Maintaining the integrity of aviation structures is crucial for ensuring safety and performance in modern flying vehicles. This section provides essential insights into the methodologies and best practices for addressing various issues that may arise in airframe components. Understanding these processes is vital for personnel involved in the upkeep of aerial transportation systems.

In the following sections, readers will discover a comprehensive overview of procedures designed to restore and enhance the resilience of critical airframe elements. Emphasizing the importance of systematic evaluation and intervention, this guide aims to equip professionals with the knowledge needed to effectively manage integrity concerns.

By delving into various aspects of maintenance, this resource highlights the significance of adhering to established protocols and employing appropriate techniques. The information presented here serves as a foundation for ensuring that aerial vehicles remain reliable and safe throughout their operational lifespan.

This section provides a comprehensive overview of a modern aircraft known for its innovative design and advanced technology. The focus will be on understanding the key features that contribute to its performance, durability, and efficiency. By examining various aspects, we can appreciate the engineering marvel behind this flying machine.

Key Features of the Aircraft

The aircraft incorporates several cutting-edge technologies that enhance its overall functionality. Some of the notable elements include:

| Feature | Description |

|---|---|

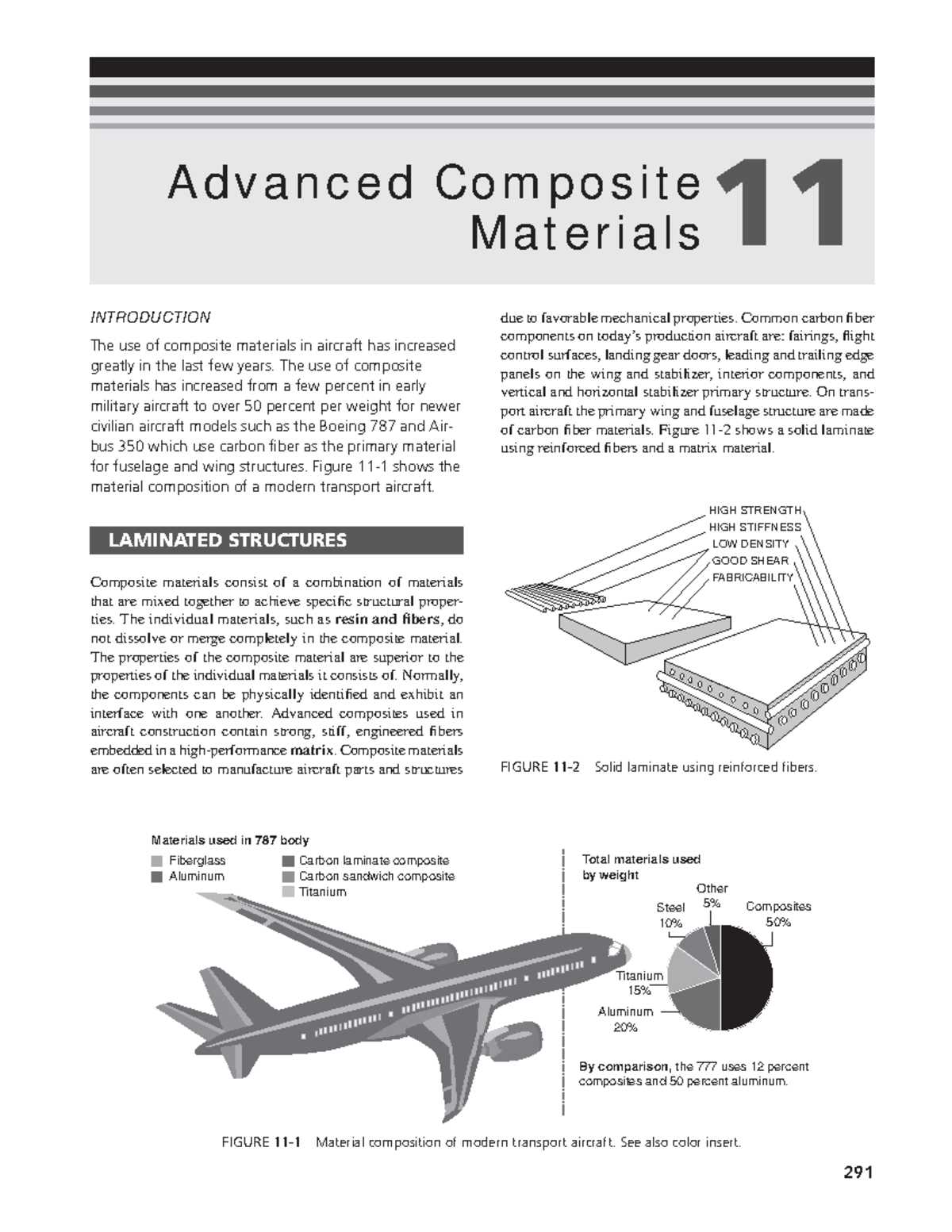

| Composite Materials | Utilizes lightweight materials to reduce weight and improve fuel efficiency. |

| Advanced Aerodynamics | Designed to minimize drag and optimize flight performance. |

| Enhanced Systems | Equipped with modern systems for improved safety and reliability. |

Importance of Maintenance

Regular maintenance is crucial for ensuring the longevity and safety of the aircraft. Proper procedures must be followed to address any wear and tear, ensuring that all components function optimally. This not only preserves the integrity of the aircraft but also enhances passenger comfort and operational efficiency.

Understanding Structural Integrity

The concept of maintaining the soundness of an aircraft’s framework is crucial for its overall performance and safety. Ensuring that each component withstands various stresses and strains is essential in preventing failures that could jeopardize operation.

Key Principles

Several fundamental principles guide the assessment and maintenance of an aircraft’s framework:

- Load Distribution: Proper distribution of forces across various parts ensures balanced stress levels.

- Material Properties: Understanding the characteristics of the materials used aids in predicting their behavior under different conditions.

- Fatigue Management: Regular monitoring of wear and tear helps identify potential weaknesses before they lead to significant issues.

Assessment Techniques

Various methods are employed to evaluate the integrity of an aircraft’s framework:

- Visual Inspections: Routine checks for visible signs of damage or degradation.

- Nondestructive Testing: Techniques like ultrasonic or radiographic testing detect internal flaws without causing harm.

- Load Testing: Applying simulated forces to verify that components can endure expected loads.

Key Components of the Aircraft

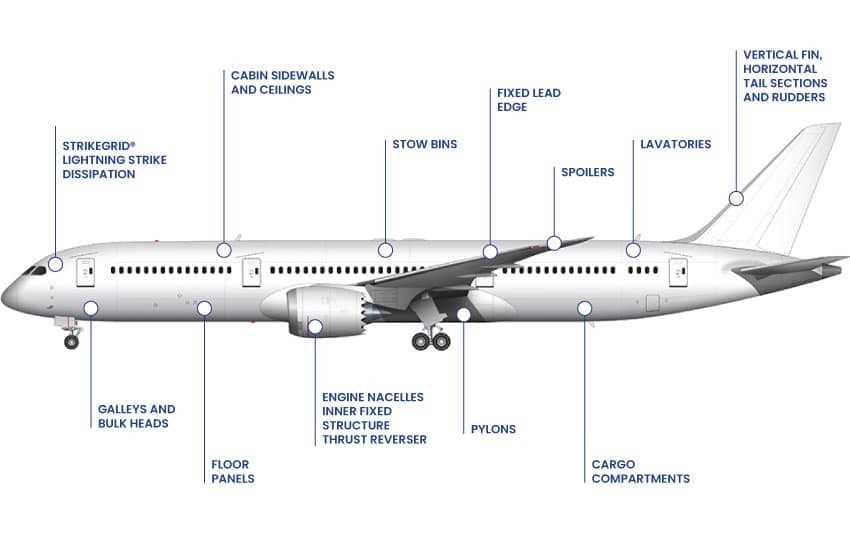

The design and functionality of modern aircraft are supported by several crucial elements that work together to ensure safe and efficient operations. Understanding these components is essential for anyone involved in aviation maintenance and operations. Each part plays a vital role in the overall performance and safety of the aircraft.

Fuselage

The fuselage serves as the main body of the aircraft, providing structural integrity and housing passengers, cargo, and systems. It is designed to withstand various aerodynamic forces while ensuring comfort and safety for those onboard. The materials used in its construction are chosen for their strength and lightweight properties, contributing to the overall efficiency of the aircraft.

Wings

Wings are critical for generating lift, allowing the aircraft to ascend and maintain altitude during flight. Their shape and design are optimized for aerodynamic performance, with various components like ailerons and flaps that enhance control and maneuverability. The construction materials are engineered to provide durability while minimizing weight, further improving the aircraft’s fuel efficiency.

Importance of Repair Manuals

Documentation that provides detailed guidance on maintenance procedures is essential in the aviation industry. Such resources ensure that technicians follow standardized processes, promoting safety and efficiency in aircraft operations.

Ensuring Safety

Safety is paramount in aviation. Comprehensive documentation helps prevent errors during maintenance tasks, reducing the risk of accidents. Clear instructions enable personnel to perform their duties accurately, ensuring that all systems function correctly.

Facilitating Training

Having well-structured guidance aids in the training of new technicians. Accessible information allows them to familiarize themselves with complex systems and processes, thereby enhancing their skills and confidence in performing maintenance tasks.

Repair Techniques for Boeing 787

This section outlines various methodologies for addressing structural issues in advanced aircraft. Emphasizing innovative approaches, the focus is on ensuring safety and longevity while maintaining performance standards.

Common Methods

- Composite bonding techniques to enhance strength

- Welding procedures for metallic components

- Use of advanced sealants to prevent corrosion

Inspection and Assessment

- Regular visual inspections to identify potential weaknesses

- Non-destructive testing methods to assess material integrity

- Utilization of data analytics for predictive maintenance

Common Structural Issues

In aerospace engineering, various challenges may arise concerning the integrity of airframes. These complications can significantly affect performance and safety, necessitating thorough investigation and appropriate solutions.

One prevalent concern involves fatigue cracks, which develop over time due to repeated stress cycles. These cracks can compromise the overall strength of the structure if not detected and addressed promptly.

Another issue is the corrosion of materials, often exacerbated by environmental factors. Regular inspections and preventive measures are essential to mitigate this problem and extend the lifespan of components.

Additionally, joint failures may occur, leading to misalignment and reduced structural integrity. Ensuring proper assembly techniques and adherence to specifications is crucial in preventing these occurrences.

Lastly, delamination in composite materials poses significant risks. This separation of layers can weaken the structure and requires immediate attention to avoid further complications.

Material Specifications and Requirements

This section outlines the essential characteristics and standards necessary for materials used in aircraft construction and maintenance. Understanding these specifications is crucial for ensuring the integrity and safety of airframes.

Materials employed in aviation structures must meet stringent criteria related to strength, weight, and resistance to environmental factors. The selection of alloys, composites, and other materials is influenced by their performance under various conditions, including temperature fluctuations and stress factors.

Additionally, compliance with regulatory standards is mandatory. Each material must undergo rigorous testing to verify its suitability for use in aviation applications, ensuring that it meets the necessary safety and durability requirements.

Overall, adhering to these material specifications is vital for maintaining the operational effectiveness and longevity of aircraft components.

Safety Protocols in Repairs

Ensuring the highest level of safety during maintenance procedures is essential in the aviation industry. Adhering to established guidelines not only protects personnel but also maintains the integrity of the aircraft.

Key safety measures include:

- Conducting thorough training sessions for all personnel involved in maintenance tasks.

- Implementing regular safety audits to identify potential hazards.

- Utilizing personal protective equipment (PPE) at all times.

Moreover, it is crucial to follow specific protocols:

- Always ensure that the aircraft is in a secure state before beginning any work.

- Maintain clear communication among team members during the entire maintenance process.

- Document all procedures and findings meticulously for future reference.

By prioritizing these practices, organizations can enhance operational safety and efficiency, ultimately contributing to the overall reliability of the fleet.

Documentation and Record Keeping

Effective documentation and meticulous record keeping are essential components in the maintenance and oversight of aviation components. Accurate records ensure compliance with industry standards and provide a reliable reference for future inspections and interventions. These practices enhance safety and operational efficiency.

Importance of Accurate Records

Maintaining detailed records serves several critical functions:

- Facilitates tracking of maintenance history

- Ensures adherence to regulatory requirements

- Provides essential data for audits and inspections

- Supports accountability among maintenance personnel

Best Practices for Documentation

To achieve optimal results in record keeping, consider implementing the following strategies:

- Use standardized formats for all documents to ensure consistency.

- Regularly update records to reflect any changes or actions taken.

- Store documents in a secure, accessible location to facilitate easy retrieval.

- Conduct periodic reviews to verify the accuracy and completeness of records.

Training for Maintenance Personnel

Effective education for maintenance staff is essential to ensure the longevity and safety of modern aircraft. Comprehensive training programs equip personnel with the necessary skills and knowledge to perform their duties efficiently.

These programs typically encompass various key components:

- Theoretical instruction on aircraft systems and components

- Hands-on training with specialized tools and equipment

- Understanding of safety protocols and regulations

- Continuous education to stay updated with technological advancements

To maximize the effectiveness of training, organizations often implement the following strategies:

- Conducting regular assessments to evaluate skill levels

- Encouraging participation in workshops and seminars

- Providing access to updated training materials and resources

By prioritizing education for maintenance teams, organizations can enhance operational efficiency and ensure the highest standards of aircraft maintenance.

Inspection Procedures and Standards

The process of examining aircraft components is essential to ensure their integrity and safety. This section outlines the methodologies and criteria employed to assess the condition of various elements, highlighting the importance of adhering to established guidelines to maintain operational reliability.

General Inspection Guidelines

Regular assessments are vital for identifying potential issues before they escalate. Inspectors should utilize a systematic approach, incorporating visual checks and advanced techniques to detect any signs of wear, corrosion, or structural anomalies. Each inspection should be conducted in accordance with predefined protocols to guarantee thoroughness.

Quality Assurance and Compliance

Maintaining high standards during the inspection process is crucial. All evaluations must align with regulatory requirements and organizational policies. Inspectors are encouraged to document findings meticulously, ensuring that any discrepancies are addressed promptly and that corrective actions are implemented effectively to uphold safety and performance standards.

Regulatory Compliance and Guidelines

Adhering to established standards and regulations is crucial in the aviation industry to ensure safety and performance. Compliance involves following specific directives that govern maintenance practices, materials used, and processes implemented during the lifecycle of an aircraft. These guidelines are designed to mitigate risks and enhance the reliability of the aircraft’s components.

Key Regulatory Bodies

Various organizations oversee aviation safety and regulatory compliance. Notably, the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) set forth comprehensive regulations that must be observed. These entities provide frameworks that manufacturers and maintenance organizations must follow to uphold safety standards.

Documentation and Reporting Requirements

Proper documentation is essential for compliance. Organizations must maintain accurate records of all maintenance activities, inspections, and modifications performed on aircraft. Reporting requirements also dictate that any issues or discrepancies found during inspections are documented and addressed promptly to ensure continued airworthiness.

Future of Boeing 787 Maintenance

The landscape of aircraft upkeep is evolving, driven by advancements in technology and a growing emphasis on efficiency. As the aviation industry embraces new methodologies, the approach to maintenance will likely become more proactive, focusing on predictive analytics and data-driven decisions.

One of the key trends shaping the future of maintenance is the integration of smart technologies. The implementation of Internet of Things (IoT) devices and sensors will enable real-time monitoring of aircraft components, facilitating timely interventions before issues escalate. This shift towards condition-based maintenance is expected to enhance safety and reduce operational downtimes.

| Technology | Benefits |

|---|---|

| Predictive Analytics | Anticipates issues, minimizes unexpected failures |

| IoT Sensors | Real-time data collection, enhances decision-making |

| Digital Twins | Simulates real-world performance, optimizes maintenance schedules |

Additionally, the shift towards sustainable practices will likely influence maintenance strategies. Emphasis on reducing environmental impact may lead to the adoption of eco-friendly materials and techniques, fostering a culture of sustainability within the maintenance framework.