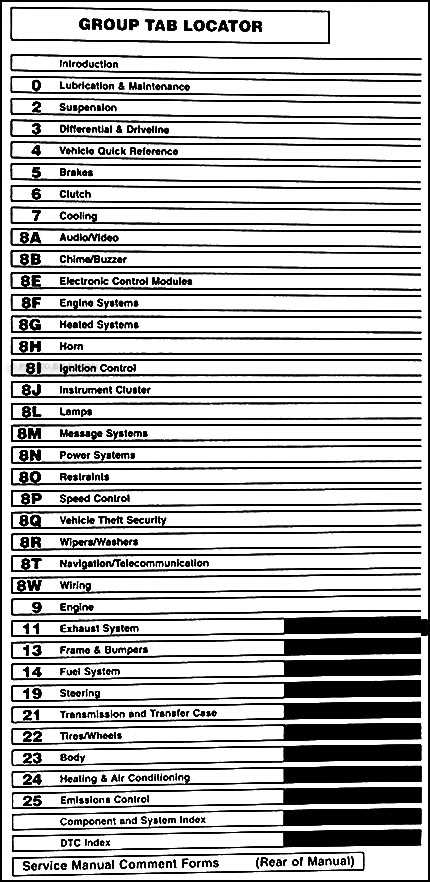

Maintaining a vehicle is essential for ensuring its longevity and optimal performance. Proper understanding of the necessary upkeep can greatly enhance the driving experience while preventing potential issues down the line. A comprehensive approach to vehicle care encompasses various aspects, from routine checks to more complex troubleshooting techniques.

In this section, we will delve into valuable insights and detailed advice that can assist owners in effectively managing their automobile. By following established protocols and recommendations, individuals can address common challenges and enhance their vehicle’s reliability. Equipped with the right knowledge, any owner can tackle maintenance tasks with confidence, ensuring that their automobile remains in excellent condition.

This section provides a comprehensive look at a compact utility vehicle known for its versatility and efficient performance. With a design that blends functionality with modern aesthetics, it caters to a wide range of driving needs, making it suitable for both urban and off-road adventures.

Key Features

The vehicle is equipped with various amenities and technologies that enhance the driving experience. Below are some of the prominent characteristics:

| Feature | Description |

|---|---|

| Engine Options | Diverse engine choices catering to different power needs and efficiency standards. |

| Interior Comfort | Spacious seating with high-quality materials ensuring a comfortable ride. |

| Safety Technologies | Advanced safety features aimed at providing peace of mind on the road. |

| Infotainment System | State-of-the-art multimedia system for connectivity and entertainment. |

Performance Overview

This vehicle demonstrates reliable handling and responsive acceleration, making it a favorite among drivers who seek both comfort and capability. Its performance metrics align with consumer expectations for a vehicle in this category, providing a well-rounded driving experience.

Common Issues and Solutions

This section addresses frequent challenges encountered with specific vehicles and provides effective remedies. Understanding these common problems can significantly enhance the longevity and performance of your automobile.

Electrical Problems: Many drivers experience issues with the electrical system, such as malfunctioning lights or battery failures. Regularly inspecting connections and replacing worn-out components can prevent these issues from escalating.

Engine Performance: Decreased efficiency may arise from various factors, including clogged filters or fuel system malfunctions. Performing routine maintenance and ensuring the use of high-quality fuel can help mitigate these concerns.

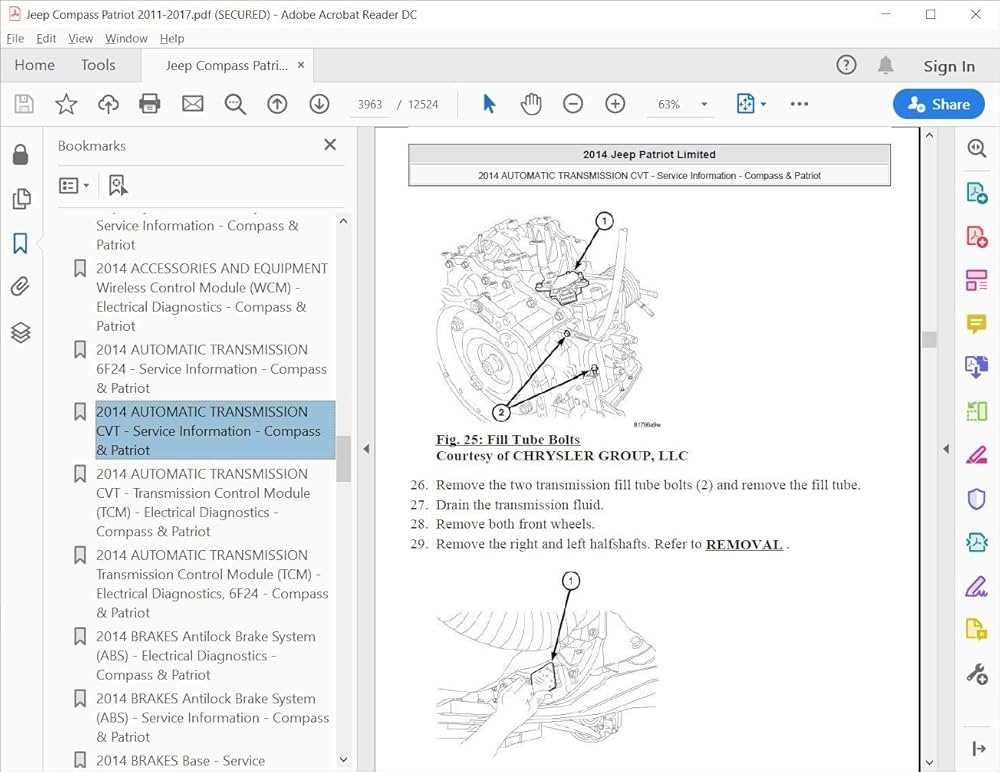

Transmission Issues: Shifting problems are common and may indicate low fluid levels or a need for system recalibration. Regular fluid checks and timely changes can resolve these complications effectively.

Essential Tools for Repair

Having the right instruments is crucial for effective vehicle maintenance and troubleshooting. A well-equipped workspace enables enthusiasts and professionals alike to tackle various tasks efficiently, ensuring optimal performance and longevity of the automobile.

Basic Hand Tools

Fundamental implements such as wrenches, screwdrivers, and pliers form the backbone of any automotive toolkit. These items allow for easy access to components and facilitate the removal and installation of parts with precision.

Diagnostic Equipment

Advanced tools, including diagnostic scanners and multimeters, are essential for identifying issues within the vehicle’s systems. These devices provide valuable data, enabling users to make informed decisions regarding maintenance and repairs.

Engine Maintenance Guidelines

Proper upkeep of the engine is essential for ensuring optimal performance and longevity. Regular attention to maintenance tasks can prevent costly repairs and enhance the overall driving experience.

- Regular Oil Changes: Change the engine oil and filter at recommended intervals to maintain proper lubrication and reduce wear.

- Check Fluid Levels: Regularly inspect coolant, transmission fluid, and brake fluid levels. Top up as necessary to ensure proper functioning.

- Air Filter Replacement: Replace the air filter periodically to ensure efficient air intake, which is crucial for combustion efficiency.

- Inspect Belts and Hoses: Check for signs of wear, cracks, or leaks. Replace damaged components to prevent breakdowns.

- Battery Maintenance: Ensure battery terminals are clean and free of corrosion. Check the battery charge regularly to avoid starting issues.

Following these guidelines will help maintain engine efficiency and reliability, ensuring a smooth and safe driving experience.

Transmission Troubleshooting Tips

When dealing with issues related to the gearbox, it is essential to approach the situation systematically. Understanding common signs of malfunction can help identify problems before they escalate, ensuring optimal vehicle performance.

Common Symptoms of Transmission Issues

Pay attention to the following signs that may indicate transmission difficulties:

| Symptom | Possible Cause |

|---|---|

| Unusual noises while shifting | Worn gears or low fluid levels |

| Slipping out of gear | Faulty transmission fluid or worn components |

| Delayed engagement | Low fluid levels or hydraulic issues |

Basic Troubleshooting Steps

Before seeking professional assistance, consider these initial troubleshooting steps:

- Check fluid levels and condition.

- Inspect for leaks around the transmission.

- Examine connections and wiring for any signs of damage.

Electrical System Diagnostics

The evaluation of electrical systems is crucial for maintaining vehicle performance and reliability. Proper diagnostics help identify issues within the electrical components, ensuring that each part functions effectively.

Identifying Symptoms: Start by observing any irregularities in the vehicle’s performance, such as flickering lights, difficulty starting, or malfunctioning electronic accessories. These signs can indicate underlying electrical problems that require attention.

Utilizing Diagnostic Tools: Employ specialized equipment to read fault codes and analyze the electrical network. Multimeters and scan tools are essential for measuring voltage, resistance, and continuity, helping to pinpoint the exact location of faults.

Wiring Inspection: Conduct a thorough examination of wiring harnesses and connections. Look for signs of wear, corrosion, or loose connections that may disrupt the electrical flow. Repairing or replacing damaged components is vital to restore proper functionality.

Component Testing: Assess individual electrical parts such as the battery, alternator, and fuses. Testing these components can reveal whether they are operating within the specified parameters or if they need replacement.

Following a systematic approach to electrical diagnostics not only resolves existing issues but also prevents future complications, enhancing the overall safety and efficiency of the vehicle.

Brake System Repair Techniques

Maintaining an efficient braking mechanism is crucial for vehicle safety and performance. This section outlines essential methods for addressing issues within the braking system, ensuring optimal functionality and reliability.

Key techniques for enhancing brake performance include:

- Inspection: Regularly check brake components for wear and tear, including pads, rotors, and calipers.

- Cleaning: Keep the braking parts free from dust and debris to prevent performance degradation.

- Adjustment: Ensure that the brake system is correctly aligned and that the pedal pressure is consistent.

- Fluid Maintenance: Regularly check and replace brake fluid as needed to maintain hydraulic pressure and responsiveness.

Implementing these techniques can greatly enhance the durability and effectiveness of the braking system, contributing to a safer driving experience.

Suspension and Steering Adjustments

The proper calibration of the suspension and steering systems is essential for maintaining vehicle stability and comfort. These components play a crucial role in ensuring a smooth ride and responsive handling. Regular adjustments help in achieving optimal performance and can prevent premature wear on associated parts.

Suspension components should be routinely inspected for alignment and balance. Adjustments may involve the modification of various links and struts to ensure that the vehicle’s height and posture are within specified limits. This can improve ride quality and enhance overall safety.

Steering adjustments focus on the angles and positions of the steering mechanism. Ensuring proper alignment can prevent uneven tire wear and improve driving precision. Regular checks and adjustments are vital, especially after any major repairs or if the vehicle experiences unusual handling characteristics.

Cooling System Checks

The cooling system plays a crucial role in maintaining the optimal operating temperature of the engine. Regular inspections are essential to ensure that the system functions efficiently and prevents overheating. This section outlines the key aspects to consider during cooling system evaluations.

Inspecting Coolant Levels: Start by checking the coolant reservoir. Ensure that the fluid is at the recommended level, as insufficient coolant can lead to engine overheating. If the level is low, add the appropriate mixture of coolant and water.

Examining Hoses and Connections: Carefully examine the hoses for any signs of wear, cracks, or leaks. Damaged hoses can result in coolant loss, compromising the system’s effectiveness. Ensure all connections are secure to prevent any potential leaks.

Assessing the Radiator: The radiator is a vital component that dissipates heat. Inspect it for any debris or obstructions that could hinder airflow. Additionally, check for signs of corrosion or leaks that may require attention.

Testing the Thermostat: The thermostat regulates coolant flow based on the engine’s temperature. If the engine is overheating or not reaching the optimal temperature, testing the thermostat’s functionality is advisable to ensure it opens and closes correctly.

By regularly performing these checks, you can help maintain the efficiency of the cooling system and prolong the life of the engine.

Routine Oil Change Procedures

Regularly changing the lubricant in your vehicle is essential for maintaining optimal engine performance and longevity. This process helps to ensure that the engine runs smoothly, reduces wear and tear, and keeps contaminants at bay.

Preparation: Begin by gathering the necessary tools and materials, including a new oil filter, the appropriate type and amount of lubricant, a wrench, and a container for used oil. It is important to consult the specific requirements for your vehicle to ensure compatibility.

Draining the Old Oil: Start by warming up the engine slightly to thin the oil, making it easier to drain. Turn off the engine and place the vehicle on a level surface. Locate the oil drain plug, usually situated at the bottom of the oil pan, and remove it carefully using a wrench. Allow the old lubricant to fully drain into the container.

Replacing the Oil Filter: Once the old oil has drained, proceed to remove the oil filter. Use an oil filter wrench if necessary, ensuring that the rubber O-ring comes off with the filter. Apply a small amount of new oil to the gasket of the new filter before installation, then screw it into place securely.

Adding New Oil: After replacing the filter, reinsert the drain plug and tighten it. Now, pour the new lubricant into the engine using a funnel. Refer to your vehicle’s specifications to determine the correct oil type and capacity. After filling, wait a moment, then check the dipstick to ensure the level is within the recommended range.

Final Steps: Start the engine and let it idle for a few minutes. This allows the new oil to circulate and the filter to fill. Check for any leaks under the vehicle, particularly around the drain plug and oil filter. Dispose of the used oil and filter properly at a designated recycling facility.

Parts Replacement Best Practices

When undertaking the process of component substitution, adhering to established guidelines is crucial for ensuring longevity and functionality. Understanding the nuances of effective replacement techniques can significantly impact the performance of the overall system.

Preparation Steps

- Gather all necessary tools and equipment before starting the task.

- Review the specifications and compatibility of the parts to be replaced.

- Ensure a clean working environment to prevent contamination of components.

Replacement Procedures

- Carefully remove the old part, noting any specific configurations or connections.

- Inspect the surrounding area for damage or wear that may need addressing.

- Install the new component, following manufacturer guidelines to secure it properly.

- Test the system to confirm that the replacement has resolved any issues.

Safety Precautions During Repairs

Ensuring safety is paramount when performing maintenance tasks on vehicles. By adhering to specific guidelines, one can mitigate risks and create a secure environment for both the technician and the vehicle. Proper preparation and awareness of potential hazards are essential in this process.

Personal Protective Equipment (PPE) plays a crucial role in safeguarding individuals involved in the maintenance work. It is advisable to wear gloves, safety glasses, and appropriate footwear to minimize exposure to harmful substances and injuries.

Additionally, maintaining a clean and organized workspace can significantly reduce the chances of accidents. Remove any unnecessary tools or materials that could obstruct movement or create tripping hazards. Keeping the area well-lit also enhances visibility, allowing for safer handling of components.

Awareness of Surroundings is another vital aspect. Be mindful of potential hazards such as hot surfaces, sharp edges, and electrical components. Familiarize yourself with the vehicle’s systems to identify any potential risks before starting the work.

Finally, ensure that all tools and equipment are in good condition and suitable for the tasks at hand. Using the right tools not only enhances efficiency but also contributes to a safer working environment.