When it comes to keeping your gardening tool in top condition, having a comprehensive resource at your disposal is invaluable. Proper maintenance not only enhances performance but also extends the lifespan of your equipment. Understanding the intricacies of your device ensures that you can tackle any issues that arise with confidence.

Essential knowledge about the various components and functions of your tool can make all the difference. From troubleshooting common problems to routine upkeep tasks, familiarity with these aspects empowers you to manage your equipment effectively. With the right guidance, you can prevent minor issues from escalating into major repairs.

Whether you’re dealing with fuel system concerns or engine performance problems, knowing how to approach these challenges is crucial. Being proactive in your maintenance routine can save time and money while ensuring that your device operates smoothly. Dive into the details and discover how to keep your tool running at its best.

Overview of Stihl FS45 Trimmer

This section provides a comprehensive look at a popular landscaping tool designed for efficient vegetation management. Known for its lightweight design and user-friendly features, this device is ideal for both homeowners and professionals. Its robust performance makes it suitable for a variety of tasks, from trimming edges to tackling thicker brush.

The trimmer is equipped with a reliable engine that delivers ample power while ensuring ease of use. Durability is a key aspect, allowing the tool to withstand frequent use in demanding environments. Additionally, the ergonomic design contributes to operator comfort, reducing fatigue during extended work sessions.

Maintenance and care are straightforward, making it accessible for users at all skill levels. The availability of various attachments enhances its versatility, enabling users to customize their approach based on specific needs. Overall, this tool is a valuable asset for achieving a well-manicured outdoor space.

Common Issues with FS45 Models

Users often encounter various challenges when operating this type of outdoor power equipment. Understanding these common problems can help maintain optimal performance and extend the lifespan of the device. Below are some frequent issues that operators should be aware of.

Fuel-Related Problems

One prevalent issue stems from the fuel system. Users may notice difficulty in starting the engine or inconsistent performance. This can often be attributed to stale fuel or improper fuel mixture. Regularly replacing old fuel and ensuring the correct ratio of oil to gasoline is crucial for smooth operation.

Starting Difficulties

Another common concern is trouble with starting the engine. This may occur due to various factors such as a faulty spark plug or a clogged air filter. It is advisable to inspect these components periodically. A clean air filter allows for better airflow, while a functioning spark plug ensures reliable ignition.

By addressing these issues promptly, users can enhance the performance of their equipment and enjoy a more efficient operation.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. Proper tools not only simplify the process but also ensure effective results. In this section, we will explore the indispensable items needed for servicing and fixing outdoor power equipment.

Basic Hand Tools

Every toolkit should include fundamental hand tools such as screwdrivers, wrenches, and pliers. These items are essential for loosening and tightening various components. A multitool can also be incredibly handy, providing multiple functions in one compact device.

Specialized Equipment

For more complex tasks, certain specialized tools are necessary. A spark plug wrench is essential for removing and installing spark plugs, while a compression tester can help diagnose engine performance issues. Additionally, a fuel line tool can assist in replacing or repairing fuel lines without causing damage.

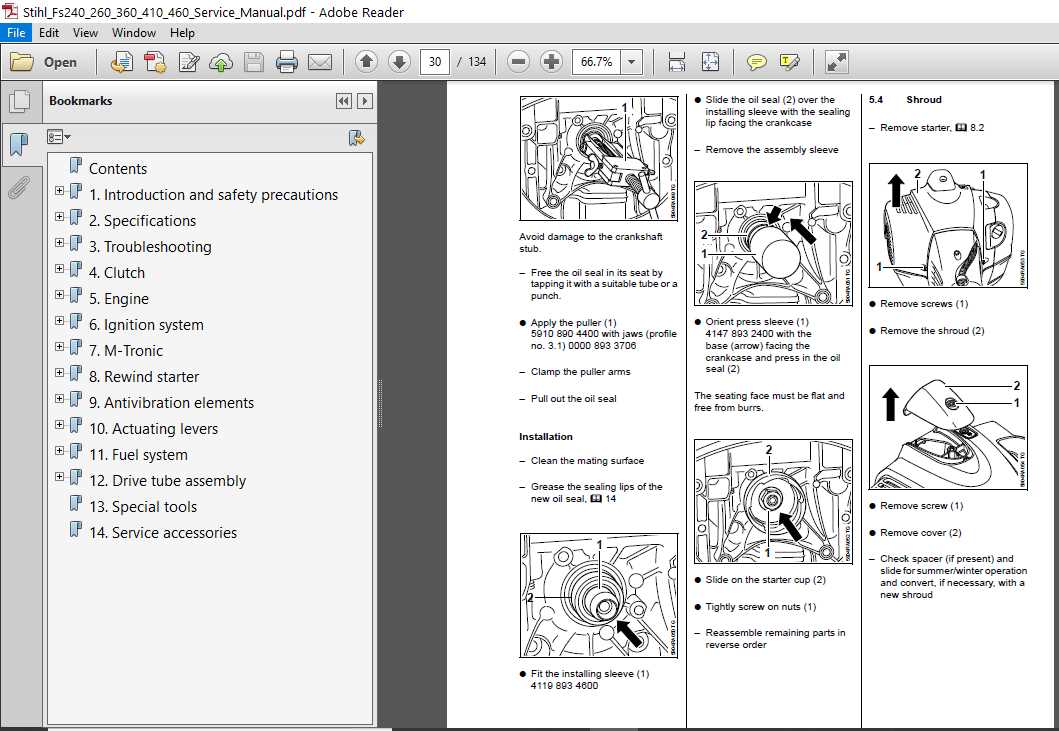

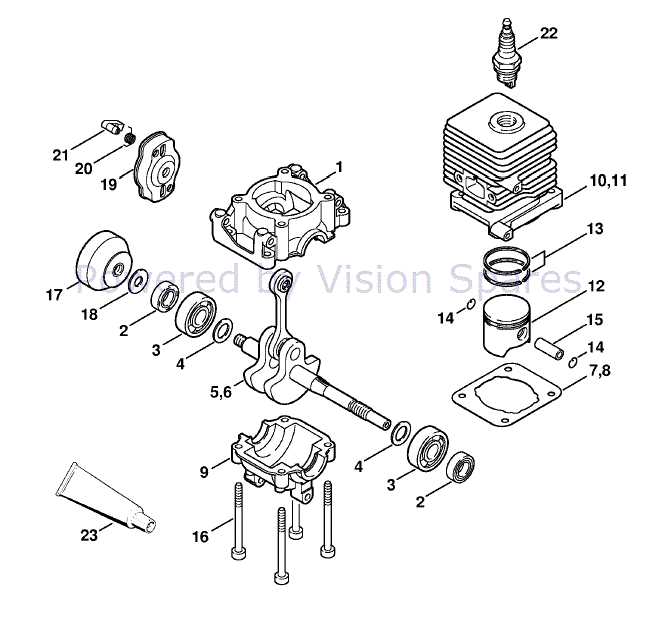

Step-by-Step Disassembly Process

Disassembling a piece of equipment is essential for maintenance and troubleshooting. This process allows for a thorough inspection and cleaning of components, ensuring optimal performance. Below is a detailed guide to effectively take apart the unit while keeping all parts organized and safe.

Preparation

- Gather necessary tools: screwdrivers, pliers, and a clean workspace.

- Ensure the device is turned off and disconnected from any power source.

- Wear safety gloves to protect your hands from sharp edges.

Disassembly Steps

- Start by removing the outer casing using the appropriate screwdriver.

- Carefully detach any attached accessories or components, noting their arrangement.

- Proceed to unscrew and remove the engine cover, taking care not to damage any wires.

- Disconnect fuel lines and electrical connectors, ensuring to remember their positions.

- Take out the spark plug to prevent accidental ignition during disassembly.

- Finally, remove the internal parts systematically, documenting each step for reassembly.

By following these steps methodically, you can efficiently dismantle the equipment while minimizing the risk of losing or damaging parts. This organized approach will make reassembly straightforward and less time-consuming.

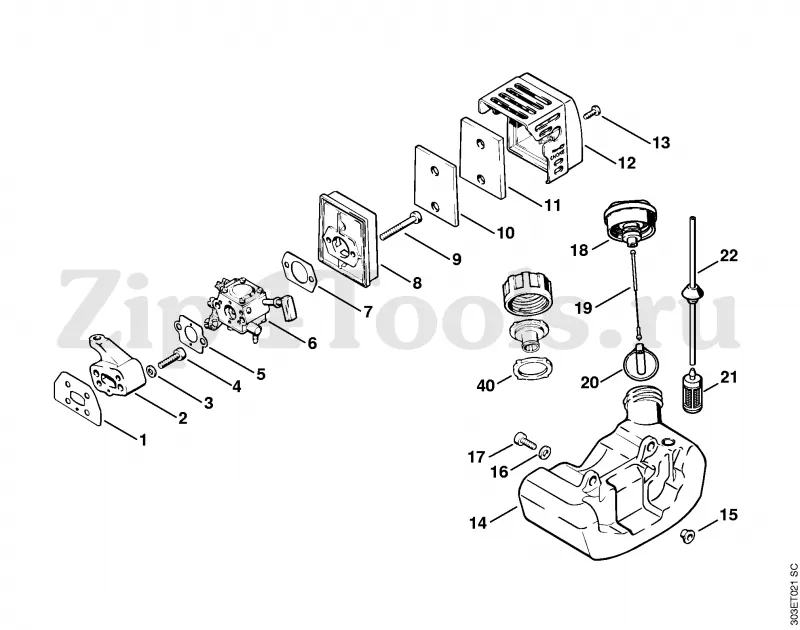

Inspecting the Fuel System

Ensuring the proper functioning of the fuel system is crucial for optimal performance and longevity of your equipment. A thorough inspection helps identify potential issues such as clogs, leaks, or damaged components that can affect fuel delivery and engine efficiency. Regular maintenance of this system not only enhances reliability but also minimizes the risk of costly repairs in the future.

Visual Examination

Start by visually inspecting the fuel lines for any signs of wear or damage. Look for cracks, leaks, or disconnections that may impede fuel flow. Ensure that all connections are secure and that the fuel filter is clean and unobstructed. Additionally, check the fuel tank for any debris or contaminants that could hinder performance.

Functional Testing

After the visual check, perform a functional test of the system. This includes priming the fuel system and checking for proper fuel delivery to the engine. Listen for any unusual sounds during operation, as these may indicate issues within the system. If the engine struggles to start or runs erratically, further investigation may be necessary to diagnose the underlying cause.

Diagnosing Electrical Problems

Identifying issues within the electrical system of outdoor equipment is crucial for ensuring optimal performance. Proper diagnosis allows users to pinpoint malfunctions, whether they stem from wiring faults, component failures, or battery-related issues. By following a systematic approach, you can efficiently troubleshoot and resolve these problems.

Common Symptoms

Electrical issues often manifest through specific symptoms. If the equipment fails to start or operates intermittently, it may indicate a weak battery or a faulty ignition system. Additionally, flickering lights or inconsistent power delivery can signal underlying wiring problems. Recognizing these signs early can save time and resources during the diagnostic process.

Testing Procedures

To accurately diagnose electrical faults, utilize a multimeter to check voltage levels at key components. Start by examining the battery for proper charge and connections. Next, inspect wiring for any visible damage or corrosion. Testing the ignition system and switches will also help isolate the source of the problem. Following a methodical testing routine ensures that you can identify and address issues effectively.

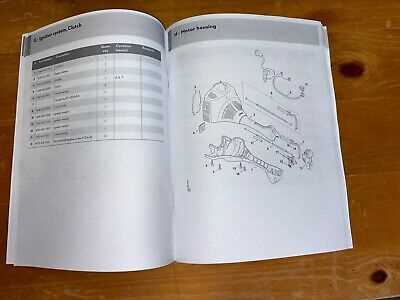

Replacing the Cutting Head

When it comes to maintaining your outdoor power equipment, one of the essential tasks is replacing the cutting head. This component plays a crucial role in ensuring efficient operation and optimal performance. Over time, wear and tear can diminish its effectiveness, making timely replacement vital for achieving the best results during use.

Tools and Materials Needed

Before beginning the replacement process, gather the necessary tools and materials. You will typically need a wrench, a screwdriver, and a new cutting head designed for your specific model. Having everything ready will streamline the procedure and minimize downtime.

Step-by-Step Replacement Process

Start by ensuring the equipment is powered off and the spark plug is disconnected for safety. Next, locate the cutting head and remove it by unscrewing any retaining screws or nuts. Once the old head is detached, align the new head with the mounting area and secure it firmly. Finally, reconnect the spark plug and perform a test run to ensure everything is functioning smoothly.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor power equipment requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of the machine, preventing costly repairs down the line.

1. Regular Cleaning: After each use, remove debris, dirt, and grass clippings from the unit. A clean exterior helps prevent corrosion and ensures that air vents remain unobstructed.

2. Check and Replace Filters: Periodically inspect air and fuel filters for clogs or wear. Replacing these components at recommended intervals maintains airflow and improves engine performance.

3. Monitor Fuel Quality: Use fresh, high-quality fuel to avoid engine issues. Stale fuel can lead to starting problems and inefficient operation. Consider adding a fuel stabilizer if the equipment will sit unused for an extended period.

4. Inspect Cutting Blades: Dull or damaged blades can hinder performance and increase wear on the engine. Sharpen or replace blades as needed to ensure clean cuts and reduce strain on the machinery.

5. Regular Lubrication: Apply lubricant to moving parts as specified in the user guide. Proper lubrication minimizes friction, helping components to function smoothly and preventing premature wear.

6. Store Properly: When not in use, store the equipment in a dry, sheltered location. Protect it from extreme temperatures and humidity to prevent rust and deterioration of materials.

By following these maintenance tips, you can significantly enhance the reliability and longevity of your outdoor power tools, ensuring they remain in top condition for years to come.

Proper Reassembly Techniques

Reassembling equipment requires careful attention to detail and methodical approaches to ensure optimal functionality. Each component must be accurately positioned, allowing for seamless interaction with surrounding parts. Following systematic procedures not only enhances performance but also extends the lifespan of the device.

Before starting the reassembly process, it is essential to organize all parts and tools, ensuring everything is easily accessible. This preparation minimizes the risk of misplacing components and helps streamline the overall workflow. Identifying each piece and understanding its role within the assembly is crucial for effective reconstruction.

During reassembly, follow the reverse order of disassembly, which provides a clear roadmap for putting everything back together. Utilize the appropriate torque specifications when fastening components to prevent damage or loosening over time. Regularly check alignment and fitment as you progress, ensuring that each part is correctly seated and operates smoothly.

Finally, conduct a thorough inspection after reassembly. Testing the functionality of the equipment in a safe environment allows for early detection of any issues that may have arisen during the process. Proper reassembly not only guarantees the equipment’s efficiency but also instills confidence in its reliability for future use.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent injuries and equipment damage. Adopting proper practices not only safeguards the user but also prolongs the lifespan of the equipment. Here are essential guidelines to follow:

- Personal Protective Equipment: Always wear appropriate gear, such as gloves, goggles, and sturdy footwear, to protect against debris and sharp objects.

- Work Environment: Choose a well-ventilated area, free from flammable materials. Ensure the workspace is clean and organized to reduce the risk of accidents.

- Disconnect Power Sources: Before starting any task, make sure to disconnect the power source or remove the battery to prevent accidental activation.

- Read Instructions: Familiarize yourself with the user guide before proceeding. Understanding the device’s components and functions is vital.

By following these precautions, individuals can conduct maintenance tasks safely and effectively, reducing the likelihood of mishaps.

When to Seek Professional Help

Understanding when to consult an expert can save time, reduce frustration, and ensure the longevity of your equipment. While many maintenance tasks can be performed independently, certain issues may require specialized knowledge and skills. Recognizing the signs that indicate a need for professional assistance is crucial for optimal performance and safety.

Signs of Malfunction

There are specific indicators that suggest you should consider enlisting a professional. These include persistent operational issues, unusual noises, or failure to start. Addressing these problems early on can prevent further damage and costly repairs.

Complex Repairs

Some repairs involve intricate components that require technical expertise. If you encounter such challenges, it is advisable to seek professional help. Attempting complex repairs without adequate knowledge can lead to additional complications.

| Signs | Action |

|---|---|

| Persistent operational issues | Consult a technician |

| Unusual noises | Seek expert advice |

| Failure to start | Request professional service |

| Complex component failures | Engage a qualified specialist |

Upgrading Components for Performance

Enhancing the efficiency of your outdoor power equipment can lead to significant improvements in its overall functionality and longevity. By focusing on specific components, users can experience enhanced power output, reduced fuel consumption, and improved reliability. This section explores various upgrades that can optimize performance, providing a comprehensive overview of options available for enthusiasts and professionals alike.

Key Components to Consider

When looking to upgrade, it is essential to identify the most impactful parts that contribute to performance. The following table summarizes the main components that can be modified to achieve better results:

| Component | Potential Upgrade | Benefits |

|---|---|---|

| Air Filter | High-Performance Filter | Improved airflow and engine efficiency |

| Fuel System | Upgraded Carburetor | Better fuel delivery for increased power |

| Exhaust | Performance Muffler | Enhanced exhaust flow and reduced back pressure |

| Ignition | High-Efficiency Spark Plug | More effective combustion and improved starts |

Implementation Tips

When upgrading components, it is crucial to ensure compatibility with your equipment. Thoroughly research each part’s specifications and consult with experts if needed. Additionally, proper installation techniques will help prevent potential issues and maximize the benefits of the upgrades. Regular maintenance and adjustments following the upgrades will further enhance performance and extend the lifespan of the equipment.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to maintenance and troubleshooting of outdoor equipment. Understanding these key aspects can greatly enhance your experience and prolong the lifespan of your tools.

What should I do if my equipment won’t start?

If you encounter starting issues, first check the fuel level and ensure that the mixture is correct. Inspect the spark plug for damage or wear, as a faulty plug can prevent ignition.

How often should I perform maintenance?

Regular upkeep is essential. It’s advisable to clean and inspect your tools after each use and conduct a thorough check at least once a season, including oil changes and filter replacements.

Are there specific signs that indicate a need for service?

Yes, unusual noises, reduced power, or excessive vibration can indicate underlying problems. Addressing these signs promptly can prevent more significant issues.

Can I handle repairs myself?

Many users can manage simple tasks such as cleaning filters or replacing spark plugs. However, for more complex issues, consulting a professional is recommended to ensure safety and proper functioning.

What are the best practices for storing my equipment?

Store your tools in a dry, protected area. Before storage, empty the fuel tank and clean the exterior to prevent corrosion and buildup.