Maintaining and rejuvenating automated collection systems is essential for ensuring their longevity and functionality. This section aims to provide insights into troubleshooting and enhancing the efficiency of these devices, ultimately leading to a smoother user experience and improved operational reliability.

Over time, these machines may encounter various issues that hinder their performance. Understanding the common challenges they face can empower technicians and users alike to address problems effectively. This guide will delve into practical techniques and tips for diagnosing faults and implementing solutions.

Whether dealing with mechanical failures or electronic glitches, the information presented here will equip you with the knowledge to tackle each situation confidently. By adopting a methodical approach, you can restore these essential systems to optimal working condition, ensuring they serve their purpose effectively for years to come.

Understanding Parking Meter Basics

This section delves into the fundamental concepts surrounding devices that manage urban vehicle occupancy. These tools serve a critical role in regulating and facilitating efficient use of public spaces, ensuring a smooth flow of traffic and maximizing accessibility for all users.

Core Components

At the heart of these devices are several key elements that work in unison to provide functionality. Understanding these parts is essential for anyone looking to gain insights into their operation.

| Component | Function |

|---|---|

| Coin Slot | Accepts payment from users. |

| Display Screen | Shows remaining time and payment status. |

| Payment Method Reader | Processes credit or debit transactions. |

| Time Management System | Keeps track of purchased duration. |

Operational Mechanism

The devices function through a combination of mechanical and electronic systems. When a payment is made, the mechanism activates, allowing a designated amount of time for the vehicle’s presence in the designated area. This interaction ensures that users adhere to established regulations while promoting a fair use of communal resources.

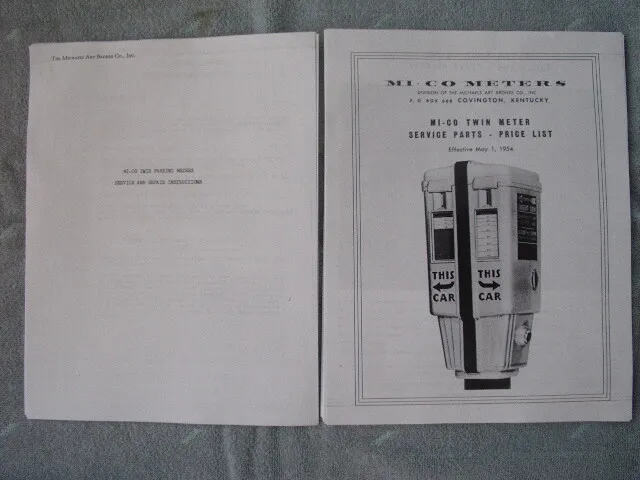

Common Types of Parking Meters

In urban environments, various devices are utilized to manage vehicle spaces effectively. Each type serves distinct purposes and caters to different user needs, ensuring efficient utilization of limited resources.

Mechanical Devices are traditional systems that often feature a coin slot and a dial. Users insert coins to activate the time, and the dial indicates the remaining duration. These systems are simple to operate and have been widely used for decades.

Digital Units represent a modern approach, allowing users to pay via credit or debit cards. They typically come with user-friendly interfaces and can display real-time information about available spaces. Many of these systems also support mobile payment options, making transactions more convenient.

Smart Solutions integrate technology for enhanced functionality. They often connect to mobile apps, enabling users to find available spots, receive notifications about expiration times, and even extend their parking remotely. These advanced systems improve overall user experience and reduce the likelihood of fines.

Solar-Powered Variants are eco-friendly options that utilize solar energy to operate. These units are particularly beneficial in areas with ample sunlight, promoting sustainability while ensuring that users have access to necessary services.

Understanding the various types of devices available can help city planners, businesses, and users make informed decisions about effective space management. Each type plays a crucial role in maintaining order and accessibility in bustling urban centers.

Essential Tools for Repairs

When it comes to maintaining and restoring mechanical devices, having the right equipment is crucial for efficiency and effectiveness. Each task may require specific instruments that ensure precision and ease of use, making the entire process smoother. Below is a list of fundamental tools that are commonly utilized for servicing these units.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For fastening and loosening screws of various sizes. |

| Wrench Set | To tighten or loosen nuts and bolts securely. |

| Multimeter | For measuring voltage, current, and resistance. |

| Wire Cutters | Essential for cutting and stripping wires. |

| Safety Gloves | To protect hands from sharp edges and hazardous materials. |

| Flashlight | For illuminating dark or cramped spaces during inspections. |

| Cleaning Supplies | To ensure components are free from dirt and debris. |

Having these essential instruments on hand not only facilitates effective maintenance but also contributes to a safer working environment. Familiarity with their usage enhances skill and confidence when tackling any task that arises.

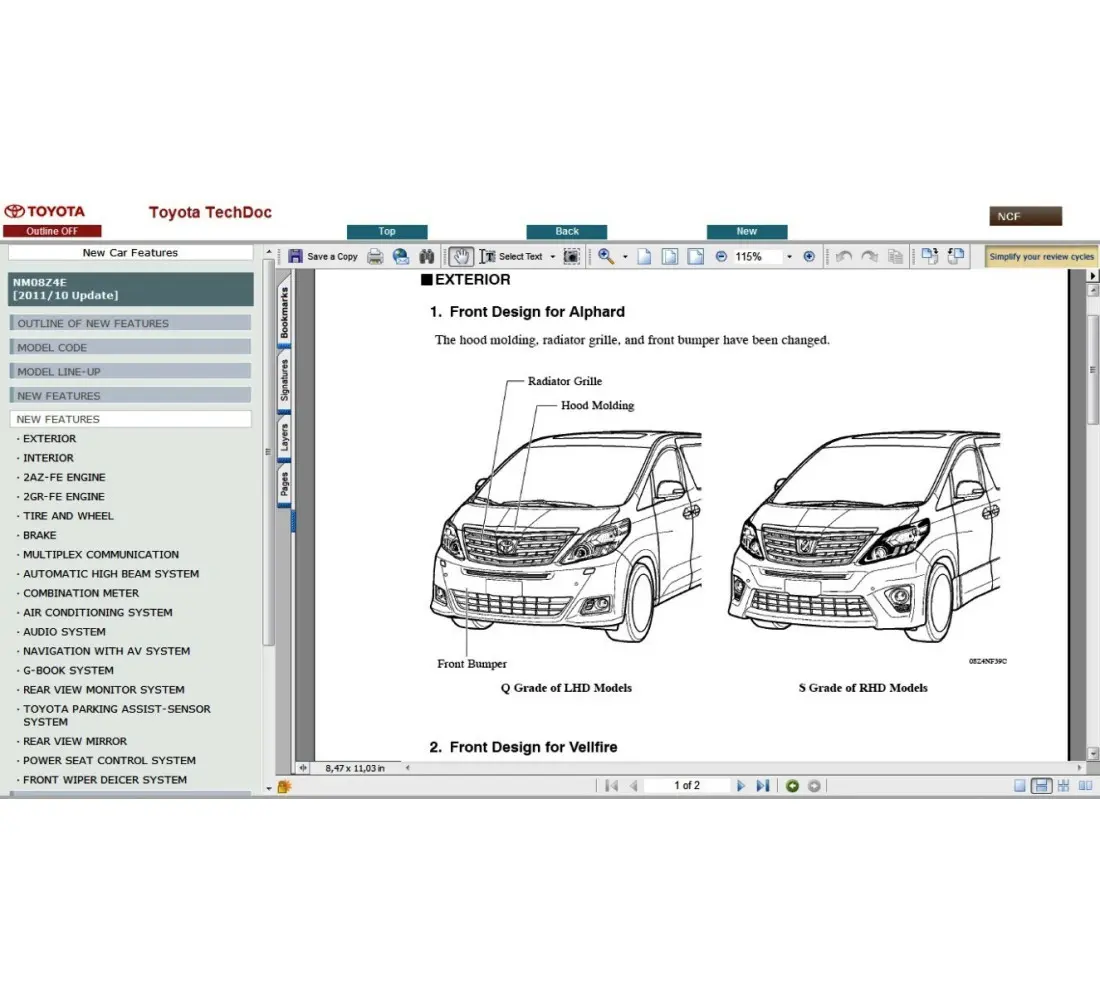

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identify and resolve common issues related to your device. By following these steps, you can efficiently diagnose problems and implement effective solutions, ensuring optimal functionality.

1. Initial Observation

Begin by closely examining the unit for any visible signs of damage or malfunction. Look for indicators such as error messages, unusual sounds, or physical defects that may point to specific issues.

2. Power Supply Check

Ensure that the power source is functioning properly. Verify connections and inspect for any signs of wear or disconnection. If necessary, replace faulty components to restore power.

3. Component Inspection

Carefully assess individual components such as buttons, screens, and sensors. Check for dirt, corrosion, or obstructions that may hinder performance. Clean or replace parts as needed.

4. Software Assessment

Review the software settings to confirm they are correctly configured. Consider performing a reset or update to address any software-related glitches that could be affecting operation.

5. Test Functionality

After making necessary adjustments, conduct a series of tests to determine if the issues have been resolved. Monitor performance closely and take note of any recurring problems.

6. Documentation

Keep a detailed log of any findings, adjustments, and tests conducted. This documentation can be invaluable for future reference and may help identify patterns in recurring issues.

7. Seek Professional Help

If problems persist despite your efforts, consider consulting a specialist. Providing them with your documented observations can facilitate a more efficient diagnosis.

Identifying Common Issues

Understanding frequent problems is essential for maintaining and ensuring optimal functionality of these devices. Various factors can contribute to malfunctions, and recognizing these signs early can facilitate timely intervention.

- Inaccurate Readings: Users may report discrepancies between time paid and time displayed.

- Display Malfunctions: The screen may become unresponsive or show garbled characters.

- Payment Processing Errors: Transactions may fail, preventing successful payment completion.

- Mechanical Jam: Coins or cards may get stuck, obstructing normal operation.

Each of these issues can stem from various underlying causes, including wear and tear, environmental factors, or user interaction. A systematic approach to identifying these problems can greatly enhance efficiency in addressing them.

- Check for visible signs of damage or wear.

- Test the device with different payment methods to pinpoint processing issues.

- Inspect connections and components for signs of corrosion or dirt.

- Observe user interactions to determine if the issue is usage-related.

Addressing these common concerns promptly can lead to improved reliability and user satisfaction.

Replacement Parts Overview

This section provides an in-depth look at the essential components necessary for restoring functionality to your device. Understanding these parts is crucial for efficient troubleshooting and ensuring optimal performance.

Essential Components

Every unit consists of various elements that may require attention over time. Familiarity with these parts will aid in timely replacements and enhance the longevity of your equipment.

| Component | Description | Common Issues |

|---|---|---|

| Control Board | The main electronic interface that manages operations. | Malfunctions due to power surges or moisture. |

| Coin Mechanism | Facilitates the collection and validation of coins. | Jamming or failure to register coins. |

| Display Screen | Shows information to users regarding usage and payments. | Flickering or complete blackout. |

| Housing | The outer shell protecting internal components. | Wear and tear or physical damage. |

Choosing Quality Parts

Selecting high-quality replacements is paramount. Investing in durable components not only ensures a smoother operation but also reduces the frequency of future replacements, thus saving time and resources.

Safety Precautions During Repairs

Ensuring safety is paramount when performing maintenance tasks on equipment. Proper precautions help to prevent accidents and injuries, creating a secure environment for both the technician and the surrounding area. Adhering to specific guidelines is essential for effective and safe work practices.

Before commencing any task, it is crucial to assess the work environment and gather the necessary safety gear. This includes personal protective equipment (PPE) to shield against potential hazards. Awareness of the tools and techniques to be used is equally important to mitigate risks.

| Safety Measure | Description |

|---|---|

| Wear PPE | Always use gloves, goggles, and hard hats to protect against injuries. |

| Check Equipment | Inspect tools and machinery for any faults before starting the work. |

| Maintain Cleanliness | Keep the work area organized and free from clutter to prevent slips and falls. |

| Follow Instructions | Adhere to guidelines provided by manufacturers to ensure safe handling and operation. |

| Stay Alert | Remain focused on the task and avoid distractions that could lead to accidents. |

By implementing these essential safety measures, technicians can significantly reduce the risk of injury and ensure a more efficient work process. Prioritizing safety not only protects individuals but also enhances overall productivity in maintenance activities.

Maintenance Tips for Longevity

Ensuring the long-lasting functionality of outdoor payment devices requires a proactive approach to care and upkeep. Regular attention to various components can significantly enhance their lifespan and performance, reducing the need for frequent servicing.

Here are some essential practices to follow for optimal maintenance:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dirt and debris from the exterior surfaces to prevent damage and ensure clear visibility of display elements. |

| Component Inspections | Conduct routine checks on internal and external components for signs of wear or malfunction, addressing issues promptly. |

| Weatherproofing | Apply protective coatings or coverings to shield against harsh environmental conditions, prolonging the life of sensitive parts. |

| Software Updates | Keep the operating system and software up to date to enhance security features and improve overall functionality. |

| Battery Maintenance | Regularly inspect and replace batteries as needed to ensure consistent operation and prevent unexpected outages. |

By implementing these straightforward strategies, you can help ensure that the devices remain reliable and efficient for years to come.

Legal Considerations for Technicians

Technicians operating in the field must navigate a complex landscape of regulations and responsibilities. Understanding the legal framework is crucial for ensuring compliance and avoiding potential liabilities. This section outlines key aspects that professionals should consider in their practice.

Licensing and Certification

Many jurisdictions require technicians to obtain specific licenses or certifications. These credentials not only demonstrate competence but also ensure adherence to local laws. Failing to secure the necessary documentation can result in fines or restrictions on practice.

Liability and Insurance

Technicians should consider obtaining liability insurance to protect against claims arising from their work. This coverage can safeguard against financial losses due to accidents or errors, providing peace of mind while performing technical tasks.

Safety Regulations

Adherence to safety standards is paramount. Technicians must stay informed about local regulations that govern their work environment. Compliance with these rules helps prevent accidents and ensures a safe working atmosphere for everyone involved.

Intellectual Property

When utilizing specialized tools or proprietary technologies, technicians must respect intellectual property rights. Unauthorized use or reproduction of patented designs can lead to legal disputes, highlighting the importance of understanding ownership rights in the industry.

Environmental Compliance

Technicians should also be aware of environmental regulations that may apply to their operations. Proper disposal of materials and adherence to eco-friendly practices are not just ethical considerations; they are often legal requirements that help protect public health and the environment.

Resources for Further Learning

Expanding your knowledge in the field of maintenance and troubleshooting can significantly enhance your skills and understanding. This section provides a variety of valuable resources that can aid in your professional development and help you stay updated with the latest techniques and tools.

Recommended Books

Books are an excellent way to gain in-depth knowledge and theoretical understanding. Here are some notable titles:

| Title | Author | Year |

|---|---|---|

| The Art of Maintenance | John Smith | 2020 |

| Understanding Equipment | Jane Doe | 2018 |

| Advanced Troubleshooting Techniques | Emily Johnson | 2022 |

Online Courses

In addition to books, online courses can provide hands-on experience and interactive learning opportunities. Consider exploring the following platforms:

| Platform | Course Title | Duration |

|---|---|---|

| Coursera | Fundamentals of Equipment Management | 4 weeks |

| Udemy | Maintenance Skills for Technicians | 3 hours |

| edX | Introduction to Troubleshooting | 6 weeks |