The intricate world of timekeeping devices holds a unique charm, blending craftsmanship with artistry. These fascinating instruments have a rich history and are often cherished heirlooms, telling stories through their melodies and movements. Understanding how to maintain and rejuvenate them is essential for any enthusiast or collector.

Whether it’s the delicate mechanisms or the beautifully carved exterior, each component plays a crucial role in the overall functionality. Learning the nuances of these mechanisms not only enhances your appreciation but also empowers you to breathe new life into these timeless treasures.

This section aims to provide comprehensive insights into the various techniques and tips for restoring such devices. By exploring both common issues and detailed solutions, you’ll be equipped with the knowledge needed to preserve these delightful creations for generations to come.

Coo Coo Clock Repair Basics

This section provides essential insights into the maintenance and restoration of intricate timekeeping devices. Understanding the fundamental components and common issues is key to ensuring their longevity and proper functionality.

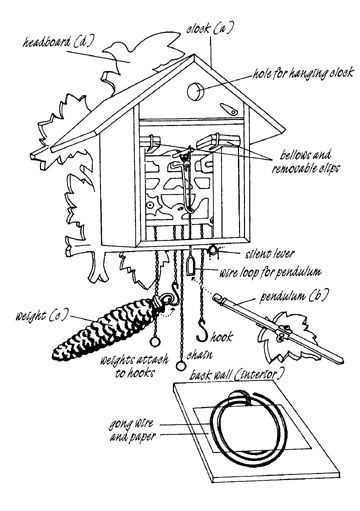

Key Components

- Movement: The mechanism that drives the hands and any additional features.

- Pendulum: A swinging weight that regulates the device’s timing.

- Weights: Often used to provide the necessary power for the movement.

- Case: The outer shell that protects the inner workings and adds aesthetic appeal.

Common Issues

- Inaccurate Timekeeping: Can result from a misaligned pendulum or worn gears.

- Stuck Weights: Sometimes weights can become entangled or obstructed.

- No Sound: The sound feature may fail due to a mechanical blockage or broken components.

Understanding these aspects will aid in diagnosing problems and implementing effective solutions for your cherished timepieces.

Common Coo Coo Clock Issues

Various timepieces can encounter a range of common problems that may affect their functionality and overall performance. Understanding these issues can help enthusiasts identify potential malfunctions and take appropriate action to restore their cherished pieces to working order.

1. Inaccurate Timekeeping

One of the most frequent challenges is inaccurate timekeeping. This can be caused by a variety of factors, including the quality of the movement, environmental conditions, or even the positioning of the timepiece. Regular maintenance and adjustments can often resolve this issue, ensuring that the mechanism runs smoothly and keeps proper time.

2. Sound Mechanism Malfunctions

Another prevalent problem is related to the auditory functions of the device. If the chimes or melodies do not play as intended, it could be due to mechanical obstructions or worn-out components. Cleaning and lubricating the sound mechanism may restore its original charm, allowing the instrument to deliver its delightful tunes once again.

Tools Needed for Repair

When embarking on the journey of restoring a timekeeping device, having the right instruments at your disposal is crucial. The appropriate tools not only enhance efficiency but also ensure the longevity of the intricate mechanisms involved. Each instrument plays a unique role, contributing to a seamless process of maintenance and adjustment.

Essential instruments include:

1. Screwdrivers: A set of precision screwdrivers is vital for accessing the internal components. Various sizes will accommodate different screw types.

2. Pliers: Needle-nose and flat-nose pliers help in gripping, bending, and manipulating small parts without causing damage.

3. Tweezers: Fine tweezers are indispensable for handling delicate pieces and springs that require careful placement.

4. Lubricants: High-quality oils or greases are essential for reducing friction and ensuring smooth operation of moving parts.

5. Cleaning brushes: Soft brushes assist in removing dust and debris from internal mechanisms, maintaining optimal function.

6. Magnifying glass: A magnifying tool aids in inspecting tiny components, allowing for detailed examination of wear and damage.

Equipped with these essential tools, you can approach the task with confidence, ensuring that your timekeeping device returns to its former glory.

Step-by-Step Disassembly Guide

Disassembling a timekeeping device requires careful attention and methodical execution. This section provides a clear framework to help you systematically take apart your mechanism, ensuring each component is preserved and understood.

-

Prepare your workspace:

- Choose a clean, well-lit area.

- Gather necessary tools: screwdriver, tweezers, and a small container for parts.

-

Remove the outer casing:

- Locate and unscrew any screws holding the front panel.

- Carefully detach the outer layer without forcing it.

-

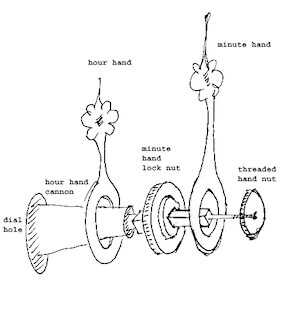

Take out the movement:

- Identify the movement assembly.

- Unscrew it from its housing.

- Gently lift it out, avoiding any unnecessary pressure on delicate parts.

-

Disassemble the movement:

- Remove the pendulum or any swinging elements.

- Carefully detach gears and levers, noting their arrangement.

- Keep track of each part in your container to avoid loss.

-

Document the process:

- Take notes or photos at each step to assist in reassembly.

- Label components if necessary for easier identification later.

Following these steps ensures a systematic approach to taking apart your device, facilitating both understanding and future reassembly.

Identifying Movement Problems

Understanding the intricacies of timekeeping mechanisms is crucial for troubleshooting any issues that may arise during operation. Observing the movement of the mechanism can reveal underlying problems that affect accuracy and performance. In this section, we will explore common indicators of malfunctioning systems and how to recognize them effectively.

Common Symptoms of Malfunction

Several signs may suggest that the mechanism is not functioning properly. For instance, irregular ticking sounds, inconsistent time display, or sudden halts in movement can all point to internal complications. Additionally, if the hands are sluggish or fail to align correctly, these are clear indications that further investigation is necessary.

Diagnostic Techniques

To identify specific issues, begin by closely observing the behavior of the mechanism during operation. Gently shaking or adjusting the apparatus may help in pinpointing loose components or areas of friction. Furthermore, comparing the performance with a known working model can provide valuable insights into the nature of the problem. By systematically analyzing these factors, you can effectively determine the root cause of the malfunction.

Cleaning Techniques for Clock Parts

Maintaining the functionality and appearance of timepieces requires a thoughtful approach to cleansing their various components. Proper cleaning techniques can enhance performance and longevity, ensuring that every piece operates smoothly and looks pristine.

Here are several effective methods for cleaning the individual components:

- Brass Components:

- Use a mixture of vinegar and baking soda to create a gentle abrasive paste.

- Apply the paste with a soft cloth, rubbing gently to remove tarnish.

- Rinse thoroughly with water and dry with a clean, soft cloth.

- Glass Surfaces:

- Mix equal parts of water and isopropyl alcohol in a spray bottle.

- Spray the solution on the glass and wipe with a microfiber cloth.

- Ensure all residues are removed to avoid streaks.

- Wooden Cases:

- Dust the surface with a soft, dry cloth to remove any loose particles.

- Use a wood cleaner specifically formulated for delicate finishes.

- Apply sparingly and polish with a clean cloth to enhance the shine.

- Mechanical Parts:

- Disassemble the mechanism carefully, noting the arrangement of parts.

- Use a soft brush to remove dust and debris from gears and pivots.

- Apply a small amount of clock oil to moving parts to ensure smooth operation.

Regular maintenance using these techniques can significantly extend the life of your timekeeping instruments while keeping them in excellent condition.

Lubrication Tips for Smooth Operation

Maintaining optimal functionality in timekeeping devices is essential for their longevity and accuracy. Proper application of lubrication can significantly enhance performance, reducing friction and wear in moving parts. Understanding the right techniques and materials for this process is crucial for achieving seamless movement.

Begin by selecting a high-quality lubricant specifically designed for intricate mechanisms. Avoid using general oils, as they may attract dust and debris, leading to further complications. A synthetic lubricant often offers superior protection and longevity.

When applying the lubricant, use a precision applicator to target specific areas without over-saturating. It’s advisable to clean the surfaces first to remove any old residue, ensuring that the new lubricant can bond effectively. Focus on pivot points, gears, and any areas that show signs of wear.

Regular maintenance is key. Establish a routine to check and refresh the lubrication, typically every few months, depending on usage. This proactive approach can prevent unnecessary damage and keep the internal mechanisms functioning smoothly.

Lastly, be mindful of the quantity used. A little goes a long way; excess lubricant can lead to buildup and impede performance. With these strategies in place, you can ensure reliable and efficient operation for years to come.

Reassembly: Ensuring Proper Function

Restoring an intricate timepiece requires careful attention to detail. Properly reassembling the components is crucial to achieving optimal performance. Each piece must fit together seamlessly, ensuring that the mechanisms operate smoothly and efficiently.

Steps for Successful Assembly

Following a systematic approach can greatly enhance the likelihood of success. Here are key steps to consider during the reassembly process:

| Step | Description |

|---|---|

| 1 | Organize all parts and tools to ensure easy access during assembly. |

| 2 | Begin by aligning the main components, verifying that they are clean and free of debris. |

| 3 | Carefully insert the gears and ensure they engage properly, without excessive friction. |

| 4 | Check the pendulum and other moving parts, ensuring they swing freely. |

| 5 | Test the assembly by gently winding the mechanism and observing its operation. |

Troubleshooting Common Issues

If problems arise during testing, identifying the source of the malfunction is essential. Common issues may include misalignment of gears or insufficient lubrication. Addressing these concerns promptly can prevent further complications and enhance longevity.

Adjusting Timekeeping Accuracy

Maintaining precise time measurement is essential for ensuring that a timepiece functions optimally. Variations in performance can occur due to various factors, which may lead to the necessity of fine-tuning mechanisms to achieve accurate timekeeping. Understanding the underlying principles and techniques involved can significantly enhance the reliability of your instrument.

Identifying the Issue

The first step in achieving precision is to recognize any discrepancies in time indication. Observing the timepiece over several days can reveal patterns of gain or loss. Noting these variations helps pinpoint whether the issue stems from environmental influences, mechanical wear, or other factors that might disrupt the internal workings.

Making Adjustments

Once the source of the discrepancy is identified, adjustments can be made to improve accuracy. This may involve altering the pendulum length, modifying the tension of the regulating mechanism, or recalibrating the gears. It’s crucial to proceed with care, making minor changes and testing the performance frequently to avoid overcompensation.

Replacing Damaged Clock Components

Maintaining the functionality of a timekeeping device often requires addressing various issues that arise due to wear and tear. This section outlines the essential steps for identifying and substituting faulty parts to restore optimal performance. Ensuring each element is in good condition is crucial for the overall accuracy and aesthetic appeal of the mechanism.

Identifying Faulty Components

Before any replacements can be made, it’s important to accurately diagnose which parts are malfunctioning. Common indicators of problems include:

- Irregular ticking sounds

- Inconsistent timekeeping

- Visible damage or corrosion

Taking the time to assess these signs will streamline the replacement process.

Steps for Component Replacement

- Gather necessary tools such as a screwdriver, tweezers, and replacement parts.

- Carefully disassemble the mechanism, taking care to note the placement of each part.

- Remove the damaged component, ensuring not to disturb surrounding elements.

- Install the new part, making sure it fits securely and is properly aligned.

- Reassemble the device and conduct tests to confirm functionality.

By following these guidelines, one can effectively restore the integrity of the timepiece, ensuring it continues to function beautifully for years to come.

Maintaining Your Coo Coo Clock

Regular upkeep is essential to ensure the longevity and proper functioning of your beloved timepiece. By following a few straightforward practices, you can keep it in excellent condition, allowing it to continue charming you and your guests for years to come. This section highlights key aspects of maintenance that every owner should be aware of.

Cleaning Your Timepiece

Dust and debris can accumulate over time, affecting both appearance and performance. To clean your item, gently wipe the exterior with a soft, dry cloth. Avoid using harsh chemicals or abrasive materials, as these can damage the finish. For more intricate parts, consider using a small, soft brush to reach delicate areas without causing harm.

Winding and Setting

Proper winding is crucial for accurate timekeeping. Refer to the specific instructions for your model, as different designs may require varying techniques. Generally, it’s best to wind your timepiece regularly, ideally once a week, to maintain its functionality. Additionally, be mindful of the settings, ensuring that the hands move freely and are properly aligned to avoid unnecessary strain on the mechanism.

By incorporating these practices into your routine, you will enhance the lifespan of your treasured item and ensure that it continues to operate smoothly.

Resources for Further Learning

Expanding your knowledge about timepieces and their intricacies can significantly enhance your skills. This section provides a curated list of resources that will help you delve deeper into the art and science behind these fascinating devices.

Books

- The Art of Watchmaking: A comprehensive guide that covers both theoretical and practical aspects.

- Understanding Timepieces: This book offers insights into various mechanisms and their histories.

- Mastering Mechanical Mechanics: Focuses on the intricacies of moving parts and maintenance techniques.

Online Courses

- Timepiece Fundamentals: An introductory course available on popular learning platforms.

- Advanced Mechanisms: A deeper exploration into complex devices and their functionalities.

- Hands-On Workshops: Local or virtual sessions for practical experience in handling various models.

Utilizing these resources will not only bolster your understanding but also inspire confidence in tackling various challenges related to these exquisite creations.