’s output measured in horsepower or kilowatts, indicating its performance potential.

- Torque: The rotational force generated, essential for understanding acceleration and load handling.

Understanding these characteristics enables operators to assess engine performance and determine the necessary care for longevity and reliability.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance on machinery is essential for both personal safety and the longevity of the equipment. Awareness of potential hazards and adherence to established guidelines can significantly reduce the risk of accidents. Proper preparation and vigilance are key components in maintaining a safe workspace.

Personal Protective Equipment

Utilizing appropriate personal protective gear is crucial when engaging in maintenance tasks. Always wear safety glasses to shield your eyes from debris, and use gloves to protect your hands from sharp objects and chemicals. Additionally, consider donning ear protection to minimize exposure to harmful noise levels during operation.

Workspace Organization

Keeping the work area tidy and free of obstacles can prevent accidents. Ensure that tools are stored properly and that any spills are promptly cleaned. Maintaining clear pathways not only enhances safety but also improves efficiency, allowing for a smoother workflow during servicing activities.

Where to Find Replacement Parts

When it comes to maintaining your machinery, sourcing the right components is crucial for optimal performance. Whether you are looking to replace worn-out elements or upgrade specific features, knowing where to find quality parts can save time and ensure reliability.

- Authorized Dealers: Many manufacturers have certified dealers who provide genuine components. This is often the best way to ensure compatibility and quality.

- Online Retailers: Websites specializing in machinery parts can offer a wide selection. Check for customer reviews and ratings to gauge reliability.

- Local Auto Parts Stores: Many brick-and-mortar stores carry a range of components for various machines. Visiting a local shop allows you to see items firsthand.

- Second-Hand Markets: Online platforms and local classifieds often have listings for pre-owned parts. Ensure they are in good condition before purchasing.

- Forums and Community Groups: Engaging with fellow enthusiasts can lead to recommendations for trusted suppliers and tips on sourcing specific components.

Always verify the specifications of the parts you are purchasing to ensure they meet your requirements. This careful approach will help maintain the longevity and performance of your equipment.

Common Upgrades for Performance

Enhancing engine efficiency and power output can significantly improve the overall performance of your machine. There are several popular modifications that enthusiasts often consider to maximize capabilities and ensure a smoother operation.

- Air Filter Replacement: Upgrading to a high-flow air filter allows for better airflow, improving combustion efficiency.

- Exhaust System Upgrade: Installing a performance exhaust system reduces back pressure and enhances sound, resulting in improved horsepower.

- Tuning Chips: Custom tuning chips optimize fuel mapping, providing a more responsive throttle and better fuel economy.

- Ignition System Enhancements: Upgrading to high-performance spark plugs and ignition coils ensures a more reliable spark and improved combustion.

- Camshaft Replacement: A new camshaft can alter the engine’s power band, providing better torque and horsepower at higher RPMs.

By exploring these options, you can significantly enhance the performance of your machine, making it more responsive and enjoyable to operate.

Resources for Troubleshooting Problems

When faced with mechanical issues, having access to reliable materials can significantly ease the process of identifying and resolving challenges. Various resources provide insights and guidance, helping users understand the intricacies of their equipment. Whether it’s through detailed documents or online forums, these tools are invaluable for anyone seeking effective solutions.

Online Forums: Engaging with online communities can be beneficial. Many enthusiasts and experts share their experiences, offering tips and troubleshooting advice that can lead to quick fixes. These platforms foster collaboration and often contain a wealth of knowledge accumulated from numerous users.

Technical Documentation: Comprehensive guides and schematics are essential for diagnosing issues. These resources outline the specifications and operational guidelines, assisting users in understanding their systems more thoroughly. Having access to well-organized documentation can streamline the troubleshooting process.

Video Tutorials: Visual aids can be incredibly helpful. Many creators produce step-by-step videos demonstrating common repairs and adjustments. Watching these tutorials can provide clarity on complex procedures, making it easier to follow along and replicate solutions.

Utilizing a combination of these resources enhances problem-solving capabilities, empowering users to tackle issues with confidence and efficiency.