In the world of off-road vehicles, maintaining optimal performance and longevity is crucial for enthusiasts and casual riders alike. Whether tackling rugged terrains or cruising through scenic trails, understanding the nuances of upkeep can significantly enhance the riding experience. This section provides an insightful look into the essential procedures and techniques necessary to ensure your all-terrain vehicle remains in top condition.

Effective maintenance encompasses a variety of aspects, from routine inspections to addressing specific issues that may arise during operation. It is vital to be equipped with the right knowledge and resources to identify potential problems early and implement appropriate solutions. By following a structured approach to upkeep, you can not only extend the life of your machine but also improve its reliability and safety on the trails.

Moreover, having a detailed reference can be invaluable, particularly for those new to vehicle maintenance. This guide aims to demystify the process by providing clear, step-by-step instructions tailored to common challenges faced by off-road vehicle owners. With this information at your disposal, you will be empowered to tackle maintenance tasks with confidence and skill.

Overview of Polaris Predator 500

This section provides a comprehensive look at a highly regarded off-road vehicle known for its performance and durability. Designed for both recreational use and competitive racing, this machine has carved out a niche for enthusiasts seeking adventure and thrill.

Engine Performance: Equipped with a powerful engine, this model delivers impressive acceleration and top speed. Its advanced engineering allows for efficient fuel consumption while maintaining high torque, making it suitable for various terrains.

Handling and Control: The vehicle boasts exceptional handling characteristics, allowing riders to navigate challenging landscapes with ease. The suspension system is finely tuned to absorb shocks and provide stability, enhancing the overall riding experience.

Durability and Build Quality: Crafted from robust materials, this off-road machine is built to withstand the rigors of intense use. Its design emphasizes longevity, making it a reliable choice for both casual riders and competitive racers.

Customization Options: Owners have the opportunity to modify and personalize their vehicle to suit individual preferences. A wide range of aftermarket parts and accessories is available, allowing for enhancements in performance and aesthetics.

This off-road vehicle represents a blend of power, agility, and versatility, appealing to a diverse group of riders who seek excitement and adventure in the great outdoors.

Common Issues with the Predator 500

When operating an all-terrain vehicle, encountering various challenges is a common experience among enthusiasts. Understanding these frequent problems can greatly enhance the overall performance and lifespan of the machine. Here, we explore some typical issues that riders may face and provide insights into potential solutions.

Electrical Problems

One of the most prevalent issues involves the electrical system. Riders often report difficulties with the starting mechanism or irregularities in lighting. Battery failure is a significant contributor, which can be attributed to age or inadequate charging. Regularly checking connections and ensuring the battery is in good condition can mitigate these concerns.

Suspension and Handling

Another area that may require attention is the suspension system. Over time, components can wear out, leading to decreased handling and ride quality. Issues such as leaking shocks or misalignment can adversely affect performance. Conducting routine inspections and replacing worn parts promptly is essential for maintaining optimal control and comfort.

Essential Tools for Repairs

When tackling maintenance and troubleshooting tasks, having the right instruments is crucial for achieving effective results. Each project requires specific gear to ensure efficiency, safety, and precision. Familiarity with essential tools not only enhances your capability but also streamlines the process of addressing issues.

1. Wrenches: A variety of wrenches, including adjustable and socket types, are indispensable for loosening and tightening fasteners. They provide the necessary leverage and grip to handle stubborn bolts.

2. Screwdrivers: A set of both flathead and Phillips screwdrivers is vital for accessing various components. These tools come in different sizes to accommodate diverse screws, ensuring versatility in your tasks.

3. Pliers: These tools are essential for gripping, twisting, and cutting wires or small parts. Needle-nose pliers, in particular, are great for reaching tight spaces.

4. Torque Wrench: For tasks requiring precise fastening, a torque wrench helps achieve the correct tension on bolts and nuts, preventing damage from over-tightening.

5. Diagnostic Tools: Equipment such as multimeters and diagnostic scanners are invaluable for troubleshooting electrical issues. They provide insights into system performance and help identify faults quickly.

6. Cleaning Supplies: Keeping your tools and work area clean is essential. Brushes, rags, and cleaning solvents help maintain the longevity of components and ensure effective functioning.

Equipping yourself with these fundamental tools will greatly enhance your ability to perform maintenance tasks efficiently and effectively.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your all-terrain vehicle in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of the machine. Following these structured steps will help ensure that all components function smoothly and safely.

Essential Pre-Maintenance Checks

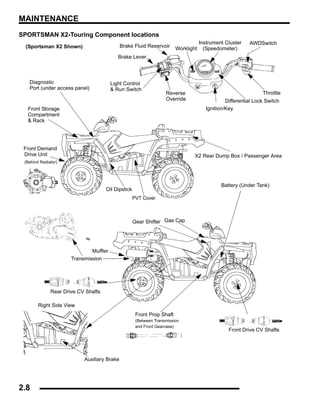

Before diving into specific tasks, it’s crucial to conduct a thorough inspection. Start by assessing the overall condition of the vehicle. Look for any visible signs of wear, leaks, or damage. Check tire pressure and tread, as well as the state of the brakes and suspension. Ensure that all lights are operational, and that there are no obstructions in the exhaust system. This preliminary evaluation sets the stage for effective maintenance.

Routine Maintenance Tasks

After the initial inspection, focus on regular maintenance tasks. Change the oil at recommended intervals to ensure engine efficiency. Replace air filters to maintain optimal airflow and performance. Additionally, inspect and clean the fuel system to prevent clogging. Pay attention to the battery’s condition and connections, ensuring they are tight and corrosion-free. Finally, regularly check the chain or drive belt for proper tension and lubrication.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of an all-terrain vehicle is crucial for optimal performance and safety. By understanding the common electrical problems and employing systematic methods, owners can effectively identify and rectify faults, ensuring a reliable riding experience.

Common Issues and Symptoms

Typical electrical malfunctions include failure to start, dim or flickering lights, and erratic gauge readings. Dead batteries are often the primary suspect when ignition problems arise, while poor connections can lead to inconsistent power delivery. Additionally, faulty wiring or short circuits may manifest as unexpected behavior in various electrical components.

Troubleshooting Steps

Begin the diagnosis by checking the battery voltage using a multimeter; a reading below the recommended level suggests the need for a recharge or replacement. Next, inspect all wiring and connectors for signs of wear or corrosion. It is essential to ensure that ground connections are secure, as poor grounding can lead to numerous electrical anomalies. If problems persist, examine the fuses and relays for continuity, replacing any that are faulty. Following these steps can help restore functionality and prevent future issues.

Engine Overhaul Procedures Explained

This section delves into the essential steps and techniques required for a comprehensive overhaul of an internal combustion engine. Understanding these procedures is crucial for restoring performance and extending the life of the machinery.

The process typically involves several key stages, each contributing to the overall effectiveness of the operation. Below are the primary phases of engine refurbishment:

- Preparation:

- Gather necessary tools and parts.

- Ensure a clean working environment.

- Review manufacturer specifications and guidelines.

- Disassembly:

- Carefully remove external components such as the intake and exhaust systems.

- Document each step to facilitate reassembly.

- Inspect parts for wear and damage.

- Inspection and Cleaning:

- Thoroughly clean all components.

- Check for cracks or excessive wear.

- Measure tolerances to ensure compatibility.

- Reassembly:

- Replace worn parts with new or refurbished components.

- Follow torque specifications for fasteners.

- Ensure proper alignment of all assemblies.

- Testing:

- Run the engine under controlled conditions.

- Monitor for leaks and unusual noises.

- Make adjustments as necessary to optimize performance.

By following these detailed steps, one can achieve a successful engine refurbishment that enhances reliability and efficiency. Each phase is critical to ensuring that the engine operates smoothly and meets performance expectations.

Braking System Repair Techniques

Maintaining an effective stopping mechanism is crucial for ensuring safety and performance. This section outlines essential methods and practices for addressing common issues related to braking systems. By understanding these techniques, users can enhance their knowledge and improve the longevity of their equipment.

Common Issues and Diagnoses

- Fading brakes: A decrease in stopping power often caused by overheating.

- Uneven wear: Typically results from misalignment or faulty components.

- Noisy operation: Can indicate worn pads or contamination of the braking surfaces.

Repair Techniques

- Inspecting Components: Regularly examine brake pads, rotors, and calipers for wear and damage.

- Replacing Worn Parts: Swap out any components showing signs of significant wear to restore function.

- Bleeding the System: Remove air from the hydraulic lines to ensure optimal brake pressure and responsiveness.

- Adjusting Alignment: Ensure that all parts are properly aligned to prevent uneven wear and maintain efficiency.

- Cleaning Surfaces: Regularly clean brake pads and rotors to remove dust and debris that could impair performance.

Suspension Adjustments and Fixes

The suspension system plays a crucial role in maintaining stability and comfort during rides. Proper adjustments can enhance performance, ensuring a smoother experience over varied terrains. This section explores common modifications and solutions to optimize your vehicle’s suspension setup.

Understanding the Basics: Familiarize yourself with the components of the suspension, including shocks, springs, and linkages. Each part influences handling and ride quality, making it essential to grasp their functions.

Adjusting Shock Absorption: Fine-tuning shock settings can significantly impact responsiveness. Consider factors such as rider weight and terrain type. For instance, increasing compression for rough terrain can improve control, while softer settings may be better for smoother surfaces.

Spring Tension: Adjusting spring tension is vital for achieving the desired ride height and comfort level. A stiffer spring can prevent bottoming out, while a softer spring may provide more cushion. Evaluate the load regularly and make adjustments as needed.

Linkage Maintenance: Inspect linkage systems for wear and tear. Lubricating joints and checking for play can prevent larger issues. Tightening loose bolts is essential to maintain overall integrity and performance.

Common Issues: Be aware of signs indicating suspension problems, such as excessive bouncing or poor handling. Addressing these concerns early can prevent further damage and enhance safety during operation.

Conclusion: Regular adjustments and maintenance of the suspension system are critical for optimal performance. By understanding and applying the right fixes, you can ensure a safe and enjoyable ride, regardless of the challenges posed by the terrain.

Transmission and Drive System Care

Maintaining the transmission and drive system of your all-terrain vehicle is essential for ensuring optimal performance and longevity. Regular attention to these components not only enhances efficiency but also minimizes the risk of costly repairs down the line. A thorough understanding of the care required can help you keep your ride in peak condition.

Routine Inspection

Performing regular checks on the transmission and drive system is crucial. Look for signs of wear, leaks, or any unusual noises during operation. Pay special attention to the belts and chains, as these components are vital for the transfer of power. Early detection of issues can save you time and resources in the future.

Fluid Maintenance

Proper fluid levels are vital for smooth operation. Ensure that the transmission fluid is at the correct level and replace it according to the manufacturer’s recommendations. Using the right type of fluid will significantly affect performance and efficiency. Additionally, inspect the seals and gaskets for any signs of degradation, as these can lead to fluid leaks.

By prioritizing these aspects of care, you can enhance the durability and reliability of your vehicle’s transmission and drive system, ensuring a safer and more enjoyable riding experience.

Preventive Measures for Longevity

Maintaining the optimal performance of your all-terrain vehicle requires proactive strategies that ensure its durability and efficiency over time. By implementing a series of routine care practices, you can significantly extend the lifespan of your machine while enhancing its reliability.

Regular Maintenance Checks: Schedule consistent inspections to identify wear and tear early. This includes checking fluid levels, tire pressure, and brake functionality. Addressing minor issues promptly can prevent major repairs later.

Cleaning and Care: After each use, thoroughly clean the vehicle to remove dirt, mud, and debris that can cause corrosion. Pay special attention to the air filter and the engine to ensure optimal performance.

Lubrication: Regularly lubricate all moving parts to reduce friction and wear. This includes chains, gears, and bearings, which are critical for smooth operation.

Storage Practices: When not in use, store the vehicle in a dry, sheltered environment. Consider using a cover to protect it from dust and moisture, which can lead to rust and other damage.

Fuel Management: Use high-quality fuel and consider adding a fuel stabilizer if the vehicle will be idle for extended periods. This helps prevent fuel degradation, ensuring efficient engine performance.

By incorporating these preventive measures into your maintenance routine, you can ensure that your vehicle remains in peak condition, providing you with enjoyable and trouble-free rides for years to come.